An integrated composite board for external wall insulation and decoration and its preparation method

An external wall insulation and composite board technology, applied in covering/lining, architecture, building structure, etc., can solve problems such as large specific gravity and poor durability, and achieve the effects of high structural compactness, similar physical properties, and low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

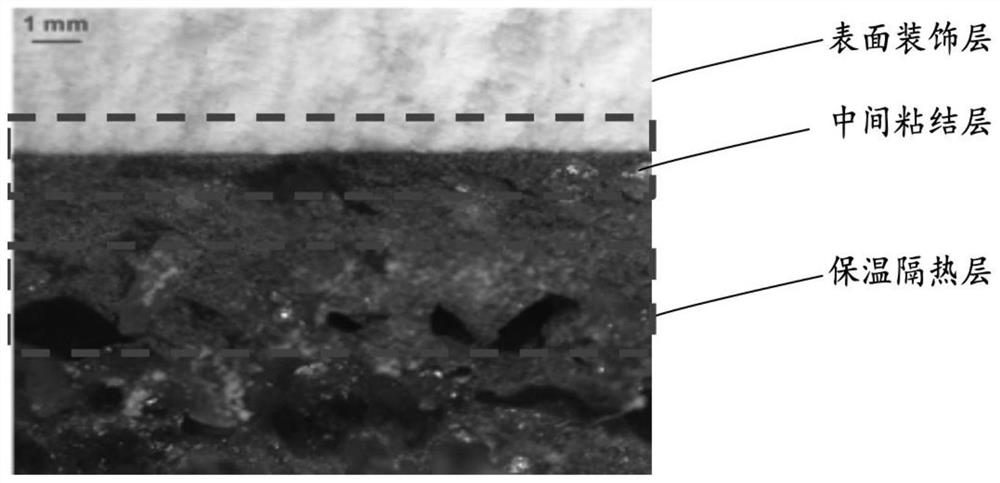

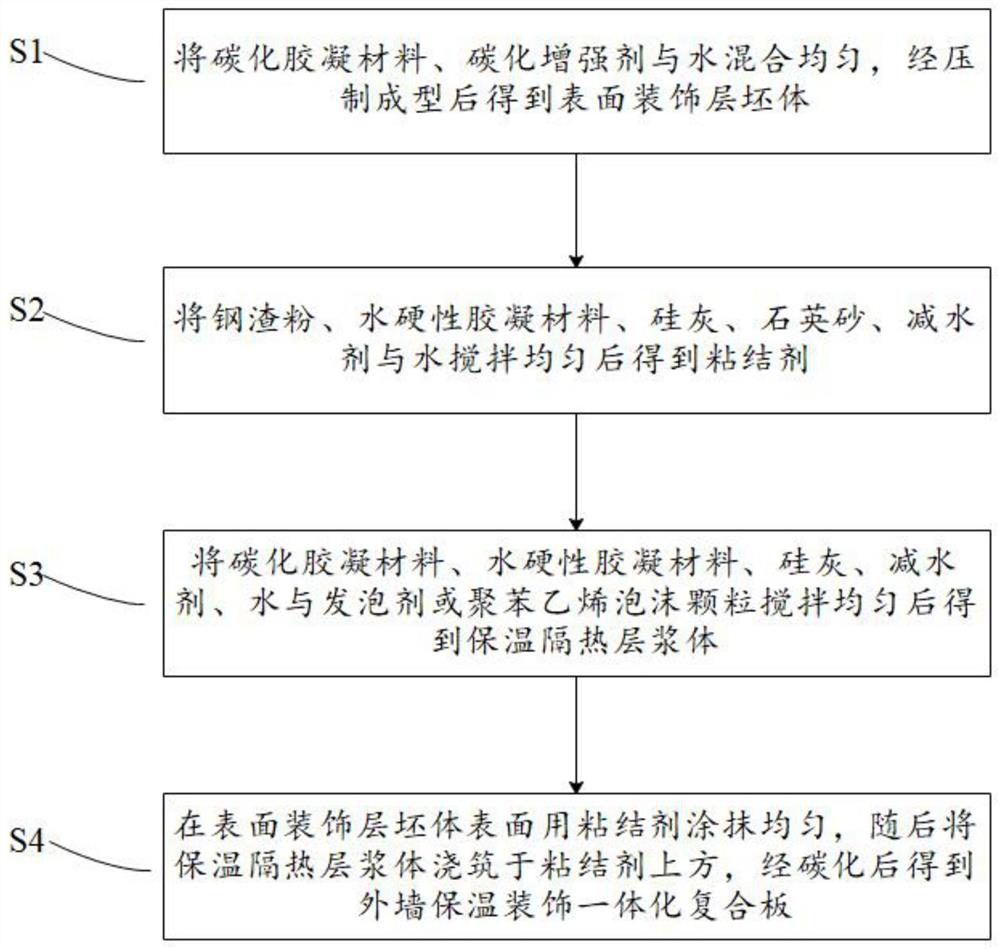

[0023] see figure 2 , the second aspect of the present invention provides a method for preparing an integrated composite panel for exterior wall insulation and decoration, comprising the following steps:

[0024] S1: Mix the carbonized gelling material, the carbonized reinforcing agent and water evenly, and obtain the green body of the surface decoration layer after pressing and molding;

[0025]S2: Stir steel slag powder, hydraulic cementitious material, silica fume, quartz sand, water reducing agent and water evenly to obtain a high fluidity binder;

[0026] S3: Stir the carbonized cementitious material, hydraulic cementitious material, silica fume, water reducer, water and blowing agent or polystyrene foam particles evenly to obtain the thermal insulation layer slurry;

[0027] S4: Spread the high-fluidity adhesive on the surface of the body of the surface decoration layer evenly, then pour the thermal insulation layer slurry on the high-fluidity adhesive, and obtain the ...

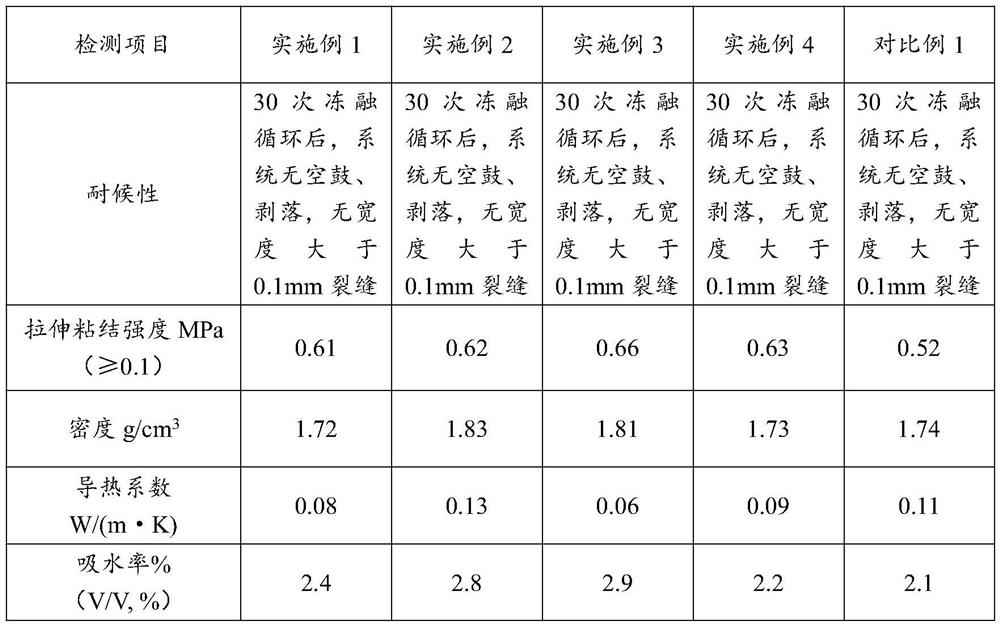

Embodiment 1

[0032] Embodiment 1 provides a method for preparing an integrated composite panel for exterior wall insulation and decoration, comprising the following steps:

[0033] 80 parts of γ-C 2 S, 0.4 parts of chitin and 15 parts of water are mixed evenly to form a wet material, and the mixed wet material is placed in an abrasive tool, and pressed and formed into a surface decoration layer green body with a molding pressure of 30 MPa;

[0034] Mix 10 parts of steel slag powder, 0.8 parts of 42.5 grade ordinary Portland cement, 0.3 parts of silica fume, 1.8 parts of quartz sand, 0.5 parts of water reducer and 1.8 parts of water, and prepare a high fluidity binder for later use;

[0035] Mix 200 parts of steel slag powder, 40 parts of polystyrene foam particles, 15.6 parts of 42.5 grade ordinary Portland cement, 6.6 parts of silica fume, 8.8 parts of water reducing agent and 34 parts of water to obtain the thermal insulation layer slurry;

[0036] Spread the binder evenly on the surfac...

Embodiment 2

[0040] Embodiment 2 provides a method for preparing an integrated composite panel for exterior wall insulation and decoration, comprising the following steps:

[0041] 80 parts of γ-C 2 S, 0.4 parts of chitin and 15 parts of water are mixed evenly to form a wet material, and the mixed wet material is placed in an abrasive tool, and pressed and formed into a surface decoration layer green body with a molding pressure of 30 MPa;

[0042] Mix 10 parts of steel slag powder, 0.8 parts of 42.5 grade ordinary Portland cement, 0.3 parts of silica fume, 1.8 parts of quartz sand, 0.5 parts of water reducer and 1.8 parts of water, and prepare a high fluidity binder for later use;

[0043] Mix 200 parts of steel slag powder, 5 parts of protein-based organic foaming agent, 15.6 parts of 42.5 grade ordinary Portland cement, 6.6 parts of silica fume, 8.8 parts of water reducing agent and 34 parts of water to obtain the thermal insulation layer slurry;

[0044] Spread the binder evenly on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com