Mask and method of making the same

A mask, conductive mask technology, used in semiconductor/solid-state device manufacturing, vacuum evaporation plating, coating, etc., can solve the problems of large pattern error and low accuracy, and achieve small pattern error and high accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the purpose, technical solution and advantages of the present application clearer, the implementation manners of the present application will be further described in detail below in conjunction with the accompanying drawings.

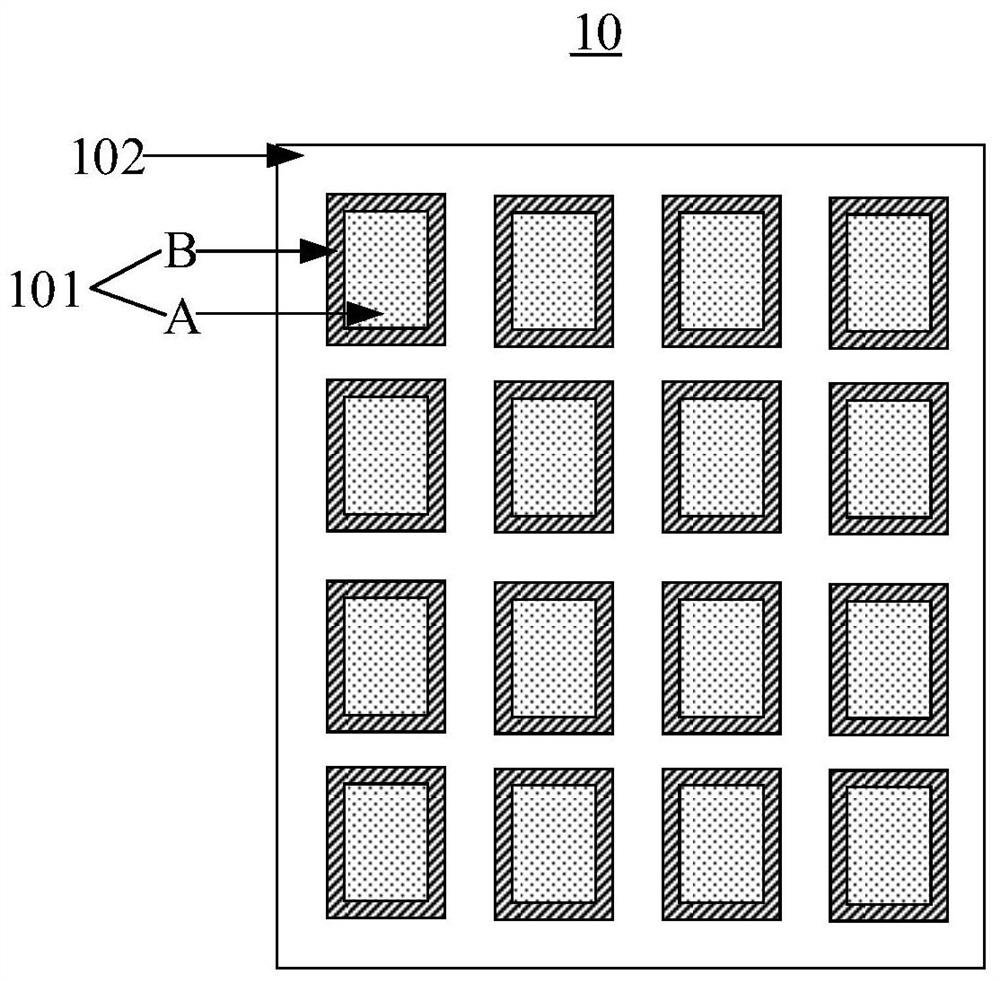

[0039] figure 1 It is a structural schematic diagram of a display motherboard known to the inventor, such as figure 1 As shown, the display motherboard 10 includes a plurality of display screens 101 formed on a base substrate 102 . Each display screen 101 includes a display area A and a non-display area B around the display area A. In the preparation obtained as figure 1 After the display screen motherboard 10 is shown, multiple display screens 101 are obtained by cutting the display screen motherboard 10 .

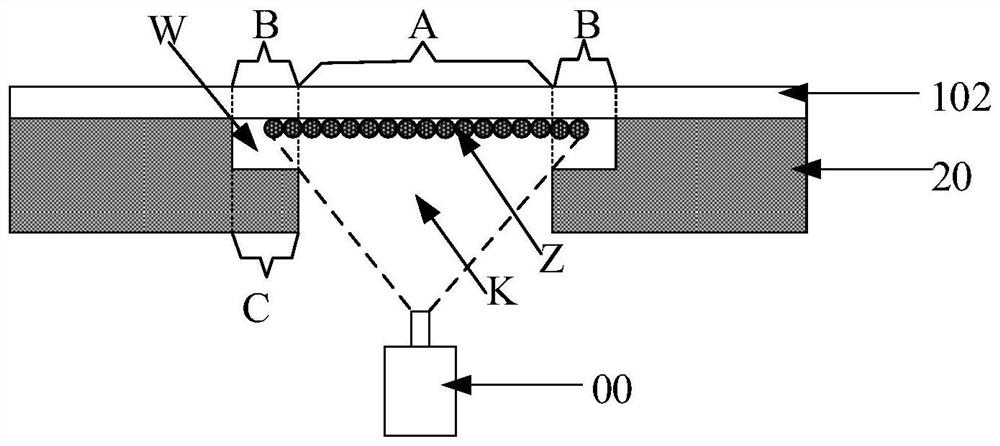

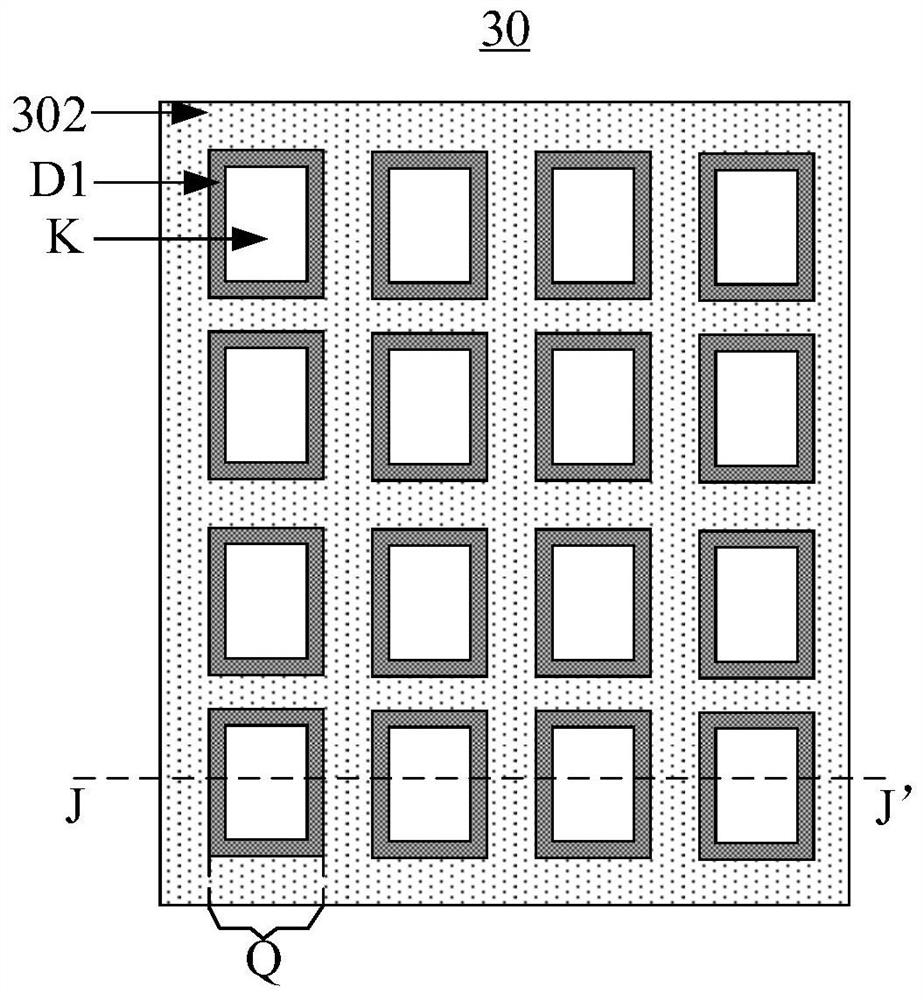

[0040] In the related art, a mask plate is usually used to form the entire layer structure in the display screen through an evaporation process. figure 2 It is a schematic diagram of a scene where a mask is used to form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com