Total mixed ration (TMR) wrapping machine for livestock feed preparation

A feed and livestock technology, applied in the field of livestock feed preparation, can solve the problems of low handling efficiency, increased manual labor intensity, and reduced efficiency of wrapping feed, etc., to achieve the effect of reducing labor intensity and reducing the number of times of handling feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

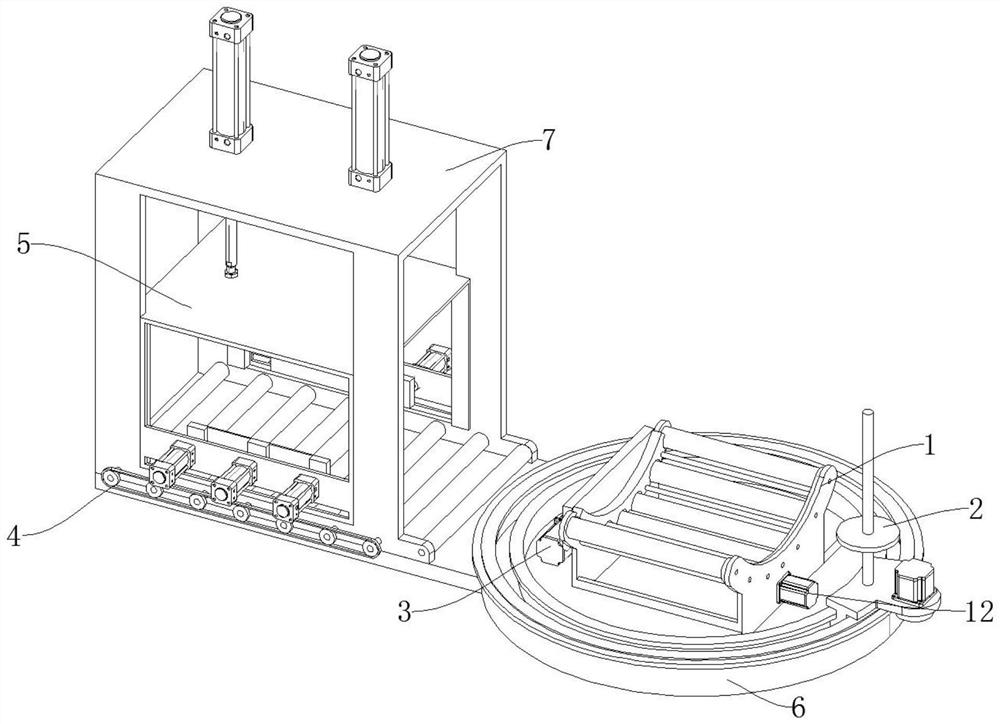

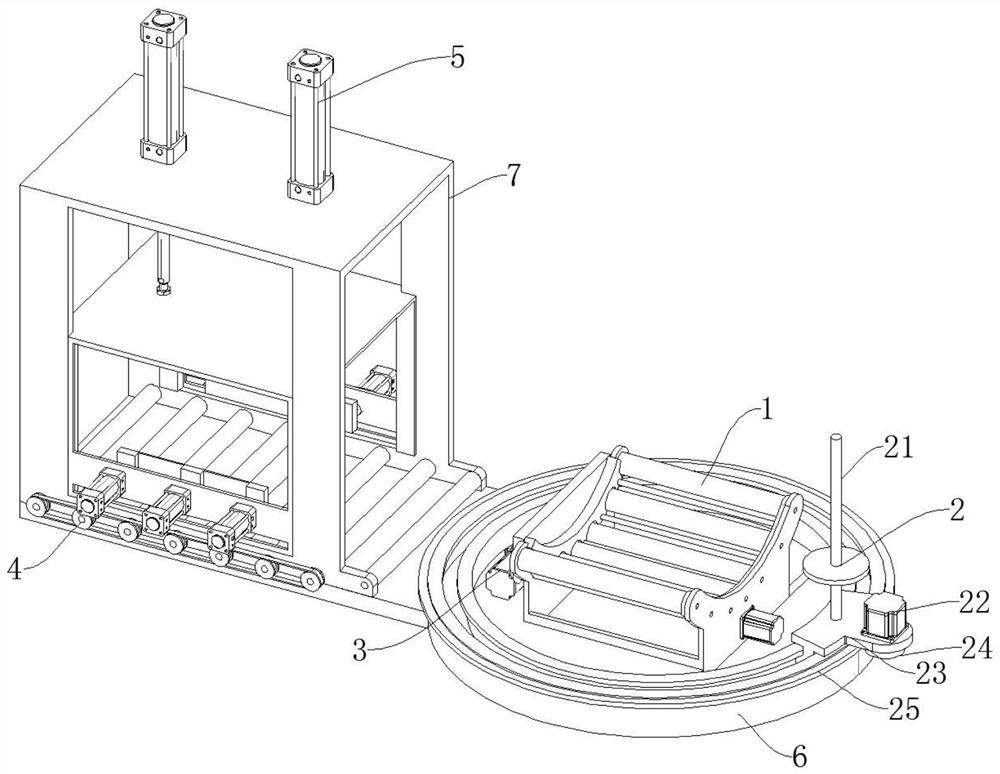

[0043] Such as figure 1 , image 3 , Figure 5 , Figure 6 , Figure 7 , Figure 8 As shown, the rotating mechanism 1 comprises a turret 11, a rotating motor 12, a rotating roller 13, a rotating wheel 14, and a rotating belt 15. The turret 11 is connected to the center position of the track disc 6 by welding, and the rotating motor 12 is connected to the turret 11 by bolts. On the side, the turning roller 13 is connected to the upper end of the inner side of the turret 11 through a bearing, and the turning wheel 14 is connected to the rotating part of the turning motor 12 by a key. The part drives the rotating wheel 14 to rotate, and the rotation of the rotating wheel 14 drives the rotating belt 15 to rotate, and utilizes the transmission of the rotating belt 15 to drive all the rotating rollers 13 to rotate; the wrapping mechanism 2 includes wrapping rods 21, wrapping Wrapping motor 22, wrapping seat 23, gear 24, ring gear 25, wrapping seat 23 is arranged on the inner si...

Embodiment 2

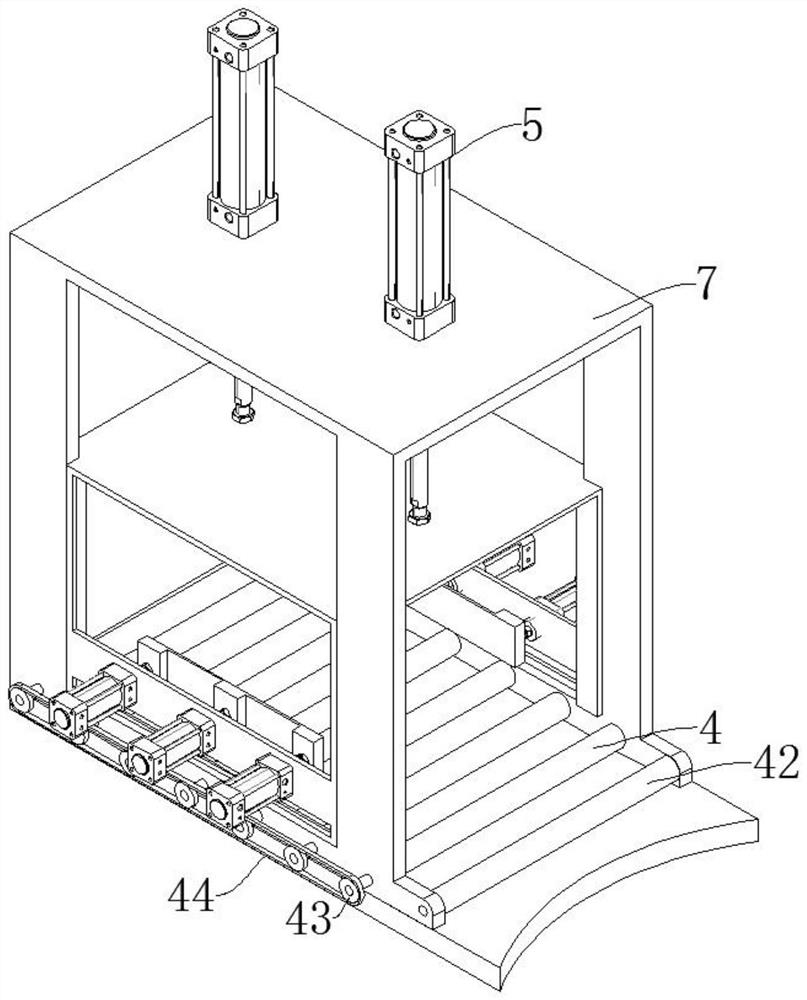

[0046] Such as figure 2 , Figure 4 As shown, the difference between Embodiment 2 and Embodiment 1 is that the conveying mechanism 4 includes a conveying motor 41, a conveying roller 42, a pulley 413, and a belt 414, and the conveying motor 41 is connected to the rear side of one end of the support frame 7 by bolts, and the conveying roller 42 is connected to the inner side of the support frame 7 through bearings, and the belt pulley 413 is connected to the front end of the conveyor roller 42 by a key. and the transmission of the belt 414 to drive all the conveying rollers 42 to rotate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com