Patents

Literature

158results about How to "Guaranteed normal feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

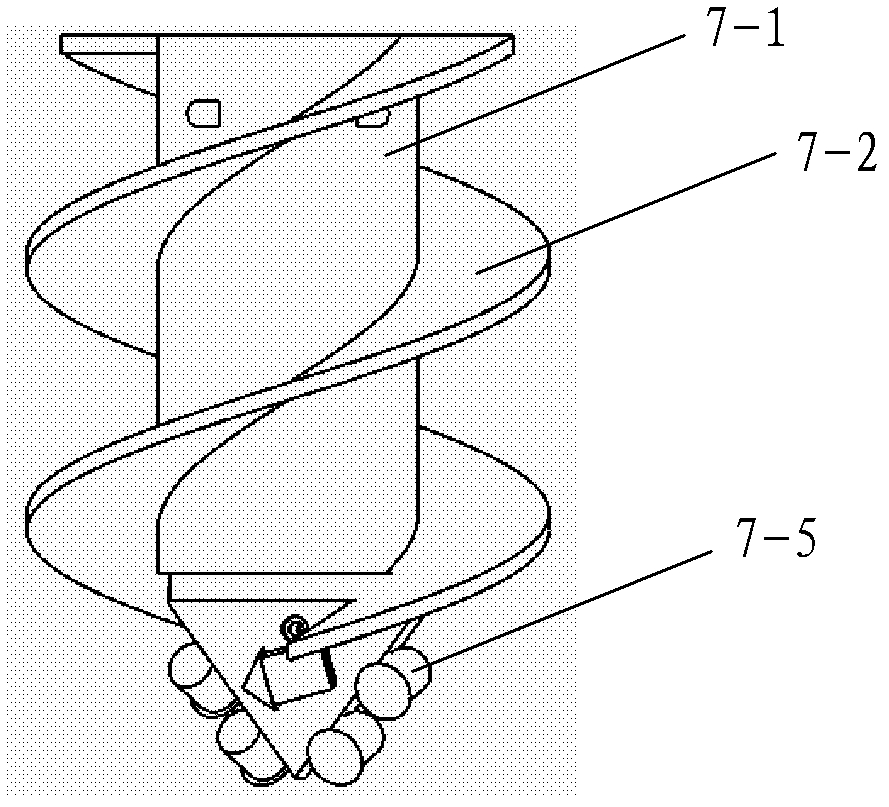

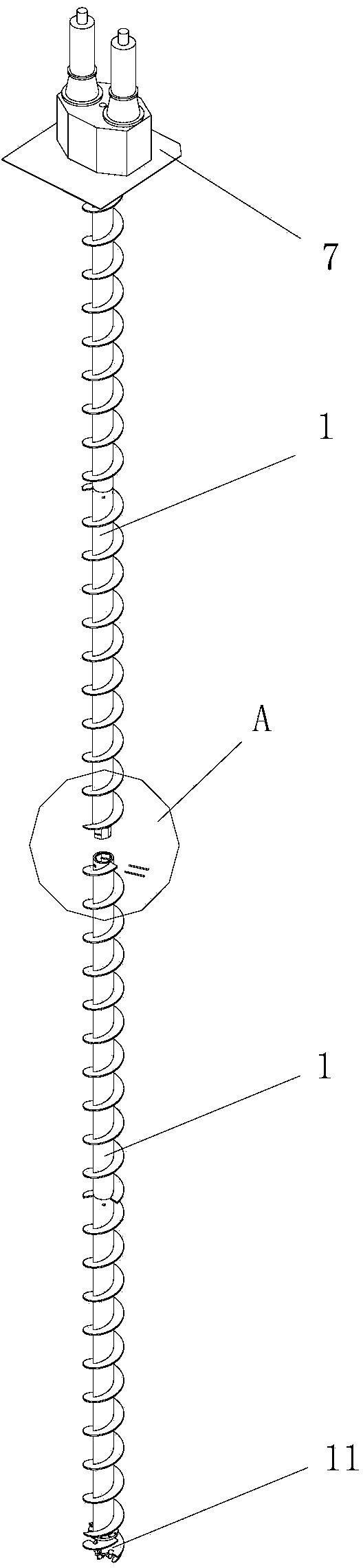

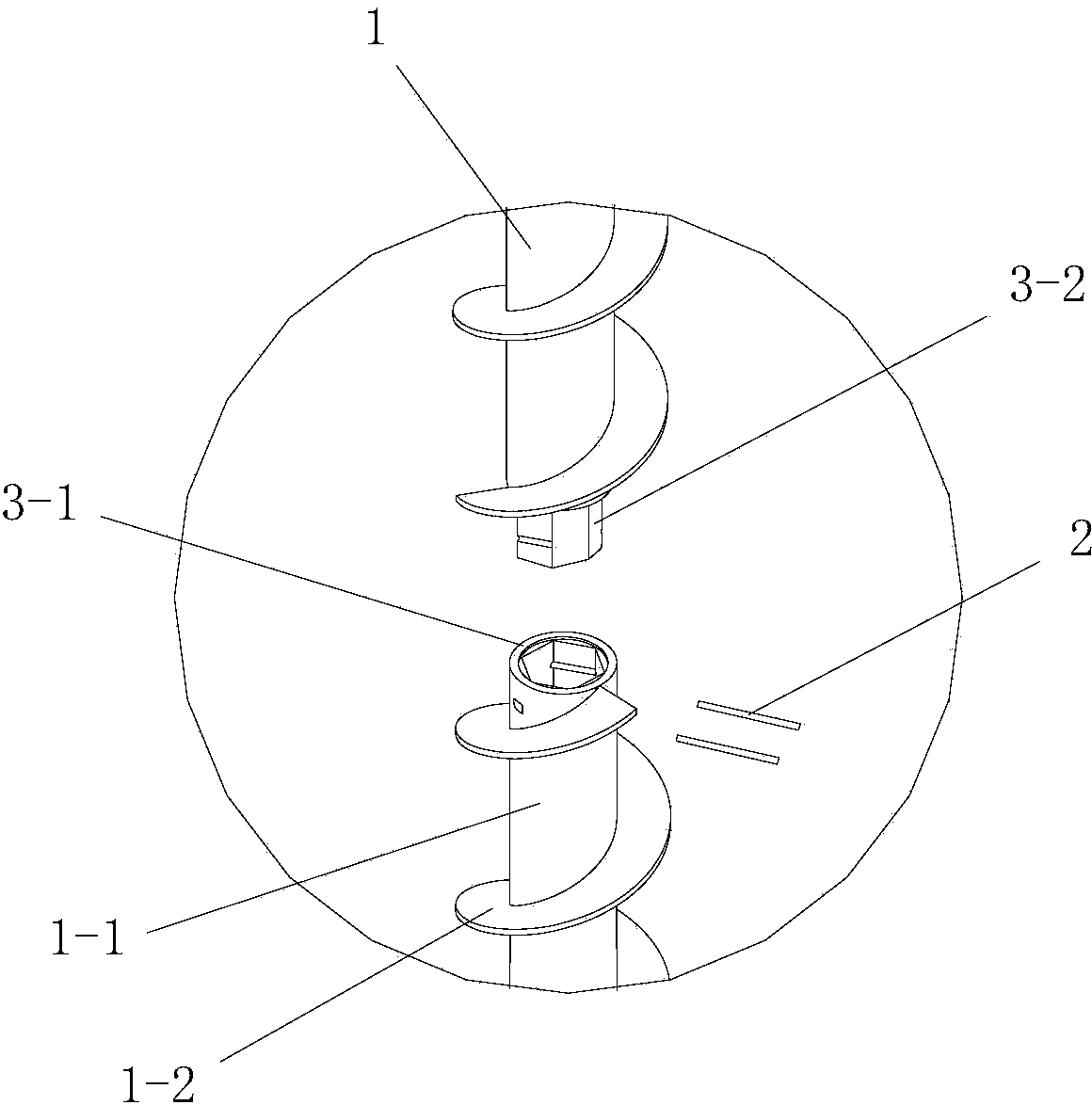

Molding device and molding method for long spiral extruding rock-entering cast-in-place pile

ActiveCN102535445AReasonable structural designEasy to operateDrill bitsDrilling rodsDevice formForming processes

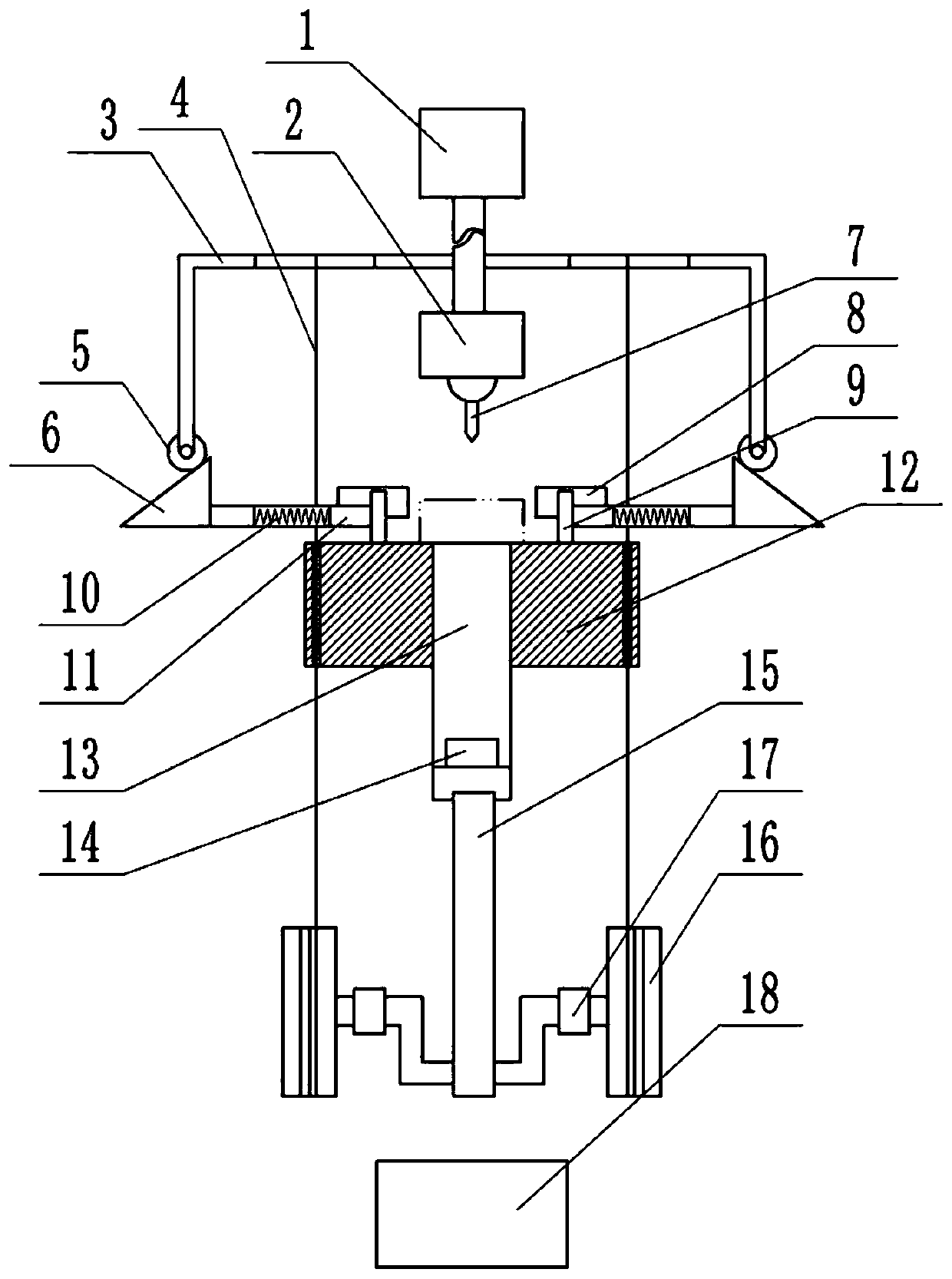

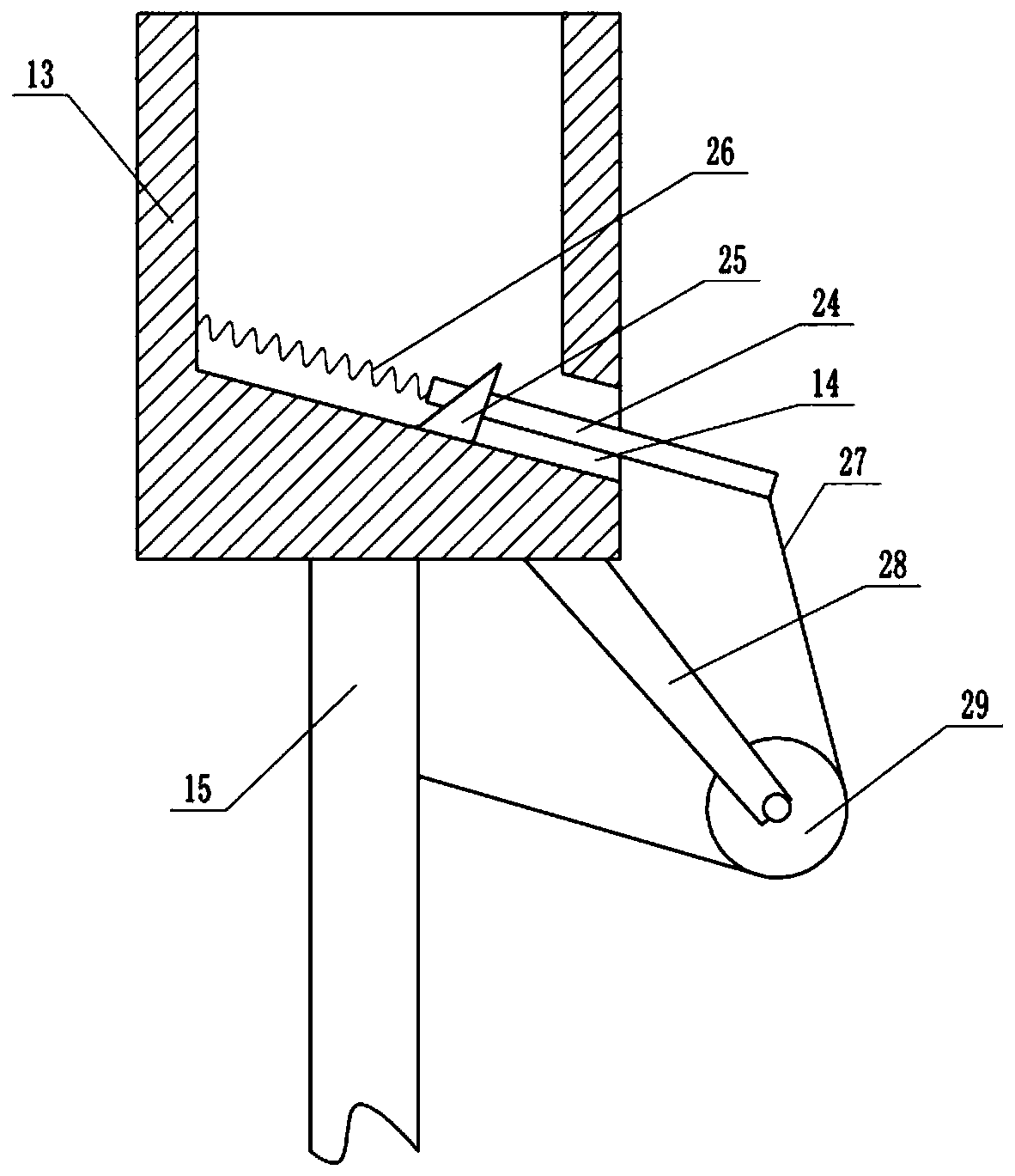

The invention discloses a molding device and a molding method for a long spiral extruding rock-entering cast-in-place pile. The molding device comprises a drilling device formed by assembling a drill stem and a drill arranged at the bottom of the drill stem coaxially, a lowering / lifting system, an electric rotating driving mechanism for driving the drilling device to rotate continuously, a slip casting device for grouting casting slip into molded drill holes continuously to form bored piles when the lowering / lifting system lifts the drill stem, a drilling depth / lifting height detecting unit, a pumping flow detecting unit, a controller and a parameter input unit connected with the controller. The molding method includes: 1 setting initial parameters; 2 drilling; 3 further processing after drilling is in place; and 4 lifting the drill and slip-casting simultaneously. The molding device and the molding method are reasonable in design, easy to use and operate, high in automation, easy in molding process, easy in controlling of pile quality, wide in application range and capable of solving a plurality of problems in the existing molding devices and molding methods for the long spiral extruding rock-entering cast-in-place pile.

Owner:SHAANXI ZHUANGXIN CONSTR ENG

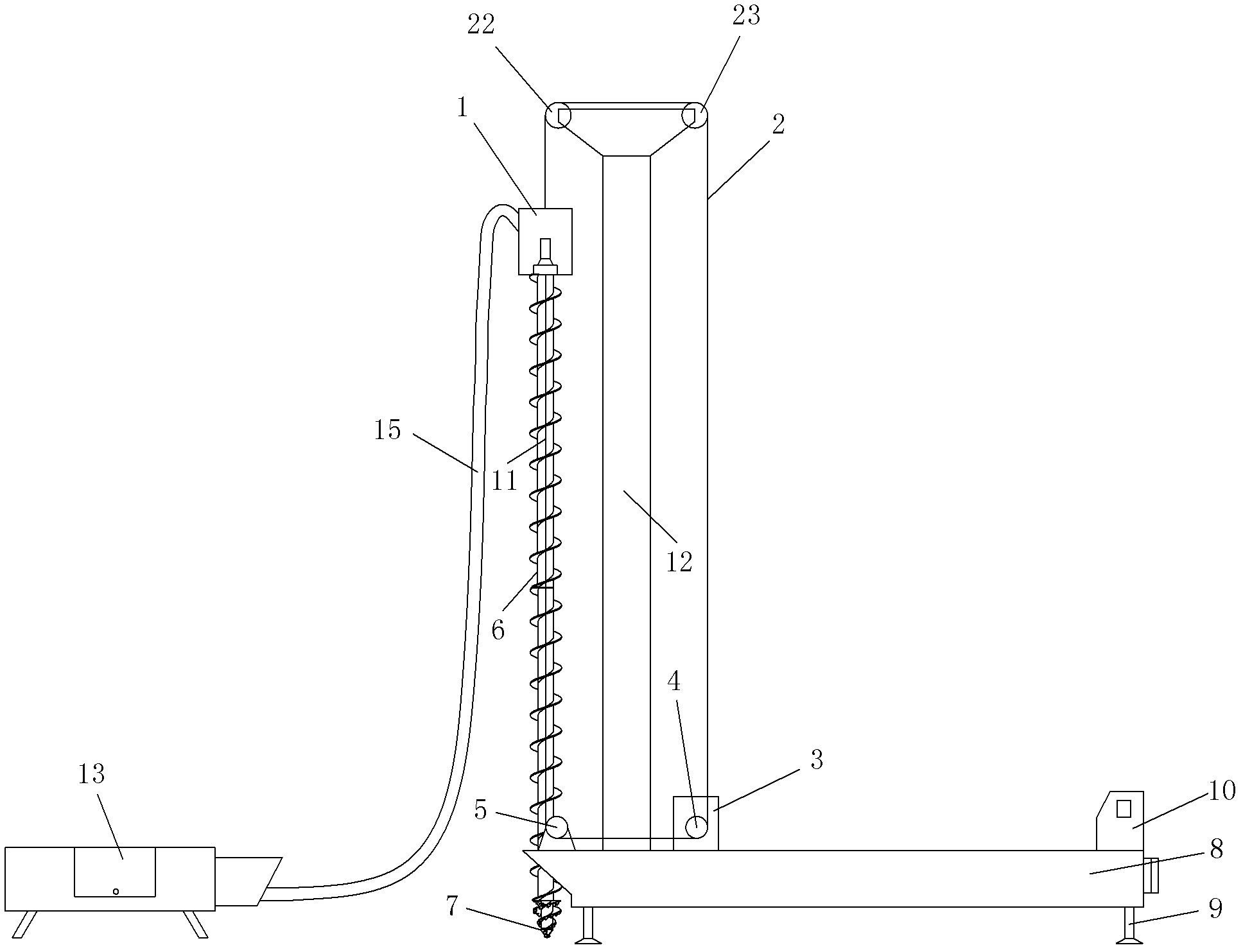

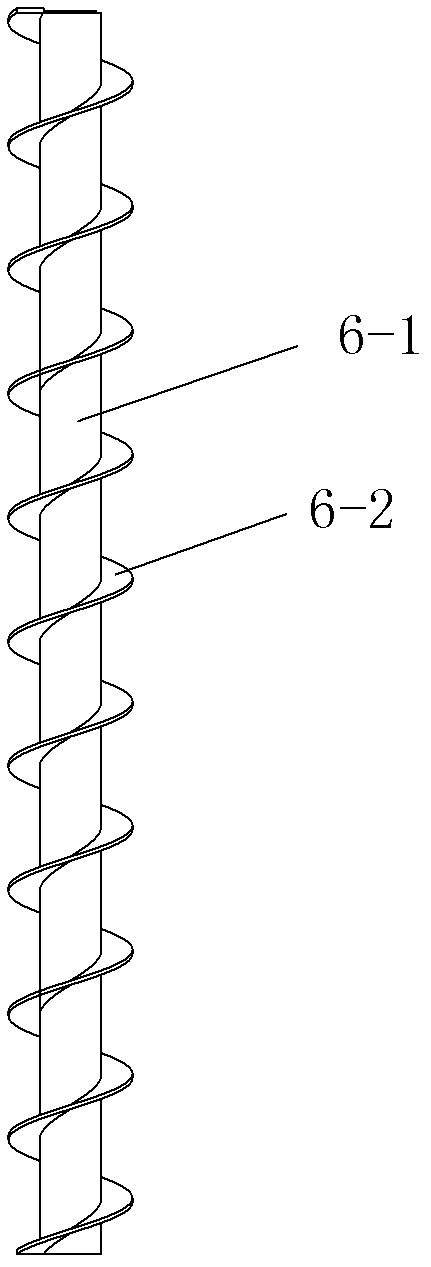

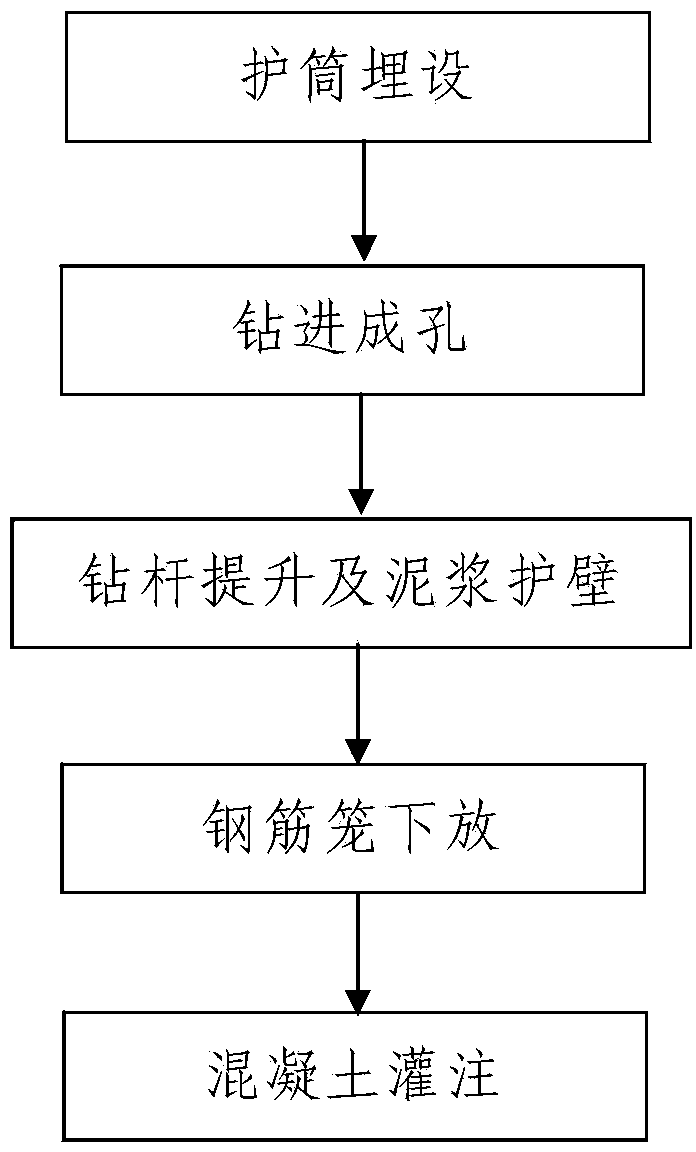

Construction technology for long-spiral cast-in-place pile extruded into rock

ActiveCN103850249AReasonable structural designEasy to operateDrilling rodsRotary drillingSlurryEngineering

The invention discloses a construction technology for a long-spiral cast-in-place pile extruded into rock. The construction technology comprises the following steps: 1) embedding a pile casing: embedding the pile casing in a pile position acquired by surveying and setting out; 2) drilling a hole: downward drilling by a long-spiral pile machine and acquiring a constructed and formed hole after drilling in place; 3) lifting a drill rod and protecting a wall with slurry: upward lifting the drill rod after drilling in place till taking the drill rod out of the formed hole, adopting a grouting device and pumping the wall-protecting slurry through the drill rod during the process of upward lifting the drill rod, and protecting the wall with the slurry for the formed hole; 4) putting down a reinforced bar cage; 5) grouting concrete: performing concrete grouting construction on the constructed long-spiral cast-in-place pile extruded into rock through a concrete pumping device and a grouting guide tube. The construction technology provided by the invention has the advantages of simple steps, convenience in realization, high hole quality, good construction effect and capability of effectively solving the problems of the present construction for the long-spiral cast-in-place pile extruded into rock that the hole wall is easy to collapse, the hole is repeatedly cleaned, the construction efficiency is low, and the like.

Owner:SHAANXI ZHUANGXIN CONSTR ENG

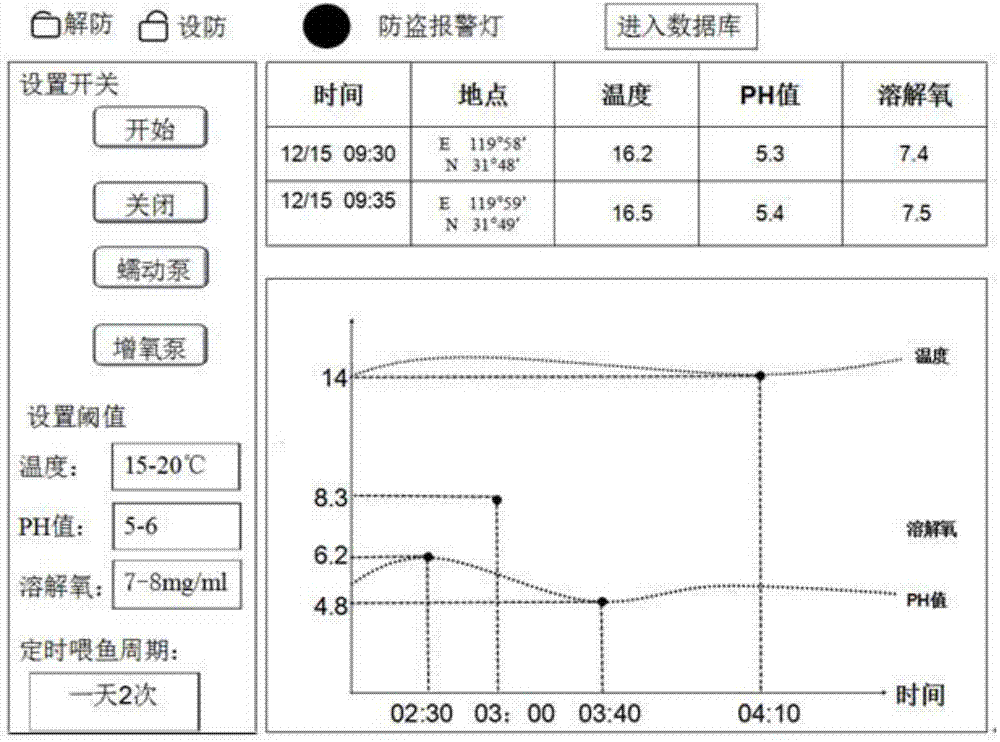

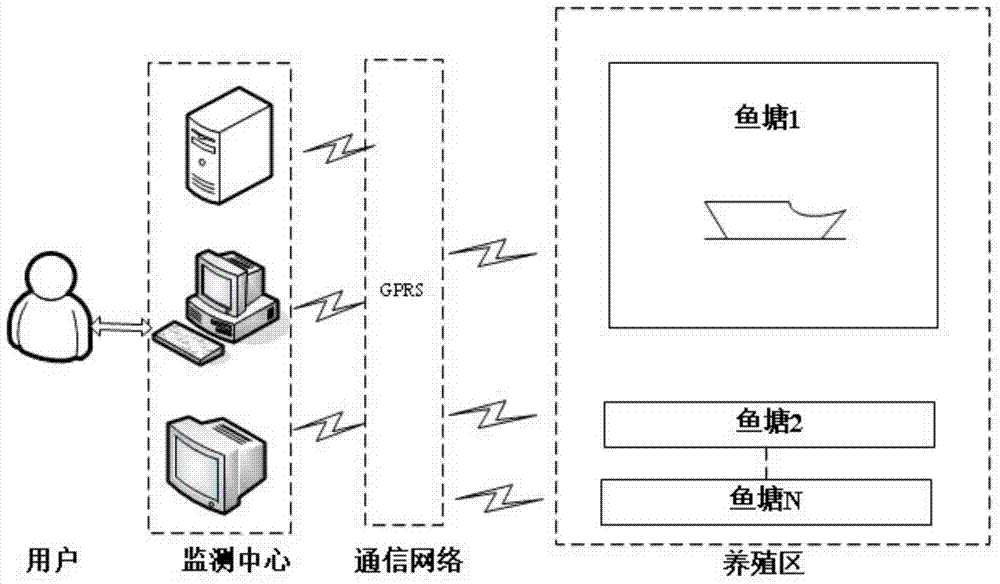

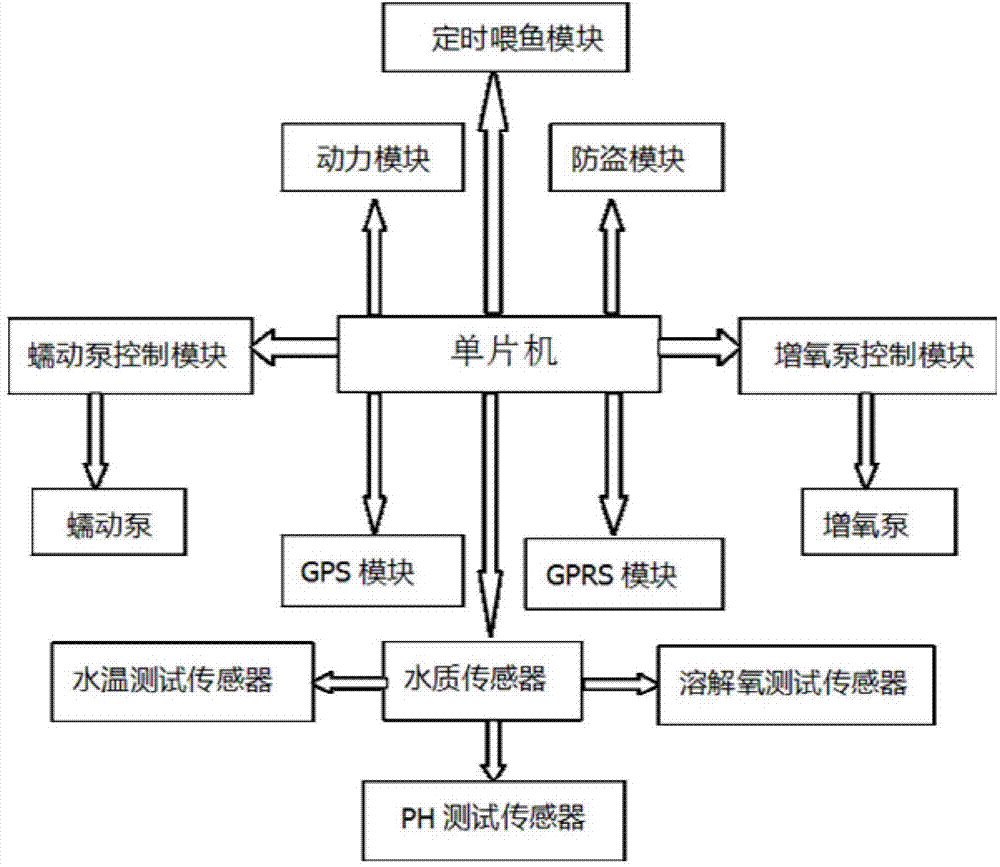

Aquaculture intelligent ship monitoring system based on GPRS

InactiveCN104765333ANo wiring requiredLow costNetwork topologiesTransmissionMicrocontrollerWater quality

The invention discloses an aquaculture intelligent ship monitoring system based on the GPRS. The aquaculture intelligent ship monitoring system based on the GPRS comprises a ship body, a power module, water quality collecting and monitoring modules, a GPS module, an anti-theft module, an automatic oxygenation module, a timing fish feeding module, a GPRS module and a far-end monitoring platform, wherein a single-chip microcomputer is connected with the water quality collecting and monitoring modules, the GPS module, the anti-theft module, the power module, the automatic oxygenation module, the timing fish feeding module and the GPRS module. The aquaculture intelligent ship monitoring system based on the GPRS automatically finishes monitoring, theft prevention, automatic oxygenation and timing feeding of aquaculture, integrates intelligent sensing, intelligent processing and intelligent control, and is high in automation degree, accurate in monitoring, timely in control and low in energy consumption. The whole system adopts network transmission, does not need wire distribution and is low in cost.

Owner:CHANGZHOU UNIV

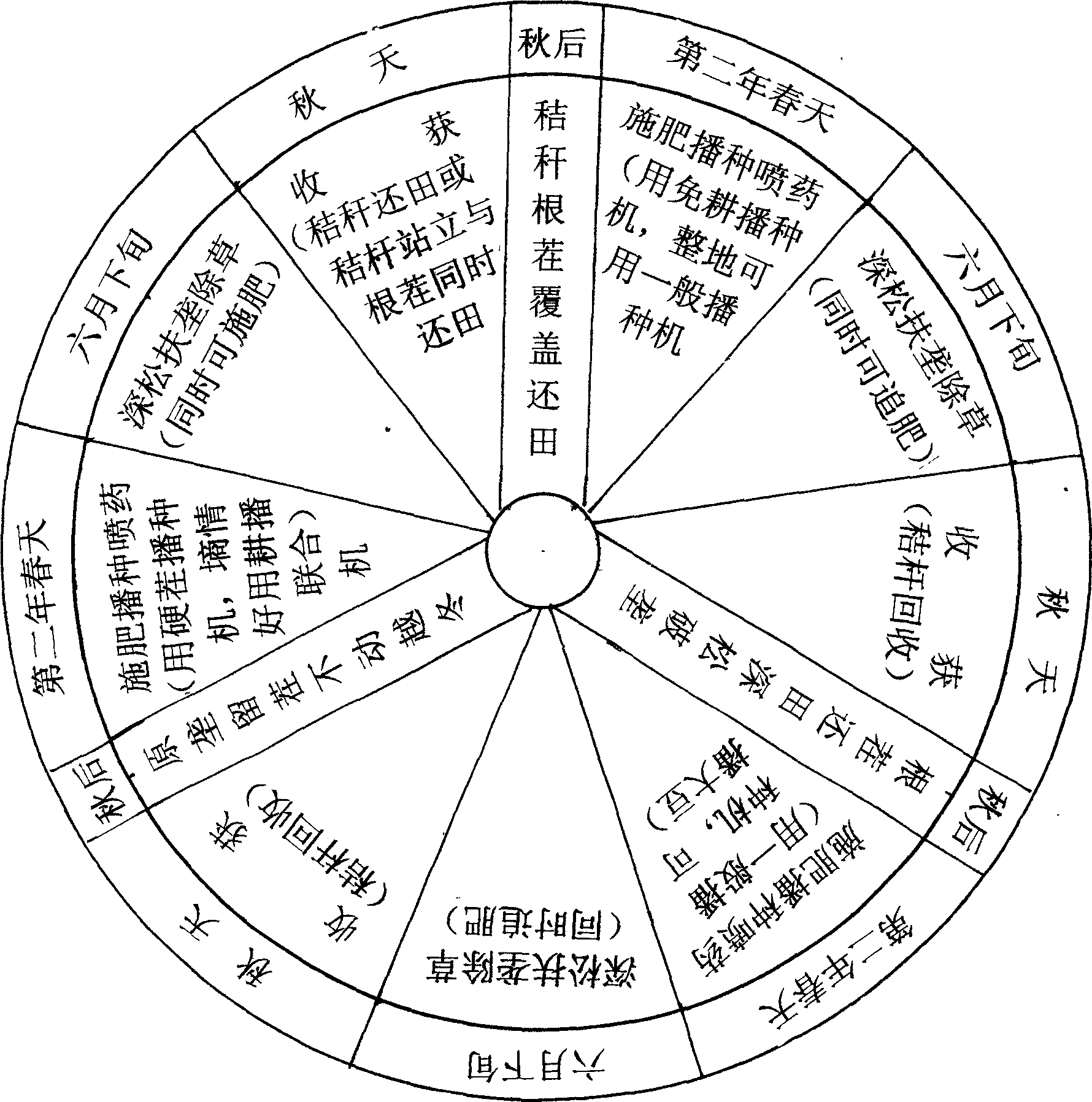

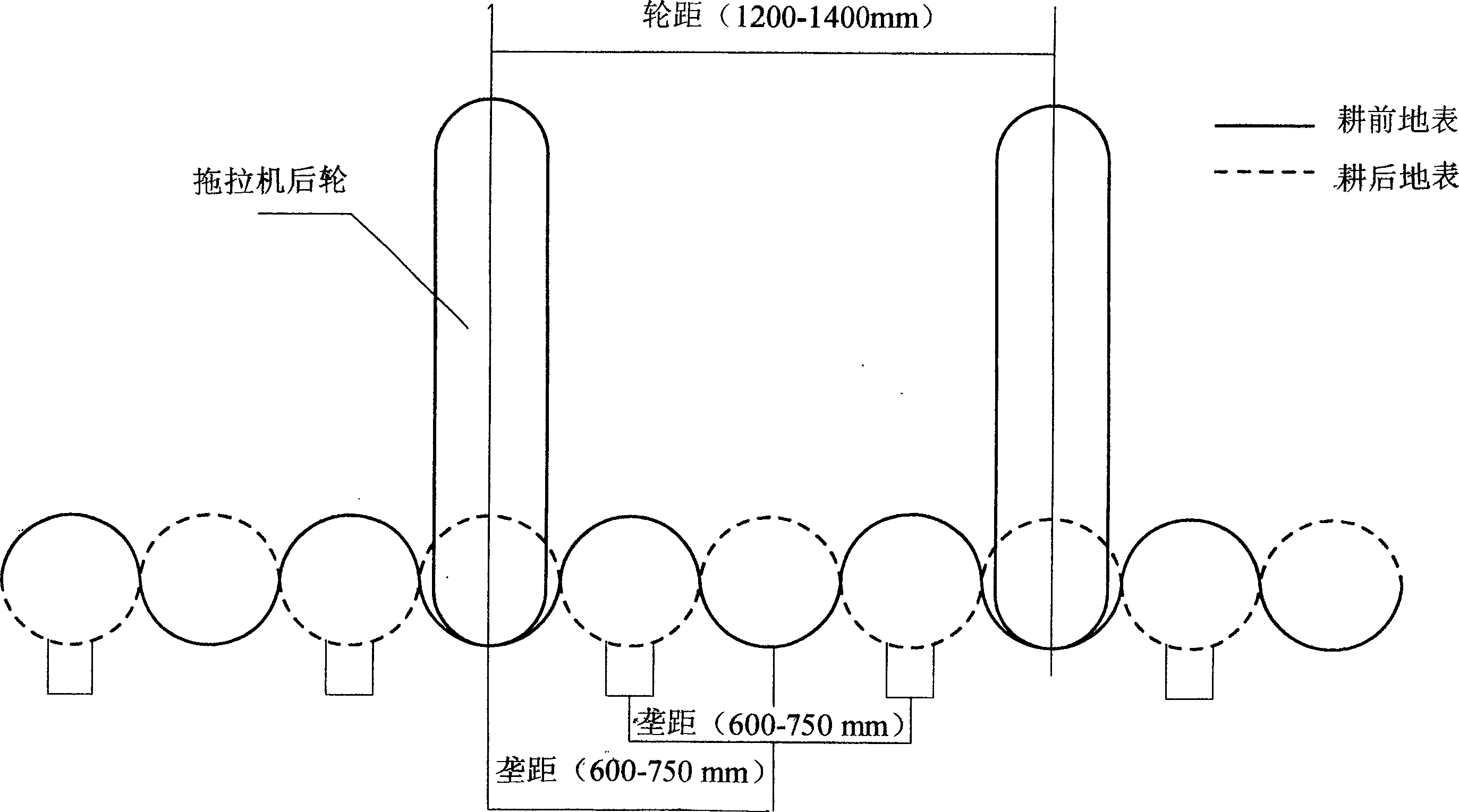

Three-year shifting mechanizaxion cultivation method of northeast ridge culture intertilled crop water reservoir moisture retension

InactiveCN1596572AMeet the requirements for returning to the fieldHigh organic contentSoil-working methodsMoistureRidge

A mechanized cultivation method with three-year rotation of crops for the northeast features that for the first year, the field is prepared in the later autum, the seeds are sowed in the spring and the crops are harvested in the autum, for the second year, the stubbles are broken and returned back to field in the later auttom, seeds are sowed in the spring and the crops are harvested in the autum, and for the third year, the stubbles are broken in the field and the seeds are sowed in the spring, and the crops are harvested in the autum. It can preserve the moisture in soil for high yield.

Owner:JILIN UNIV

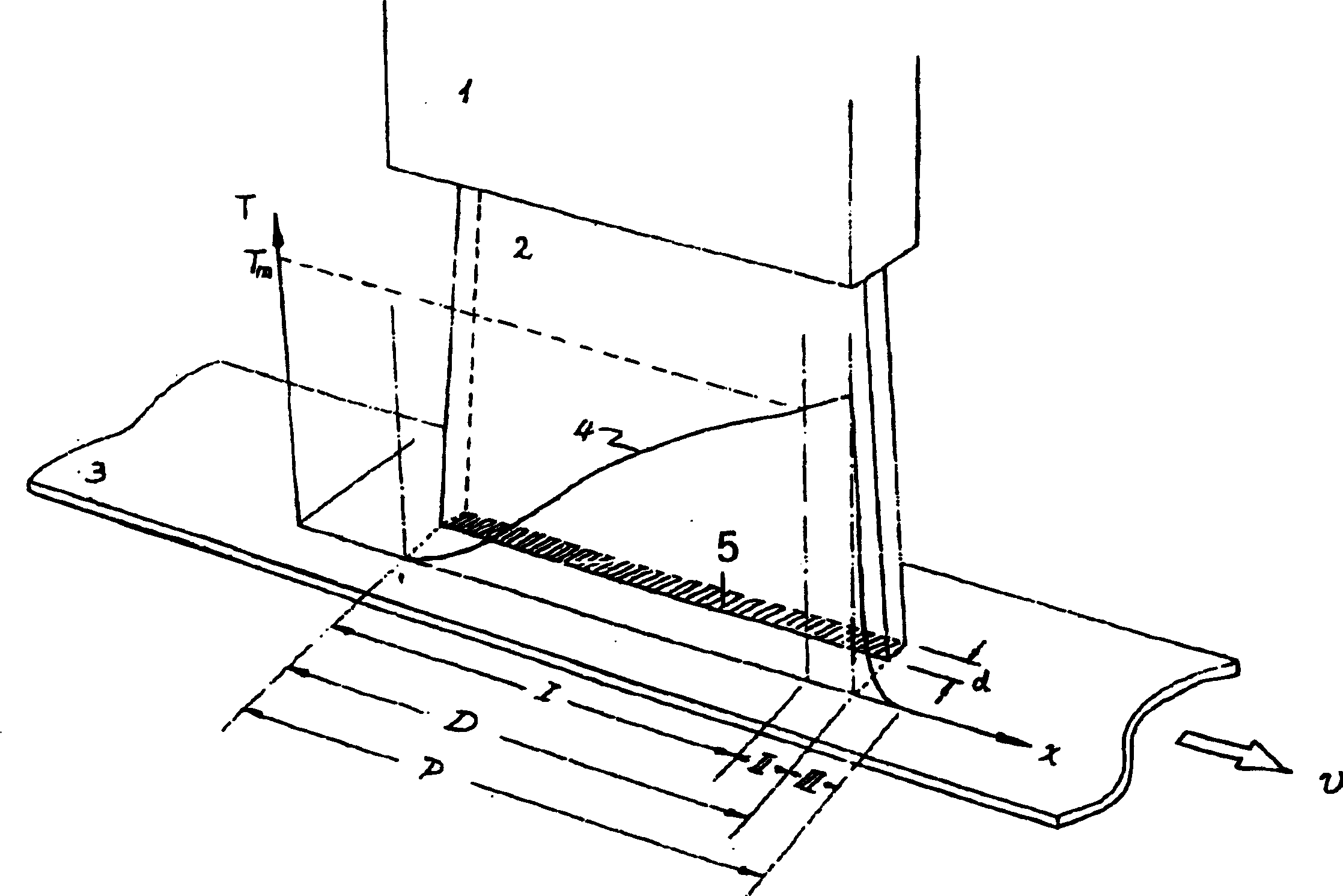

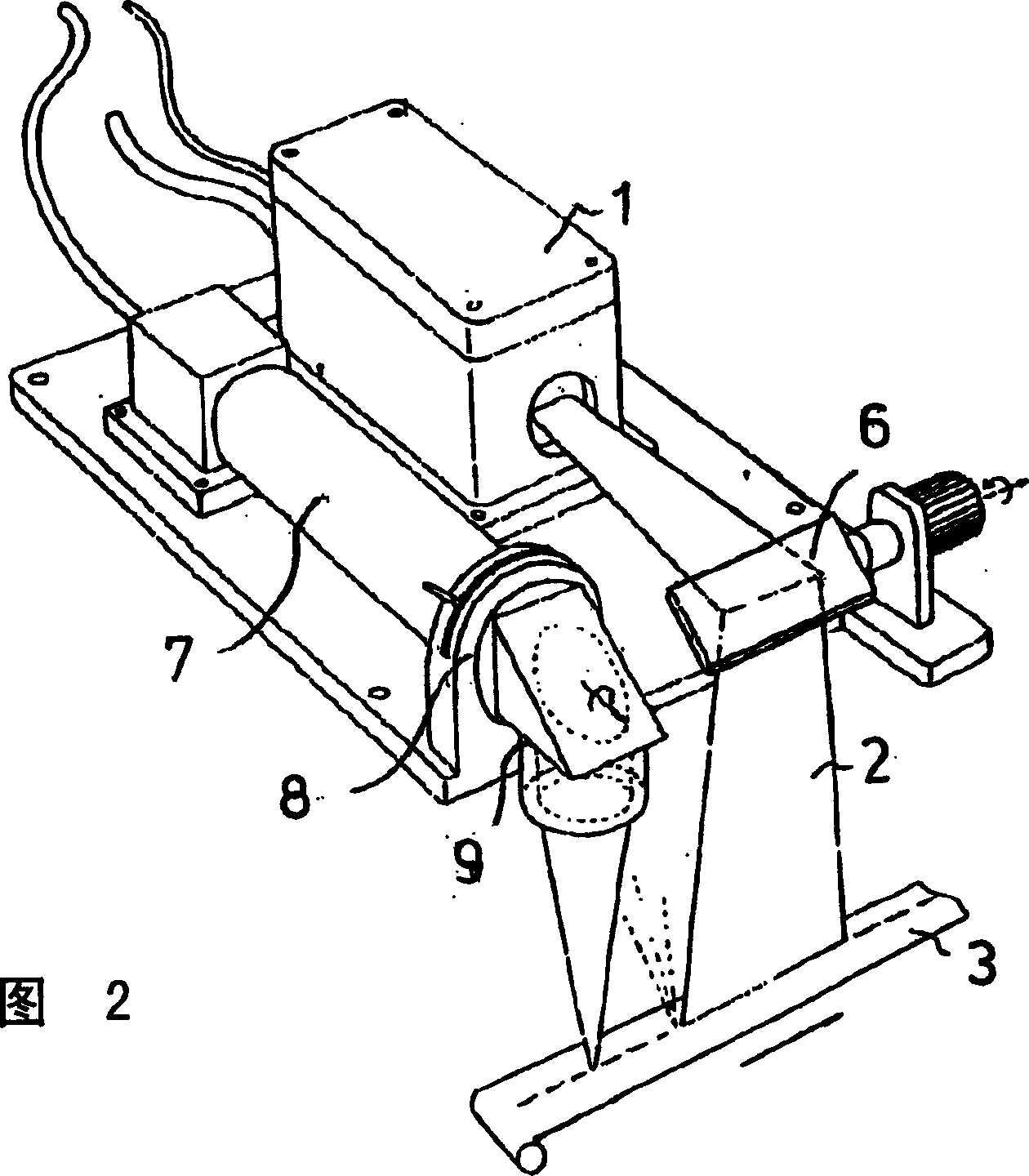

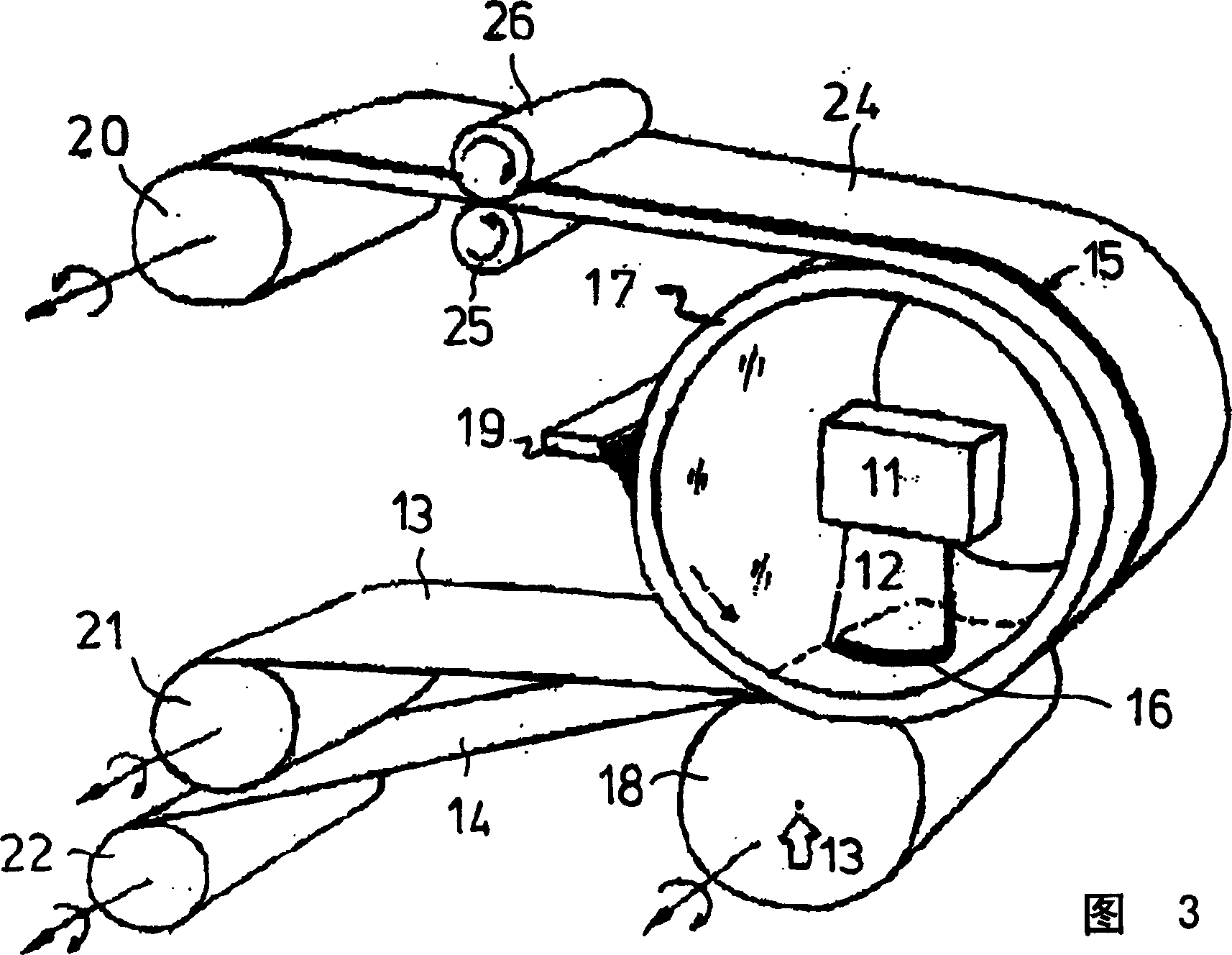

Method and device for connecting plastic material using high welding speed

InactiveCN1460589AAdjust laser powerGuaranteed normal feedingWelding/soldering/cutting articlesAdhesivesPlastic materialsWeld seam

Joining endless polymer materials (3) comprises shining upper material and contact surface between the upper and lower materials by using laser beam (2). The contact surface is transparent the laser beam. The lower material is opaque to the laser beam. The two materials are melted and joined to each other under pressure. Joining endless polymer materials (3) comprises shining upper material and contact surface between upper and lower materials by using laser beam (2). The contact surface is transparent the laser beam. The lower material is opaque to the laser beam. The two materials are melted and joined to each other under pressure. The laser beam and the materials to be joined are moved relative to each other to produce a welded seam running in the longitudinal direction at the contact surface. A process zone (P) is provided. The material is heated continuously to the melting temperature in a preheating zone (I) by using laser beams and is melted in a melting zone (II). An Independent claim is included for polymer materials joining apparatus comprising laser beam, material pressing device, and laser beam producing devices. The laser beam shines through the upper material because of transparency of the upper material and at the contact surface with the lower material. The lower material absorbs the laser beam. The laser beam heats the materials and melts them. The material pressing device joins endless materials. The endless materials are guided through two contra-rotating rollers (17, 18). The rollers press against each other. The first roller is made from a material transparent to a laser beam. The first roller is Tubular. The second roller is made from a material that can be deformed easily at the surface. The laser beam(s) producing devices produces laser beam(s) at the contact surface arranged in the first roller.

Owner:LEISTER TECHNOLOGIES

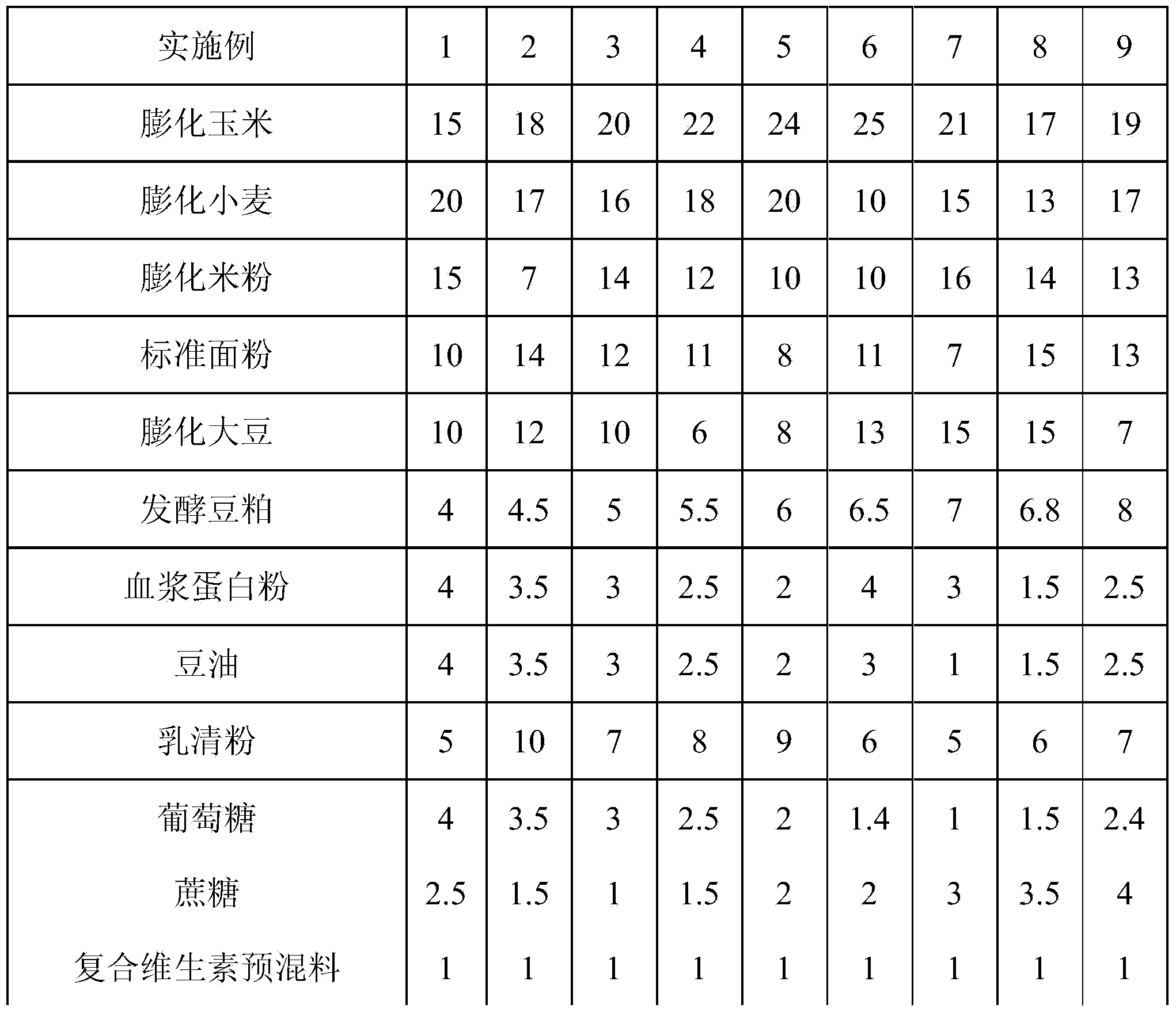

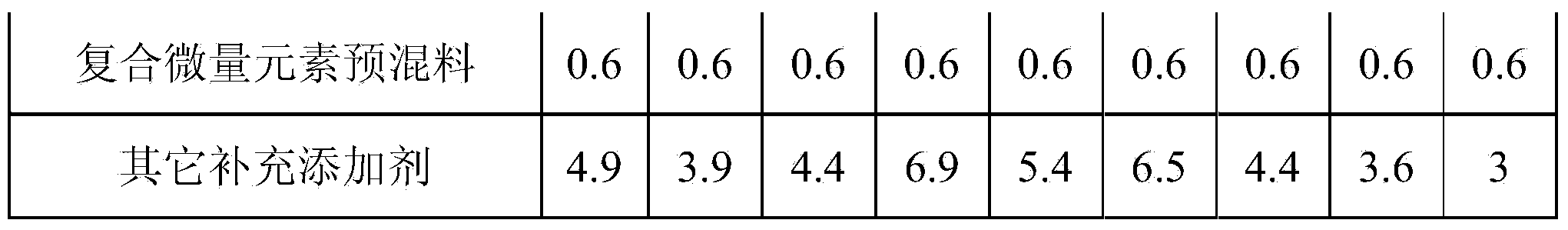

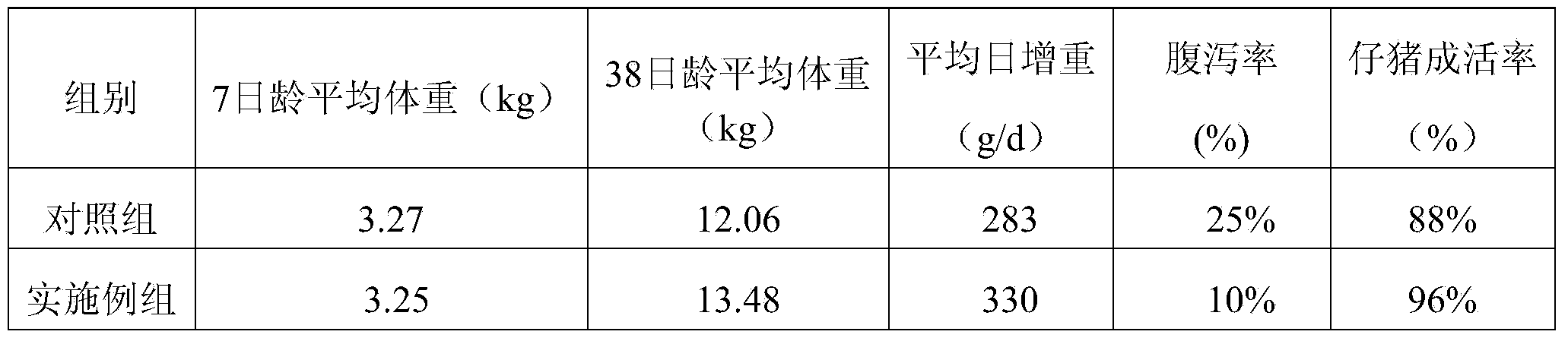

Creep compound feed applicable to 7-38-days-old piglets and preparation method of creep compound feed

InactiveCN104041712AImprove palatabilityIncrease feed intakeAnimal feeding stuffD-GlucoseGlucose polymers

The invention provides a creep compound feed applicable to 7-38-days-old piglets and a preparation method of the creep compound feed. The creep compound feed applicable to 7-38-days-old piglets is prepared from the following components by weight percent: 15-25% of puffed corns, 10-20% of puffed wheat, 5-15% of puffed rice flour, 5-15% of standard flour, 6-15% of puffed soybeans, 4-8% of fermented soybean meal, 1-4% of plasma protein powder, 1-4% of soybean oil, 5-10% of whey powder, 1-4% of glucose, 1-4% of saccharose, 1.0% of compound vitamin premix, 0.6% of compound microelement premix and 4-6% of other supplement additives. The invention provides a creep compound feed applicable to the 7-38-days-old piglets and the preparation method of the creep compound feed. The creep compound feed is capable of effectively meeting the nutritional requirements before and after weaning of the piglets, effectively reducing stress of the piglets after weaning and improving the feed intake of the piglets after weaning.

Owner:SHAANXI SHIYANG AGRI TECH

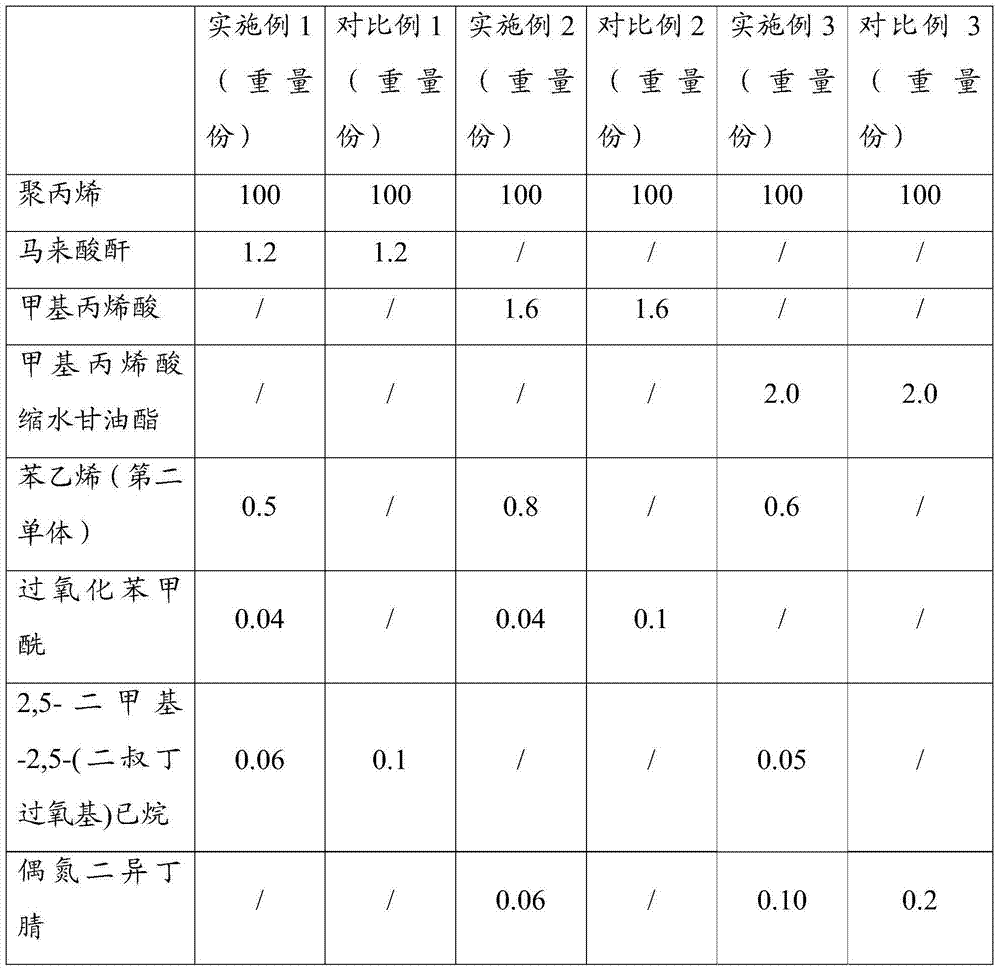

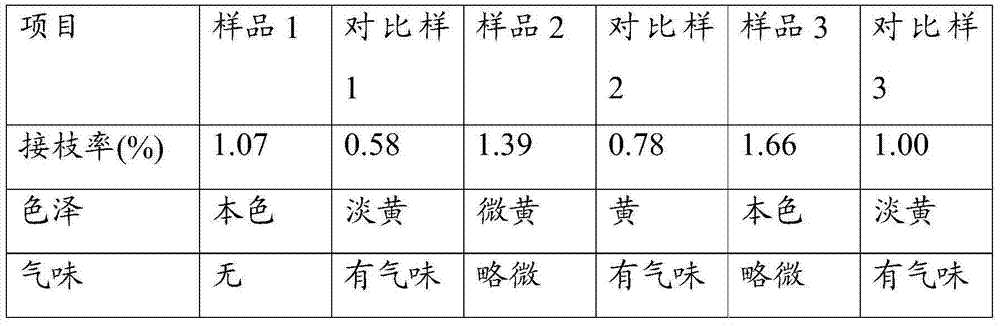

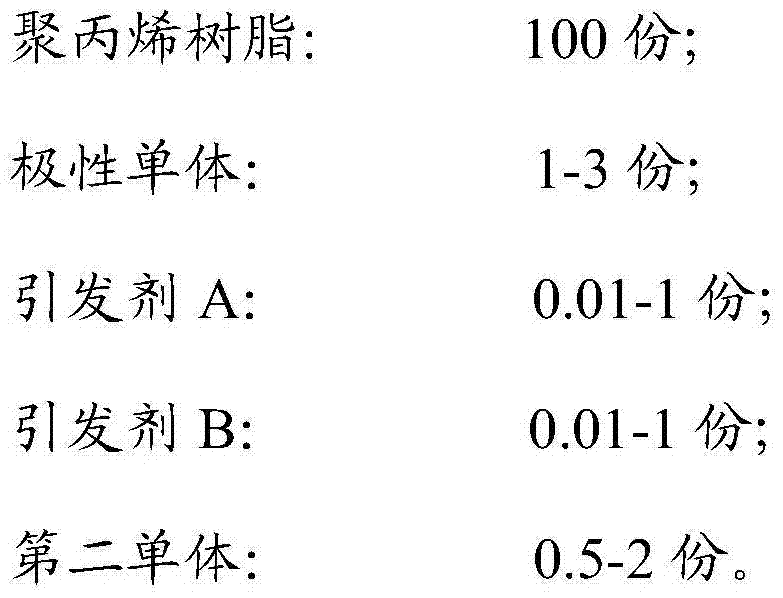

High-grating-rate and low-odor polypropylene resin composition and preparation method thereof

The invention provides a high-grating-rate and low-odor polypropylene resin composition and a preparation method thereof. The polypropylene resin composition consists of the following components in parts by weight: 100 parts of polypropylene resin, 1-3 parts of a polar monomer, 0.01-1 part of an initiator A, 0.01-1 part of an initiator B and 0.5-2 parts of a second monomer. The preparation method comprises the steps of weighing raw materials according to the weight part, mixing the raw materials in a high-speed mixer for 2-5min and discharging materials; and implementing reactive extrusion grafting on the mixed raw materials through a dual-screw extruder. The polypropylene resin composition disclosed by the invention, through selecting initiator and comonomer, reduces pungent odor of materials and improves grafting efficiency. The prepared polypropylene disclosed by the invention has the advantages of light product odor, high grating rate and low gel rate, and is applicable to a flexibilizer and a compatilizer of polar monomer and non-polar polymer alloy; the polypropylene resin composition is used for filling or strengthening polypropylene, and is capable of improving the mechanical performance and the heat resistance of the material.

Owner:GUANGZHOU LUSHAN NEW MATERIALS

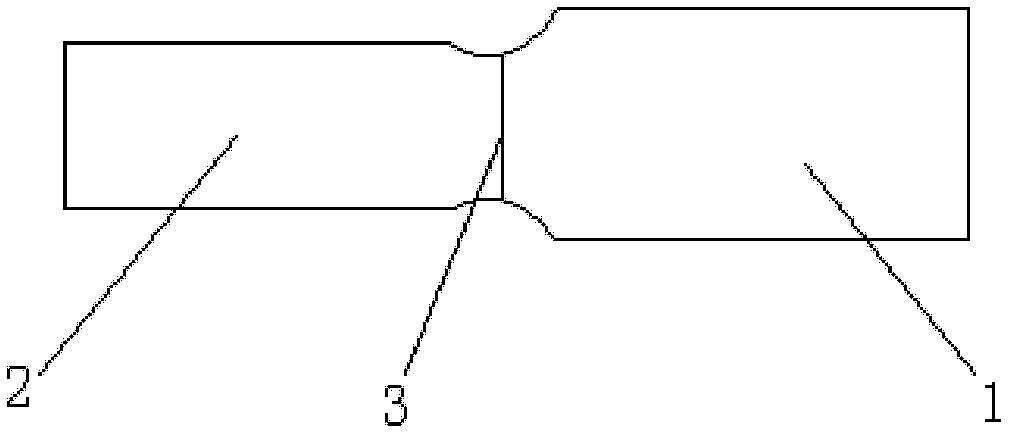

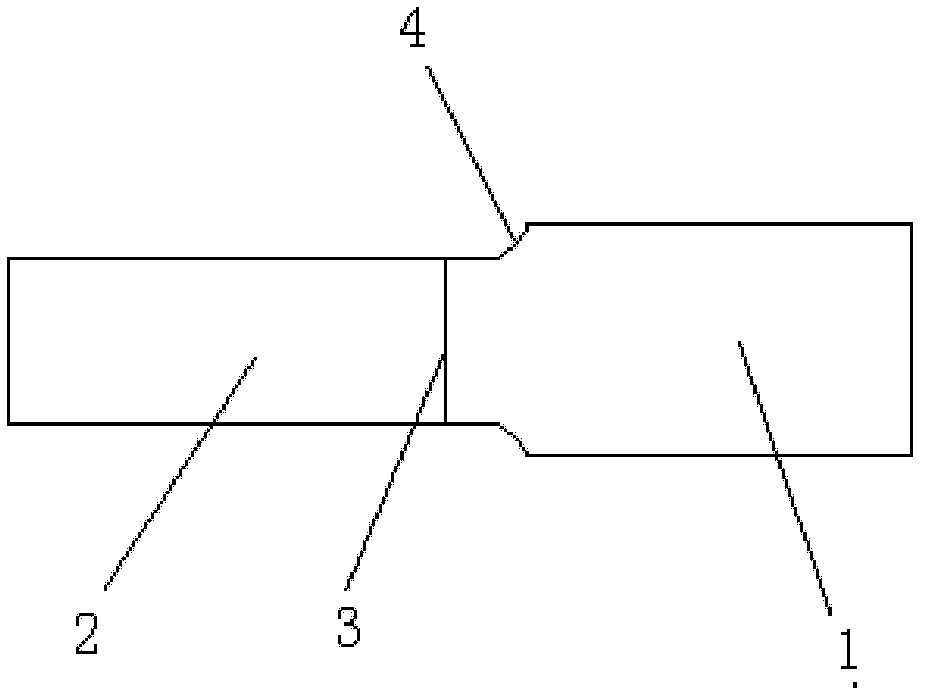

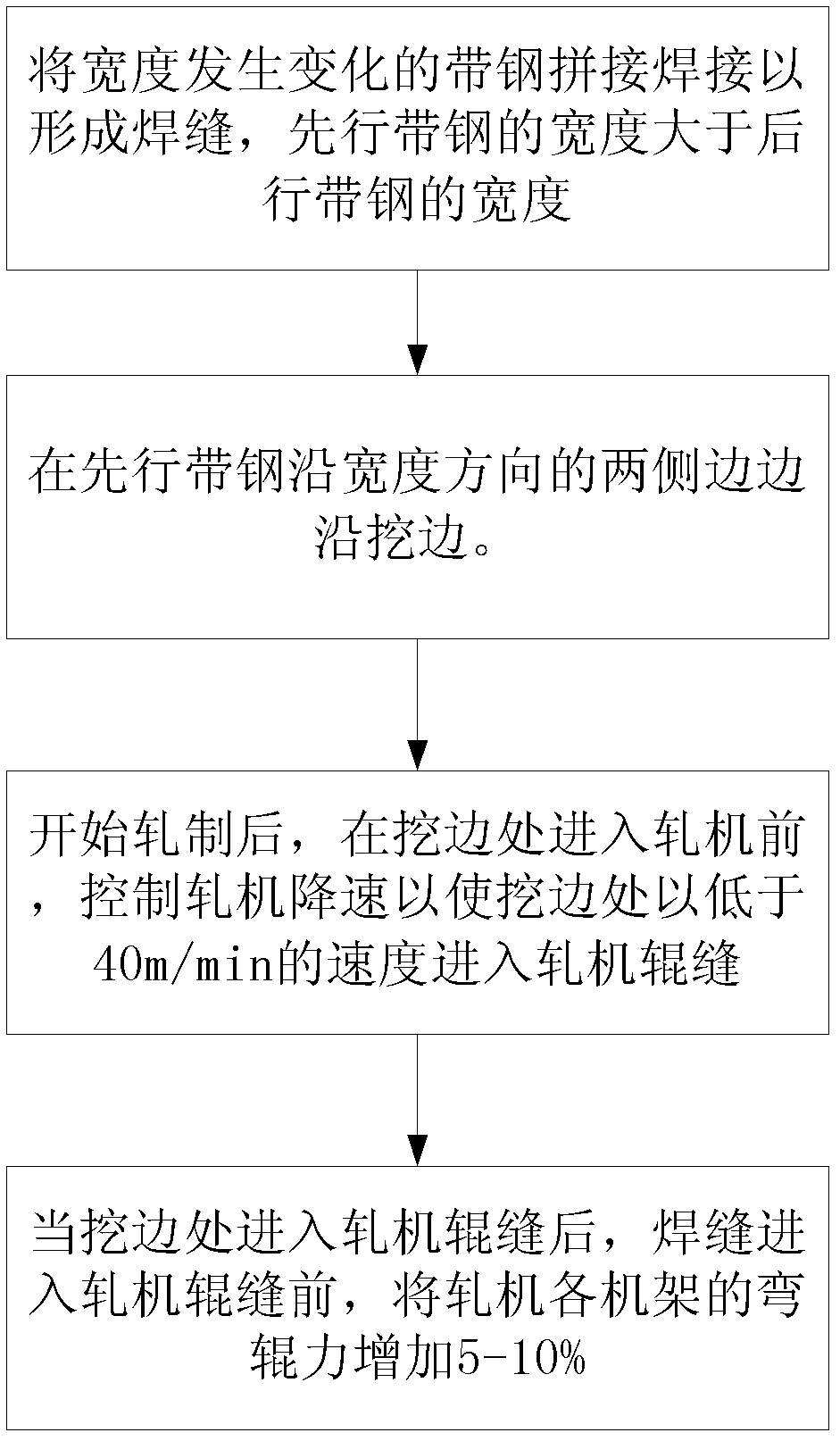

Plate connecting method for improving flying gauge change rolling stability

ActiveCN103252346AImprove stabilityExcellent plate passabilityMetal rolling arrangementsWeld seamStrip steel

The invention discloses a plate connecting method for improving flying gauge change rolling stability. The plate connecting method includes the steps: splicing and welding strip steel with changed widths to form a welding seam; digging two side edges of the advanced strip steel along the width direction; and controlling a rolling mill to slow down before edge digging positions enter the rolling mill, and enabling the edge digging positions to enter a roll gap of the rolling mill at the speed lower than 40m / min after rolling. The advanced strip steel is wider than the succeeding strip steel, and the distance between each edge digging position and the welding seam is 1-5m in the advancing direction of the strip steel. By the plate connecting method for improving flying gauge change rolling stability, normal feed of a disk shear can be ensured, the sectional area of the strip steel at the welding seam can be unchanged, accordingly, accidents such as strip breakage are avoided, the stability of the rolling mill in the flying gauge change process is remarkably improved, and the productivity of a unit is greatly improved.

Owner:BAOSHAN IRON & STEEL CO LTD

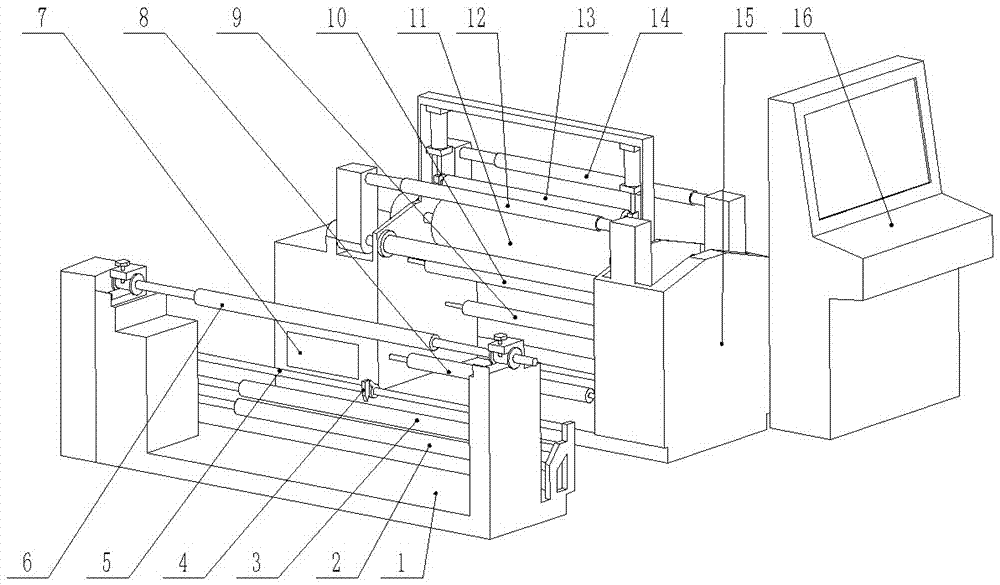

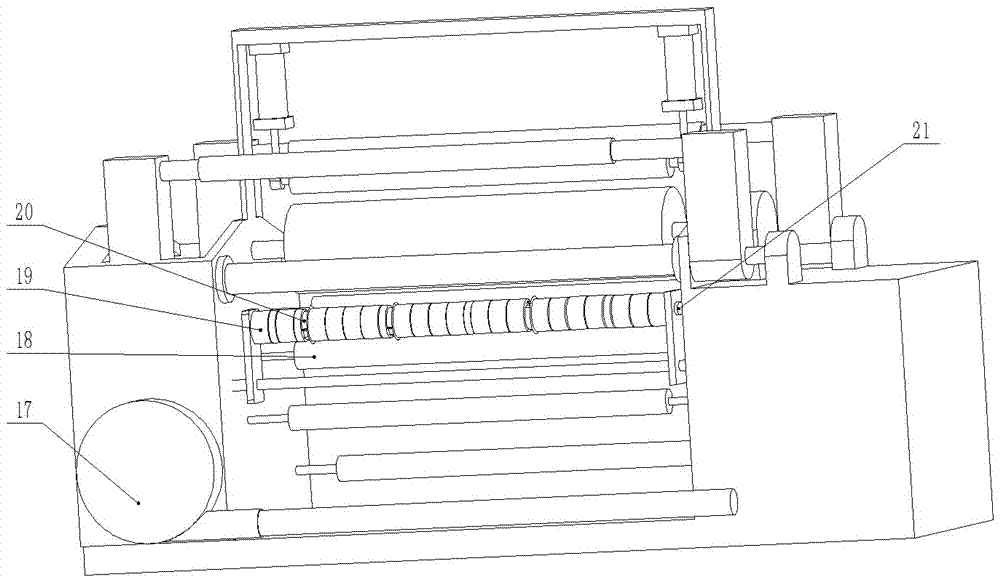

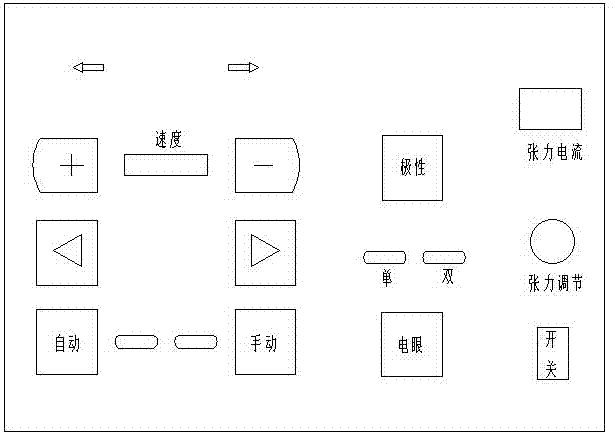

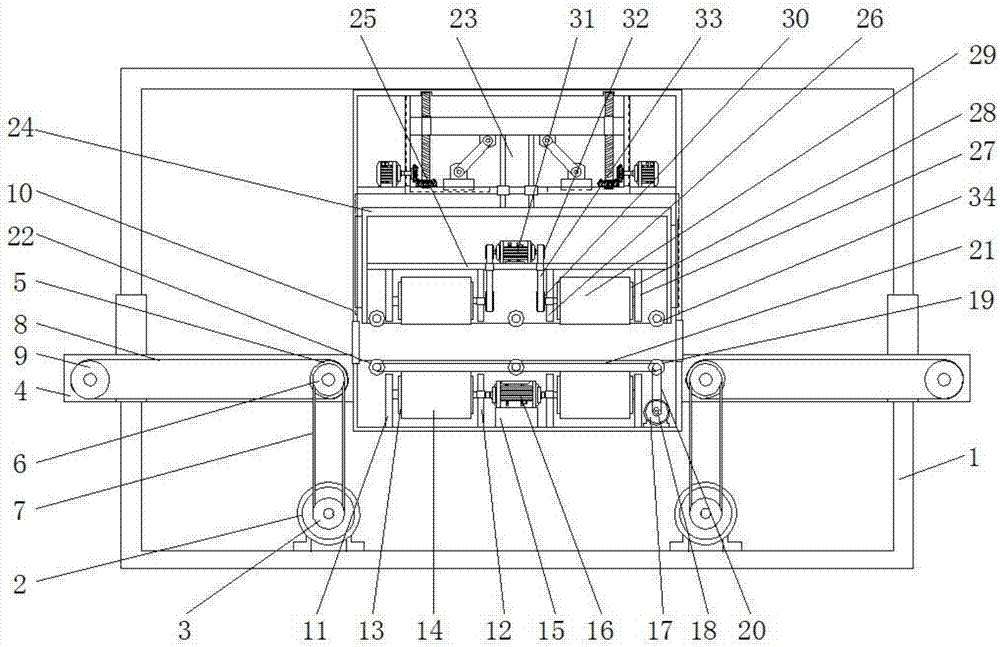

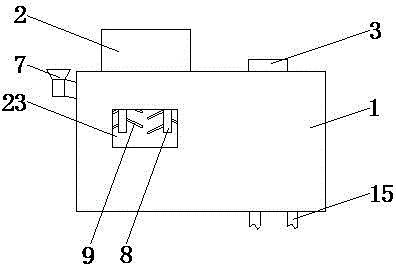

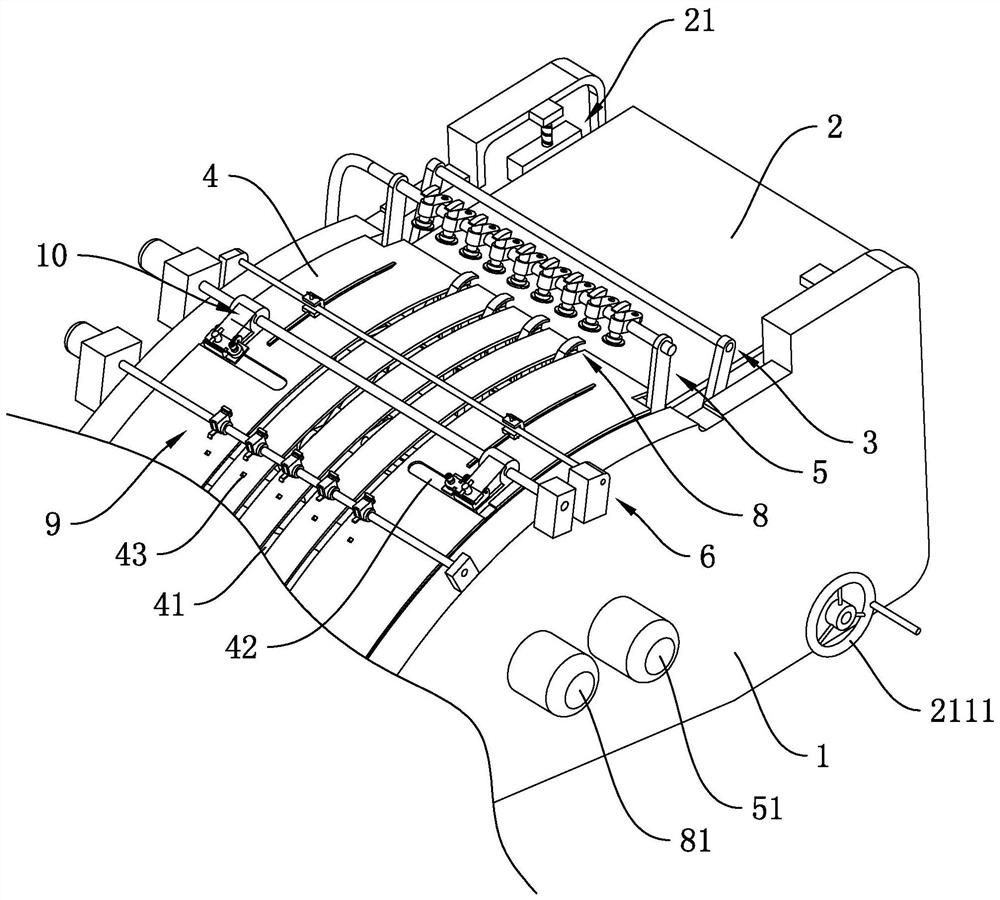

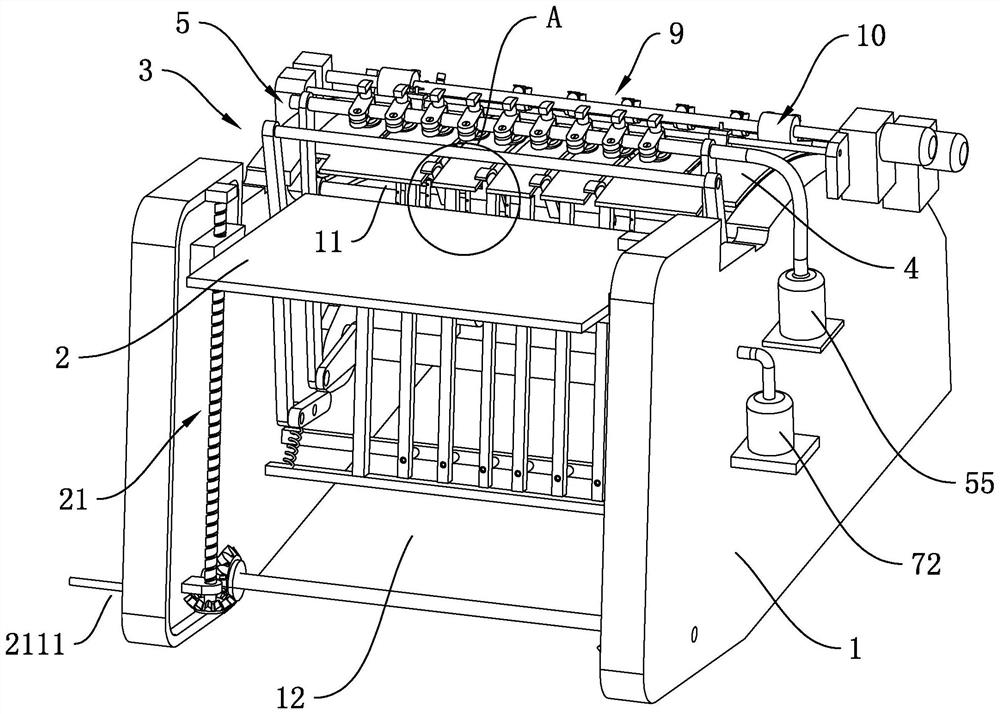

Glass cloth automatic cutting machine

ActiveCN107012682AReduce clampingGuarantee normal feedingSevering textilesEngineeringMaterial supply

The invention relates to the field of mechanical device manufacturing, in particular to a glass cloth automatic cutting machine. The cutting machine comprises a base I, a base II, a control cabinet, a material supply mechanism, a correction mechanism, a tension control mechanism, a cloth cutting mechanism and a dust removal device. The material supply mechanism is arranged on the base I, the cloth cutting mechanism and the dust removal device are arranged on the base II, and the correction mechanism, the base I, the tension control mechanism, the base II and the control cabinet are sequentially connected. A cloth roll is inflated and fixed by means of an inflation shaft, cloth is prevented from relatively sliding between a tension shaft and a feeding shaft, and accordingly the cloth cannot be excessively stretched. A filling medium in the cutting machine can effectively buffer tension generated in the cloth clamping and whole machine running processes, accordingly the force fluctuation in the running process is reduced, and cloth wrapping is convenient.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

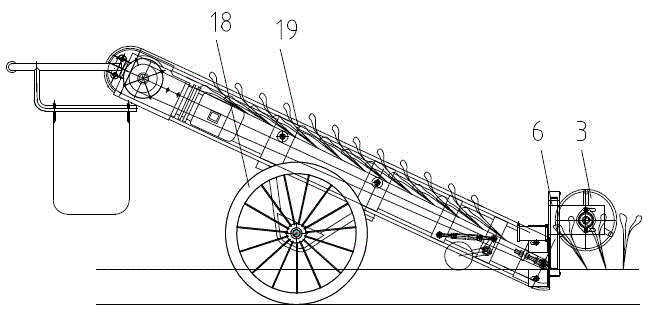

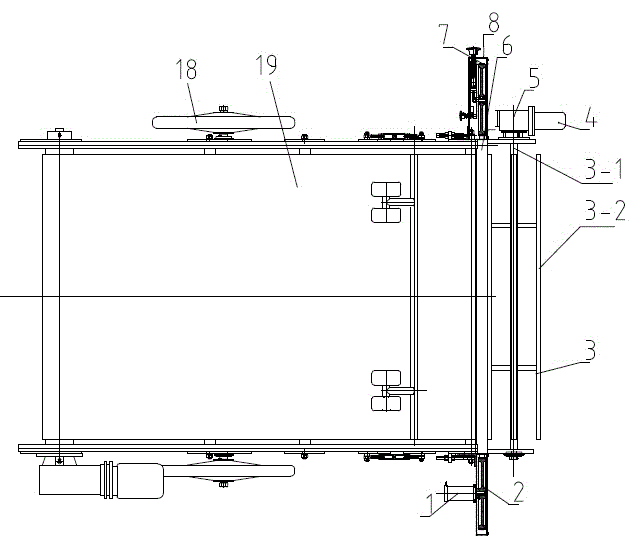

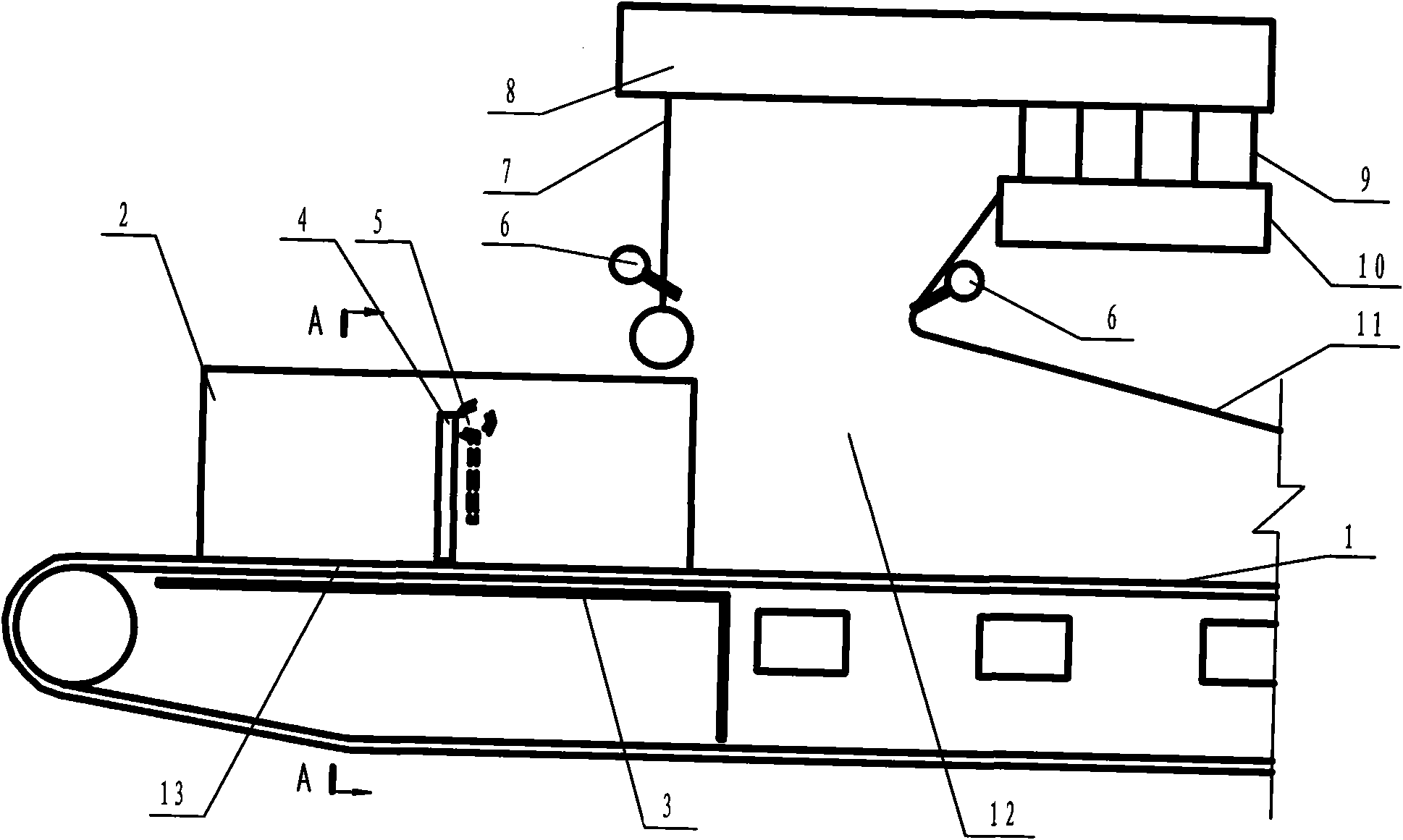

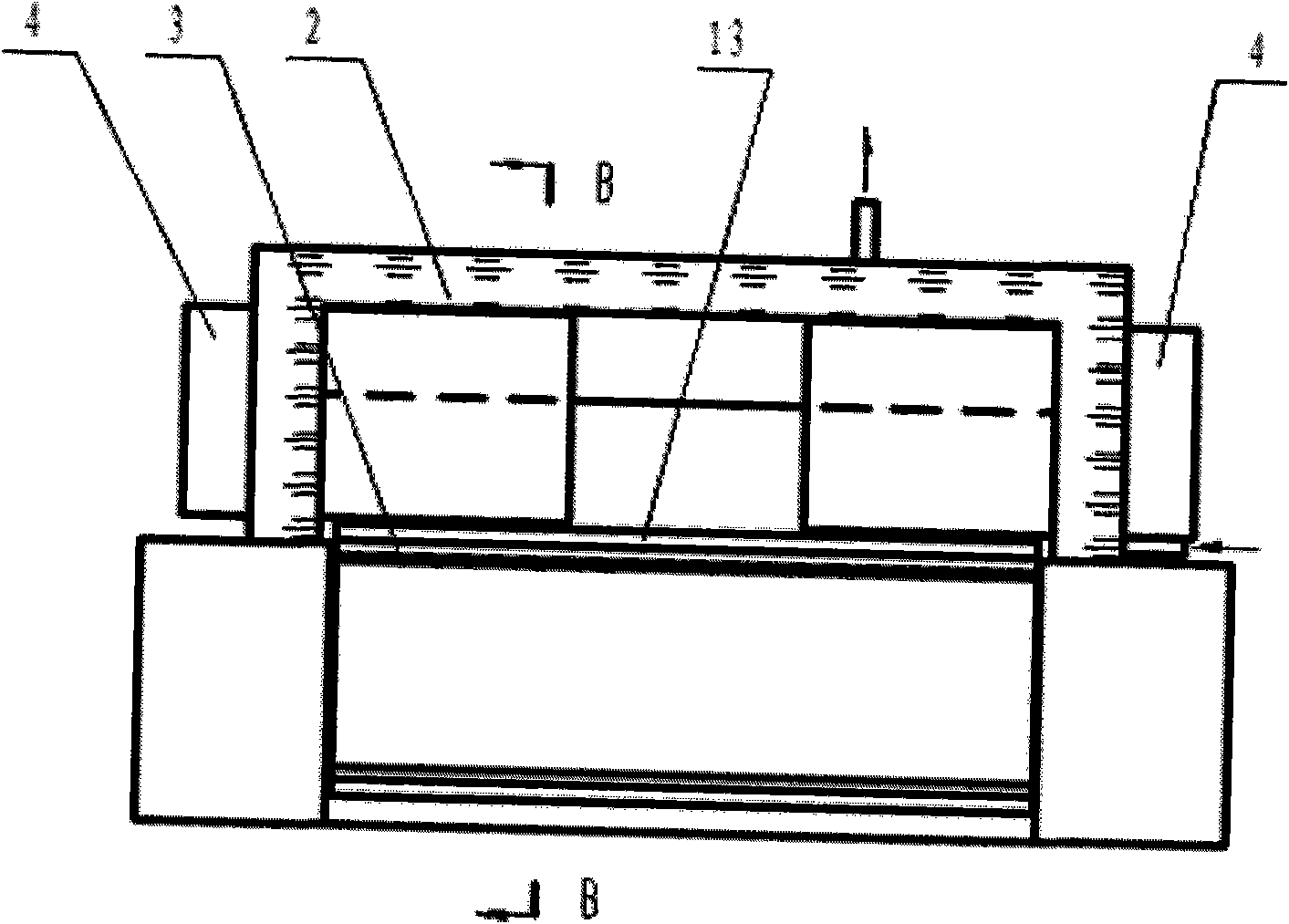

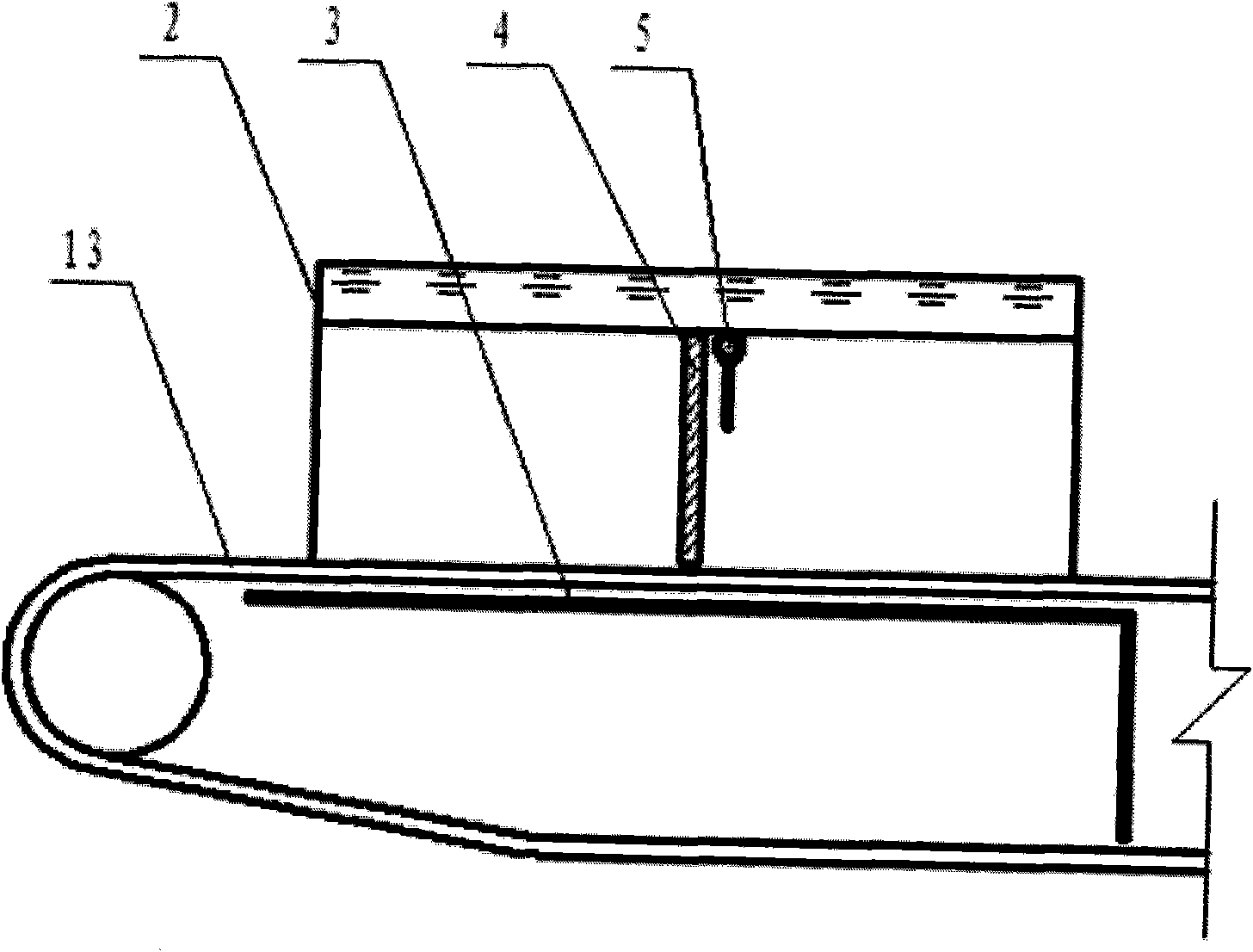

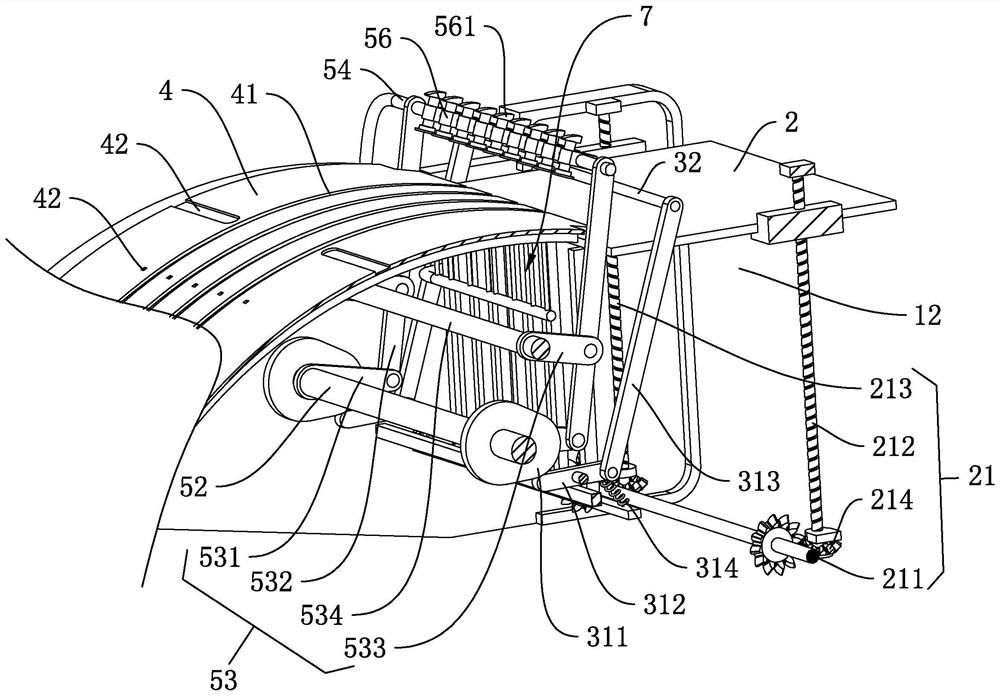

Feeding cutting device and orderly vegetable harvesting machine with same

The invention relates to a feeding cutting device and an orderly vegetable harvesting machine with the same, and belongs to the technical field of agriculture and forestry machines. The device comprises a forward-stretching vegetable cutting mechanism installed at the front end of a conveying device. The vegetable cutting mechanism comprises a frame-shaped transmission rack which is basically perpendicular to the advancing direction. The left end and the right end of the transmission rack support a driving wheel and a driven wheel respectively, and an annular belt cutter is wound around the driving wheel and the driven wheel. When the harvesting machine advances, the belt cutter is driven to conduct looped movement to achieve cutting, so that the harvesting machine is suitable for cutting and harvesting rootless vegetables on soil and also suitable for cutting and harvesting rooted vegetables under the soil, and it is unnecessary to replace the belt cutter with other different ones; due to one-side cutting of the belt cutter, the problem that a reciprocating dual-acting cutter is prone to getting stuck by sandy soil when moving under the soil is avoided, so that convenient operation and use are guaranteed.

Owner:卢建强 +1

Heavy oil and residual oil combined treating process

ActiveCN101089144AExtended operating cycleGuaranteed normal feedingTreatment with hydrotreatment processesResidual oilSolvent

The heavy oil and residual oil combined treating process includes the following steps: hydrocracking heavy oil and residual oil material in a suspended bed in mild condition; fractionating the hydrocracked resultant into light fraction, heavy fraction and un-converted vacuum residue, which accounts for 20-45 wt% of the material; catalytically cracking the heavy fraction; and solvent deasphalting the un-converted vacuum residue to obtain deasphalted oil serving as the catalytically cracking material. The process of the present invention has stable hydrocracking operation in suspended bed, can utilize all the fractions in the material, and is suitable for treating various kinds of heavy oil and residual oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

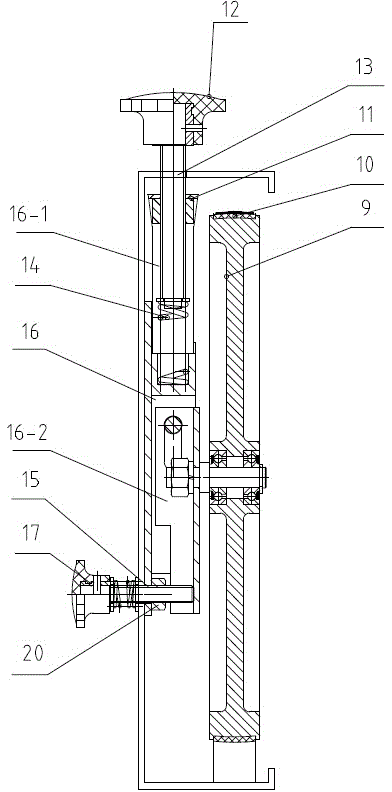

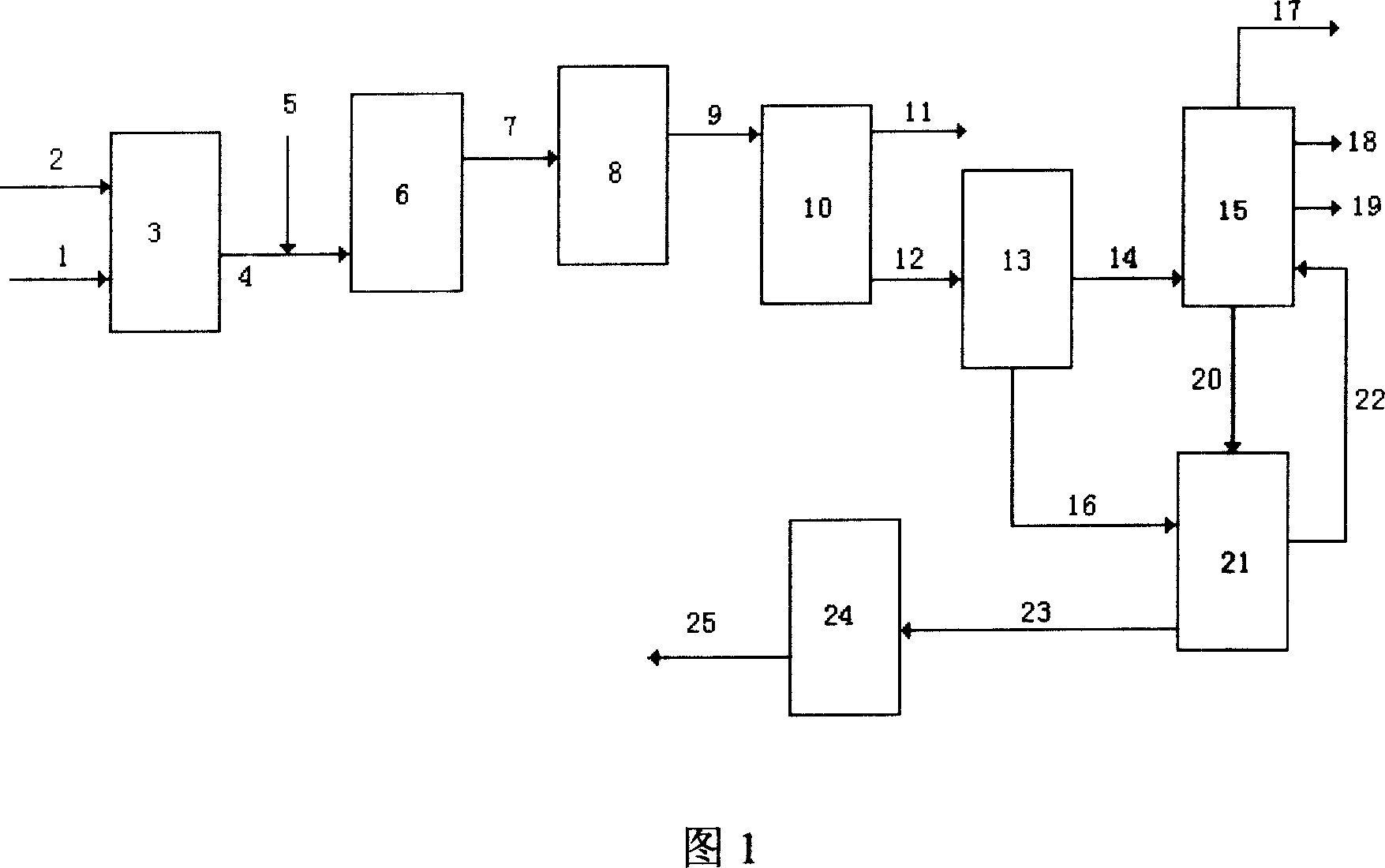

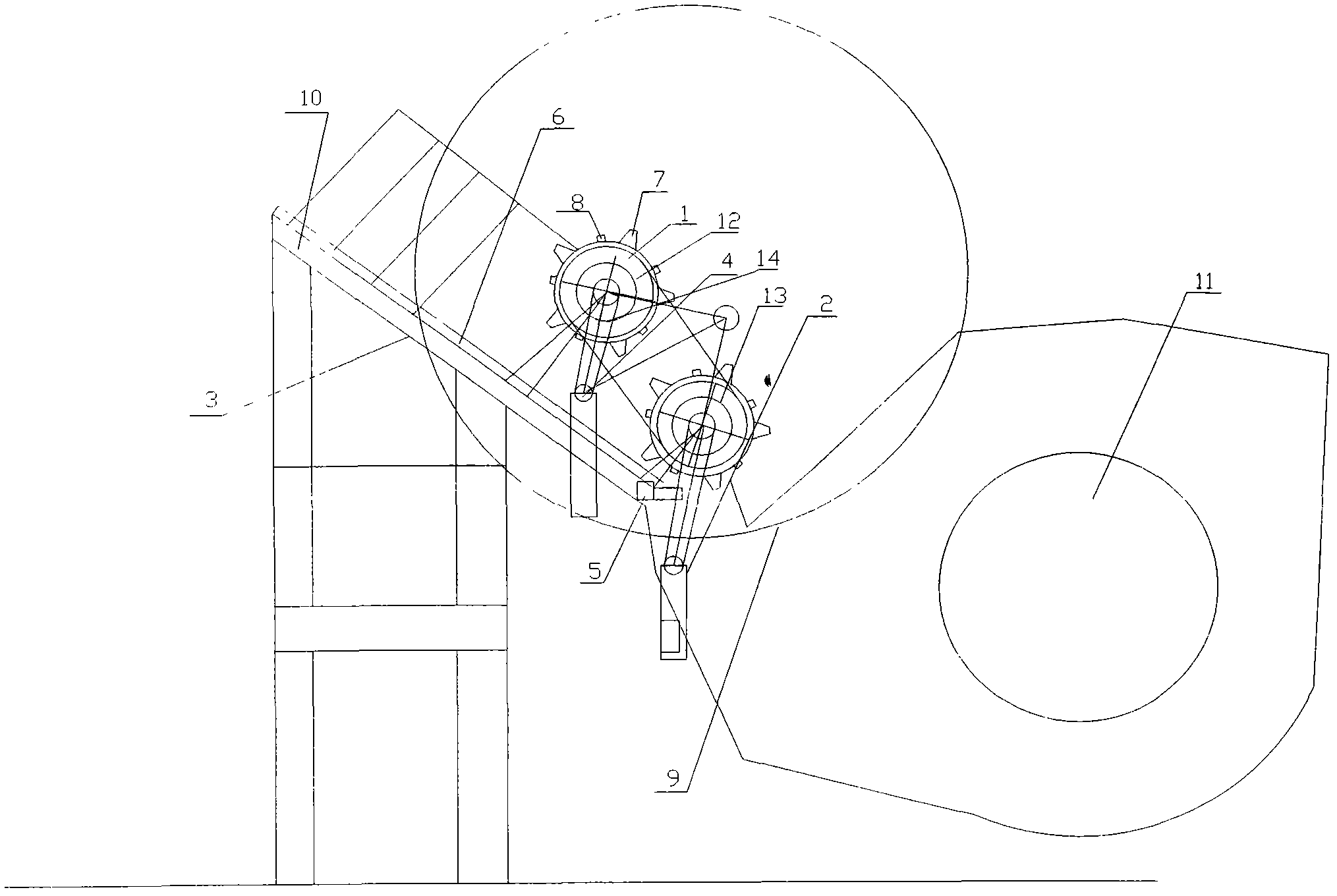

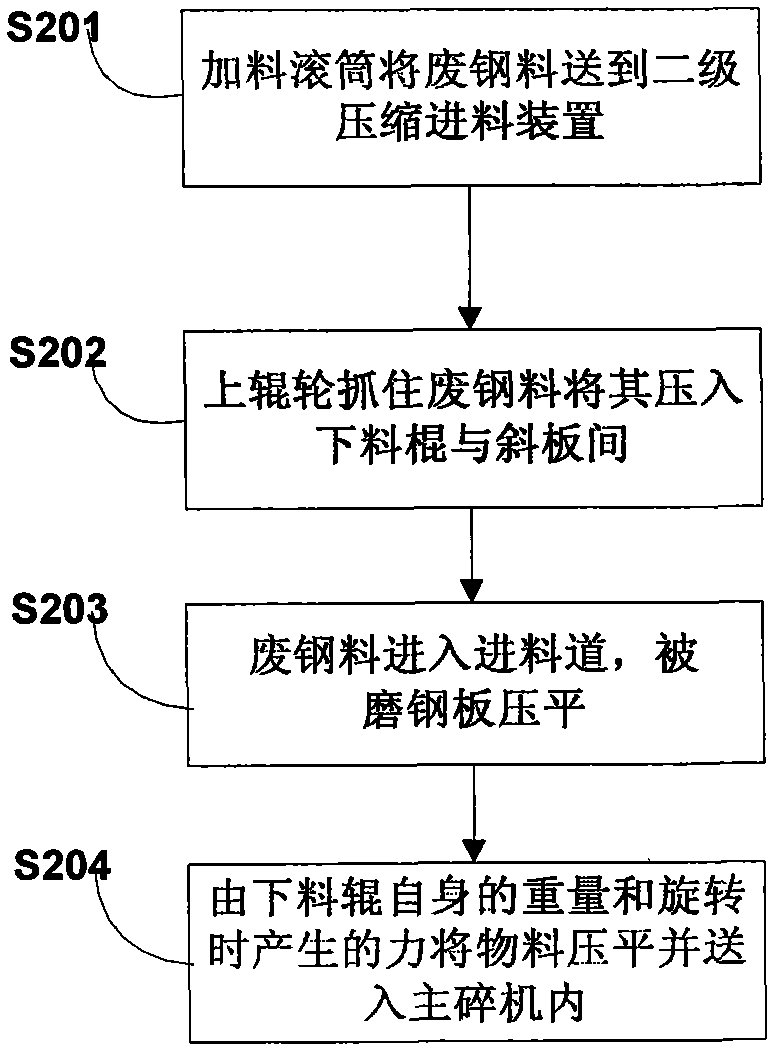

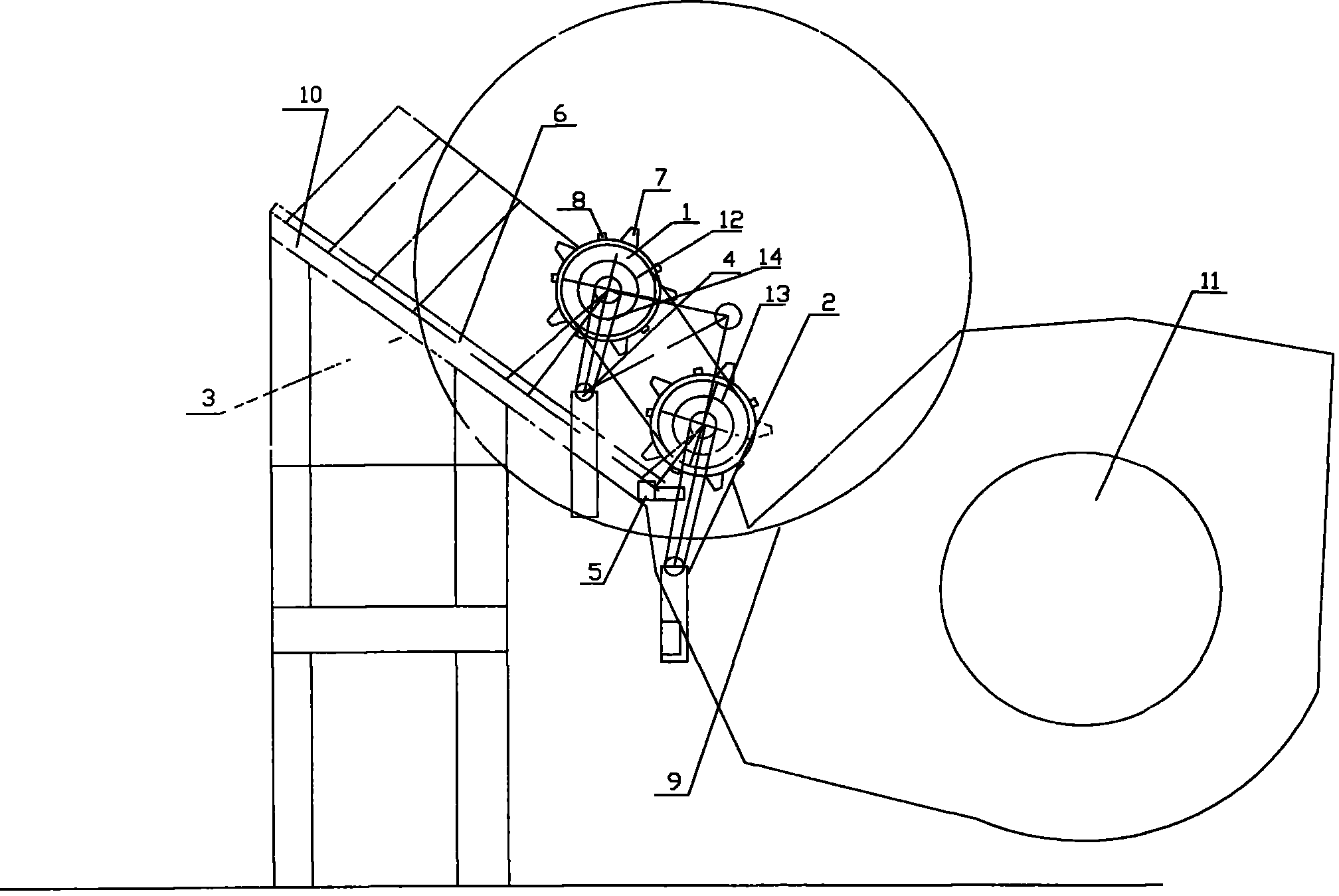

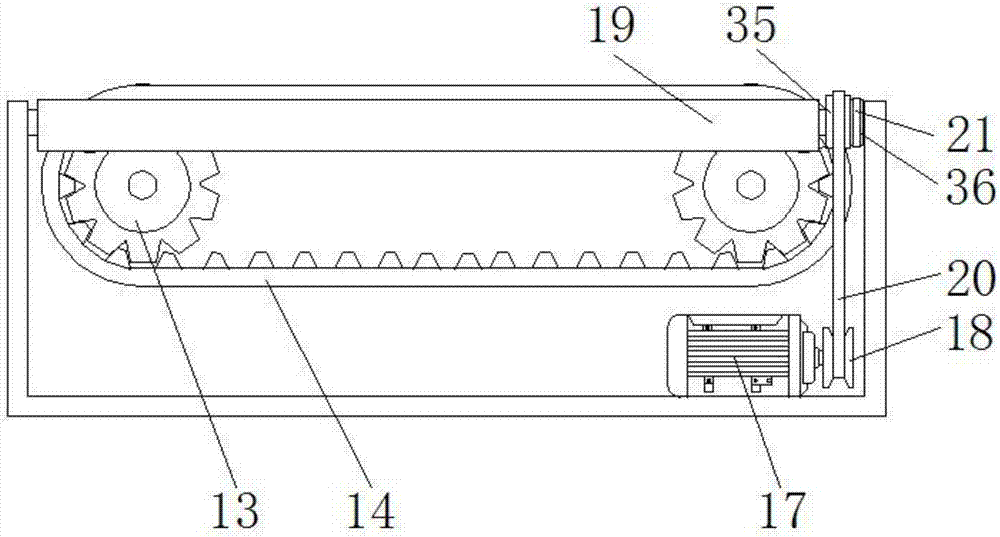

Double-roller preliminary crushing and compression feeding device for crusher and feeding method

The invention relates to a double-roller preliminary crushing and compression feeding device for a crusher and a feeding method. Double-roller preliminary crushing and compression feeding are adopted, and triangular toothed blocks and horizontal strips are arrayed on a wheel face of a double-roller body. A feeding port is provided with double rollers, the problems of continuous rolling and continuous conveying of materials such as long and high waste steel and the like and preliminary crushing of shell feeding are effectively solved, and various materials such as the waste steel and the like are effectively conveyed into a main crusher. The double rollers are hydraulically driven to be controlled and are different in linear speed, the fronts of the double rollers are high while the backs of the double rollers are low relative to a feeding channel, and the materials such as the long and high waste steel and the like can be fed. The double rollers are mounted on a double-roller moving frame hydraulically driven, two lower sides of the double-roller moving frame are respectively controlled by a group of hydraulic cylinders, and the space between each roller and the feeding channel can be adjusted. The hydraulic cylinders are narrowed to the shortest in normal operation, the moving frame is positioned at the lowest point, and the height of the moving frame can be properly adjusted when large materials need to pass through the moving frame. The hydraulic cylinders can be elongated in maintenance and can be fixed by a fixing pin when reaching the highest point.

Owner:韩清洁

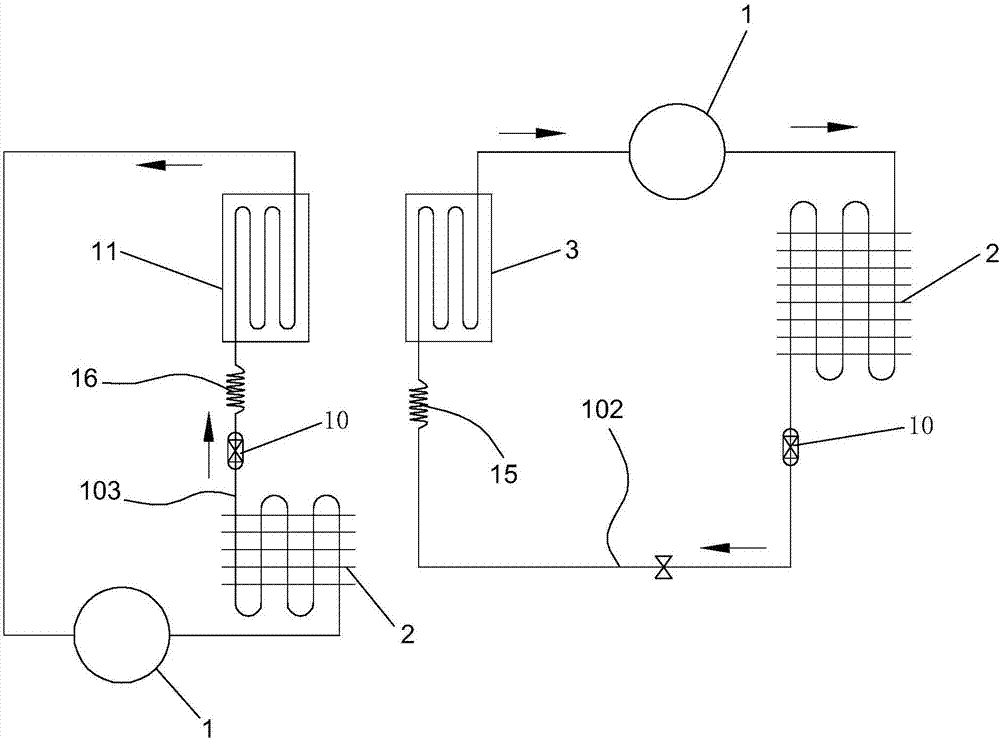

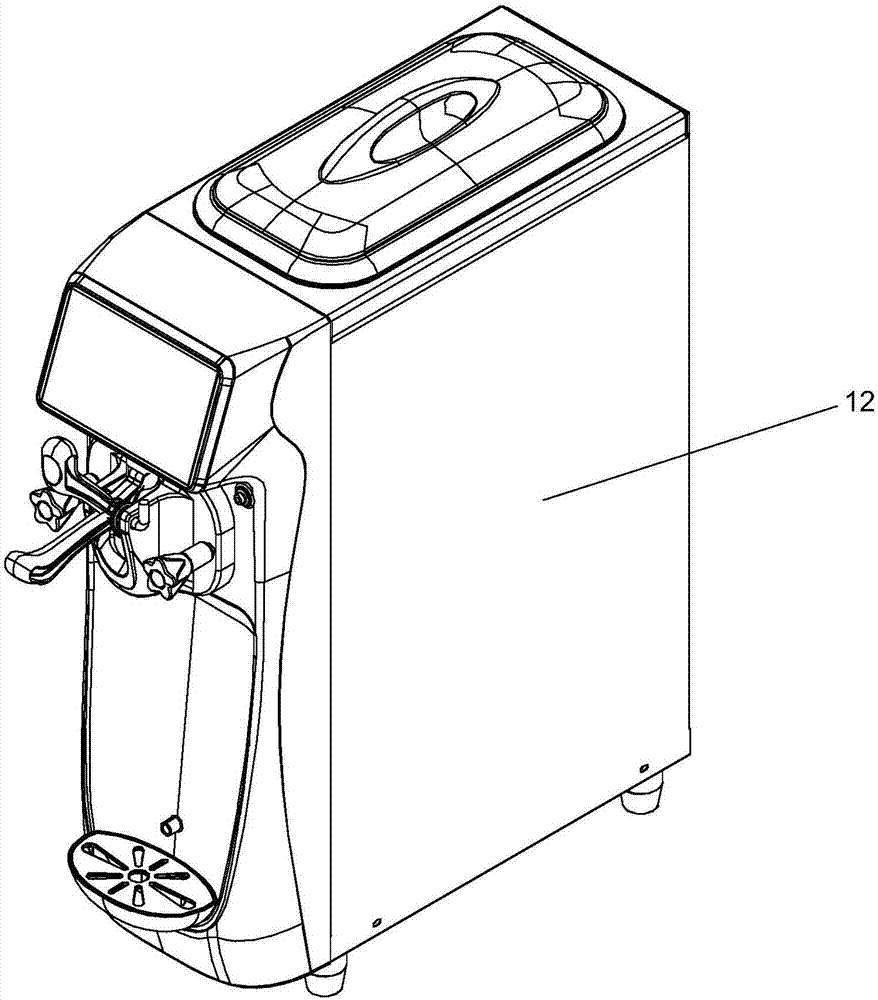

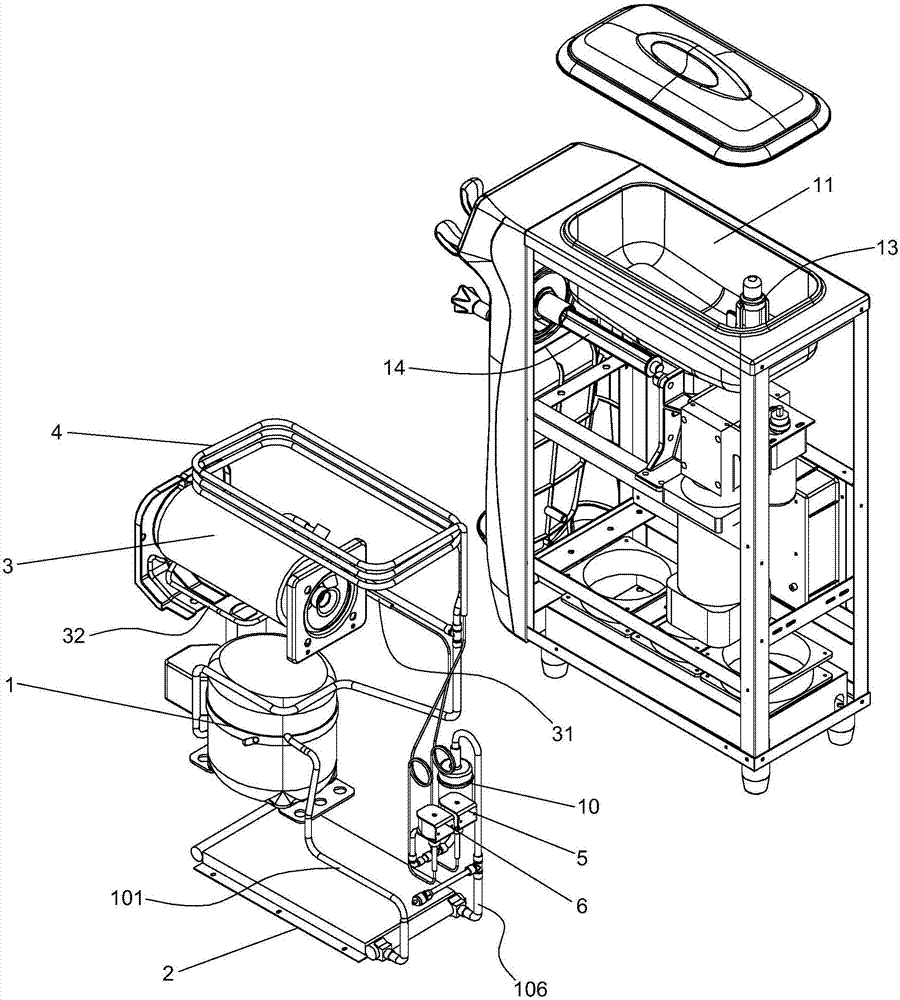

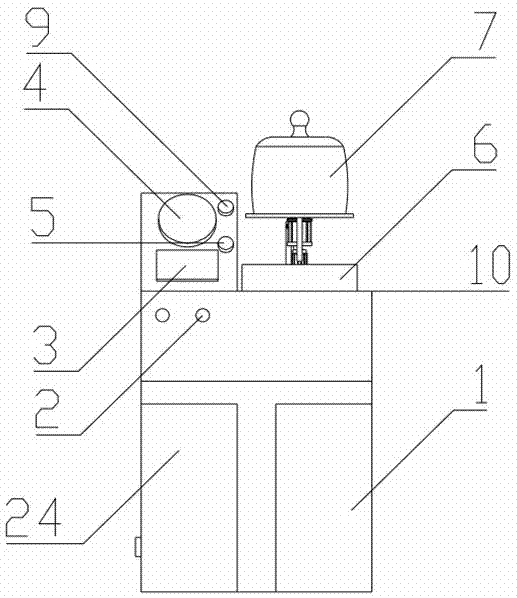

Cold control device of dual-throttle precooling and freshness preserving ice-cream machine, cold control method and ice-cream machine

The invention discloses a cold control device of a dual-throttle precooling and freshness preserving ice-cream machine, a cold control method and an ice-cream machine. The cold control device comprises a compressor, a condenser, a bowl evaporator, a freezing cylinder refrigeration inlet pipe and a freezing cylinder refrigeration outlet pipe, wherein an outlet end of the condenser is connected with an outlet pipeline of the condenser, the outlet pipeline of the condenser communicates with three branch pipes separately, the three branch pipes comprise a freezing cylinder refrigeration pipeline, a bowl precooling pipeline and a bowl freshness preserving pipeline which are arranged in parallel, the freezing cylinder refrigeration pipeline communicates with the freezing cylinder refrigeration inlet pipe, both the bowl precooling pipeline and the bowl freshness preserving pipeline communicate with an inlet end of the bowl evaporator, and an outlet end of the bowl evaporator and the freezing cylinder refrigeration outlet pipe separately communicate with the compressor. The cold control device can truly achieve the separation of two modes, i.e., precooling and freshness preserving of a bowl. The invention simultaneously discloses the cold control method and the ice-cream machine.

Owner:ZHONGSHEN TECH (GUANGDONG) CO LTD

Wood hole-opening device for table

InactiveCN109834770AGuaranteed stabilityHigh precisionStationary drilling machinesBark-zones/chip/dust/waste removalPulp and paper industryDrilling machines

The invention relates to the field of wood processing, in particular to a wood hole-opening device for a table. The wood hole-opening device comprises a processing table, a vertically moving drillingmachine and a first cylinder for pushing the movement of the drilling machine, the drilling machine is located above the processing table, the processing table is slidably connected with two clampingblocks, two clamping blocks are connected with telescopic rods, the telescopic rods are provided with elastic members, and wedge blocks are fixedly connected to the ends, away from the clamping blocks, of the telescopic rods; a cylinder rod of the first cylinder is fixedly connected with an abutting rod, and the end, away from the first cylinder, of the abutting rod abuts against the wedge blocks;first reset members are connected to the wedge blocks; and the wood hole-opening device further comprises two conveying mechanisms arranged above the processing table, and the two conveying mechanisms intermittently convey the wood. According to the scheme, it is realized that a table board automatically moves on the processing table without manual pushing.

Owner:重庆市跃扬教学设备有限公司

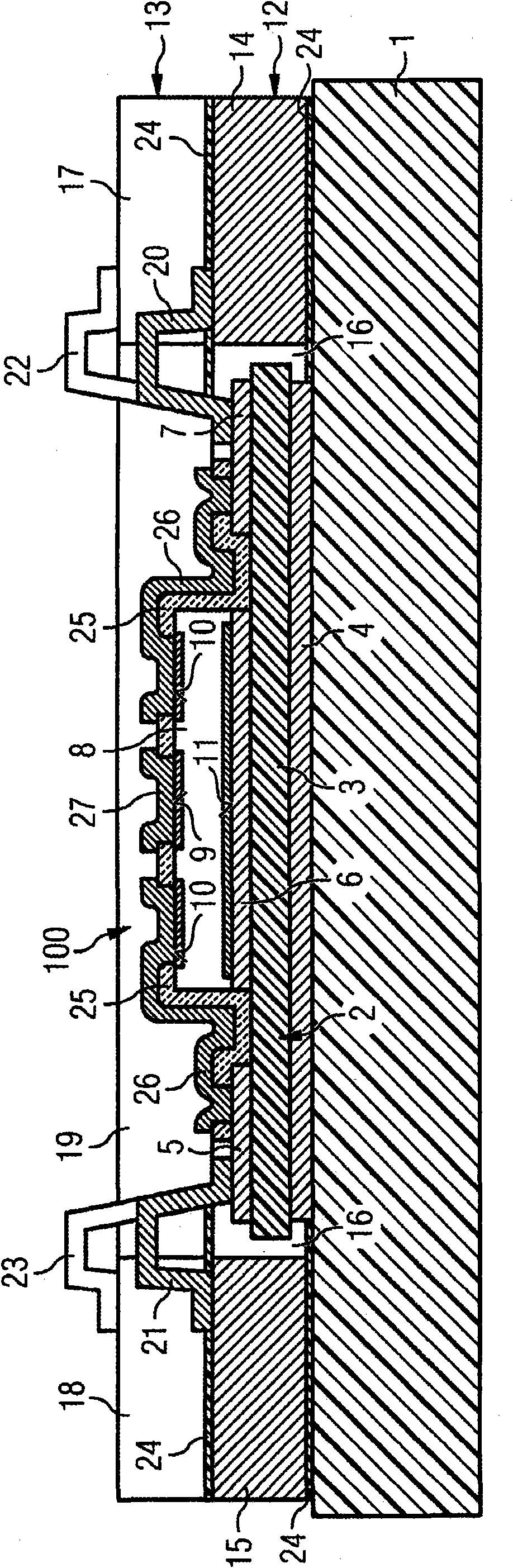

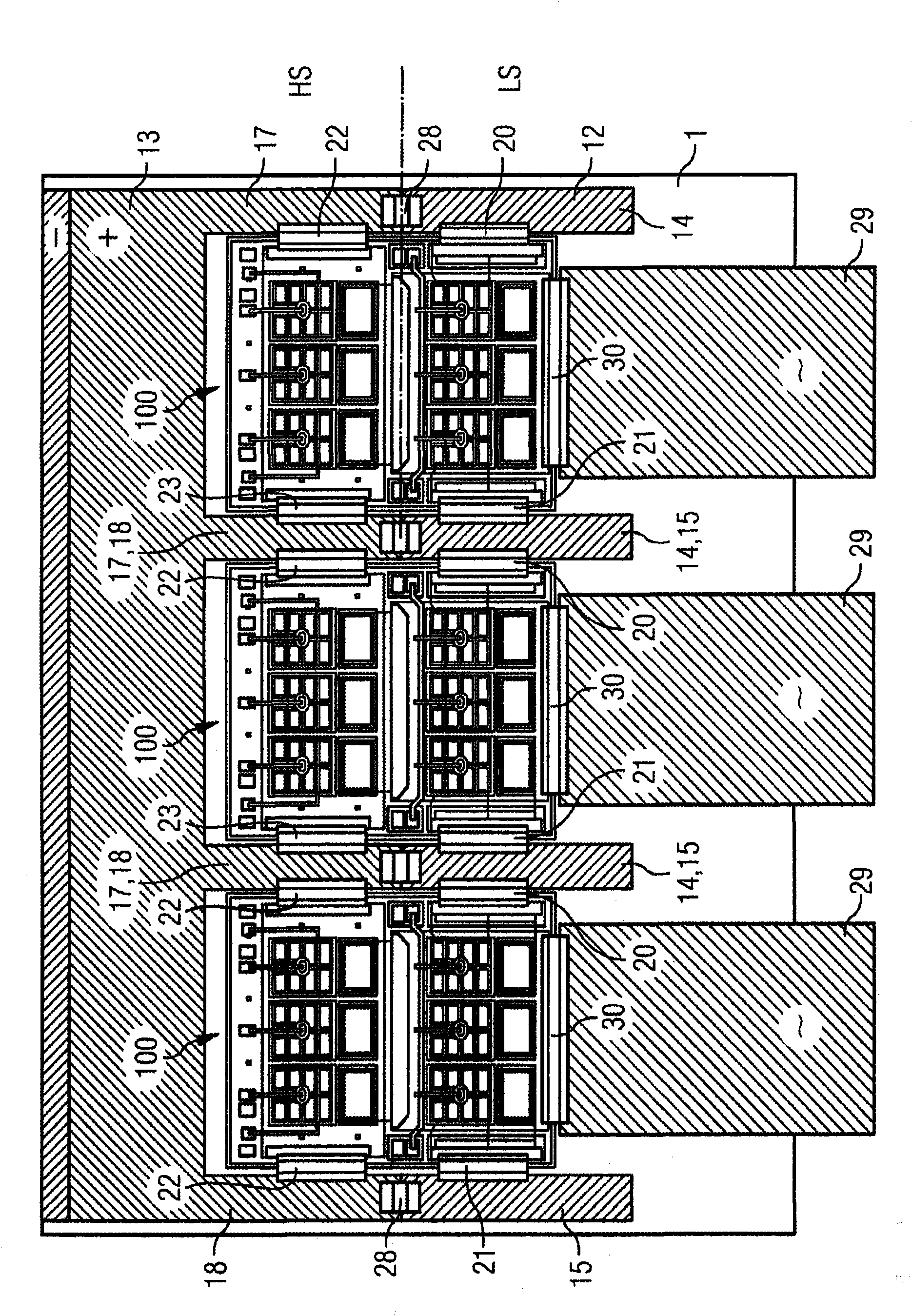

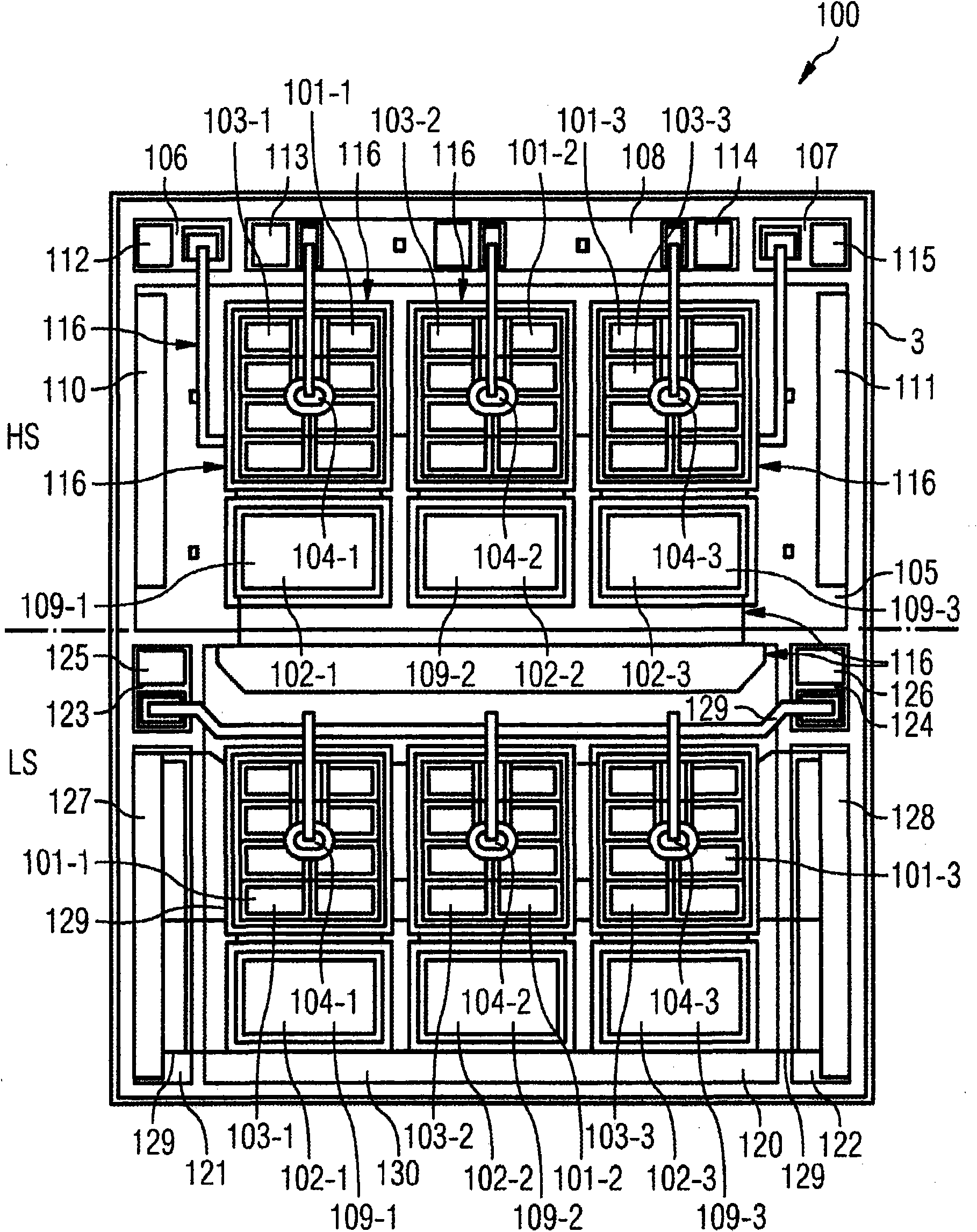

Arrangement comprising at least one semiconductor component, in particular a power semiconductor component for the power control of high currents

ActiveCN101809741AImprove utilizationImproved thermal connectionSolid-state devicesSemiconductor devicesPower semiconductor deviceBusbar

The description is given of an arrangement comprising at least one semiconductor component (8; 101-1, 101-2, 101-3), in particular a power semiconductor component for the power control of high currents, in which the at least one semiconductor component (8; 101-1, 101-2, 101-3) has in each case at least two electrical connection pads arranged separately from one another and is arranged on a commoncarrier body (1) in a manner electrically insulated from the latter. Furthermore a first and a second busbar (12, 13) are fixed on the carrier body (1) alongside the at least one semiconductor component (8; 101-1, 101-2, 101-3) and in a manner electrically insulated from the at least one semiconductor component (8; 101-1, 101-2, 101-3). One electrical connection pad of the at least one semiconductor component (8; 101-1, 101-2, 101-3) is electrically connected to the first busbar (12, 13) and another electrical connection pad of said semiconductor component (8; 101-1, 101-2, 101-3) is electrically connected to the second busbar (12, 13). The first and / or the second busbar (12, 13) have / has sections arranged at opposite sides of the semiconductor component (8; 101-1, 101-2, 101-3), wherein a current is applied to the connection pad electrically connected to the relevant busbar (12, 13) from both sections.

Owner:SIEMENS AG

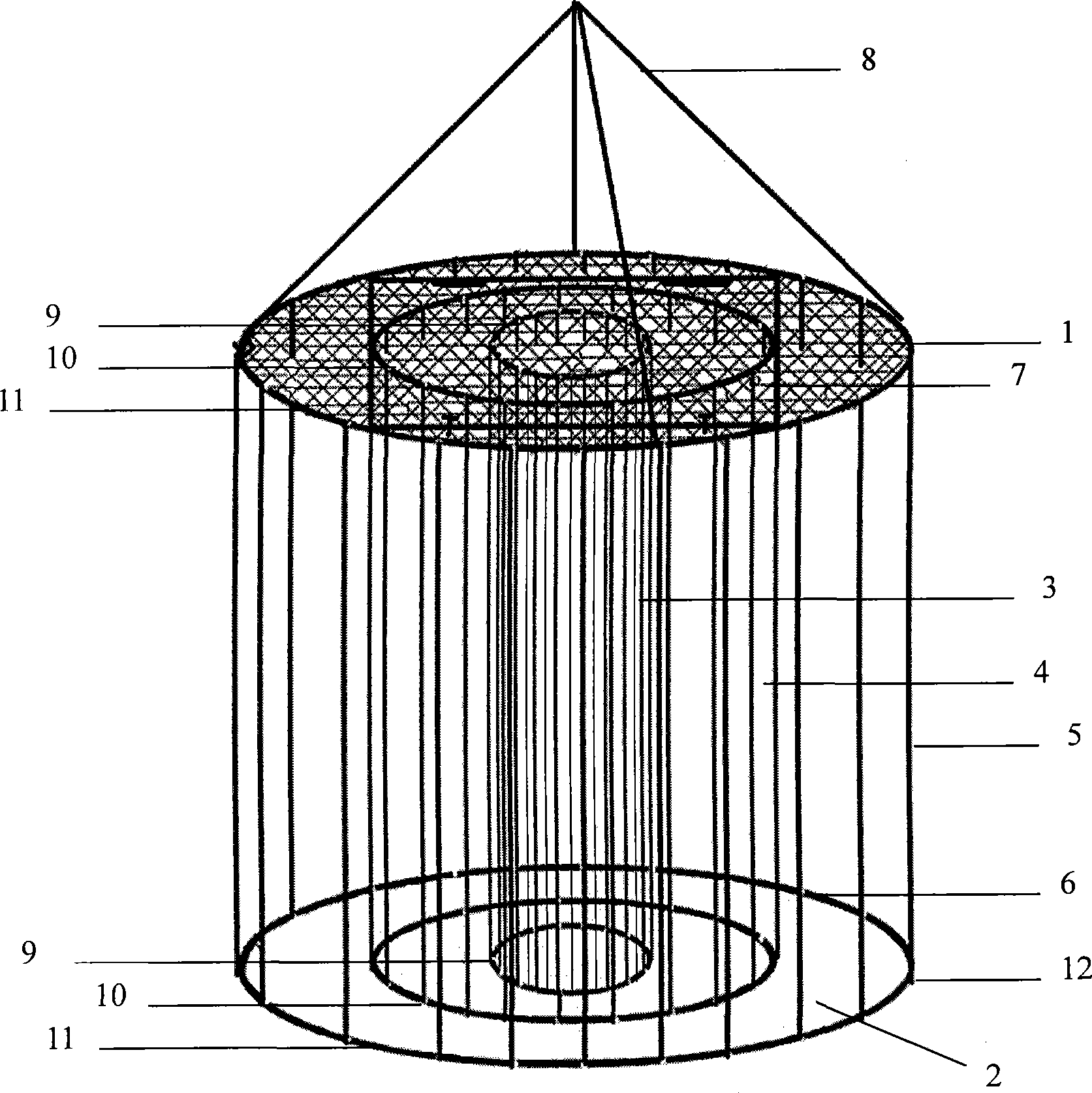

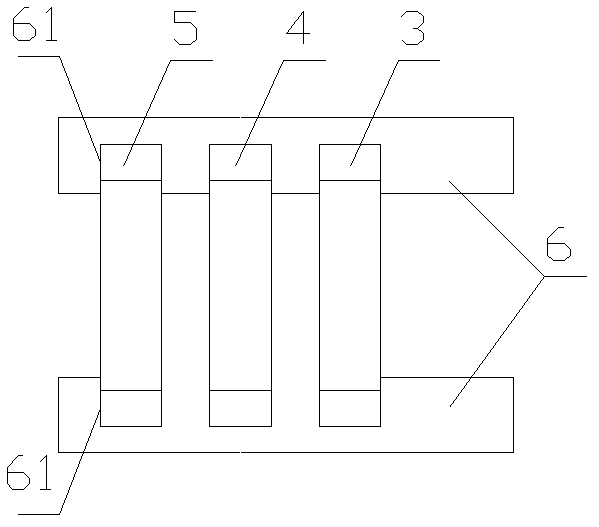

Carnivorous fish high success-ratio cultivation method and feeding device according different standard

InactiveCN101507421ANo waste of feedDoes not pollute the water environmentClimate change adaptationPisciculture and aquariaWater environmentHigh survival rate

The invention relates to a carnivorous fish seed culture method with high survival rate, which comprises: (1) separating a fish seed culture area in a culture pond by a separating mesh, and putting fish seeds into the area after water is filled in the pond; (2) placing a feeding device according to different specifications in the culture area, putting feeder into the feeding device regularly, and making the fish seeds with different sizes fed in spacer layers with different specifications of the feeding device respectively; and (3) after the fish seeds are grown up, detaching the separating mesh of the fish seed culture area to perform mass production culture. The feeding device according to different specifications comprises a top cover and a chassis between which fences with different specifications are arranged; and the fences comprise an inner layer fence, a middle layer fence and an outer layer fence, which are in movable connection with the top cover and the chassis. The culture method and the feeding device according to different specifications can guarantee feeding sufficiency for the fish seeds, do not waste the feeder or pollute the water environment, and ensure the even growth and high survival rate of the fish seeds.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

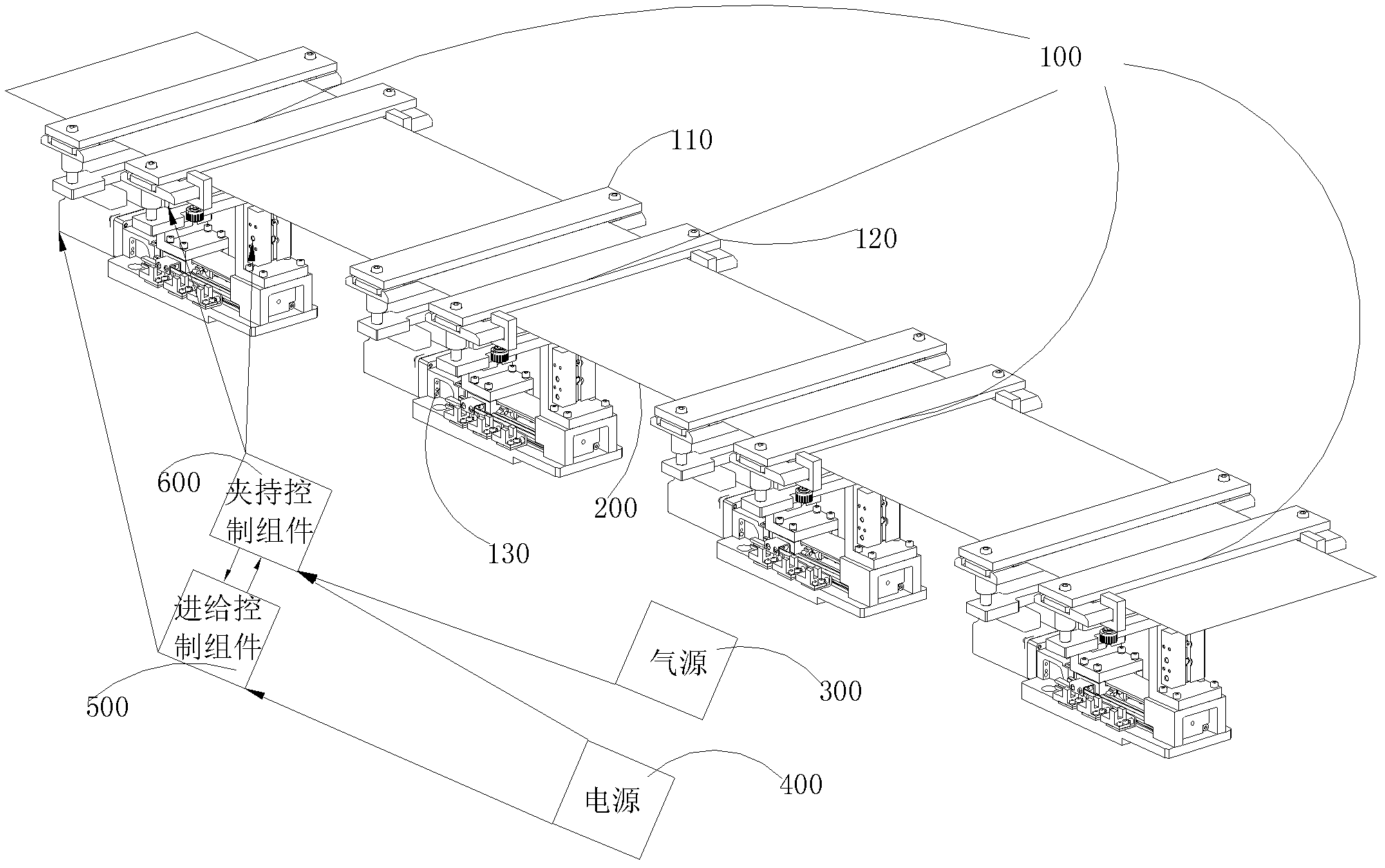

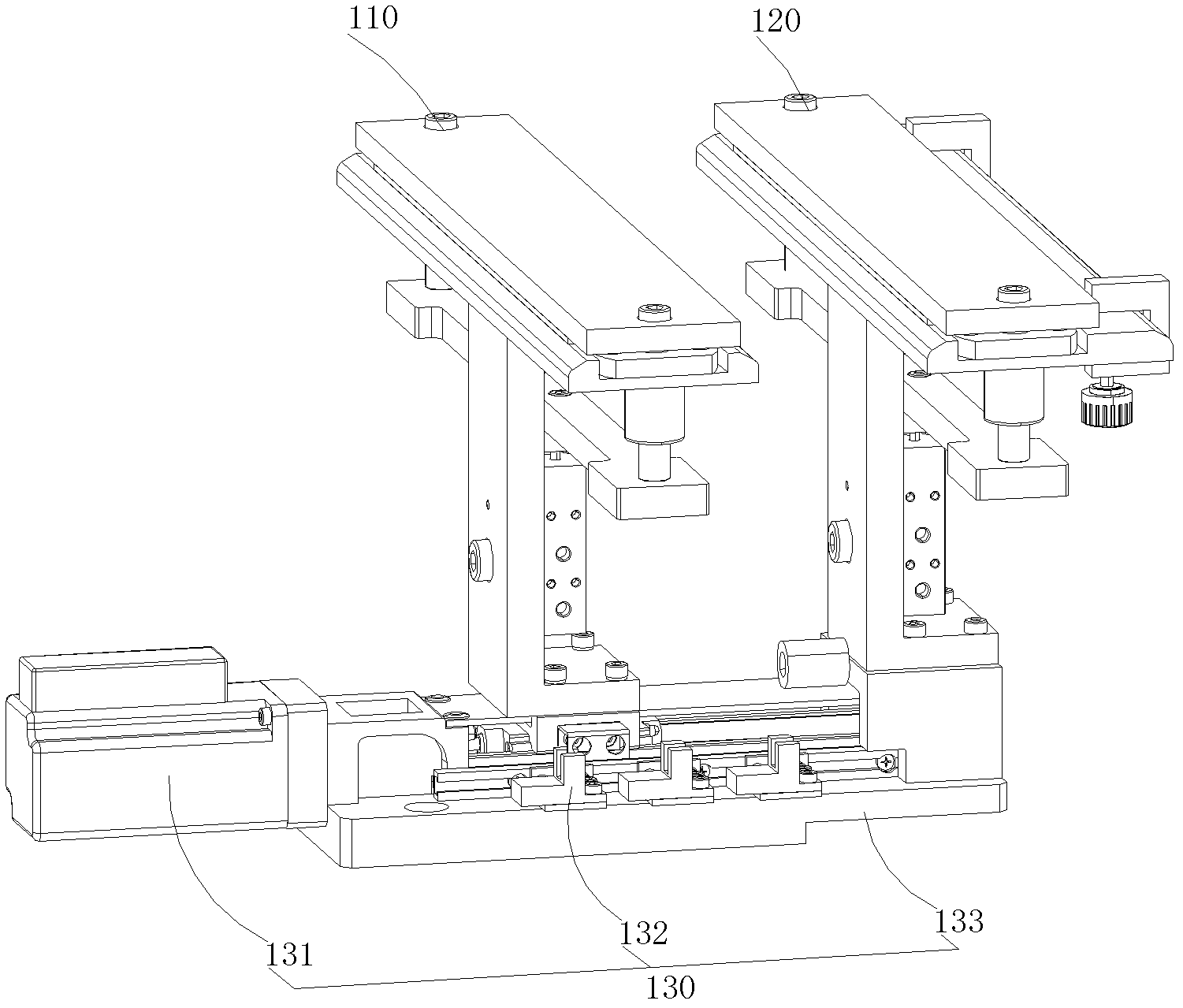

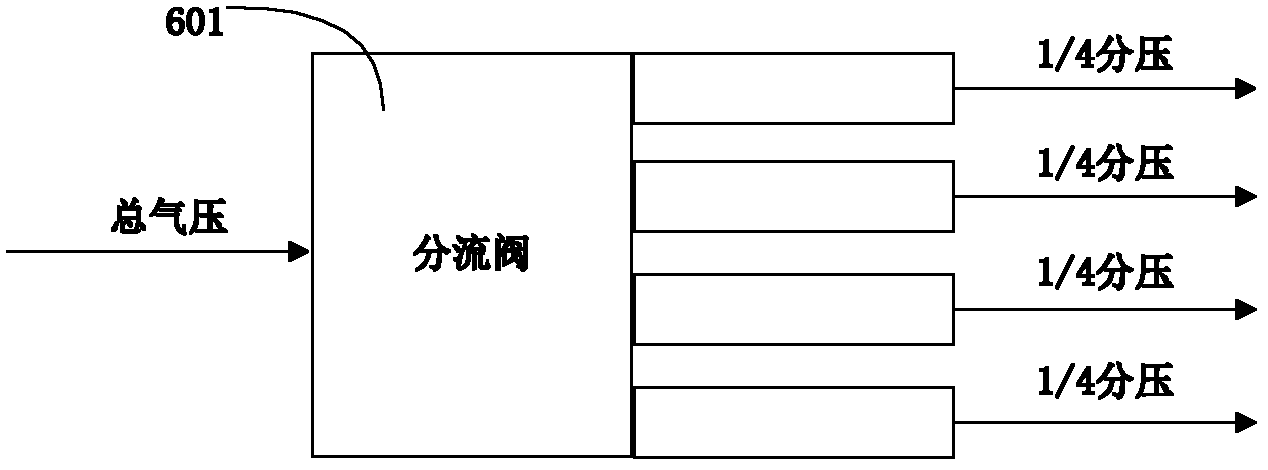

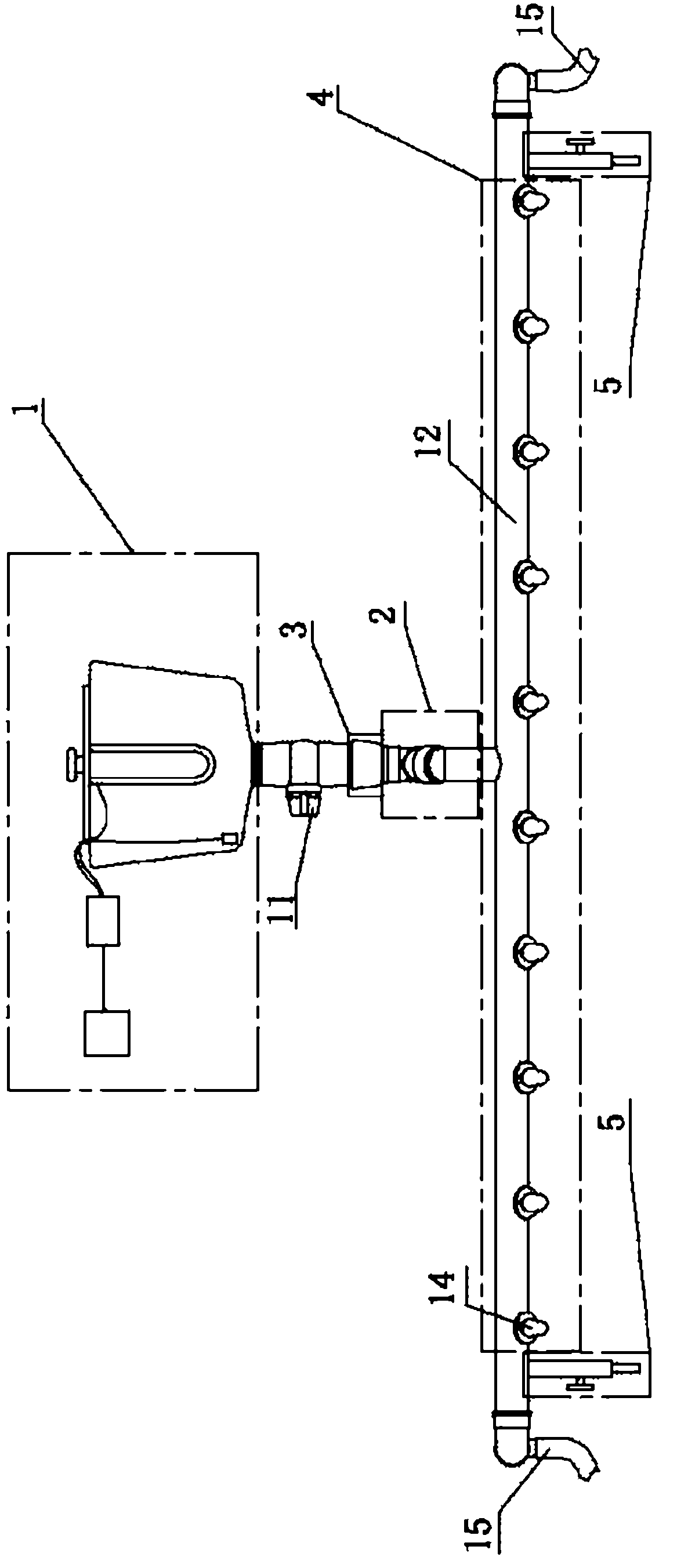

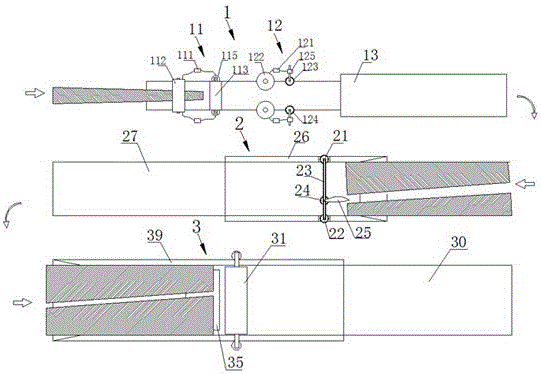

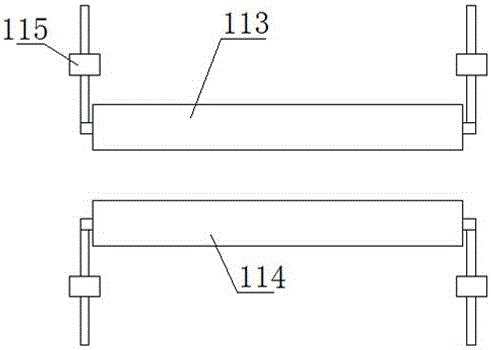

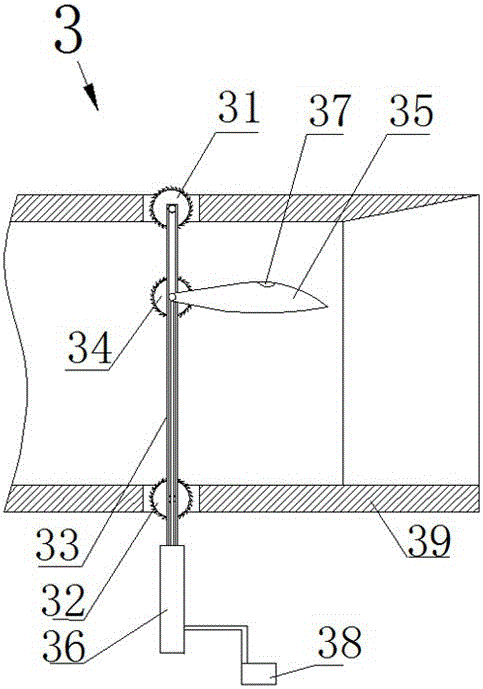

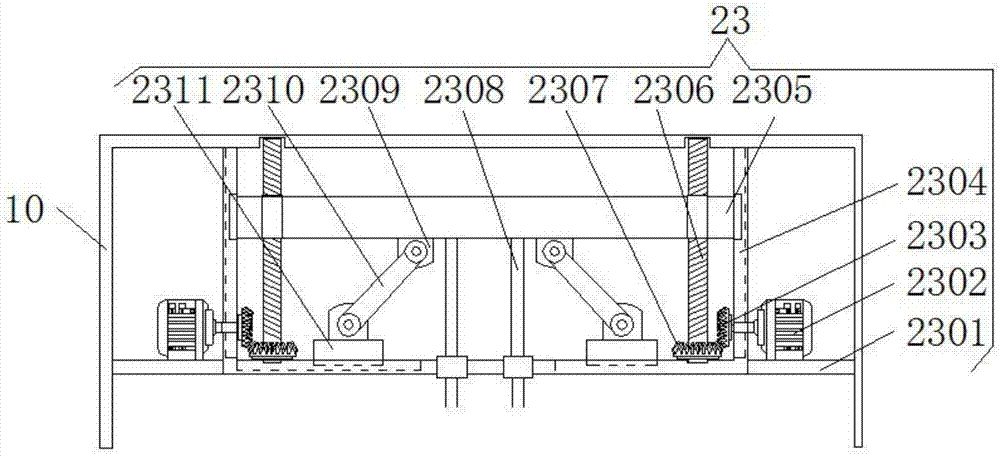

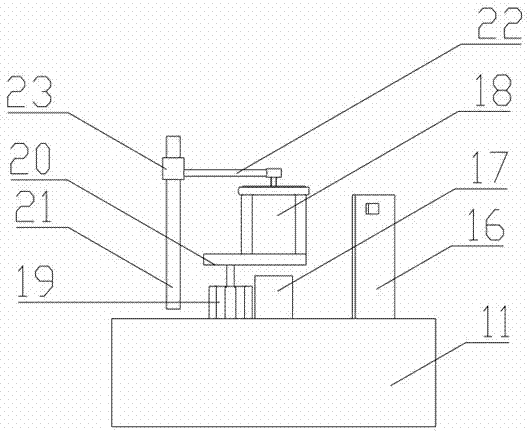

Clamping and feeding system used for synchronous transmission of flexible membranes and application thereof

ActiveCN102674056ASynchronous Feed GuaranteeGuaranteed normal feedingWebs handlingCyclic processEngineering

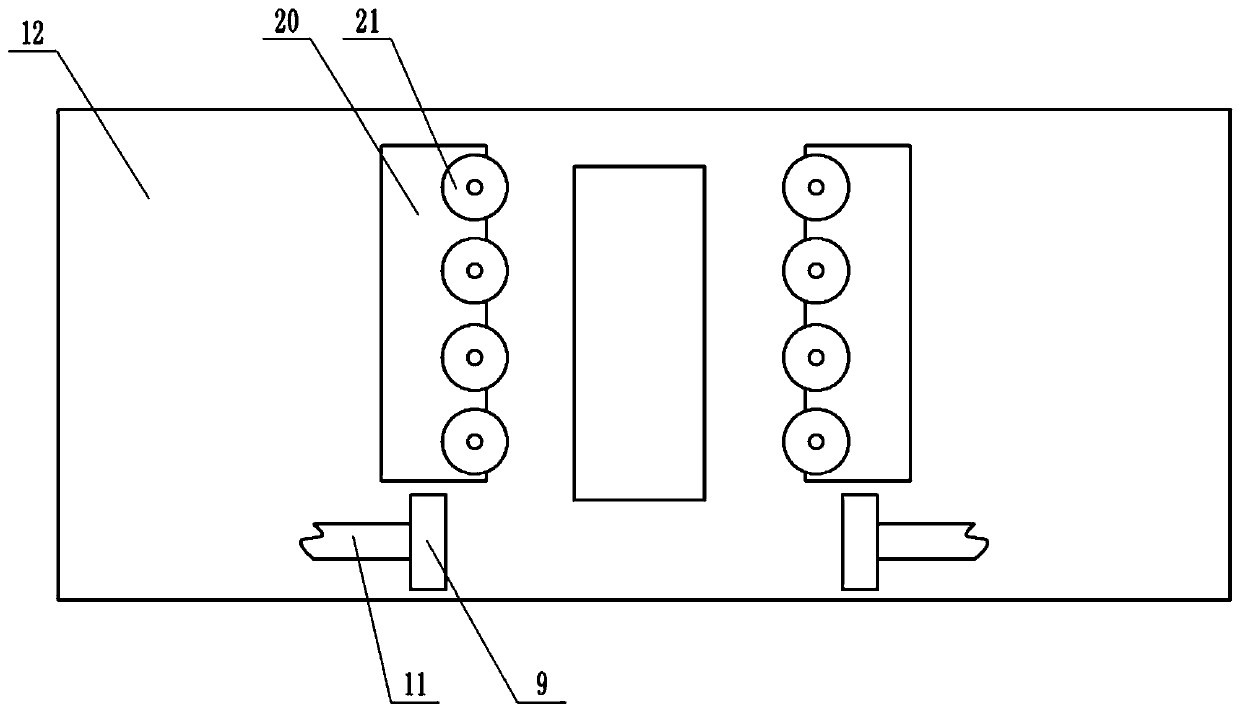

The invention discloses a clamping and feeding system used for the synchronous transmission of flexible membranes, and the system comprises multiple clamping and feeding devices successively arranged at intervals along the feeding direction, wherein each clamping and feeding device comprises a movable clamping and feeding assembly and a stationary clamping and feeding assembly; the flexible membranes can be alternately clamped by each movable clamping and feeding assembly and the stationary clamping and feeding assembly; when the movable clamping and feeding assembly clamps, the movable clamping and feeding assembly moves along the feeding direction; and when the stationary clamping and feeding assembly clamps, the movable clamping and feeding assembly returns the circulating process of an initial clamping position to realize a purpose of feeding and transmitting the flexible membranes. The invention discloses a method which utilizes the system to synchronously transmit the flexible membranes. In the transmission process of the flexible film, the flexible film is always clamped by the clamping and feeding assembly. Meanwhile, the flexible membranes are returned and fed intermittently by the alternate switch of clamping or loosening. In addition, the feeding and driving assembly simultaneously moves to guarantee that the flexible membranes can be simultaneously fed on a plurality of positions.

Owner:HUAZHONG UNIV OF SCI & TECH

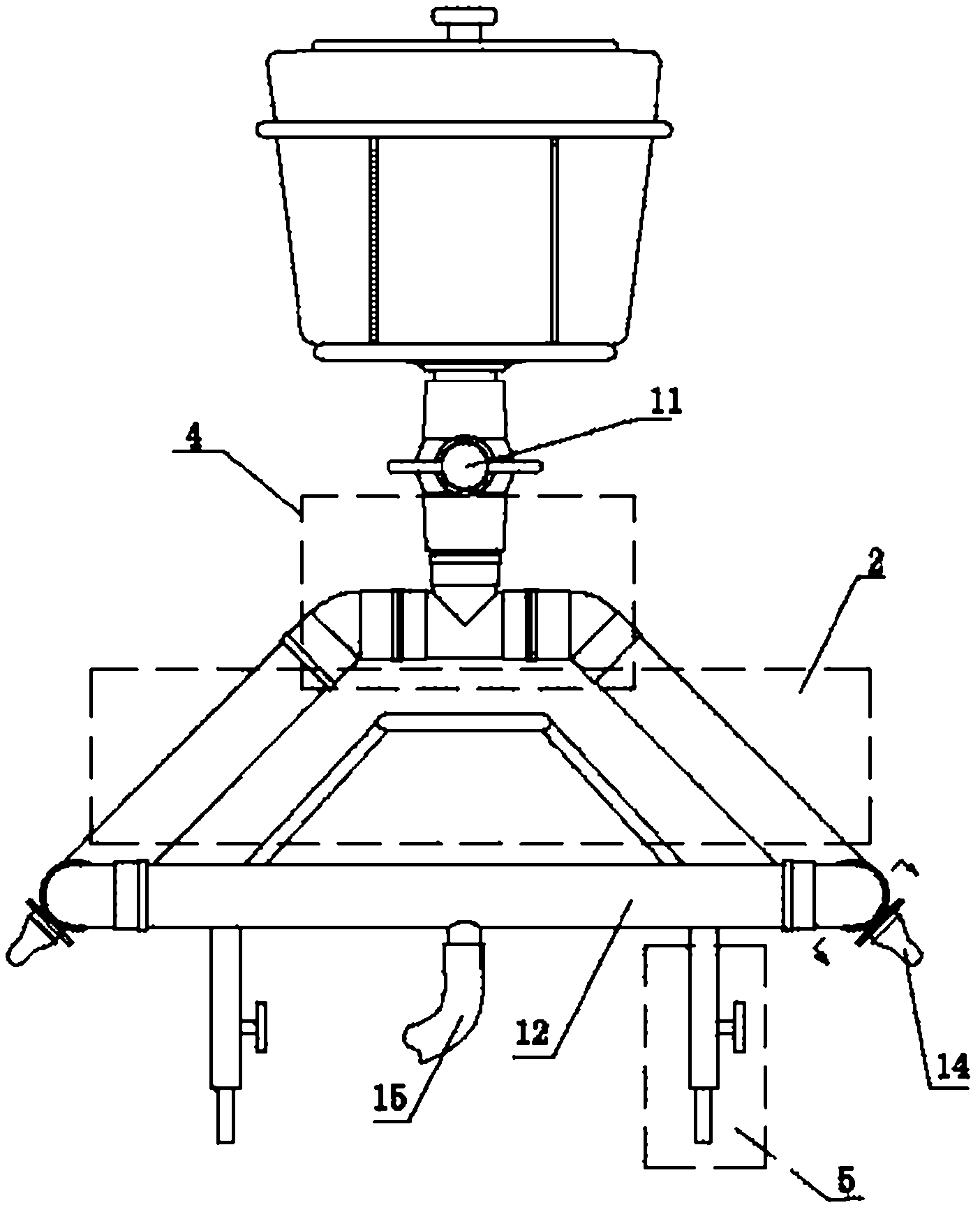

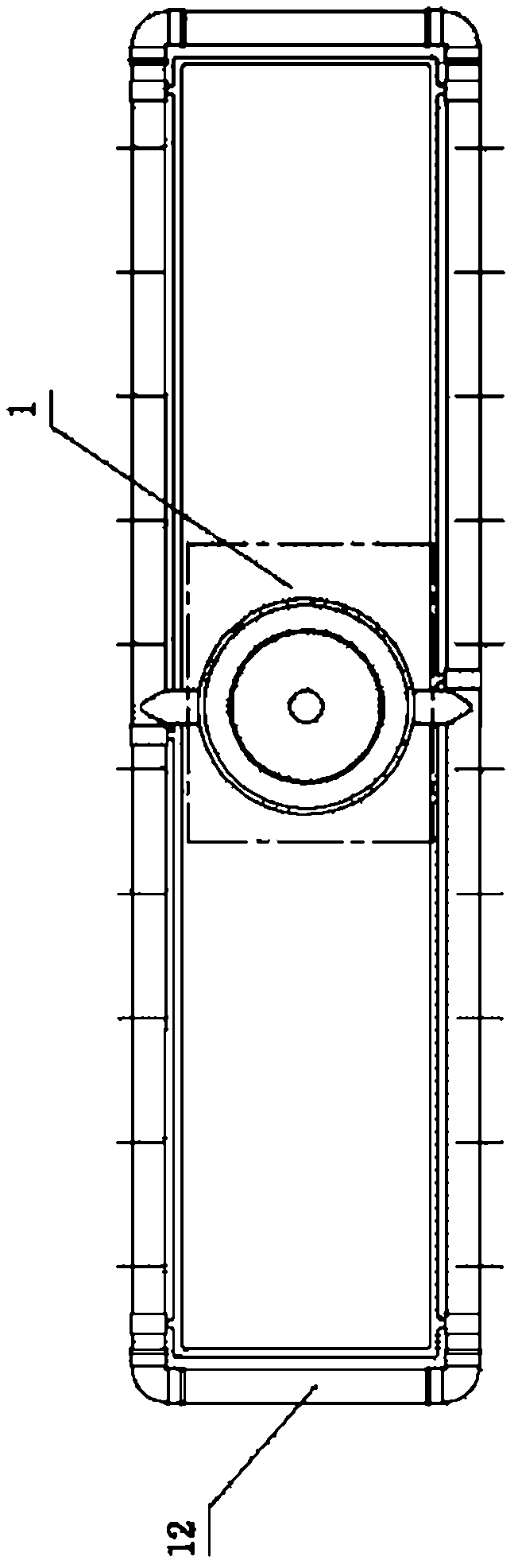

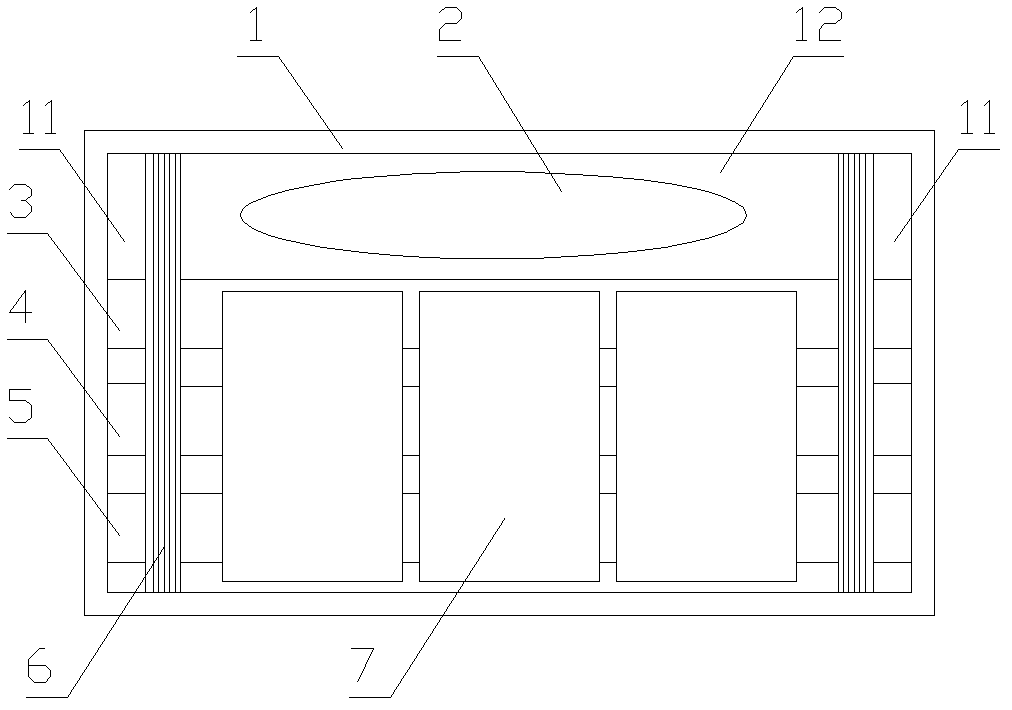

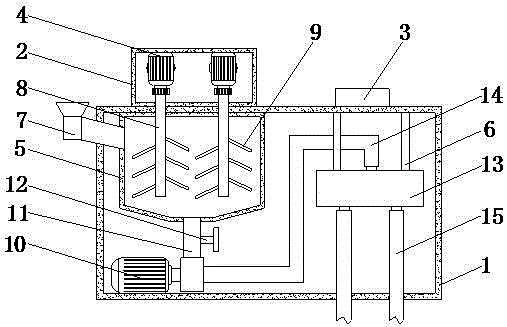

Intensive lamb lactation device

InactiveCN102318564AControl the proper temperatureGuaranteed normal feedingAnimal feeding devicesTemperature controlLiquid temperature

The invention relates to an intensive lamb lactation device, which belongs to the modern livestock facility equipment and is used for scale, intensive and standard lamb feeding management. The intensive lamb lactation device mainly comprises a milk storage unit, a milk conveying unit, a milk drinking unit, an automatic temperature control unit, a filter unit, a fixed unit and a peripheral protection unit in the main design. The intensive lamb lactation device has the advantages that: 1, the intensive liquid feedstuff feeding on the lamb group can be programmed, and the liquid temperature can be automatically controlled to be maintained in the most proper range; 2, the manufacture price is moderate, the structure is refined, the dismounting is easy, the cleaning is convenient, the time and the labor are saved; and 3, the functions are complete, and the intensive lamb lactation device can be used for various purposes such as milk feeding, water drinking, medication and the like and is applicable to various production occasions such as grazing lands, playing fields, lamb houses and the like.

Owner:ANHUI AGRICULTURAL UNIVERSITY

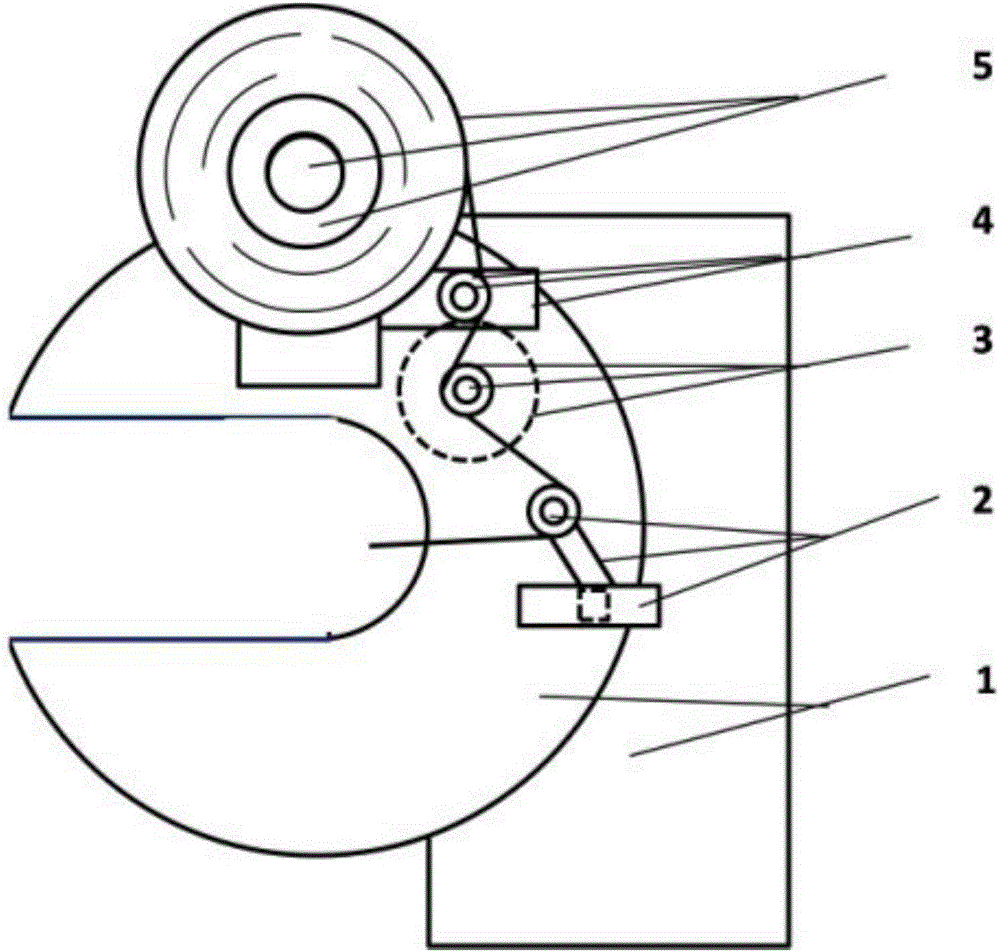

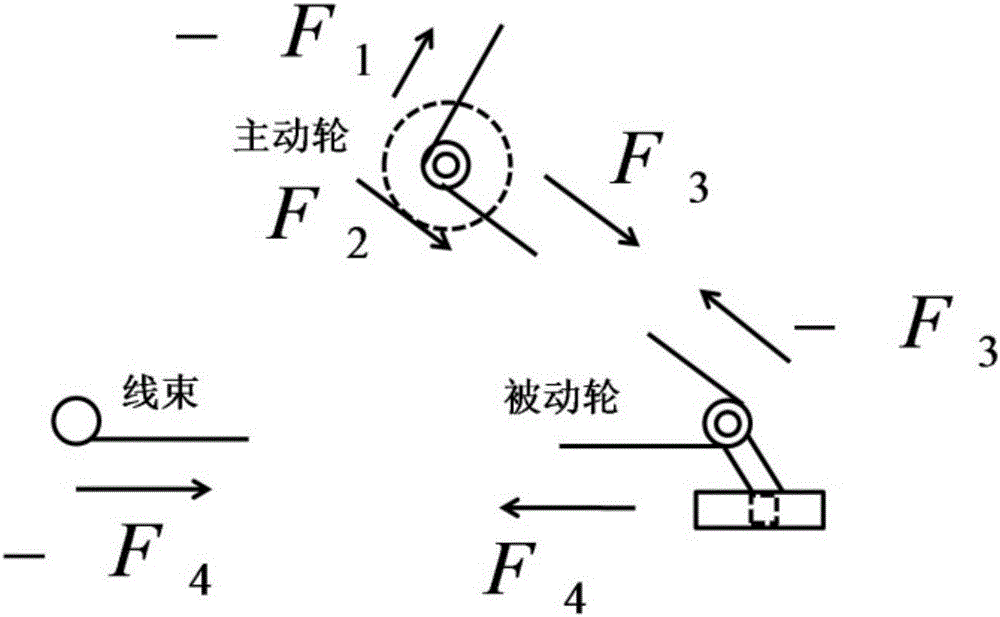

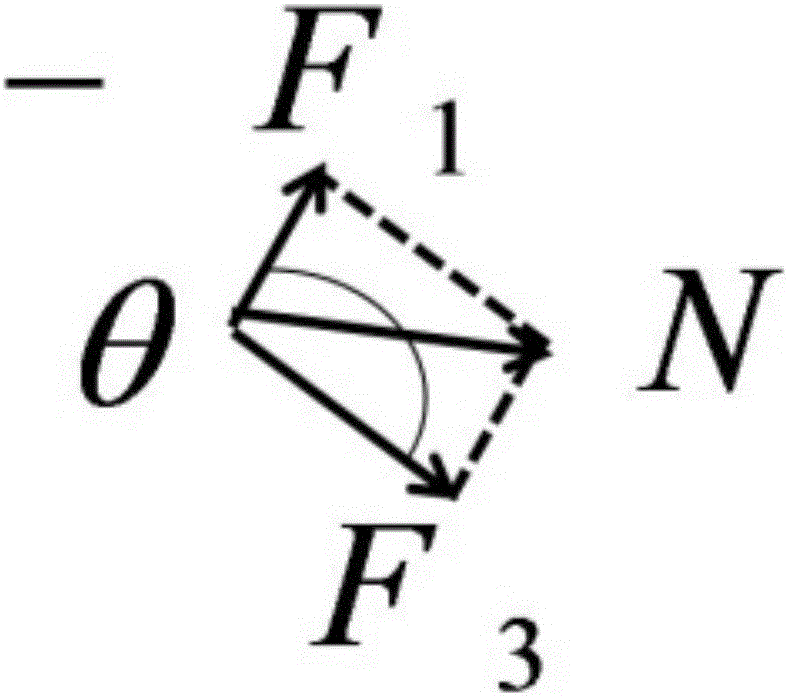

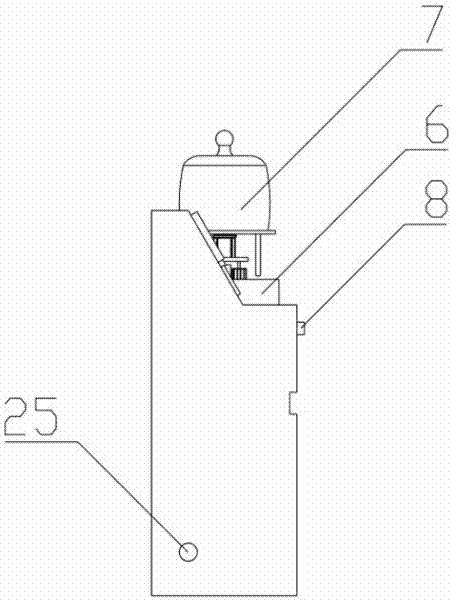

Adhesive tape wrapping machine feeding mechanism with force unloading function and achieving method

ActiveCN105836181AGuaranteed normal feedingGuaranteed feed speedBundling machine detailsEngineeringMaterial supply

The invention discloses an adhesive tape wrapping machine feeding mechanism with a force unloading function and an achieving method. The adhesive tape wrapping machine feeding mechanism comprises a main rotating mechanism body, a feed angle self-adaptive mechanism body, a force unloading mechanism body, a force unloading angle adjusting mechanism body and a material disc mechanism body. The main rotating mechanism body is the carrier of the feed angle self-adaptive mechanism body, the force unloading mechanism body, the force unloading angle adjusting mechanism body and the material disc mechanism body. The feed angle self-adaptive mechanism body, the force unloading mechanism body, the force unloading angle adjusting mechanism body and the material disc mechanism body are all arranged on the same side surface of the main rotating mechanism body. A material belt pulled out through the material plate mechanism body sequentially passes the force unloading angle adjusting mechanism body, the force unloading mechanism body and the feed angle self-adaptive mechanism body and then is used for supplying continuable adhesive tape or a belt-shaped material to the wire hardness wrapping process. According to the adhesive tape wrapping machine feeding mechanism with the force unloading function and the achieving method, the stress environment of the material supply process of an adhesive tape wrapping machine can be improved, the wrapping effect is improved, the wrapping application range is enlarged, and the adhesive tape wrapping machine feeding mechanism with the force unloading function and the achieving method can be applied and popularized in the automobile wire harness industry in a batched mode.

Owner:ZHUJI CANU AUTOMATION EQUIP CO LTD

Bamboo strip grinding device

The invention relates to a bamboo strip grinding device. The bamboo strip grinding device comprises a single-strip grinding device and a dual-strip combined grinding device which are sequentially arranged; the single-strip grinding device comprises an upper and lower end face automatic grinding mechanism and a left and right end face automatic grinding mechanism which are sequentially arranged; the upper and lower end face automatic grinding mechanism comprises a first upper grinding roller and a first lower grinding roller which are horizontally arranged and vertically correspond; the left and right end face automatic grinding mechanism comprises a first left grinding roller and a first right grinding roller which are vertically arranged and correspond to each other in a left-and-right manner; the dual-strip combined grinding device comprises a second left grinding roller, a second right grinding roller and a first movable grinding roller which are vertically arranged and correspond to one another; the first movable grinding roller slides between the second left grinding roller and the second right grinding roller in a left-and-right manner through a first sliding rail.

Owner:福州吉晟竹业有限公司

Biomass grate firing boiler

InactiveCN101949534AGuaranteed sealingReduce heat lossSolid fuel combustionCombustion apparatusEngineeringTuyere

The invention discloses a biomass grate firing boiler. The boiler comprises a movable grate, a hearth, a water jacket, secondary air, a front-wall membrane type water cooling wall, an upper drum, a lower drum, a convection bank and a rear arch, wherein the front part of the hearth of the grate firing boiler is not provided with a front arch and has a membrane type wall structure; the lower part of a feeding section at the front part of the movable grate extended out of the hearth is provided with an L-shaped sealing partition plate; the feeding section of the grate and the water jacket form a water cooling feeding passage; the two sides of the front part of the water cooling feeding passage are provided with adjustable gates; the top end of the middle part is provided with a movable folding door; and a throat part formed by the front-wall membrane type water cooling wall and the rear arch is correspondingly provided with a secondary air port. By using the unique water cooling feeding passage and a folding door sealing device, the annealing in the combustion process of a biomass fuel can be effectively prevented, the running safety of the boiler is increased, and meanwhile, the amount of the cold air which enters the hearth through the feeding passage is reduced; the front wall of the boiler has a membrane type wall structure, so that the sealing property of the boiler is improved and the heat dissipation loss is reduced; and the boiler has the advantages of safety, high efficiency and the like.

Owner:TSINGHUA UNIV +1

Bee colony special for pollination

The invention discloses a bee colony special for pollination. A box body is provided, wherein a queen bee is put in the box body and three frames of bee combs are arranged in parallel from front to back in the box body; the three frames of bee combs respectively comprise to a frame of sealed brood, a fame of larva comb and a frame of honey and pollen combs; bee spaces at the interval of 1.5cm are arranged among the three frame of bee combs; a bee space at the interval of 1.5cm is arranged between the frame of comb bee on the most front side and the front wall of the box body for the bees to enter and leave; a syrup chamber is left between the frame of comb bee on the most rear side and the rear wall of the box body; syrup is stored in the syrup chamber; the three frames of bee combs are spaced with fixed intervals by fixed clapboards; and the upper parts of the three frames of bee combs are provided with bee bread bricks. One bee box is provided with one queen bee and three frames of comb bees to just finish pollination. In addition, about 2.5kg of syrup is filled in a plastic bag, and 1.5kg of bee bread bricks are put on the syrup to provide enough food for bees to eat for one month, wherein the weight of each bee bread brick is 0.5kg. The bees can be guaranteed to be feed with the syrup in the plastic bag and the bee bread bricks on the upper parts of the three frames of comb bees during pollination, and bee keepers only need to check one time in one month.

Owner:平湖市全清养蜂科技研究所

Deburring device for metal plate

ActiveCN107457641ARealize automatic feedingReduce participationEdge grinding machinesGrinding feedersSoftware engineeringDrive motor

The invention discloses a deburring device for a metal plate. The deburring device comprises a box body. First motors are fixedly connected to two sides of the bottom of the inner wall of the box body; the output shaft end of each of the first motors is in transmission connection to an automatic feeding device through a belt; a fixed box is fixedly connected to the top of the inner wall of the box body; a lower deburring device is connected to the bottom of the inner wall of the fixed box through a first double-drive motor; one side of the bottom of the inner wall of the fixed box is fixedly connected to a second motor; the output shaft end of the second motor is connected to an auxiliary conveying device through a belt; a lifting device is fixedly connected to the top of the inner wall of the fixed box; and an upper deburring device is connected to the bottom of the lifting device through a mobile plate. The invention relates to the technical field of metal processing. The deburring device for the metal plate disclosed by the invention feeds the metal plate automatically, so that participation of personnel in a processing course is reduced, and the labor force is reduced; double sides are deburred at the same time, so that the processing efficiency is increased and the time is shortened.

Owner:临沂尚昊金属家具有限公司

Large-scale breeding method for laodelphax striatellus

InactiveCN106305632AFull of nutritionGood moisturizing effectAnimal feeding stuffTriticeaeGreenhouse

The invention relates to a large-scale breeding method for laodelphax striatellus by utilizing wheat as main feed, and belongs to the technical field of insect breeding. The large-scale breeding method comprises the following steps: screening wheat seeds and accelerating germination of the wheat seeds, sowing the germinated wheat seeds in a green house, and taking the wheat seeds as laodelphax striatellus feeding feed when wheat grows to the two-leaf one-heart period, and is 6cm high; and covering the wheat by an insect breeding cover, and breeding laodelphax striatellus on wheat seedlings covered by the insect breeding cover. According to the large-scale breeding method for the laodelphax striatellus provided by the invention, a method which takes wheat as feed to carry out laodelphax striatellus annual breeding is gradually formed based on multi-year research on diseases infected with viruses transmitted by insects such as the maize rough dwarf disease, the wheat rosette dwarf and the wheat yellow-stripe dwarf disease. The large-scale breeding method is simple and convenient to operate, guarantees consistent larva instar and a high laodelphax striatellus breeding rate, realizes annular continuous feeding for a large number of laodelphax striatellus, can provide enough test insects at any time, and meets experimental needs of many units.

Owner:INST OF PLANT PROTECTION HEBEI ACAD OF AGRI & FORESTRY SCI

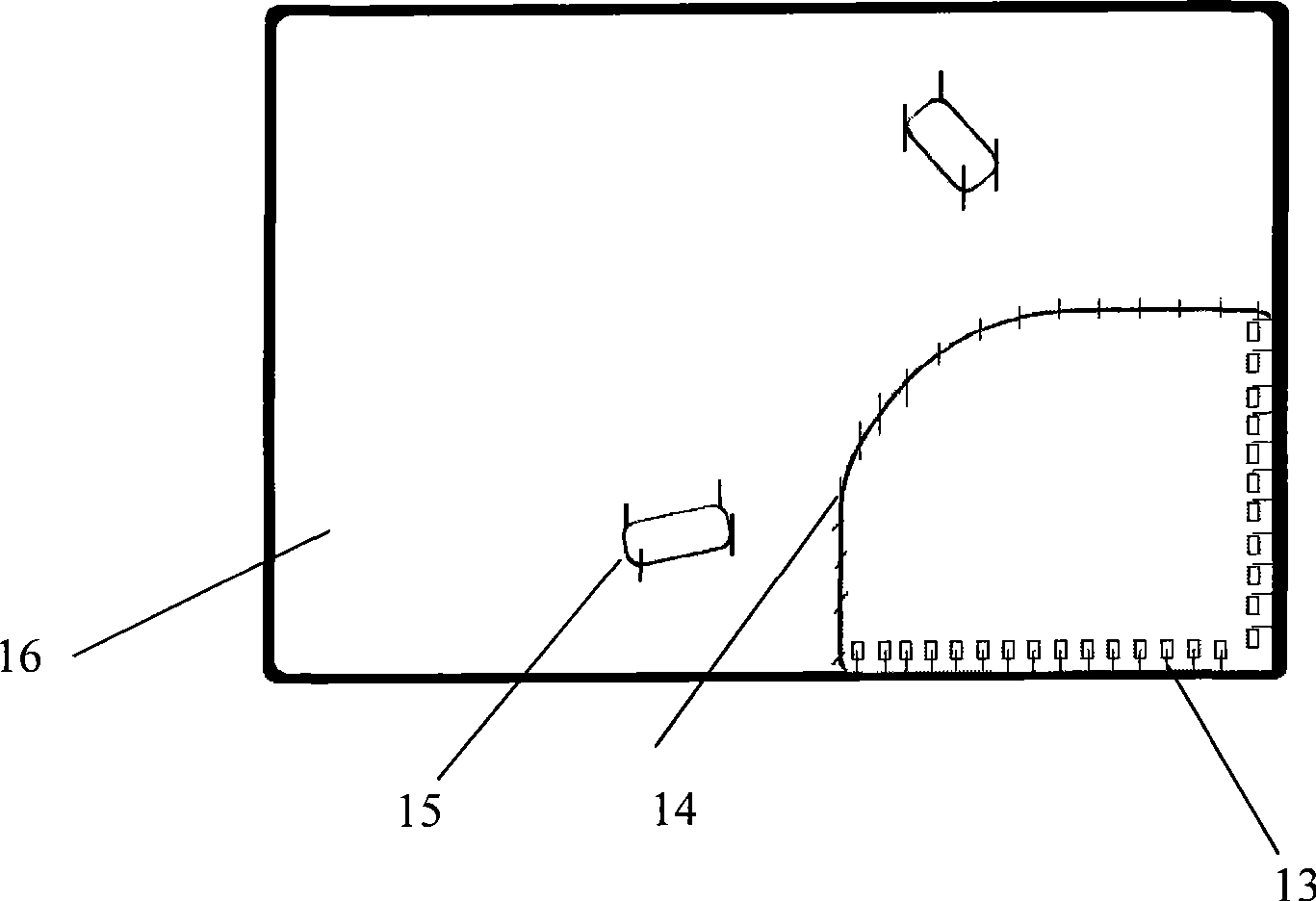

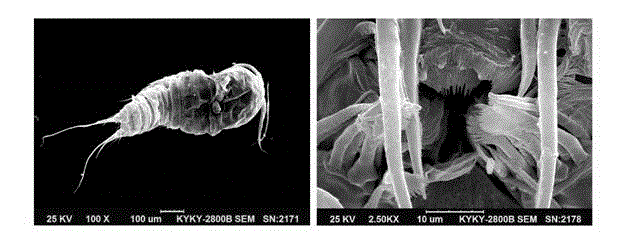

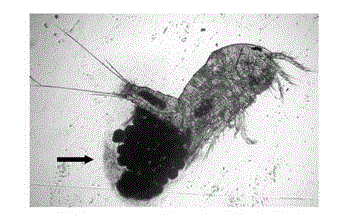

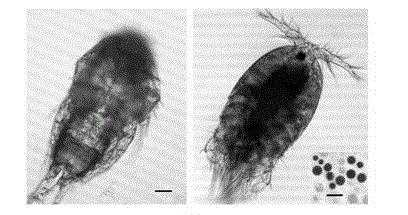

Method for clearing wild algae contamination in live history micro-phase of large economic algae

InactiveCN103999763AWidely distributedEasy to separateClimate change adaptationCultivating equipmentsPhacusMicro level

The invention belongs to the field of biotechnologies of algae and relates to a method for clearing wild algae contamination in the live history micro-phase of large economic algae. According to the method, water fleas inhabiting in the lower middle of an ocean are mixed with contaminating wild algae in the live history micro-phase of large economic algae so as to remove the contaminating algae by natural feeding behaviors of the water fleas. The method has the advantages that the contaminating algae in the live history micro-phase of various economic algae can be cleared efficiently and thoroughly and no harm is caused to the economic algae.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

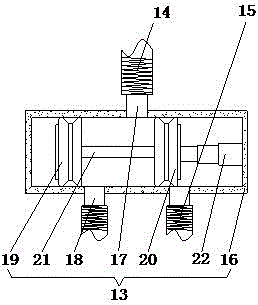

Pet feed stirring and feeding device

InactiveCN106135030AGuaranteed normal feedingEasy feedingAnimal feeding devicesEngineeringHigh pressure

Owner:WUXI DONGCHENG BIO TECH CO LTD

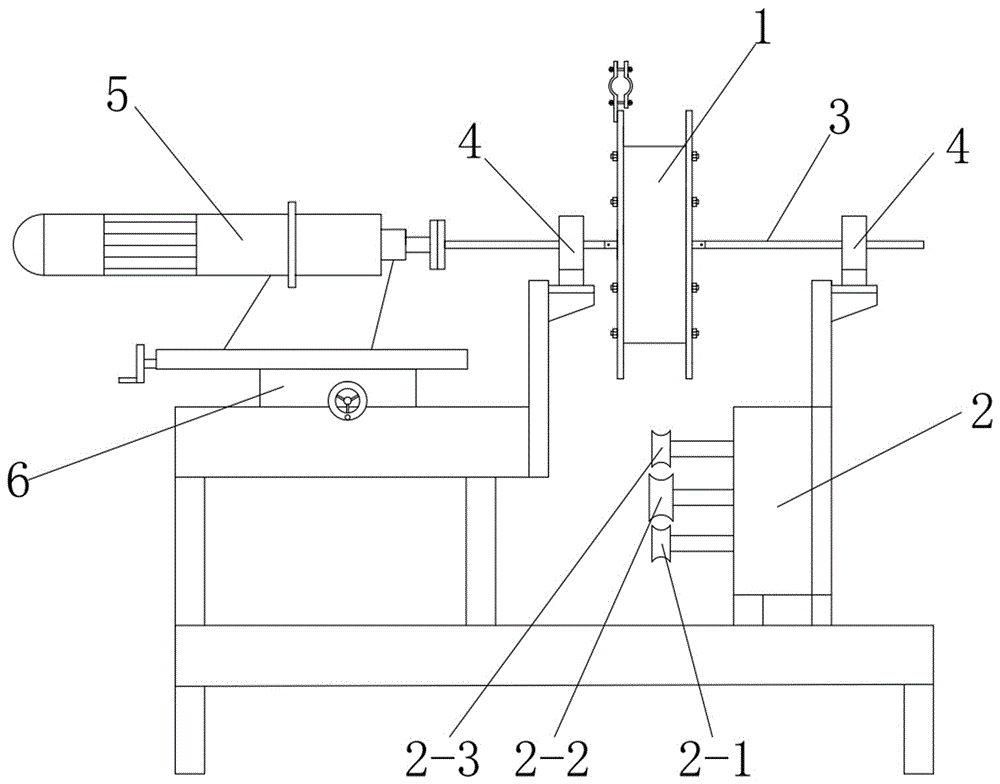

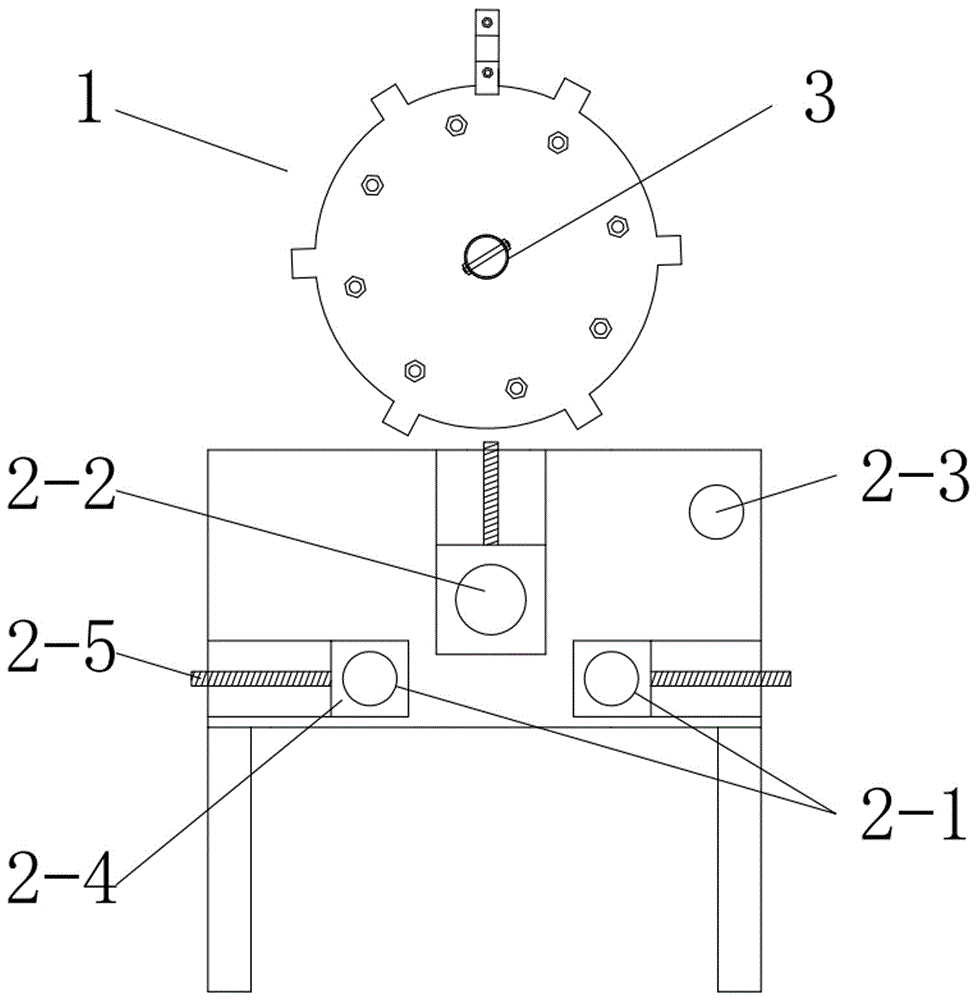

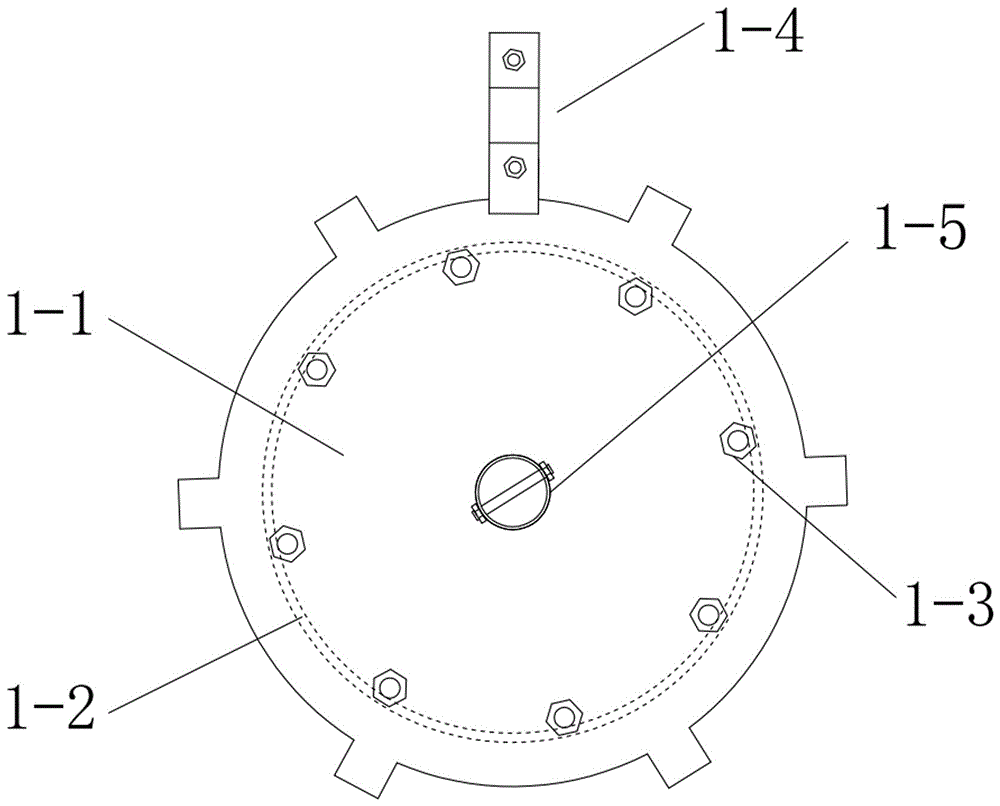

Equipment for automatically welding vacuum corrugated pipe

InactiveCN102500859AEasy to operateEasy maintenanceMetal working apparatusSoldering auxillary devicesProgrammable logic controllerArchitectural engineering

The invention discloses equipment for automatically welding a vacuum corrugated pipe. According to a fixture for automatically welding the corrugated pipe, a round fixture fixing base is adopted; 12 equant round holes are formed in the round fixture fixing base; a fixed baffle plate is arranged between any two adjacent round holes; proximity switches are respectively arranged on two sides of eachfixed baffle plate along a circumferential direction; an air exhaust hole is formed in the round fixture fixing base, and a hollow shaft is arranged in the center of the round fixture fixing base; anair cylinder is fixed on the base on the side face of the hollow shaft; a baffle plate is arranged on a main shaft of the air cylinder; a stepping motor is fixed on the baffle plate; one end of a link rod is connected with a main shaft of the motor, and the other end of the link rod is connected with a welding pen sleeve; a welding pen is vertically arranged in the welding pen sleeve; one end of a power line and one end of an air source line are introduced from the hollow shaft, and are connected with the stepping motor and the air cylinder respectively; and the other end of the power line and the other end of the air source line are connected with an air pump and a programmable logic controller (PLC) respectively. According to the equipment, the shortcomings of low welding precision, complicated operation, high time consumption, low efficiency and high equipment abrasion during manual welding of the corrugated pipe and the shortcoming that the welding quality and the welding speed are limited by the technical level of operators are overcome.

Owner:CHINA JILIANG UNIV

Paper feed mechanism of adhesive sticker die cutting machine

ActiveCN111792408APrevents sticking of multiple layersPaper Feed GuaranteeRegistering devicesArticle deliveryPaperboardIndustrial engineering

The invention discloses a paper feed mechanism of an adhesive sticker die cutting machine, and relates to the technical field of packaging and printing. The paper feed mechanism comprises a die cutting machine body, wherein a storage tray is arranged at the paper feed end of the die cutting machine body in a lifting manner, an arc-shaped paper feed plate is arranged on the die cutting machine body, a paper adsorption mechanism used for adsorbing paper pieces to the arc-shaped paper feed plate is arranged between the storage tray and the arc-shaped paper feed plate, a limit space used for limiting the paper pieces is formed between the higher part of the arc-shaped paper feed plate and the storage tray, a paper blowing mechanism used for preventing the paper pieces from adhering to each other is arranged in the limit space, and a knife biting mechanism used for transporting paper is arranged on the arc-shaped paper feed plate in a sliding manner. By means of the paper blowing mechanismand the arc-shaped paper feed plate, the condition of multilayer adhesion of the paper pieces in a paper adsorbing process and a paper transporting process is avoided, single-piece paper feeding is guaranteed, and normal running of later die cutting work is ensured.

Owner:上海祥仓包装印刷有限公司

Copper casing pipe coiler

The invention relates to the field of a bending forming processing technology of casing pipe materials, in particular to the field of a preparing technology of a multi-layer spiral-structure copper casing pipe for a heat exchanger. The invention particularly discloses a copper casing pipe coiler. The copper casing pipe coiler comprises a rack, and a bending mechanism and a pipe coiling disc which are arranged on the rack, wherein the pipe coiling disc is driven by a speed reducer with a motor to rotate through a rotating shaft, the rotating shaft penetrates through a bearing and is supported by bearing pedestals arranged on the rack, and the speed reducer is fixed to a sliding table of the rack and can move on the surface of the rack in the axial direction of the rotating shaft through the sliding table; the bending mechanism comprises a dynamic pipe conveying wheel group arranged below the pipe coiling disc, a bending wheel arranged among the dynamic pipe conveying wheel group and a guide wheel which is positioned between the dynamic pipe conveying wheel group and the pipe coiling disc and is close to the periphery of the pipe coiling disc; and a pipe head positioning clamp is arranged on the pipe coiling disc. The copper casing pipe coiler can process the copper casing pipe and make a multi-layer spiral coiled pipe for the heat exchanger and has the advantages of being high in processing efficiency, neat and even in coiled pipe appearance and low in worker labor intensity.

Owner:常熟在路上创业孵化器有限公司

Mixed-color core-spun yarn and production device and production method thereof

The invention relates to mixed-color core-spun yarn and a production device and a production method thereof. The production method includes following steps: subjecting sliver A prepared through a drawing process and thick yarn B prepared through a roving process to roving to obtain thick yarn C, wherein the thick yarn C is core-spun yarn, the sliver A is skin yarn, and the thick yarn B is core yarn; subjecting the thick yarn C and filament D to a spinning core-spun yarn process to produce the mixed-color core-spun yarn. The mixed-color core-spun yarn produced by the method is of a three-layeroverlapped structure, has the advantages of high shape maintaining performance, elasticity and obvious functional feature, can form special color effect according to color selecting, matching and adjusting, can be widely used for knitting, weaving and knitwear and is prime yarn for making fashionable fabric for high-grade underwear, sports T shirts and casual wear.

Owner:ZHEJIANG HUAFU COLOR TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com