Dispersing and stirring apparatus for producing oil paint

A technology for dispersing, mixing and painting, which is applied in the direction of mixer accessories, transportation and packaging, dissolution, etc. It can solve the problems of slow mixing efficiency and unguaranteed quality of paint mixing, and achieve the effect of uniform mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

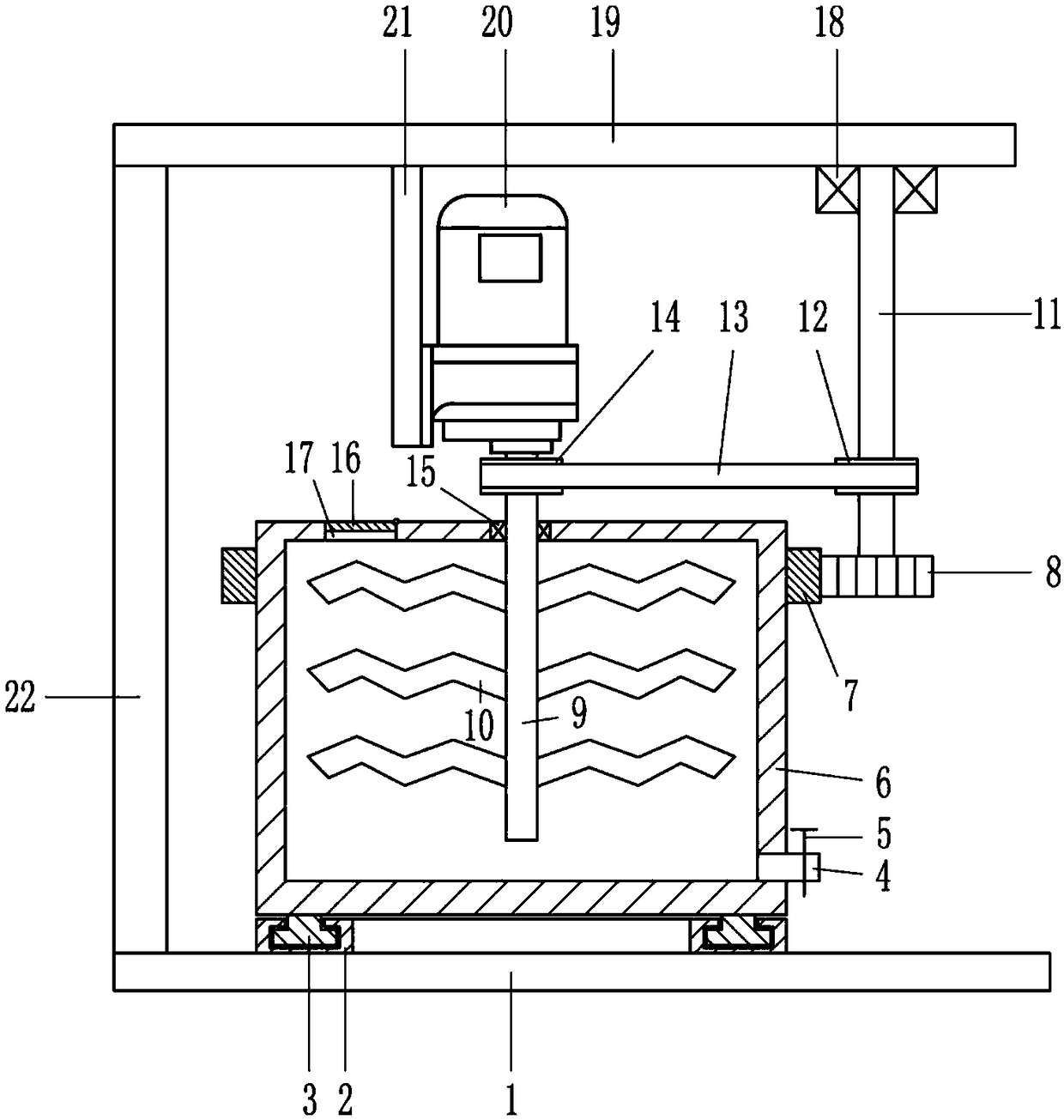

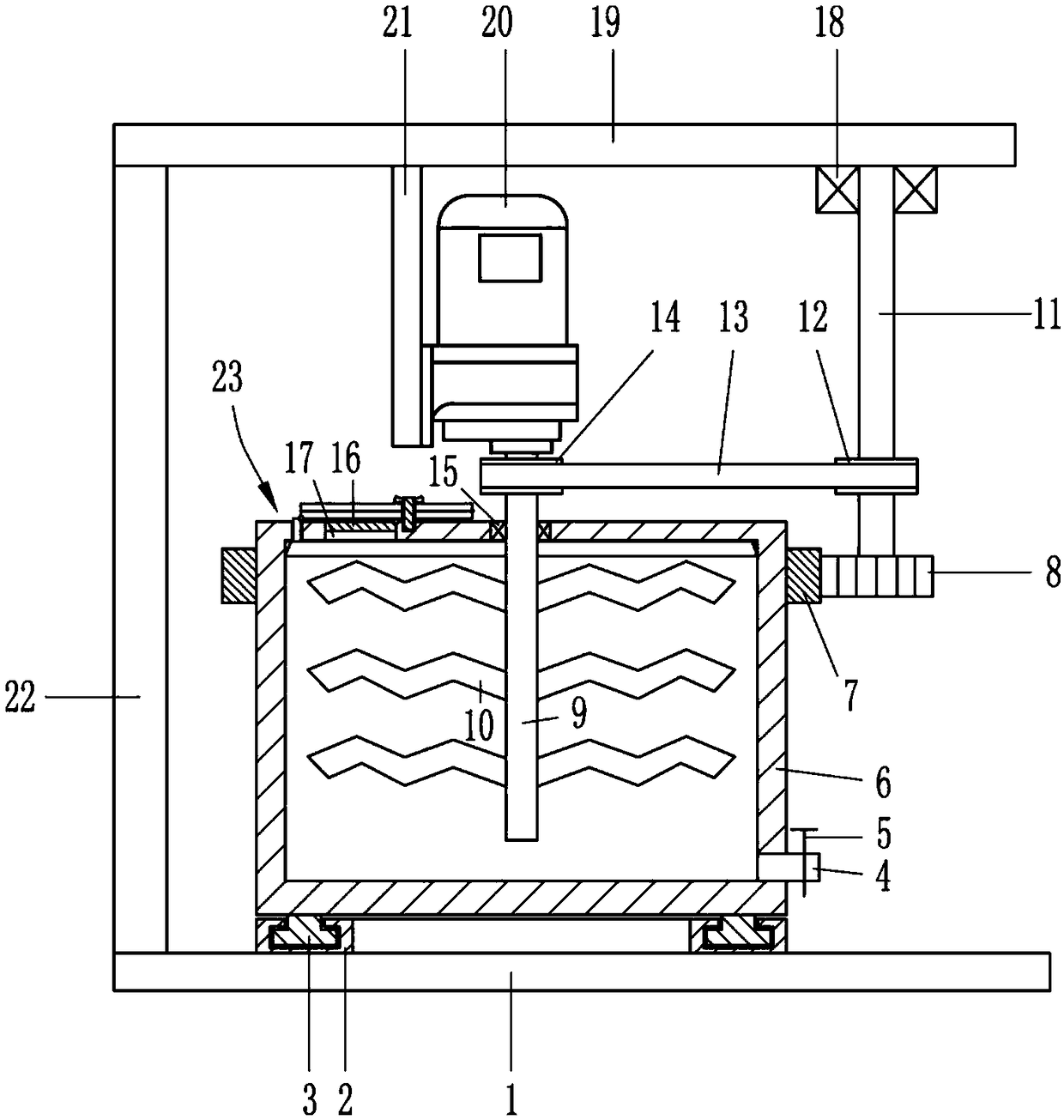

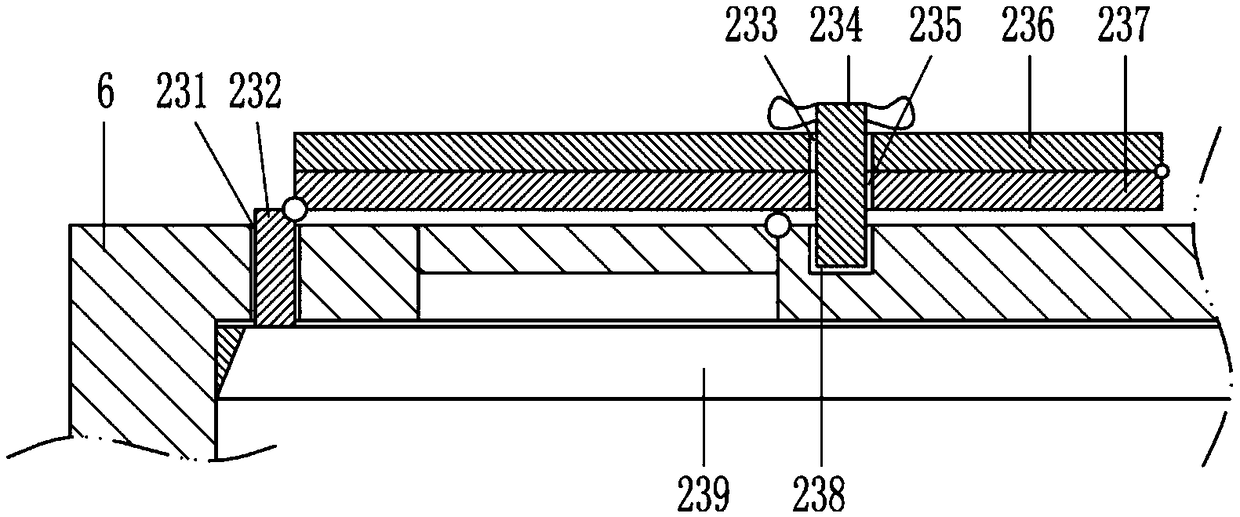

[0029] A dispersing and stirring device for paint production, such as Figure 1-7 As shown, it includes a first mounting plate 1, an annular slide rail 2, a slider 3, a discharge pipe 4, a valve 5, a stirring frame 6, an outer gear ring 7, a first gear 8, a stirring rod 9, and a first stirring blade 10. First rotating shaft 11, first pulley 12, flat belt 13, second pulley 14, first bearing seat 15, cover plate 16, second bearing seat 18, second mounting plate 19, motor 20, third mounting plate 21 and a side plate 22; the side plate 22 is fixed on one side of the first mounting plate 1, the ring slide rail 2 is fixed on the top of the first mounting plate 1, and the stirring frame 6 is slidably connected with the ring slide rail 2 through the slider 3, The discharge pipe 4 is fixedly connected to one side of the stirring frame 6, the valve 5 is installed on the discharge pipe 4, the outer ring gear 7 is fixed to the side of the stirring frame 6, the first bearing seat 15 is emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com