Quick repairing method of old cement concrete pavement

A technology of concrete pavement and old cement, which is applied to cohesive pavement paved on site, roads, roads, etc. It can solve the problems of easy falling off, long construction time, and low cement concrete cohesion, so as to strengthen the bond and reduce the Project cost, effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

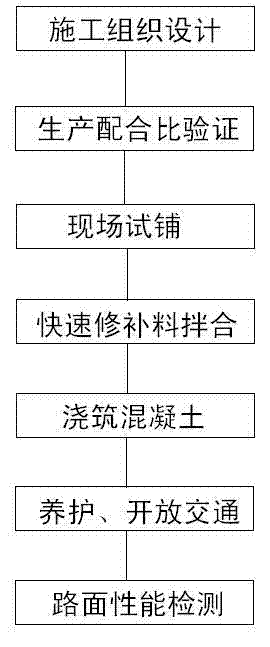

[0029] The quick repair method of 0.3 cm ultra-thin overlay includes the following steps:

[0030] Step 1) Concrete mix design;

[0031] Step 2) Verify the design mix ratio and fine-tune it according to the actual situation;

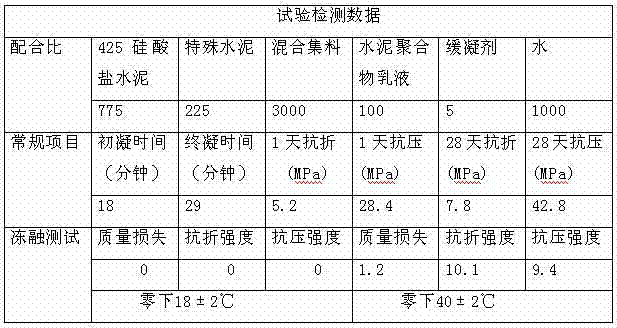

[0032] (a) Add cement and quartz sand to the mixing pot for dry mixing at a weight ratio of 15:35, and the cement is 425 Portland cement;

[0033] (b) Add water-based ethylene-vinyl acetate emulsion, retarder and water in a weight ratio of 10:0.5:10 to a stirring pot for stirring to obtain a high-viscosity mortar mixture;

[0034] Step 3) Clean up the site, treat road surface diseases, chisel out loose structures, clean up, and test pavement on site;

[0035] Step 4) According to the above parts by weight, mix the aqueous ethylene-vinyl acetate emulsion and water evenly, then slowly add 425 Portland cement, quartz sand and retarder, and stir at a temperature above 5°C, either by using a mixing plant Large-scale factory mixing can also ...

Embodiment 2

[0040] The quick repair method of 0.6 cm ultra-thin overlay includes the following steps:

[0041] Step 1) Concrete mix design;

[0042] Step 2) Verify the design mix ratio and fine-tune it according to the actual situation;

[0043] (a) Add cement and quartz sand to the mixing pot for dry mixing at a weight ratio of 20:45, and the cement is 525 Portland cement;

[0044] (b) Add water-based ethylene-vinyl acetate emulsion, retarder and water in a weight ratio of 15:0.8:20 into the stirring pot for stirring to obtain a high-viscosity mortar mixture;

[0045] Step 3) Clean up the site, treat road surface diseases, chisel out loose structures, clean up, and test pavement on site;

[0046] Step 4) According to the above parts by weight, mix the aqueous ethylene-vinyl acetate emulsion and water evenly, then slowly add Portland cement, quartz sand and retarder, and stir at a temperature above 5°C, which can be carried out in a mixing building Large-scale factory m...

Embodiment 3

[0051] The quick repair method of 0.9 cm ultra-thin overlay includes the following steps:

[0052] Step 1) Concrete mix design;

[0053] Step 2) Verify the design mix ratio and fine-tune it according to the actual situation;

[0054] (a) Add cement and quartz sand to the mixing pot for dry mixing at a weight ratio of 25:55. The cement is self-made special cement, and the special cement is powder anti-stripping agent, mineral powder, polymer rubber powder and sulphoaluminate cement. mixture;

[0055] (b) Add water-based ethylene-vinyl acetate emulsion, retarder and water in a weight ratio of 25:1:25 into the stirring pot for stirring to obtain a high-viscosity mortar mixture;

[0056] Step 3) Clean up the site, treat road surface diseases, chisel out loose structures, clean up, and test pavement on site;

[0057] Step 4) According to the above parts by weight, mix the aqueous ethylene-vinyl acetate emulsion and water evenly, then slowly add Portland cement, q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com