Polyimide film with surface coated with high-cohesiveness compact silicon dioxide layer and preparation method of polyimide film

A polyimide film, silicon dioxide technology, applied in coatings, photovoltaic power generation and other directions, can solve the problems of surface inorganic coating breakage, peeling and other problems, achieve high controllability, simple implementation, good adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

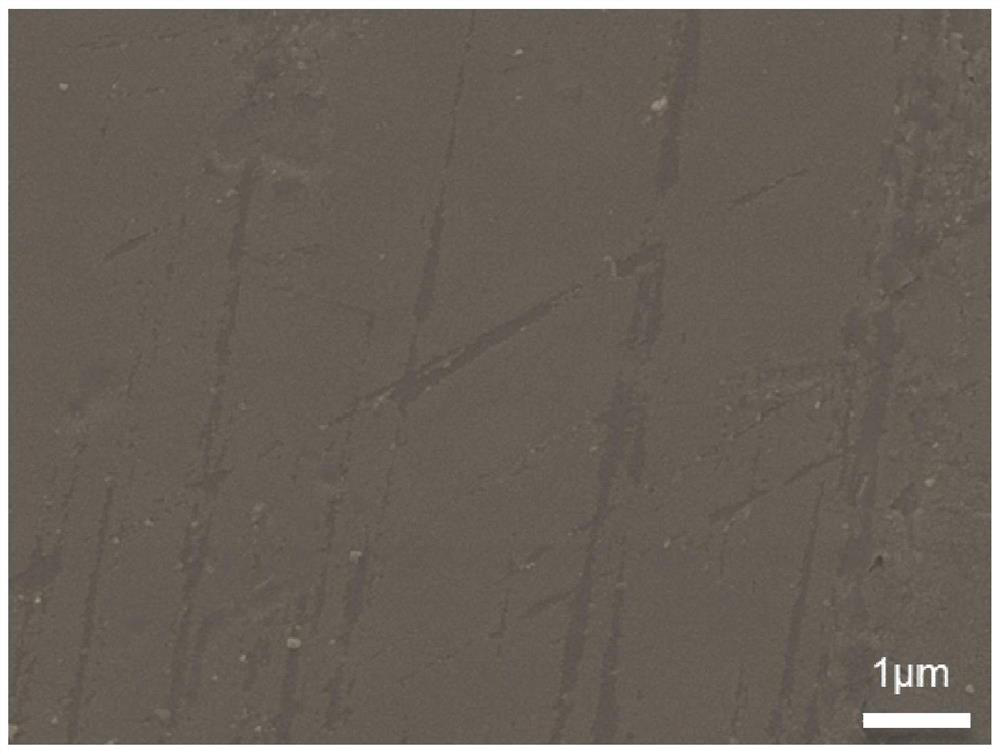

[0039] A: Use 3,3',4,4'-biphenyltetracarboxylic dianhydride (BPDA) and p-phenylenediamine (PDA) as monomers, and control the molar ratio of the two to 1:1. Condensation polymerization in methyl acetamide (DMAc) solvent obtains a polyamic acid (PAA) solution with a solid content of 12%. Add TEOS to the PAA solution. The quality of TEOS is that the silicon dioxide finally generated by its entire reaction accounts for the PAA thermal ring. 30% of the mass of PI after melting;

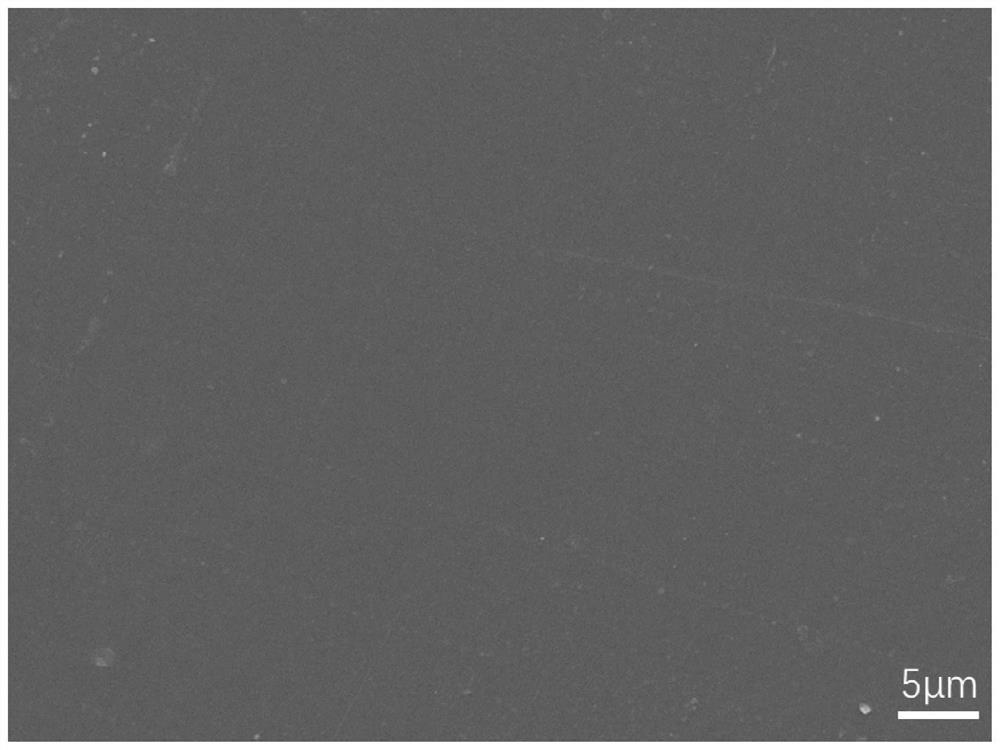

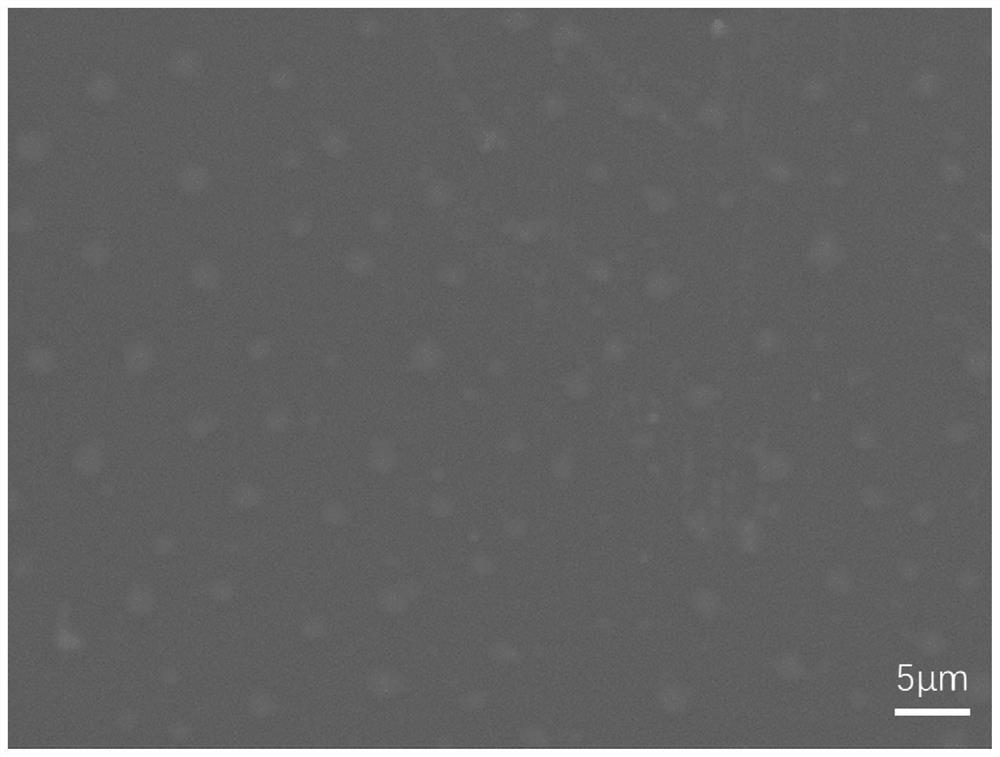

[0040] B: PAA / SiO was prepared by electrospinning PAA / TEOS solution 2 Precursor nanofibrous membrane 15 μm,;

[0041] C: The finished PI base film is etched and modified with 1mol / L KOH aqueous solution for 10 minutes, and then acidified with 1wt% hydrochloric acid aqueous solution for 30 minutes to obtain a polyimide film with a PAA modified layer on the surface. The layer thickness is 2 μm;

[0042] D: Spread the PAA / TEOS nanofiber membrane in step B evenly on the PAA modified layer in step C, keep th...

Embodiment 4

[0062] A: Use 3,3',4,4'-biphenyltetracarboxylic dianhydride (BPDA) and p-phenylenediamine (PDA) as monomers, and control the molar ratio of the two to 1:1. Condensation polymerization in methyl acetamide (DMAc) solvent obtains a polyamic acid (PAA) solution with a solid content of 12%. Add TEOS to the PAA solution. The quality of TEOS is that the silicon dioxide finally generated by its entire reaction accounts for the PAA thermal ring. 30% of the mass of PI after melting;

[0063] B: PAA / SiO was prepared by electrospinning PAA / TEOS solution 2 Precursor nanofibrous membrane 15 μm,;

[0064] C: The same finished PI base film as in Example 1 was etched and modified with 1mol / L KOH aqueous solution for 10 minutes, and then acidified with 1 wt% hydrochloric acid aqueous solution for 30 minutes to obtain a polyimide film with a PAA modified layer on the surface. Amine film, the thickness of the modified layer is 2 μm;

[0065] D: Spread the PAA / TEOS nanofiber membrane in step B ...

Embodiment 5

[0069] A: Use 3,3',4,4'-biphenyltetracarboxylic dianhydride (BPDA) and p-phenylenediamine (PDA) as monomers, and control the molar ratio of the two to 1:1. Condensation polymerization in methyl acetamide (DMAc) solvent obtains a polyamic acid (PAA) solution with a solid content of 12%. Add TEOS to the PAA solution. The quality of TEOS is that the silicon dioxide finally generated by its entire reaction accounts for the PAA thermal ring. 30% of the mass of PI after melting;

[0070] B: PAA / SiO was prepared by electrospinning PAA / TEOS solution 2 Precursor nanofibrous membrane 35 μm,;

[0071] C: The same finished PI base film as in Example 1 was etched and modified with 1mol / L KOH aqueous solution for 10 minutes, and then acidified with 1 wt% hydrochloric acid aqueous solution for 30 minutes to obtain a polyimide film with a PAA modified layer on the surface. Amine film, the thickness of the modified layer is 2 μm;

[0072] D: Spread the PAA / TEOS nanofiber membrane in step B ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com