Quick construction method for segment No.0 of continuous beam

A construction method and rapid technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of long construction period of No. 0 block of continuous beams, and achieve the effects of shortening the construction period, less investment, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

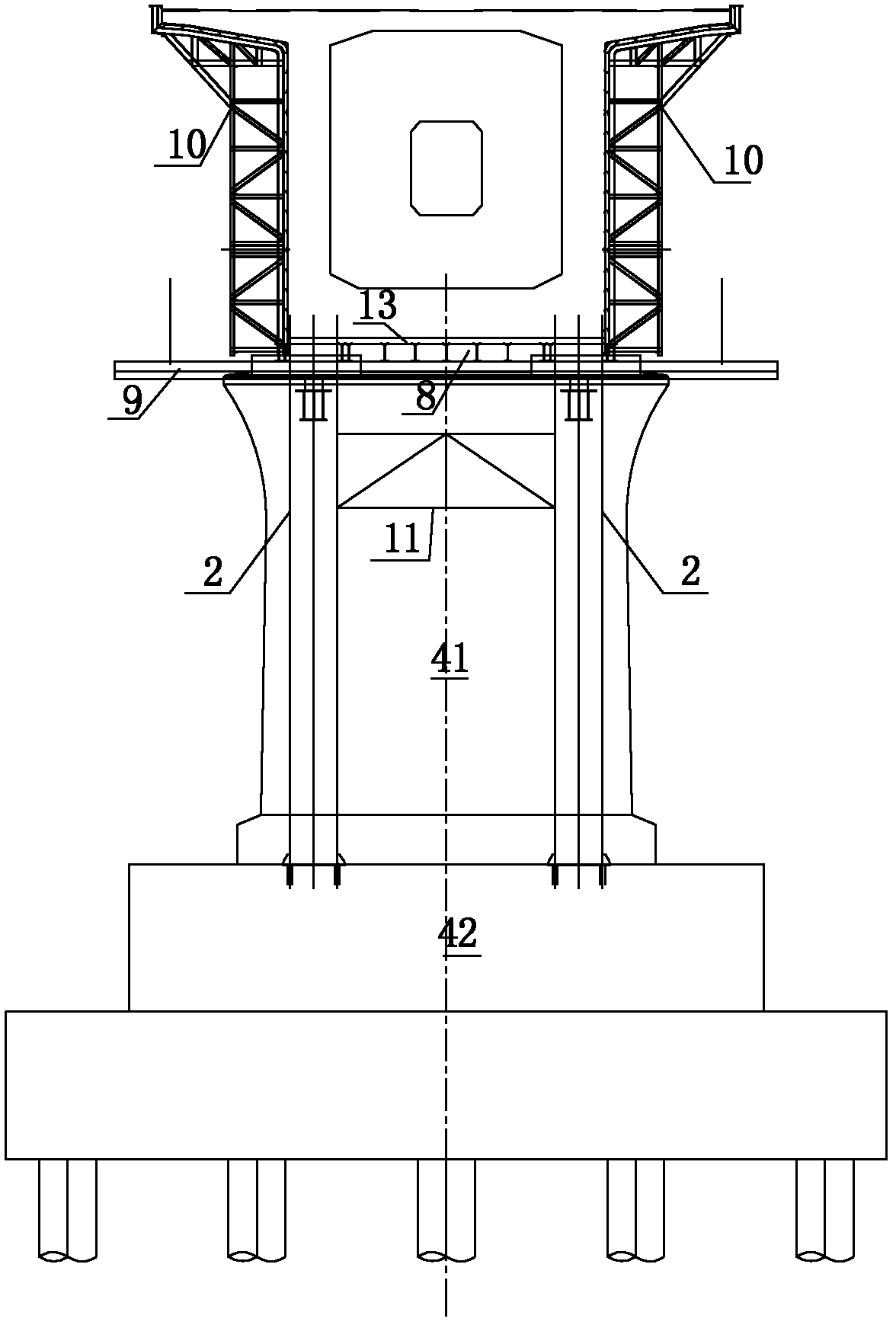

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings. For ease of description, in the following embodiments, the direction along the bridge is used as the front-rear direction, and the direction across the bridge is used as the left and right directions.

[0025] The continuous beam No. 0 block rapid construction method provided by the present invention comprises the following steps:

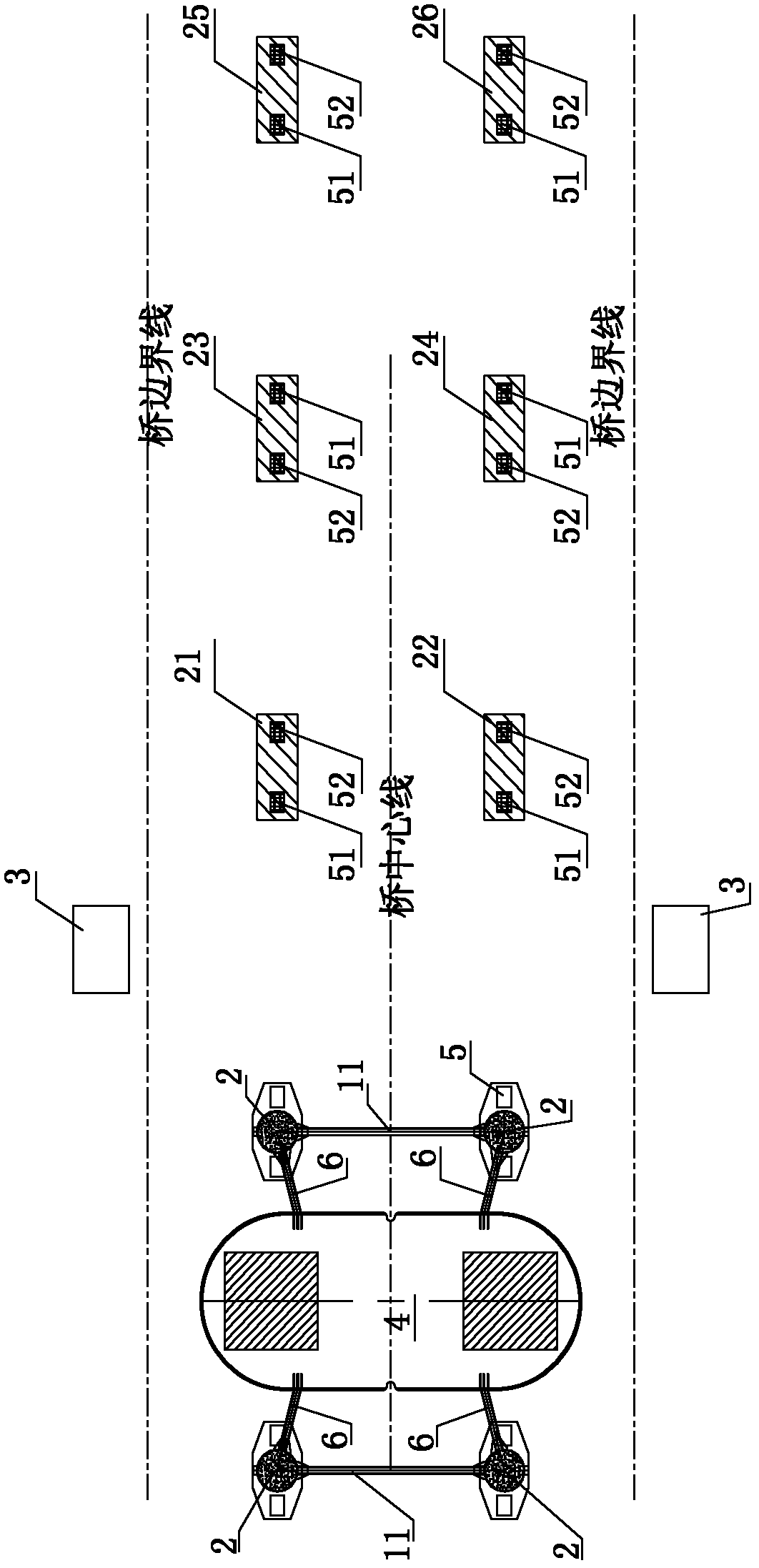

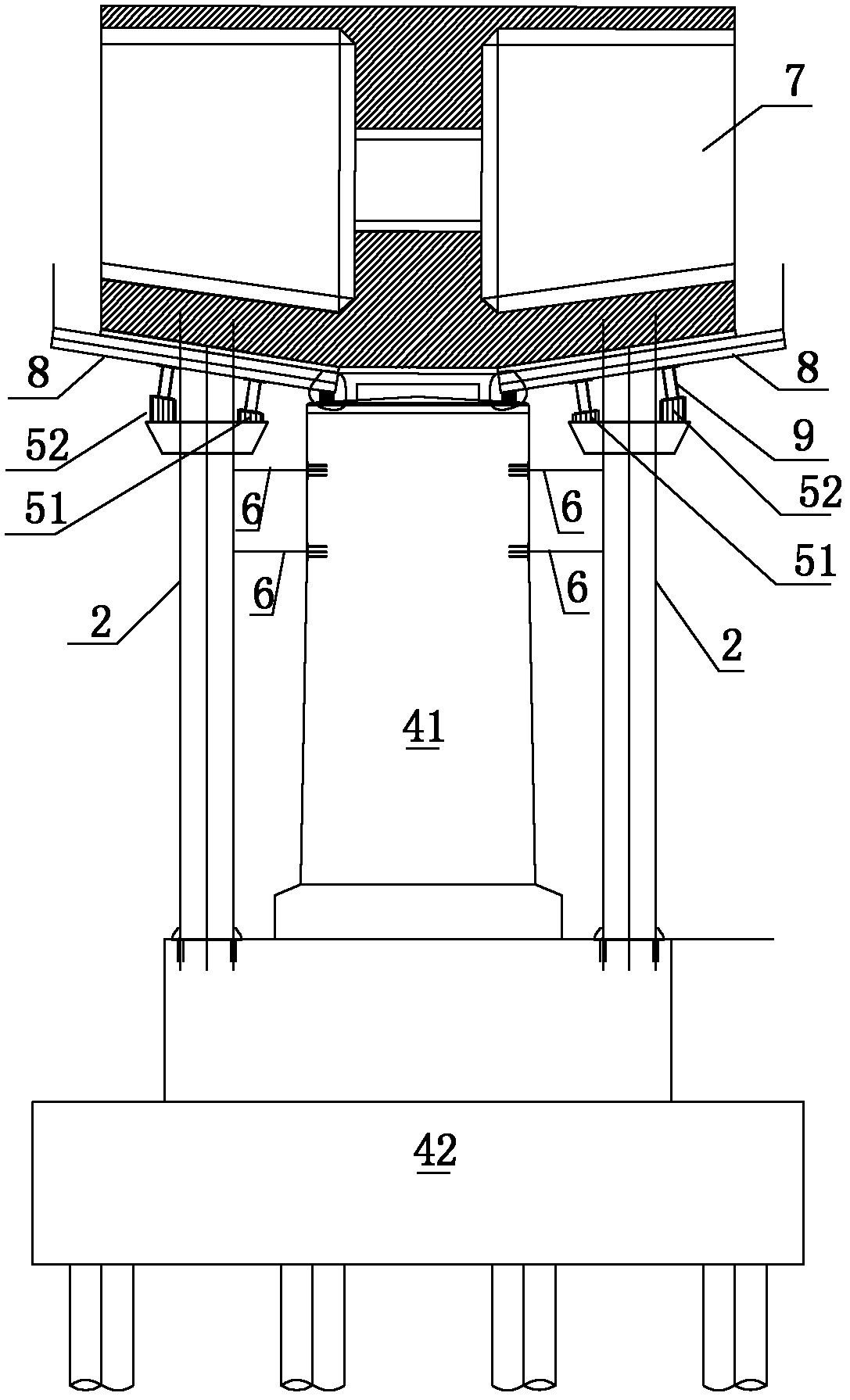

[0026] A10, such as figure 1 As shown, six assembled foundations 21, 22, 23, 24, 25 and 26 are constructed next to the pier position of the main pier 4. The above six assembled foundations are arranged in two rows along the bridge direction, and on the top surface of each assembled foundation The first and second wedges 51, 52 are spot welded respectively on the top, the first and second wedges 51, 52 are arranged along the bridge direction, and the first wedges 51 on the assembled foundations 21, 22 and 25, 26 are close to the main pier 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com