Variable cross section tunnel excavation construction method based on climbing pilot tunnel

A tunnel excavation and construction method technology, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of limited construction space and length, complex construction procedures, and many temporary supports, and achieve rapid and effective support protection, Improved excavation efficiency and flexible construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

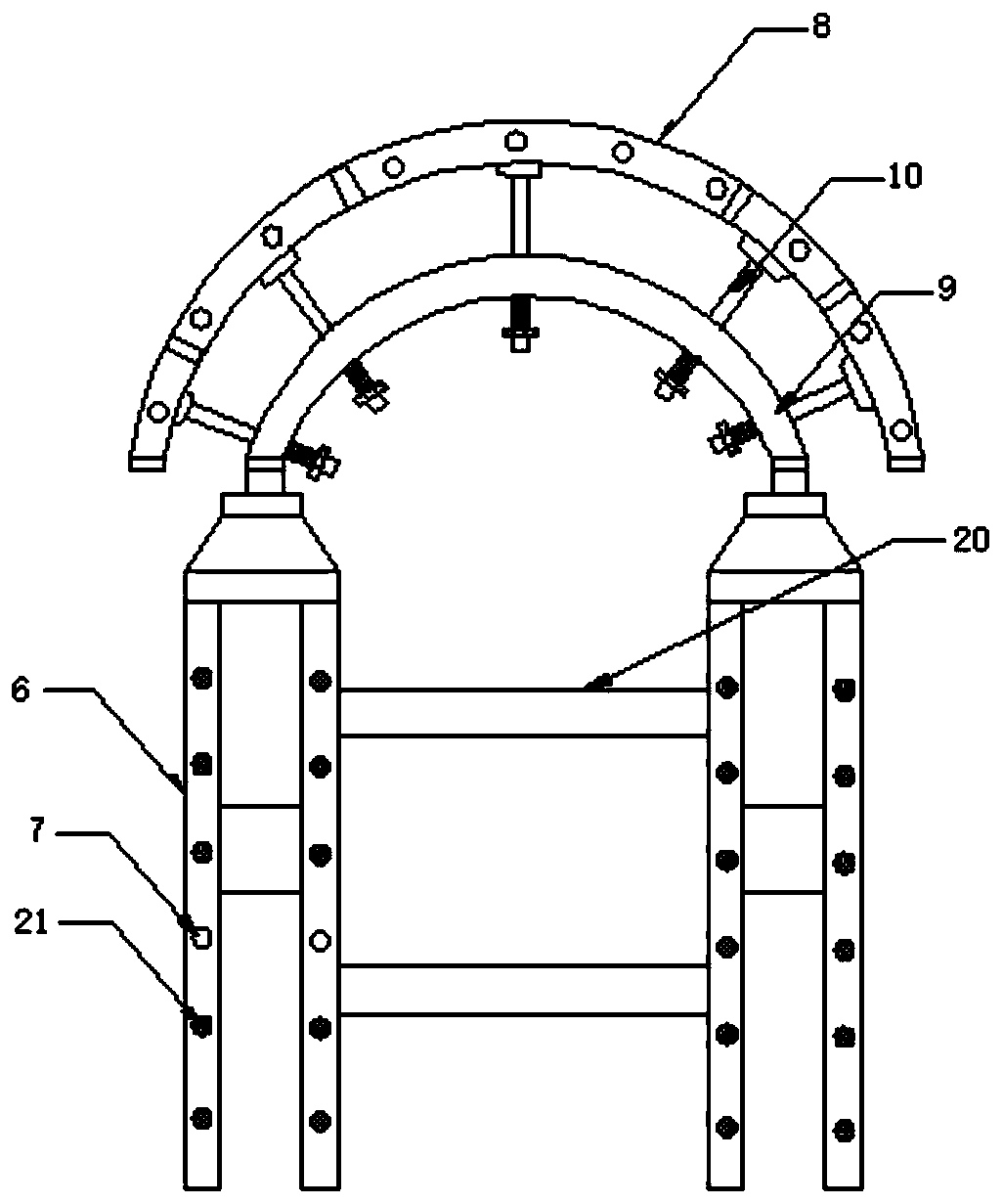

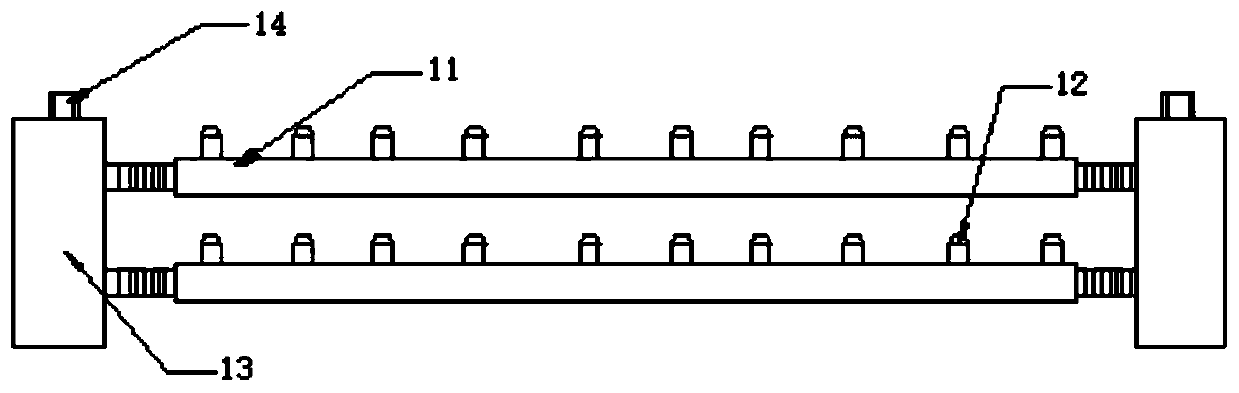

[0067] The longitudinal distance of the 16 climbing sections of the small pilot tunnel with overhead roof is 10m in total, and the slope is 38.2%. Longitudinal distance 0.5m, ring distance 0.8m; φ8 single-layer steel mesh 20cm×20cm and C25 shotcrete thickness 25cm; when excavating, set up small lead pipe φ42 every 2m, length 3.5m, longitudinal distance 2m, ring distance 0.3m ; Longitudinal connecting bars φ22, ring distance 1m, staggered internally and externally; locking foot anchor pipes φ42, each 4 pieces, length 3.5m, and its support parameters can be adjusted according to the rock formation conditions.

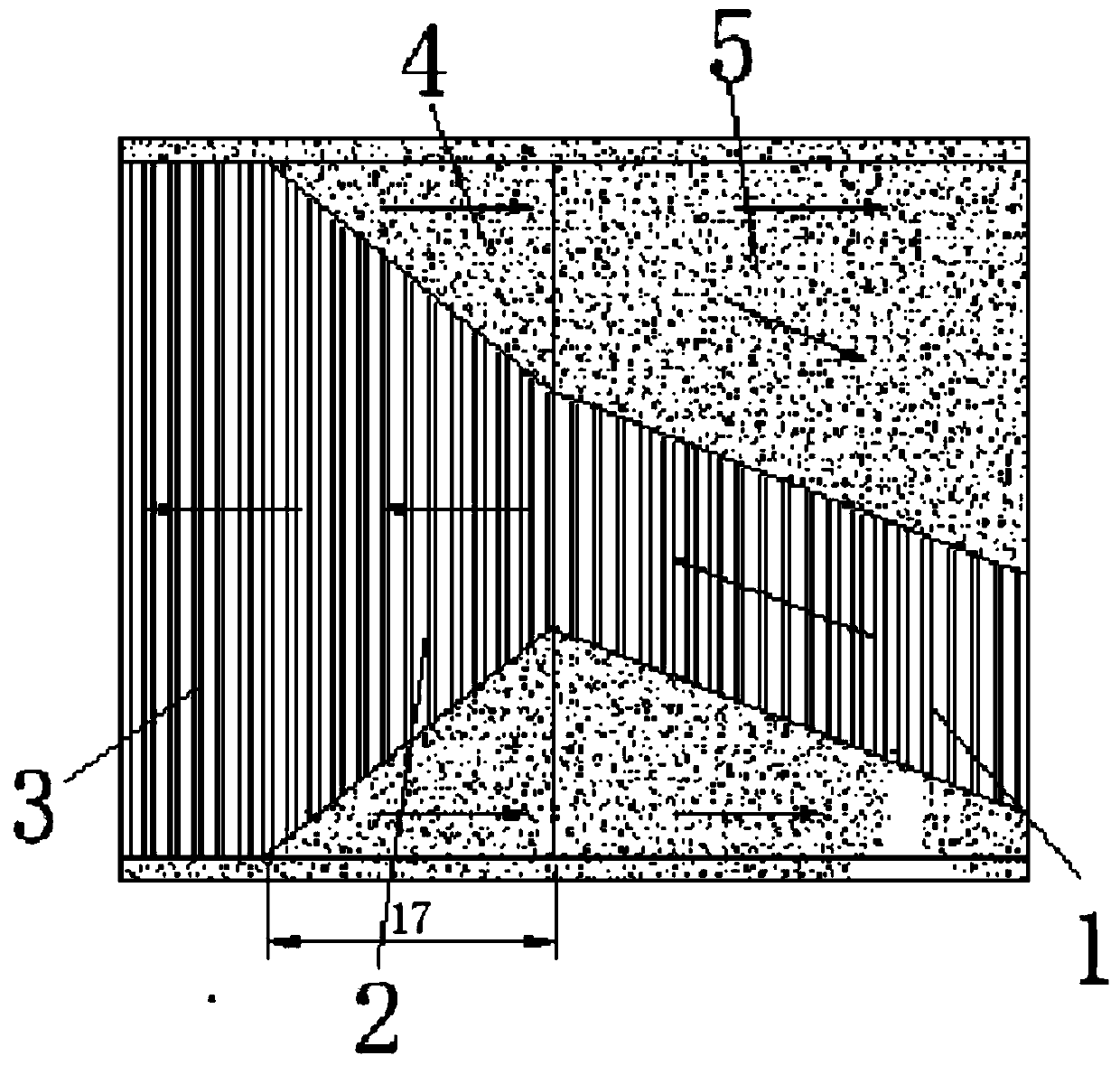

[0068] The vault is provided with a transition section 17 that is expanded to both sides. The transition section 17 adopts concentric circular arch walls, and the radius change size gradually transitions to the width of the high-level tunnel of the large section 18 along with the average change per linear meter. The transitional section 17 expansion excavation 2 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com