Injection mold with deformed mold core

An injection mold and mold core technology, applied in the field of molds, can solve the problems of kit product quality and affect the production efficiency of kits, and achieve the effects of reducing production time, facilitating control, and facilitating collection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

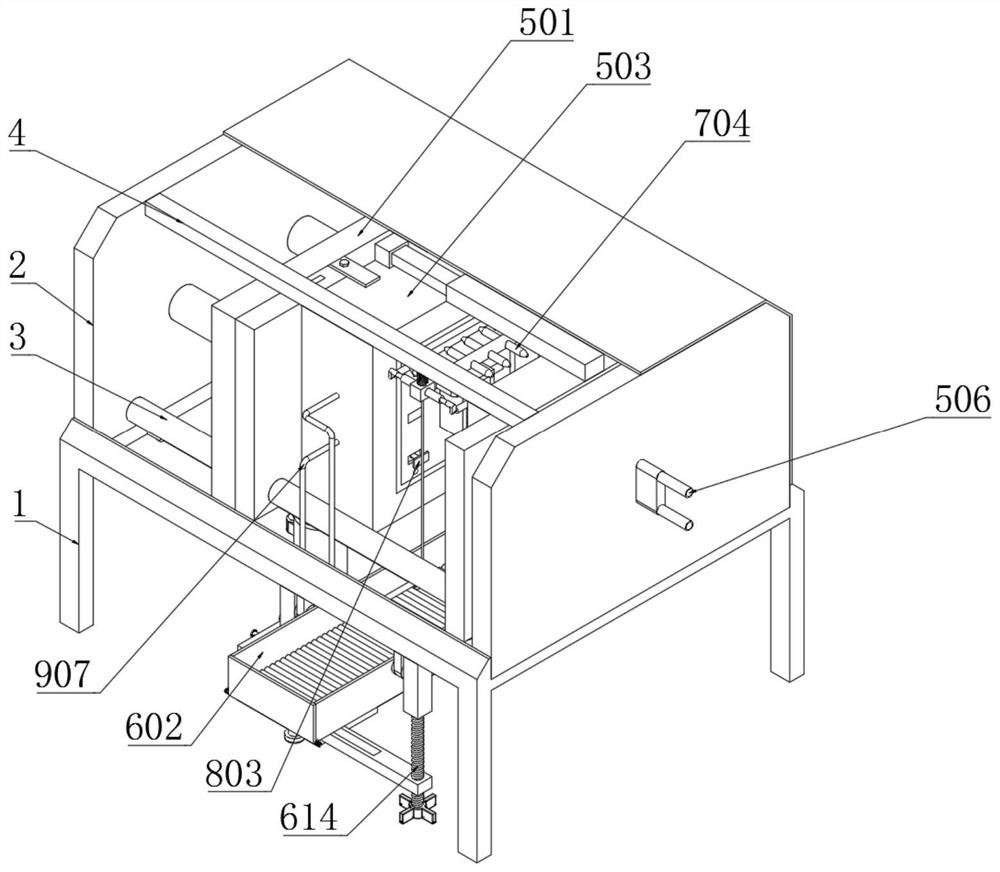

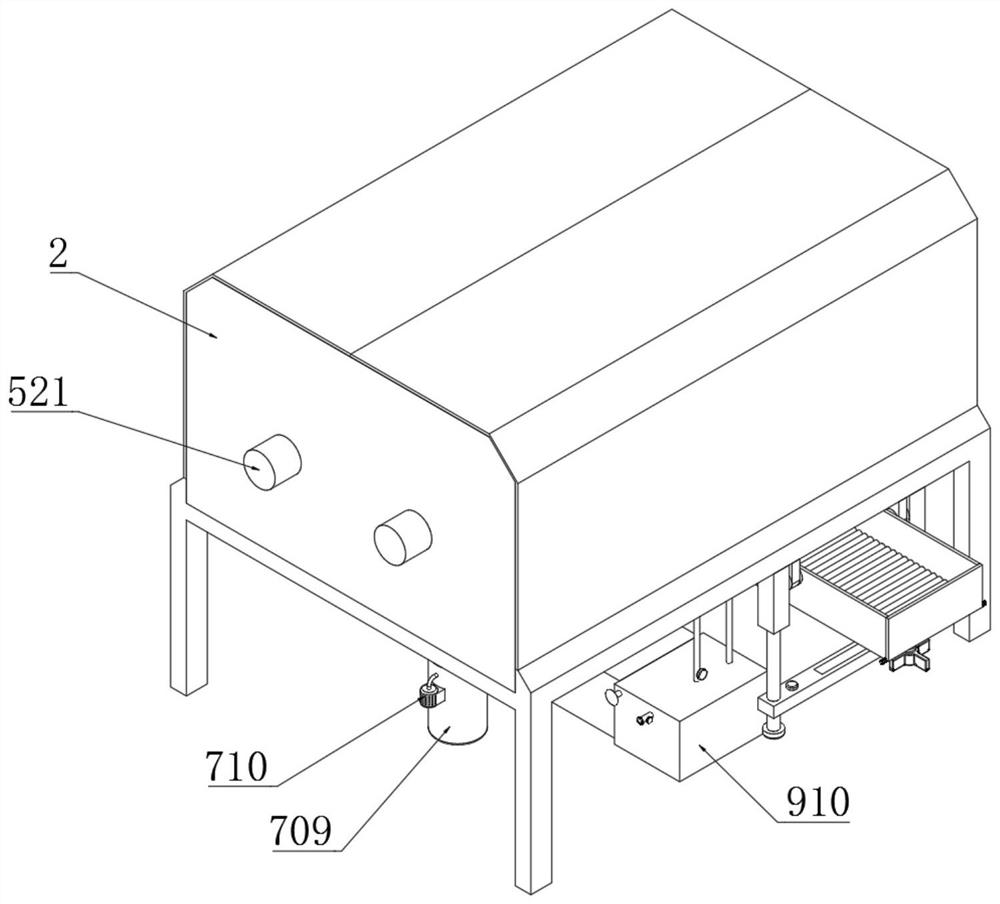

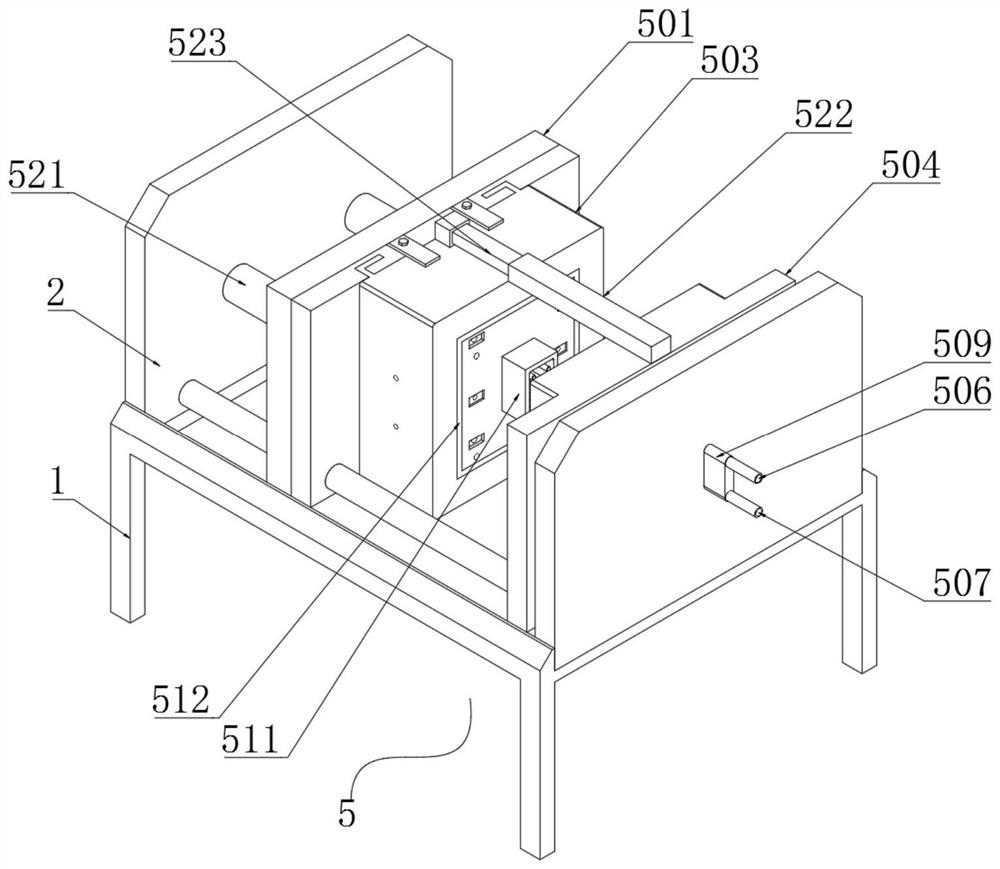

[0043] Example: such as Figure 1-12 As shown, the present invention provides a technical solution, an injection mold with mold core deformation, including a mounting frame 1, the top of the mounting frame 1 is fixedly connected to the mounting box 2, and the inner bottom of the mounting box 2 is symmetrically fixed and fixed with a supporting column 3 , the top of the inner side of the installation box 2 is symmetrically fixedly connected with a support fixing rod 4, and a double-layer injection molding assembly 5 is installed on one side of the support sliding column 3, which is used for product molding in the injection molding process. By changing the size of the internal mold core during injection molding, thereby Realize the injection molding of a variety of products of different sizes, so that the injection molding of the socket can be completed in the same mold, without the need for personnel to perform secondary operations;

[0044] One side of the installation frame 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com