Track movable stretchable chute

A mobile and rail-based technology, applied in the field of concrete pouring, can solve the problems of difficult concrete pouring, high cost, and complicated construction of long foundation pits, and achieve the effect of simple and easy control, easy operation, and reduced construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

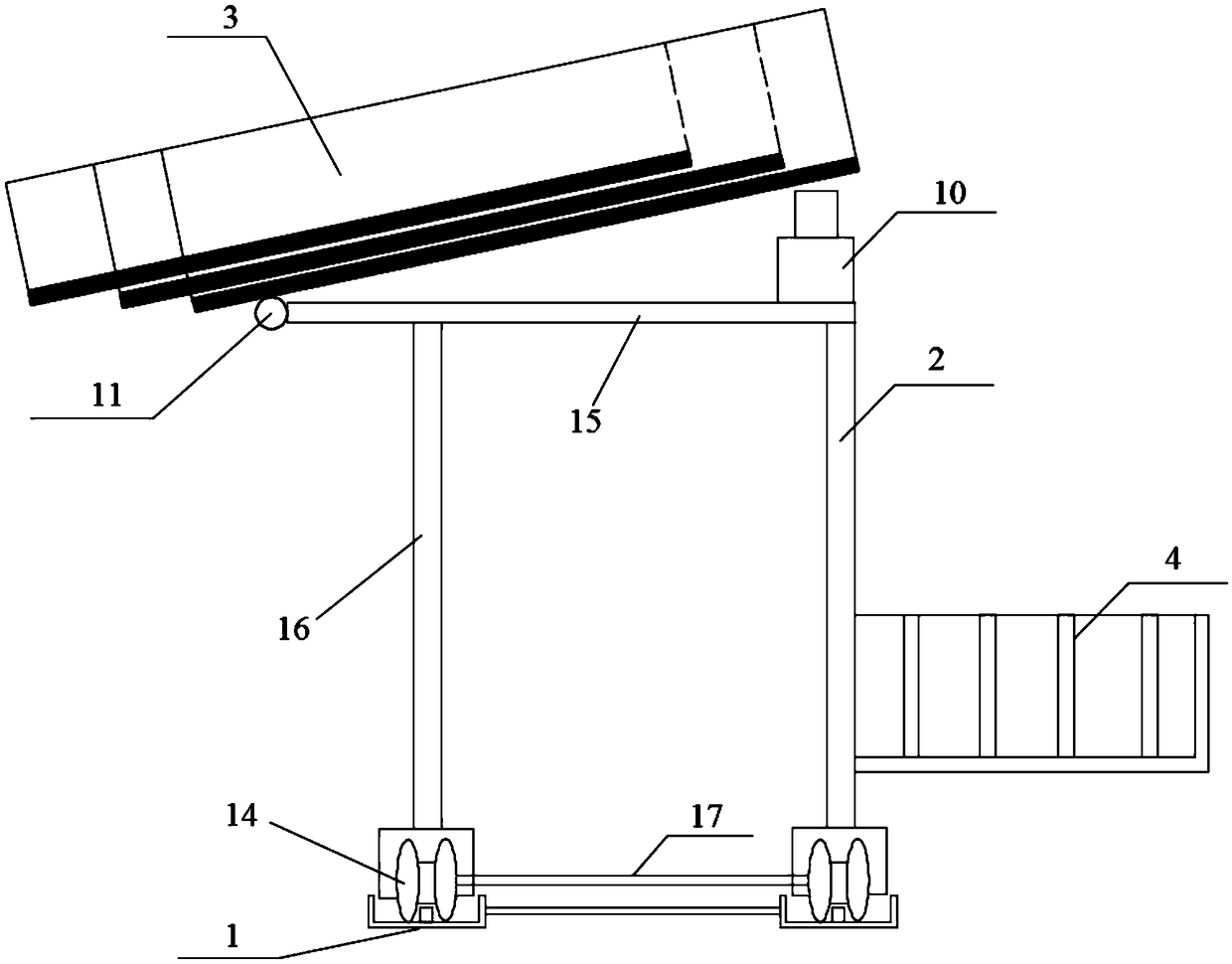

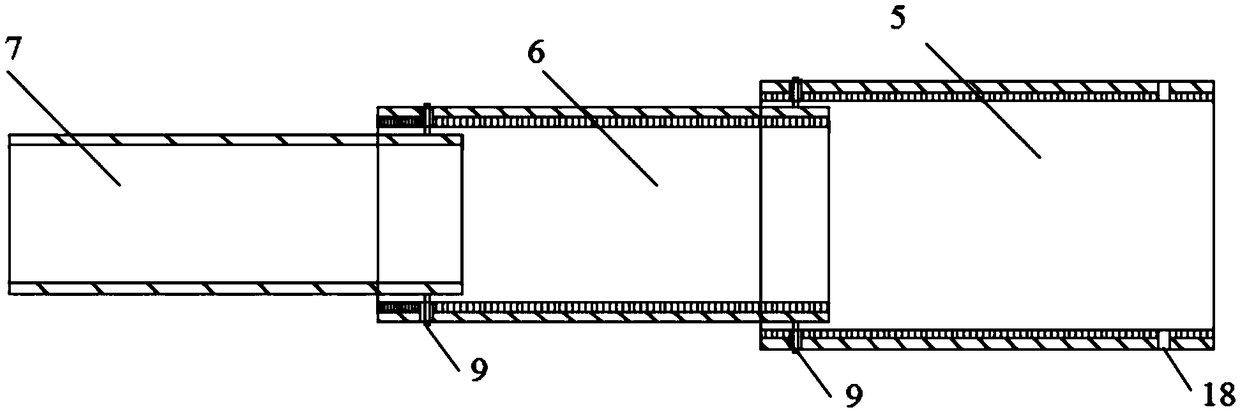

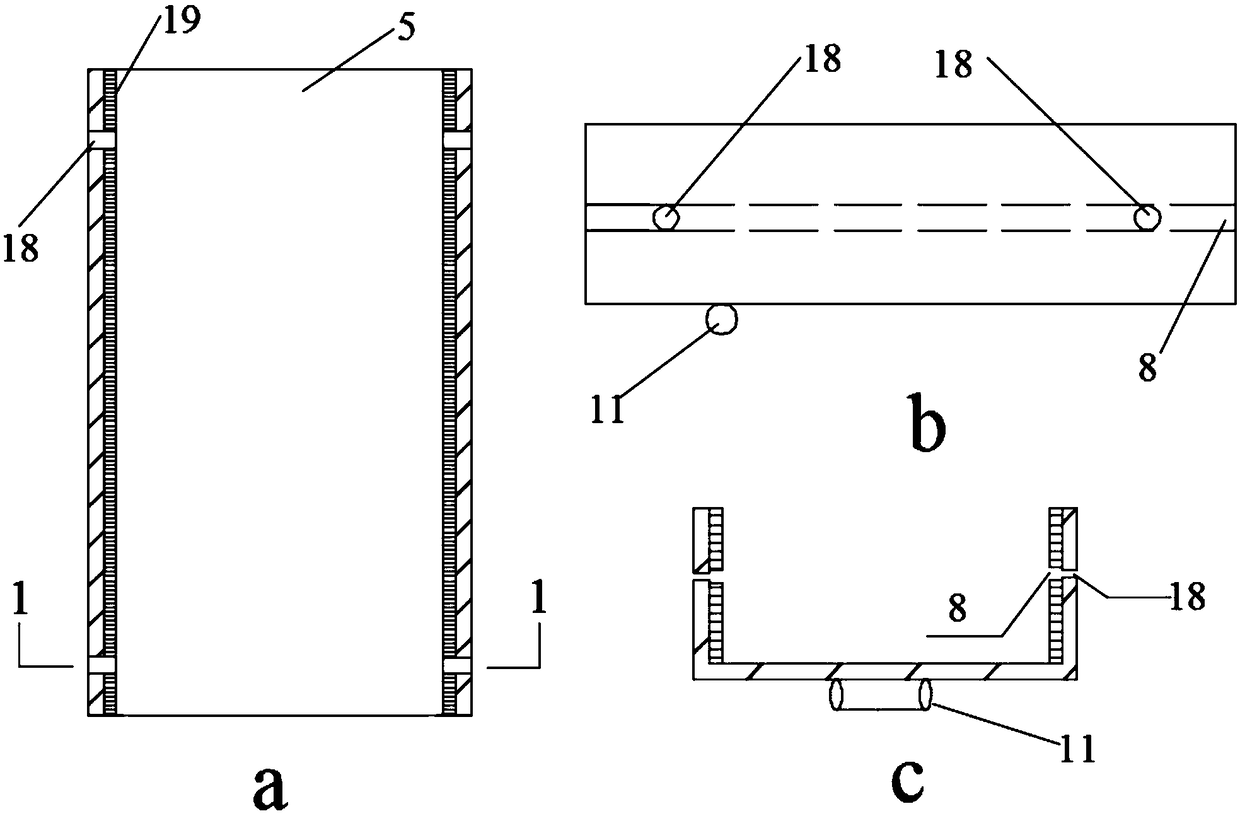

[0033] Below in conjunction with accompanying drawing, the present invention is described by way of example. The present embodiment takes the telescopic chute formed by three U-shaped grooves as an example.

[0034] Such as Figure 1 to Figure 7 As shown, a rail mobile telescopic chute includes a rail 1, a mobile bracket 2 and a telescopic chute 3, the rail 1 is installed along the pipe groove to be poured, and the mobile bracket 2 is installed on the rail 1 through the traveling wheels 14, The telescopic chute 3 includes the first section U-shaped groove 5, the middle section U-shaped groove 6 and the last section U-shaped groove 7, which are successively reduced in size and nested and installed. The bottom of the front end of the U-shaped groove 5 of the first section is hinged on the mobile bracket 2, the rear end is supported on the mobile bracket 2 by the lifting device, the U-shaped groove 6 of the middle section and the U-shaped groove 7 of the last section are installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com