Fabricated super-high-rise steel-concrete combination residence

A steel tube concrete and concrete technology, applied in protective buildings/shelters, shockproof, walls, etc., can solve the problems of large deformation of prefabricated steel structures, complex structure of prefabricated components, and small lateral rigidity, so as to increase the structural resistance Effects of lateral stiffness, reduction of component section, and improvement of comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Prefabricated super high-rise steel-concrete composite housing, including:

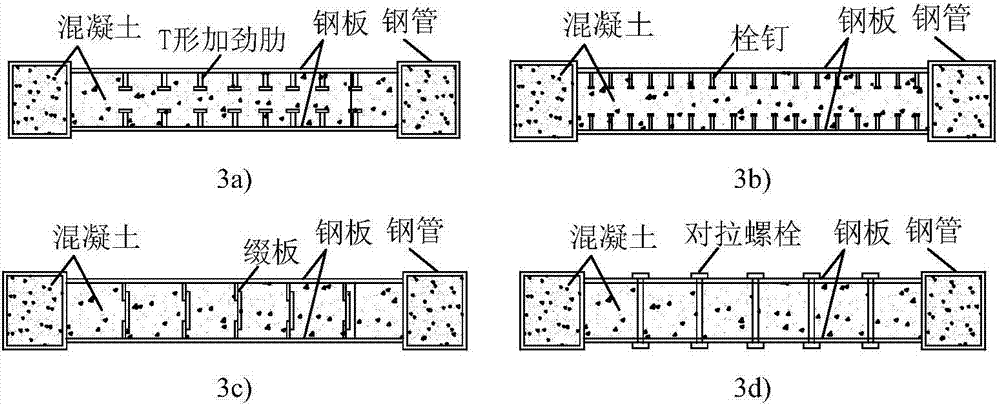

[0032] Concrete-filled steel tube composite columns and steel-concrete composite beams form the frame, steel plate composite shear walls are arranged in the core tube area between the frames, and energy-dissipating concrete-filled steel tube composite buckling-constrained braces serve as lateral force-resisting members and energy-dissipating functions. The buckling-restrained braces of energy-type concrete-filled steel pipe composites are arranged obliquely in a frame composed of beams and columns, and are connected with the beam-column gusset plate by bolts, where:

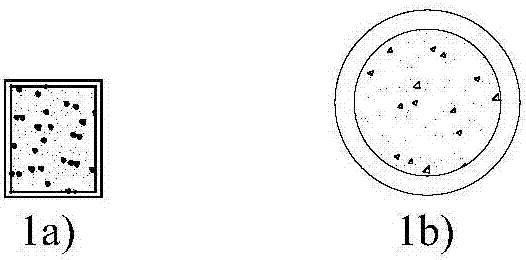

[0033] 1) The cross-section of steel tube concrete composite column is as follows: figure 1 As shown, the rectangular steel tube concrete composite column ( figure 1 a);

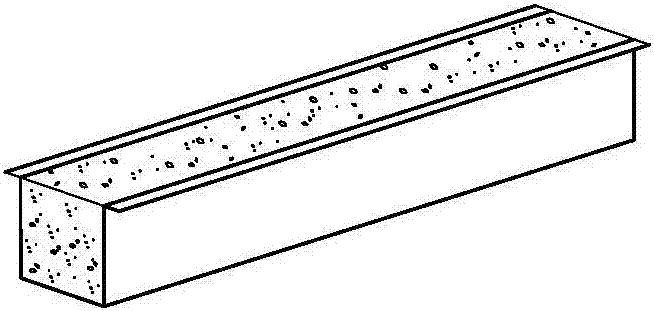

[0034] 2) The section of the outsourcing steel-concrete composite beam is as follows figure 2 As shown, the U-shaped steel plate is directly cold-formed by ...

Embodiment 2

[0039] Prefabricated super high-rise steel-concrete composite housing, including:

[0040] Concrete-filled steel tube composite columns and steel-concrete composite beams form the frame, steel plate composite shear walls are arranged in the core tube area between the frames, and energy-dissipating concrete-filled steel tube composite buckling-constrained braces serve as lateral force-resisting members and energy-dissipating functions. The buckling-restrained braces of energy-type concrete-filled steel pipe composites are arranged obliquely in the frame composed of beams and columns, and are connected with the beam-column gusset plate by means of pins, among which:

[0041] 1) The cross-section of steel tube concrete composite column is as follows: figure 1 As shown, the rectangular steel tube concrete composite column ( figure 1 a);

[0042] 2) The section of the outsourcing steel-concrete composite beam is as follows figure 2 As shown, the U-shaped steel plate is directly...

Embodiment 3

[0047] Prefabricated super high-rise steel-concrete composite housing, including:

[0048] Concrete-filled steel tube composite columns and steel-concrete composite beams form the frame, steel plate composite shear walls are arranged in the core tube area between the frames, and energy-dissipating concrete-filled steel tube composite buckling-constrained braces serve as lateral force-resisting members and energy-dissipating functions. The buckling-restrained braces of energy-type concrete-filled steel pipe composites are arranged obliquely in a frame composed of beams and columns, and are connected with the beam-column gusset plate by welding, in which:

[0049] 1) The cross-section of steel tube concrete composite column is as follows: figure 1 As shown, the rectangular steel tube concrete composite column ( figure 1 a);

[0050] 2) The section of the outsourcing steel-concrete composite beam is as follows figure 2 As shown, the U-shaped steel plate is directly cold-forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com