Coal seam low-temperature fixed-point frozen sampling device and use method thereof

A sampling device and low-temperature technology, applied in the direction of extracting undisturbed core devices, earthwork drilling, wellbore/well components, etc., can solve the problems of affecting the accuracy of gas content, backward development of sampling tools, and unsatisfactory cooling effect, etc., to achieve structural Compact, innovative design, simple sampling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

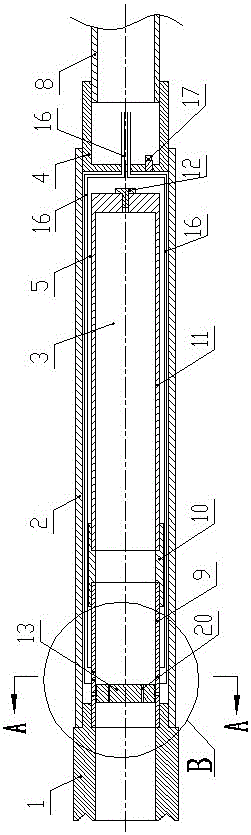

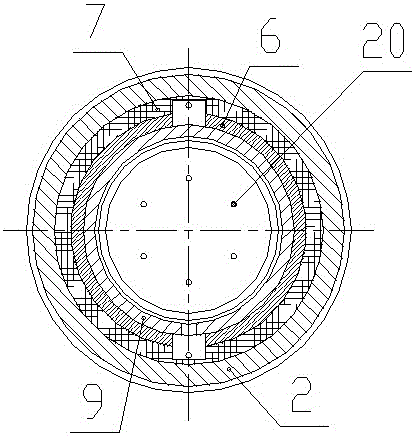

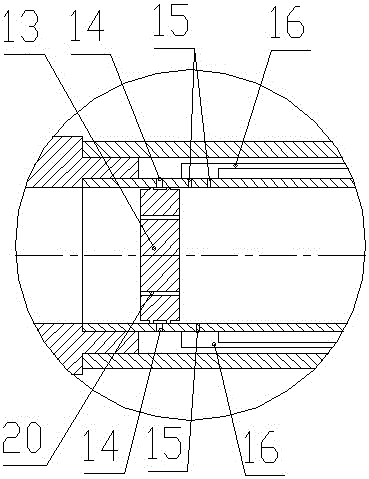

[0029] Example: such as Figure 1-3 A coal seam low-temperature fixed-point ice-sealing sampling device is shown, comprising a through-hole coring bit 1, a sampling drill pipe 2 is fixedly connected to the outer wall of the right end of the through-hole coring bit 1, and a sampling drill pipe 2 is fixedly connected to the right end inner wall of the through-hole coring bit 1. In the frozen cryogenic sample holder 3, the inner wall of the right end of the sampling drill pipe 2 is fixedly connected with a drill pipe adapter 4, the left end of the drill pipe adapter 4 is closed and the right end is open, and the right end surface of the frozen cryogenic sample holder 3 is connected to the drill pipe adapter 4. There is a gap between the left end faces, and the right end face of the through-hole coring bit 1, the left end face of the drill pipe adapter 4, the inner wall of the sampling drill pipe 2 and the outer wall of the frozen cryogenic sample holder 3 form a cavity 5, the cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com