Cold control device of dual-throttle precooling and freshness preserving ice-cream machine, cold control method and ice-cream machine

An ice cream machine, double throttle technology, applied in the fields of frozen desserts, food science, application, etc., can solve the problems of poor temperature control accuracy, great influence on the refrigeration performance of the main cylinder, limited refrigeration capacity and refrigeration speed of the material basin, etc. The effect of rapid cooling and stable control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

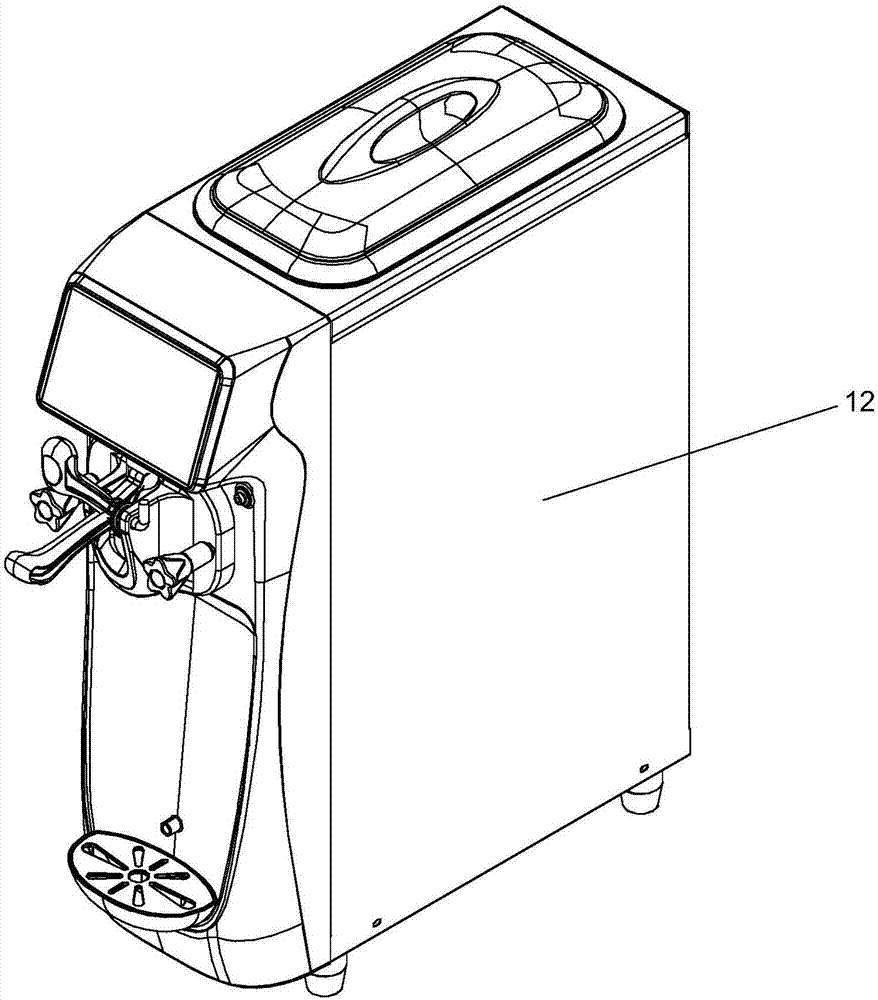

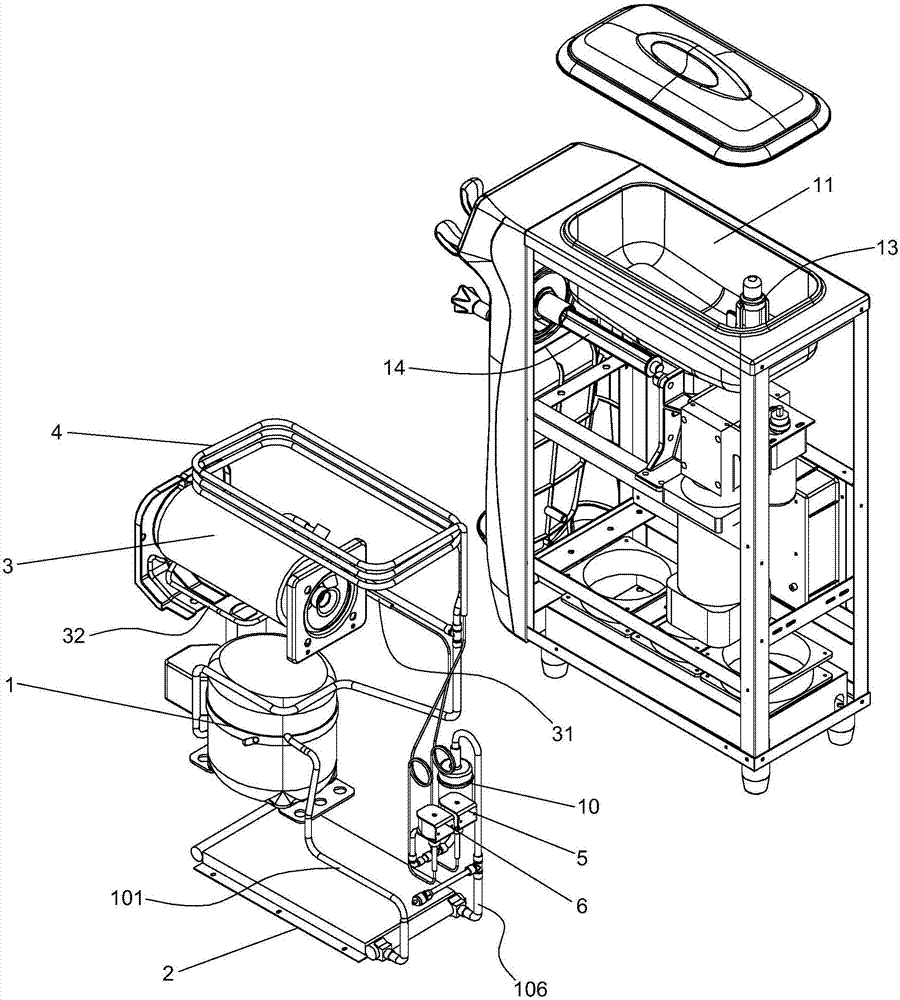

[0074] The embodiment of double-throttling precooling fresh-keeping ice cream machine of the present invention is as Figure 5 to Figure 7 As shown, the ice cream machine includes a fuselage 12, a material basin 11, a material basin agitator 13, a material basin stirring motor, a freezing cylinder 3, a freezing cylinder agitating motor 14, a freezing cylinder stirring motor, a discharge head, a sensor, and an electric control board , control display board and cold control device, the material basin agitator 13 is installed in the material basin 11, is connected with the material basin stirring motor, the freezing cylinder agitator 14 is inserted in the freezing cylinder 3, is connected with the freezing cylinder stirring motor, The electric control board is used to control the actions of various components.

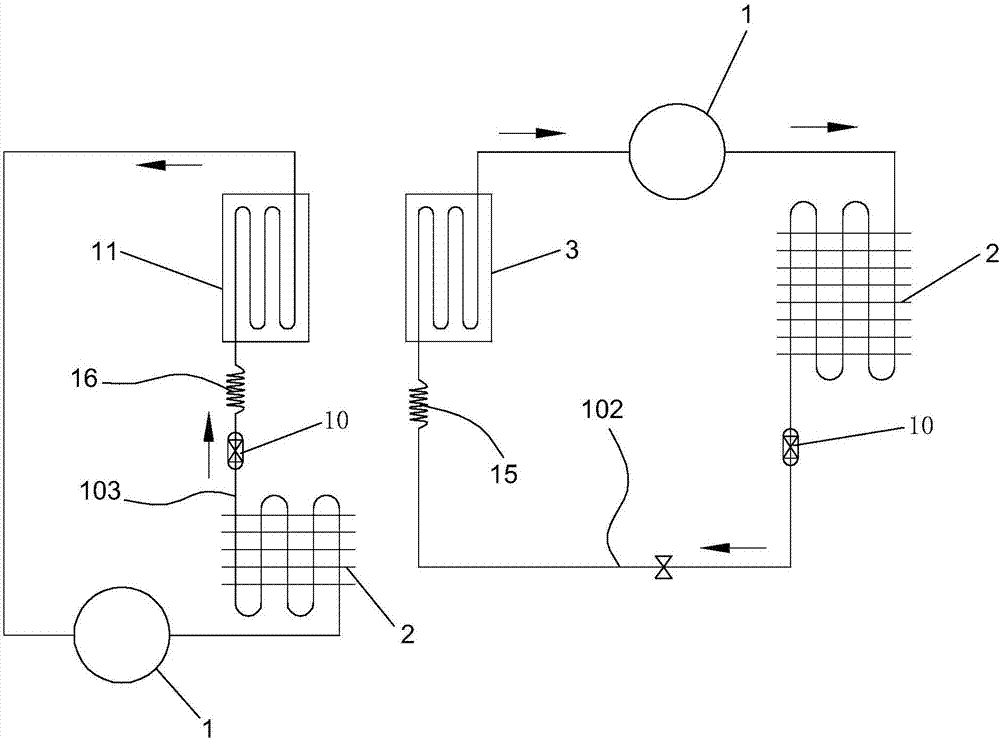

[0075] The cooling control device in this embodiment includes a compressor 1, a condenser 2, a material basin evaporator 4, a freezing cylinder refrigeration inlet pipe 3...

Embodiment 2

[0102] Embodiment 2 of the present invention's double-throttling pre-cooling and fresh-keeping ice cream machine Figure 8 to Figure 10 As shown, the difference from the first embodiment is that this embodiment does not have the thawing pipeline 105, cannot perform thawing treatment on the freezing cylinder, and does not have a freezing cylinder thawing mode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com