Gypsum block molding device and operation method thereof

A gypsum block and forming device technology, which is applied in the field of gypsum block forming and construction machinery, can solve the problems of low utilization rate of work space, inconvenient maintenance and low safety, etc., and achieve improved stability and safety, and easy access Lower maintenance, improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

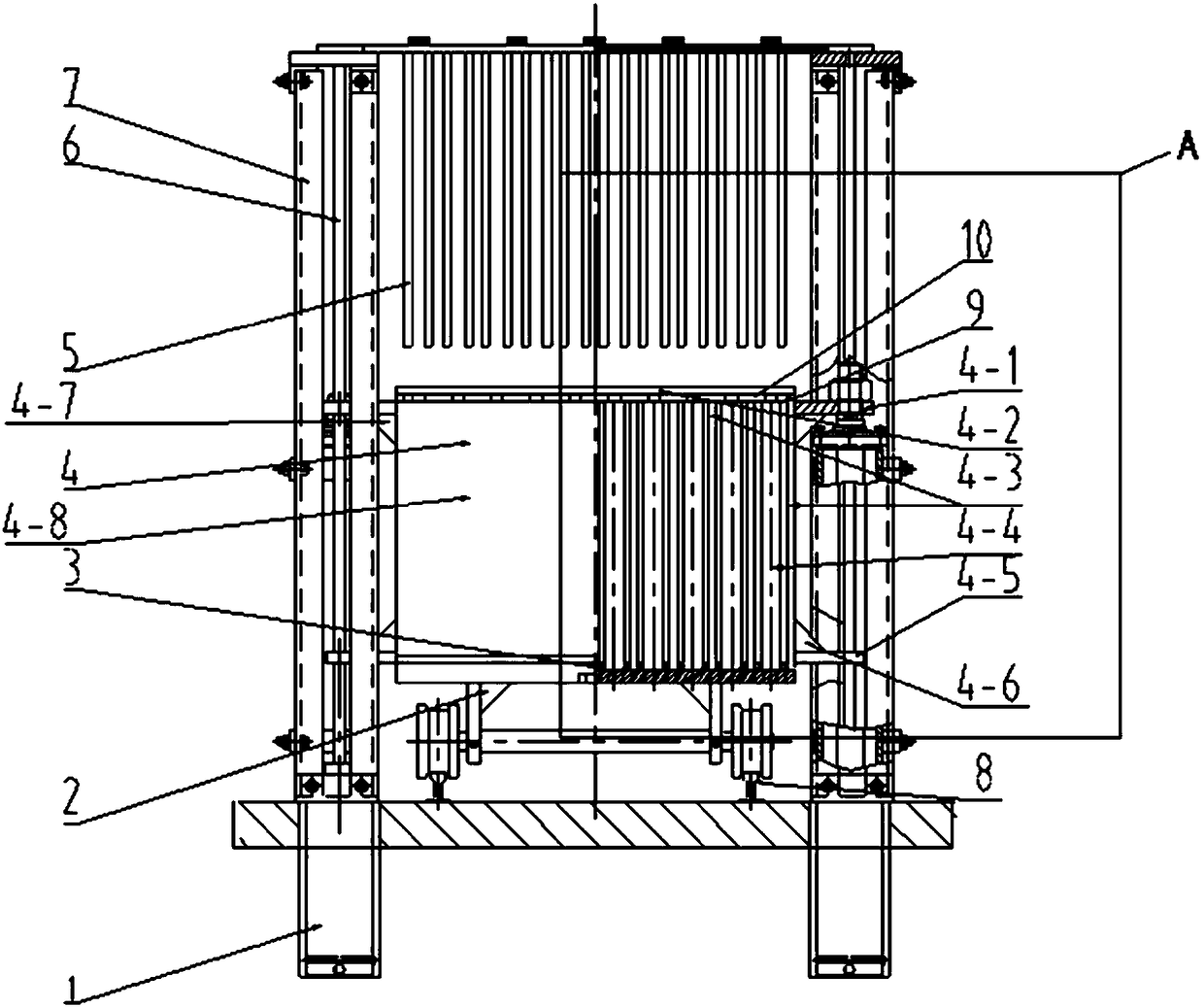

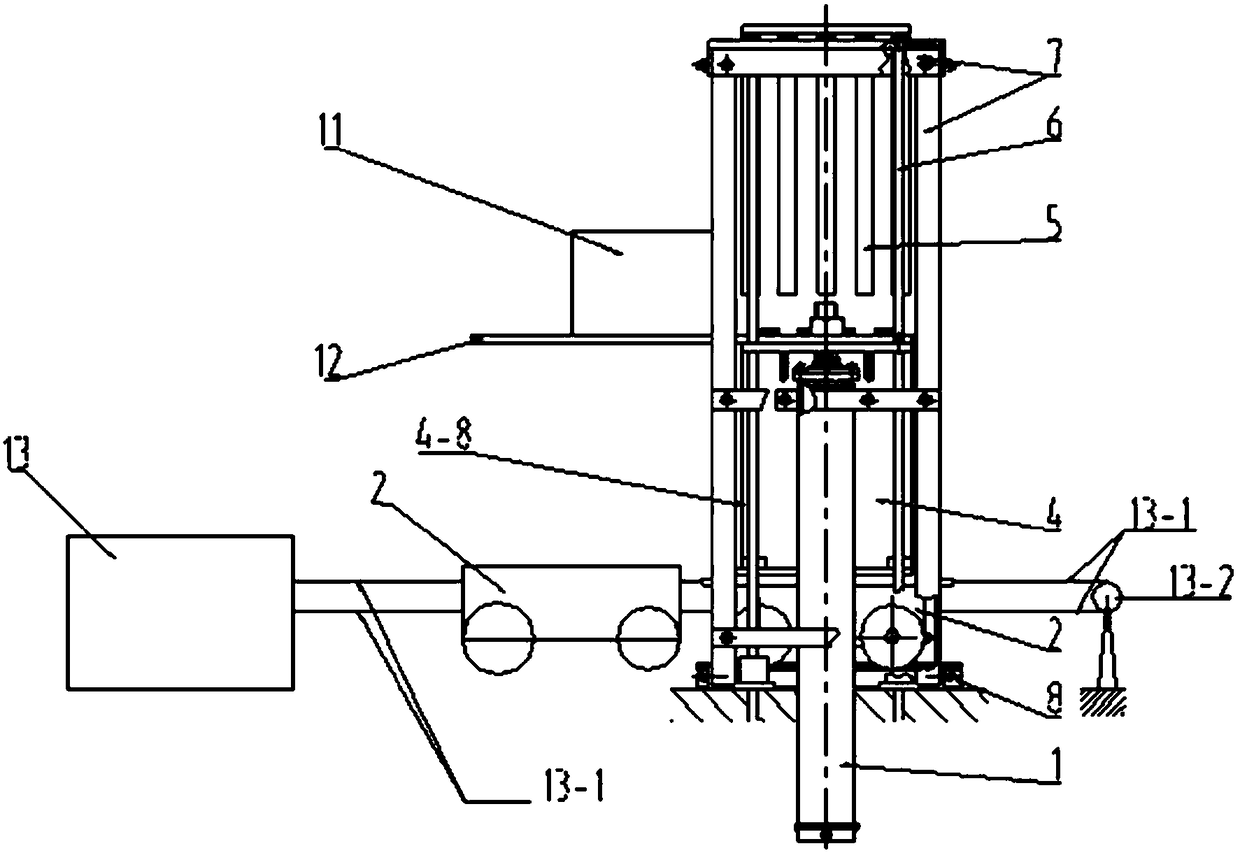

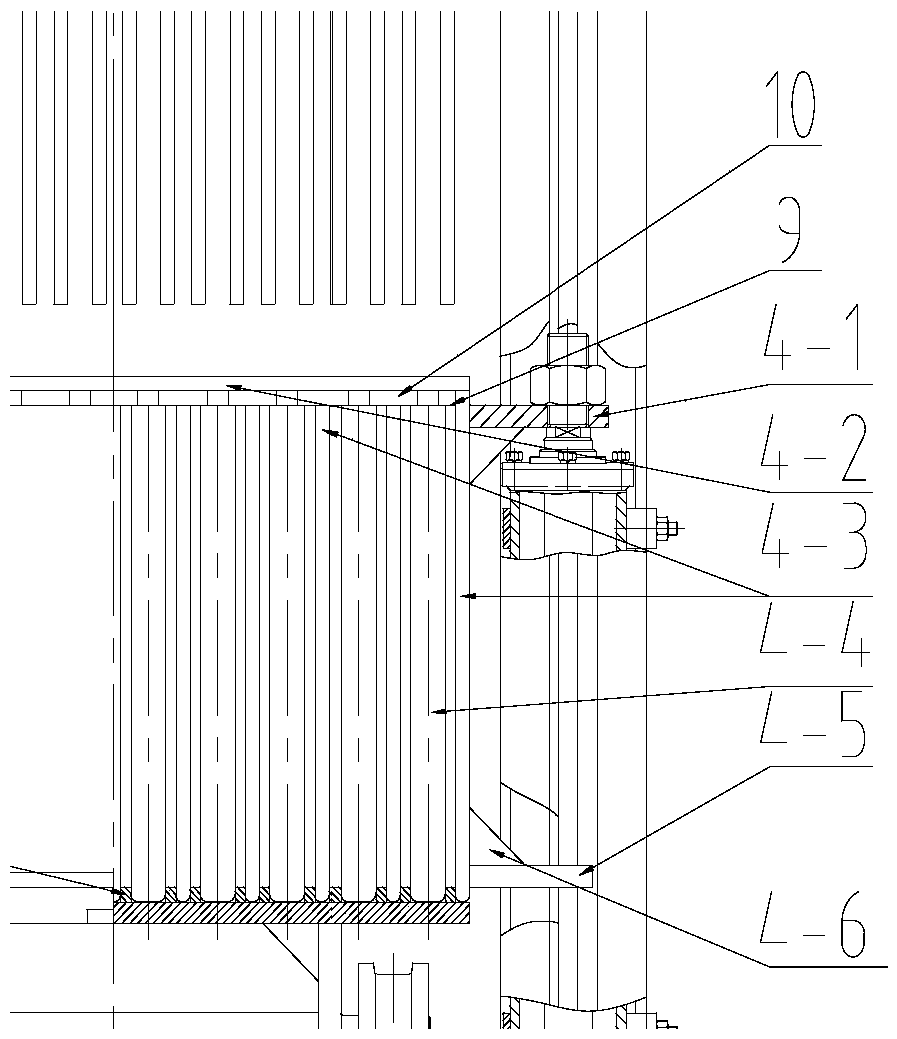

[0052] Please refer to Figure 1 to Figure 6 , a kind of gypsum block forming device of the present invention, after comprehensive consideration of various factors, the bottomless mold is designed as a group that can produce 10 gypsum blocks, and the number of ejector pins and cores is the same as the number of gypsum blocks. The number of cavities matches.

[0053] A new type of practical gypsum block forming device is characterized in that it includes: hydraulic device 1, transport vehicle 2, mold bottom plate 3, bottomless mold 4, ejector rod 5, guide post 6, frame 7, rail 8, Wherein the mold box part does not include the bottom plate and is also called a bottomless mold by an upper push plate, a core, a core holder, a baffle plate, a partition plate and a positioning plate; the bottomless mold 4 is provided with a pouring port 9, and Connected to the hydraulic device through the upper push plate 4-1; the top of the bottomless mold 4 is facing the ejector rod 5 fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com