Glass cloth automatic cutting machine

A technology of cutting machine and glass cloth, which is applied in the cutting of textile materials, textiles and paper making, etc. It can solve the problems of no device for correcting the deviation of the cloth, the inconvenience of cutting the cloth, and the inability to form feedback, etc., so as to facilitate clamping and reduce labor. Strength, quality-enhancing and efficiency-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

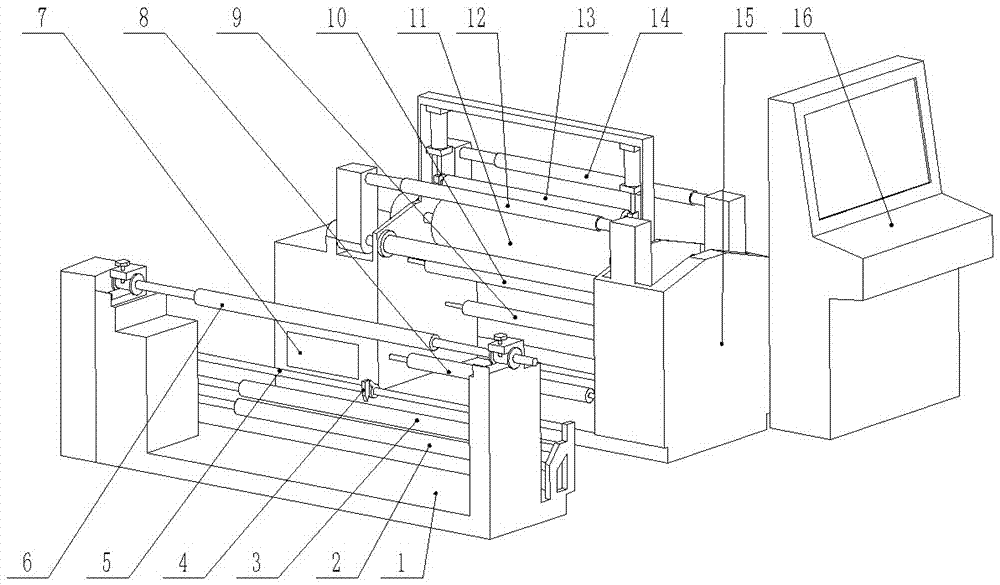

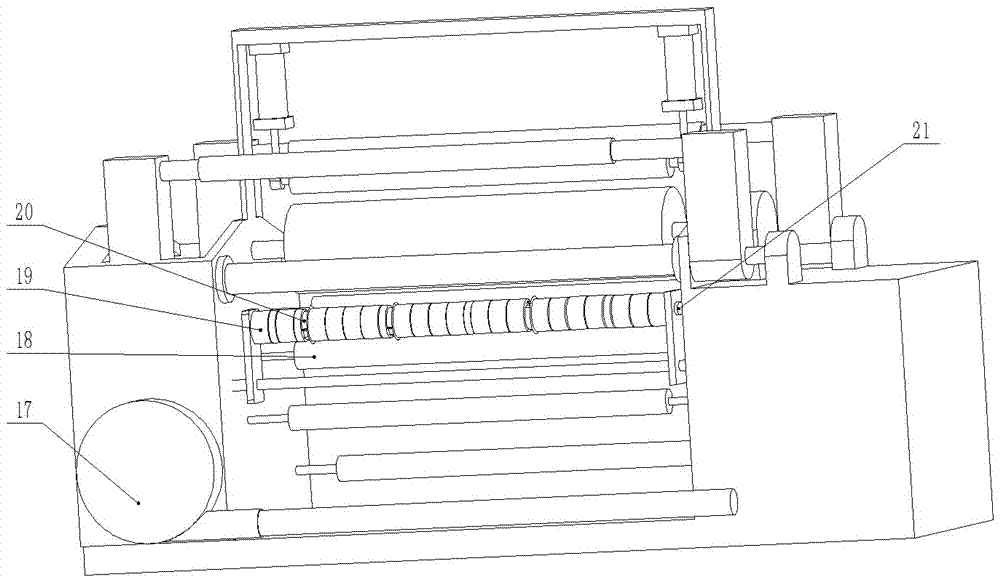

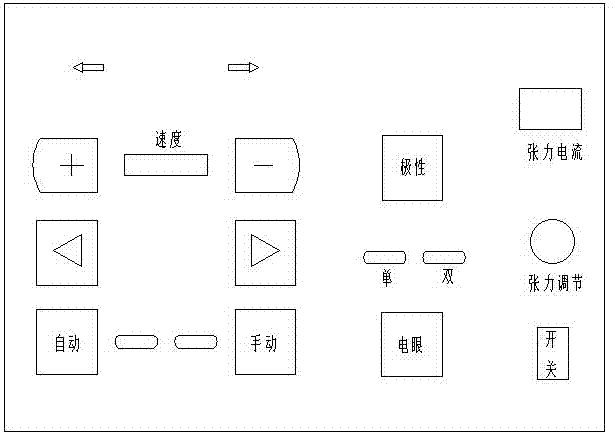

[0020] Such as figure 1 , 2 , 3, 4, 5, 6, 7, 8, the present invention includes base I1, base II 15, control cabinet 16, feeding mechanism, correction mechanism, tension control mechanism, cloth cutting mechanism and dust removal device; The feeding mechanism is set on the base I1, the cloth cutting mechanism and the dust removal device are set on the base II15, and the deviation correction mechanism, the base I1, the tension control mechanism, the base II15 and the control cabinet 16 are connected in this order; Described feeding mechanism comprises feeding shaft 6, main shaft 11, transmission mechanism, magnetic powder clutch and servomotor, and described transmission mechanism comprises motor, magnetic powder clutch and gear, and described motor output end is connected with magnetic powder clutch, and described magnetic powder clutch and Gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com