Patents

Literature

41results about How to "Easy to remove for maintenance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

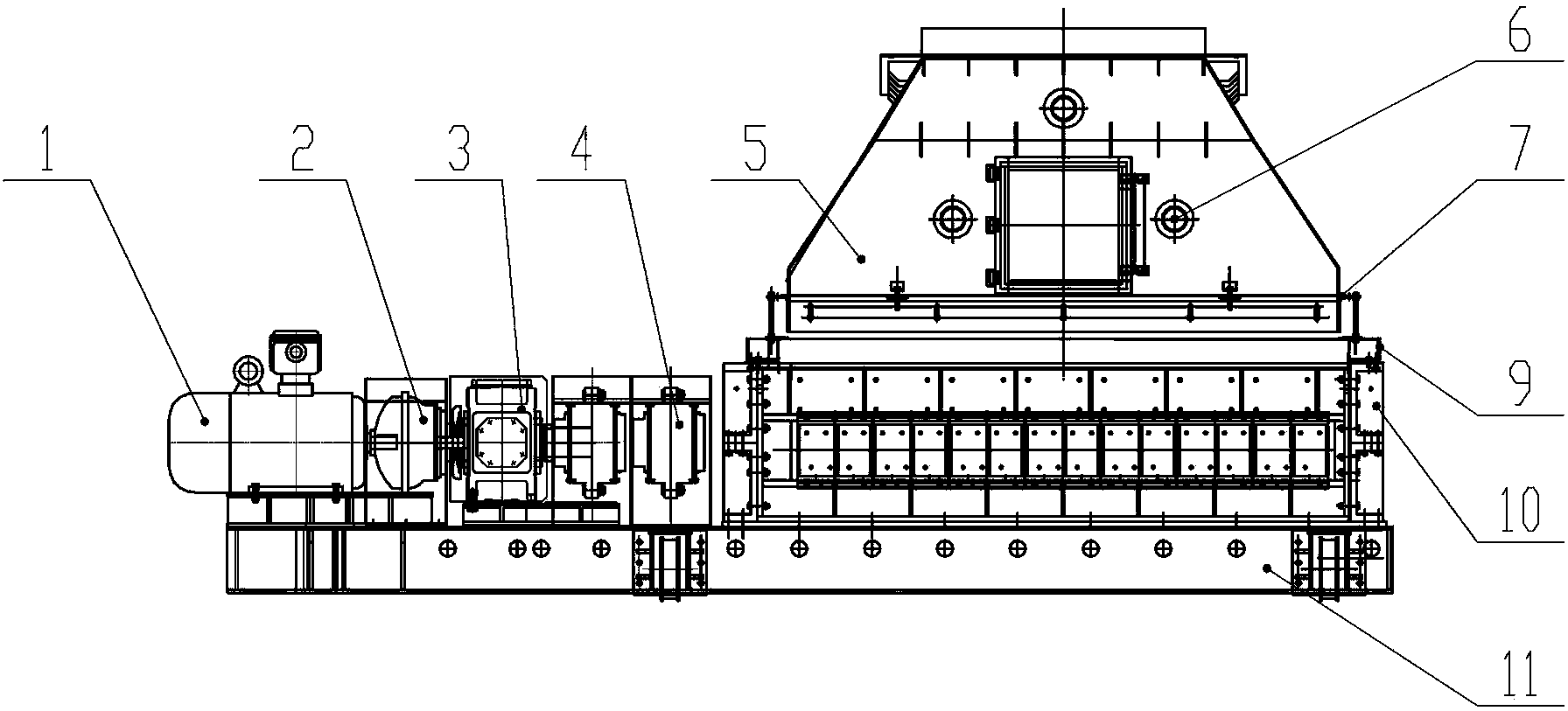

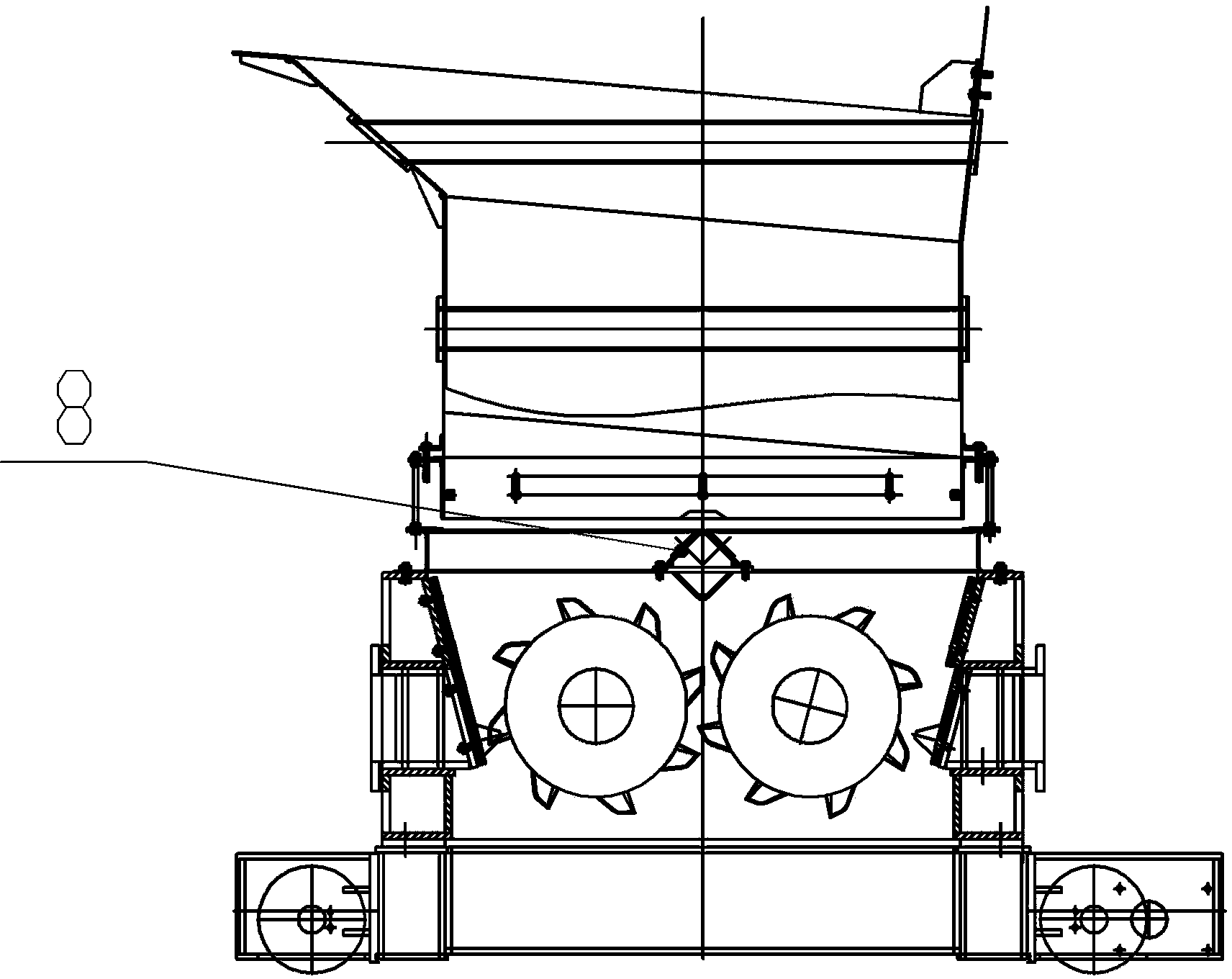

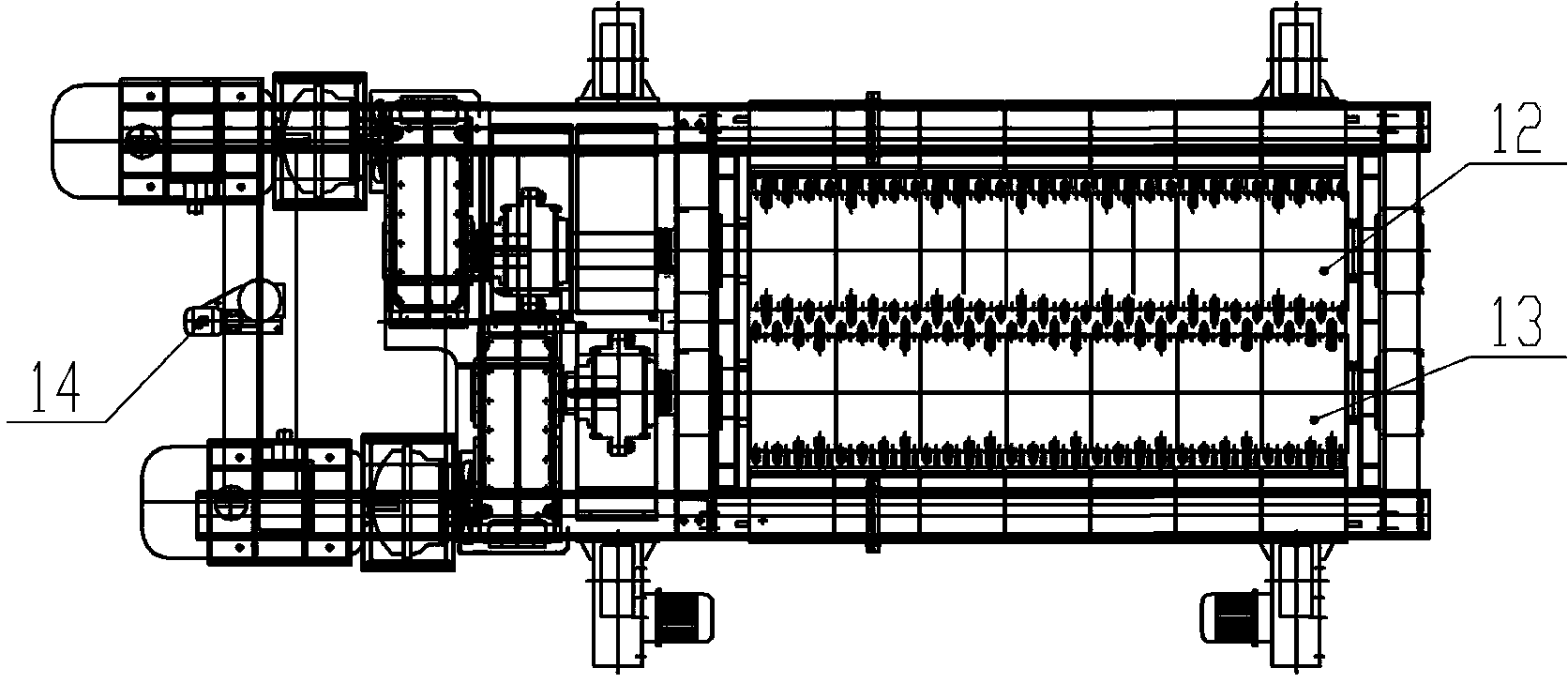

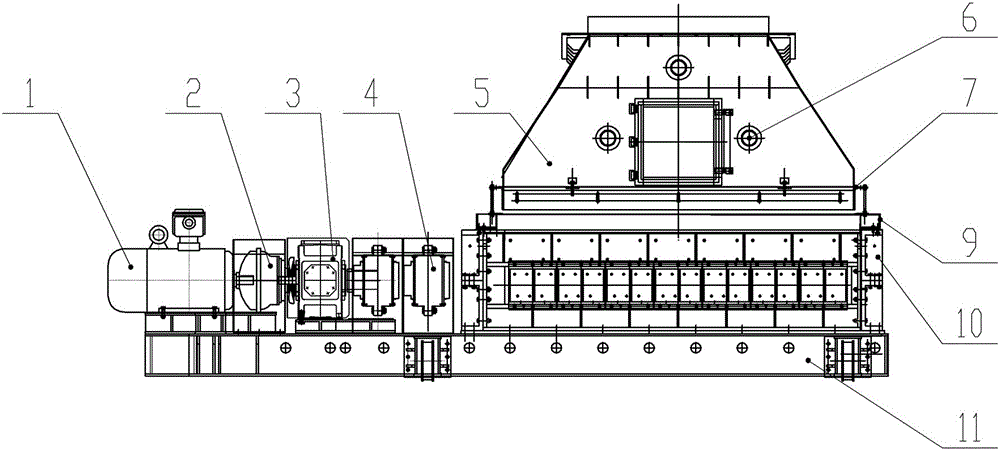

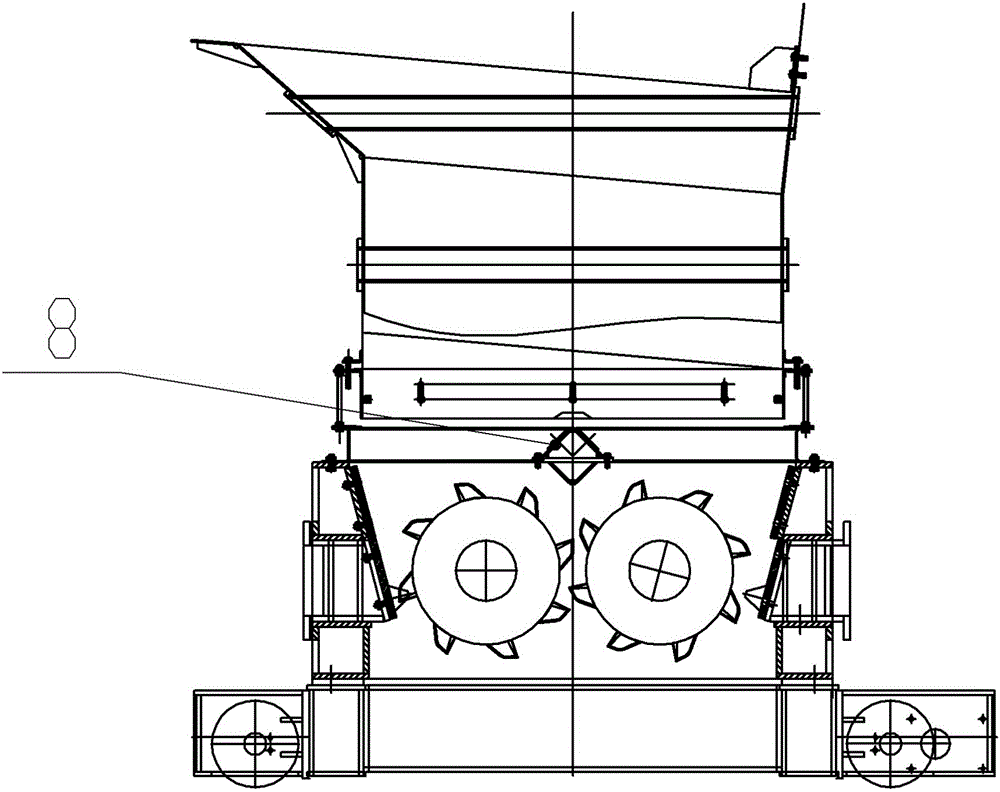

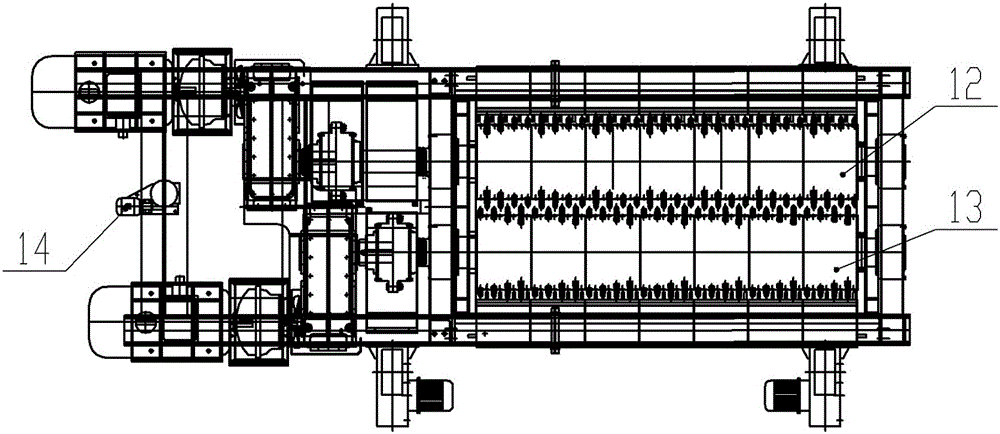

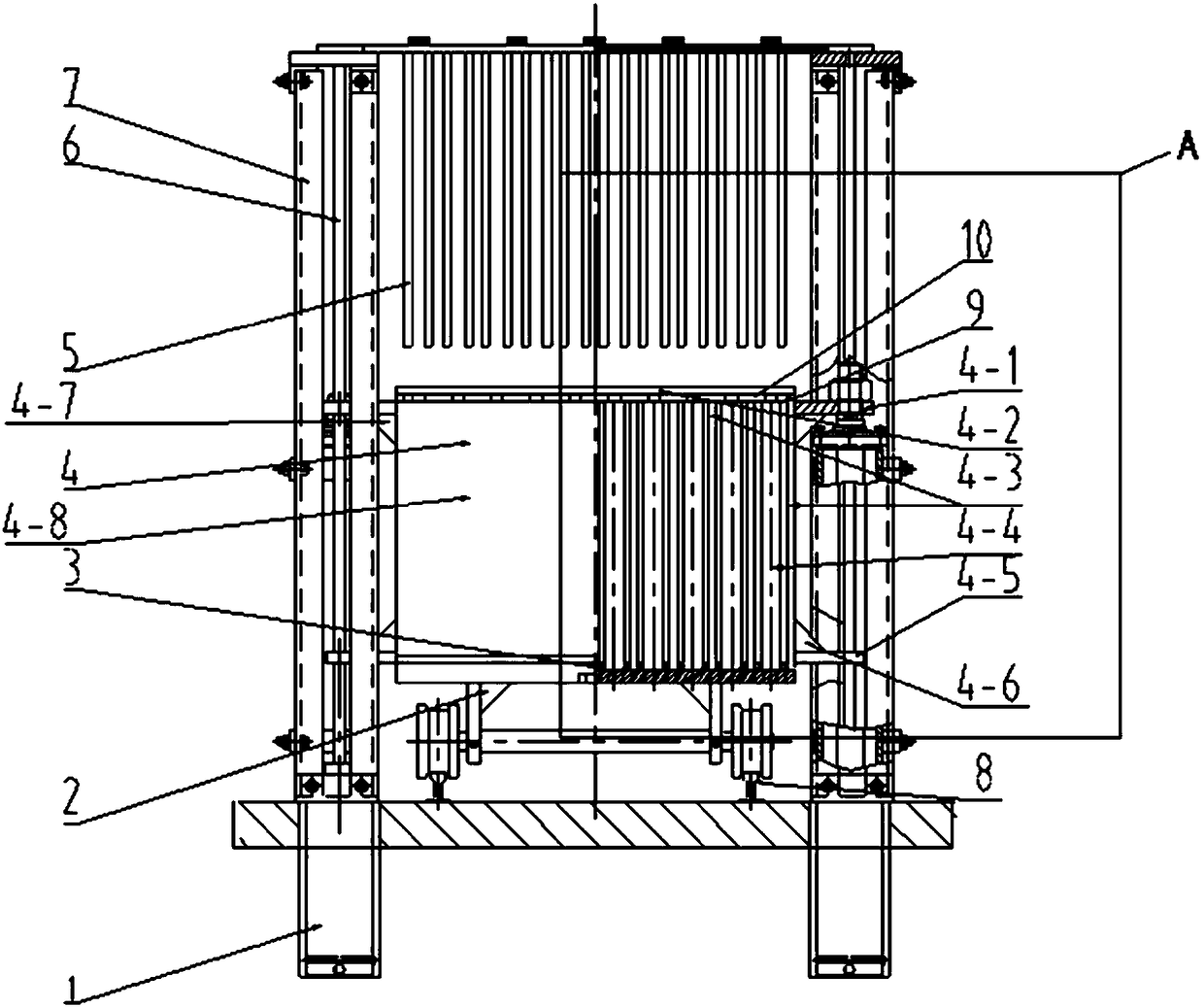

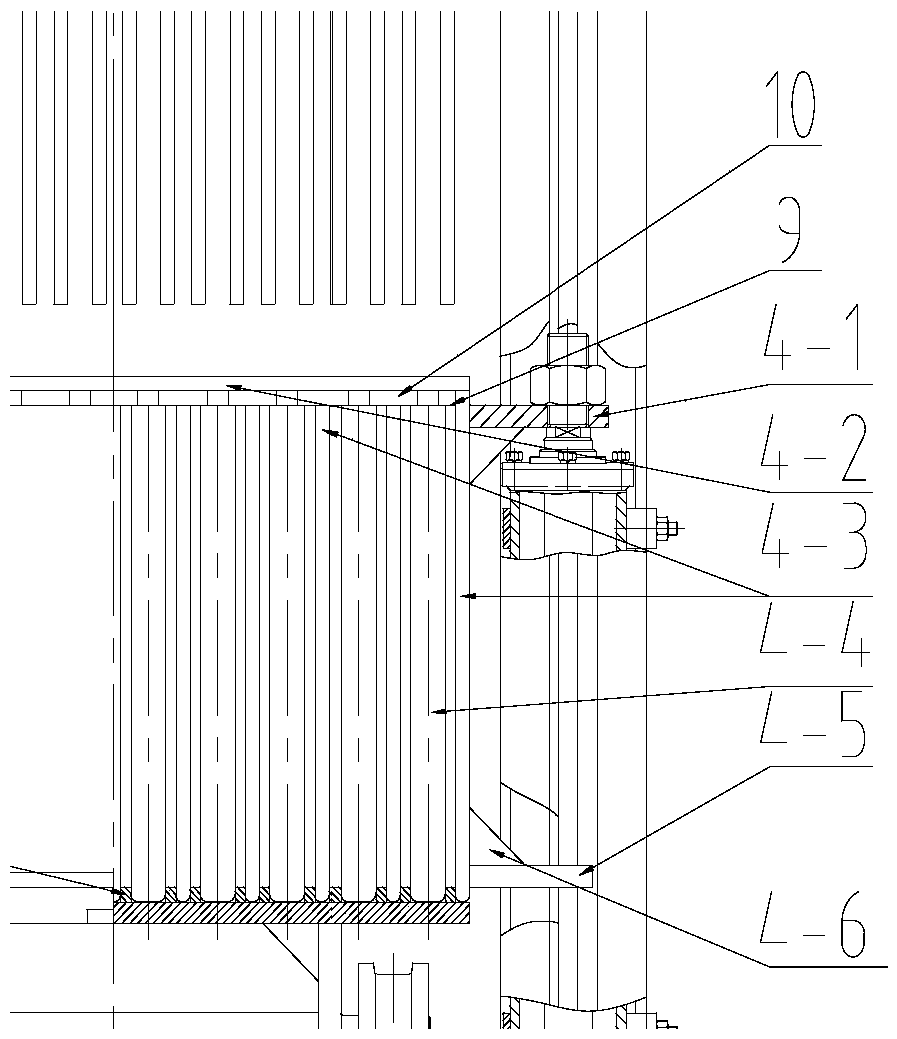

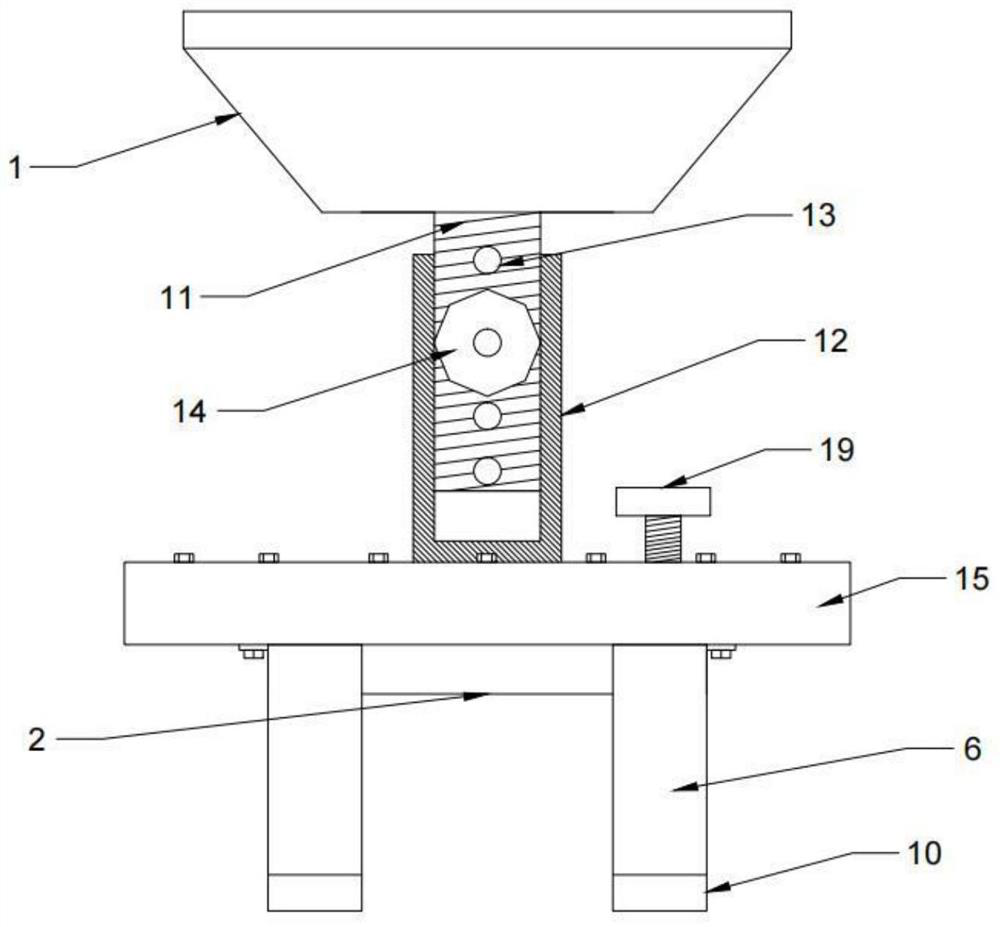

Large efficient screening-type double-toothed roll crusher provided with distribution device

The invention discloses a large efficient screening-type double-toothed roll crusher provided with a distribution device. The double-toothed roll crusher comprises a crushing device and the distribution device. The crushing device comprises a crushing drive motor, a fluid coupling, a reducer, a double-drum gear coupling, a crushing box, a base support, a left toothed roll, a right toothed roll and a lubricating grease pump, wherein the crushing drive motor, the fluid coupling, the reducer and the double-drum gear coupling form two sets of crushing drive units; and the two sets of crushing drive units are connected wit the left toothed roll and the right toothed roll inside the crushing box respectively. The distribution device comprises a distribution chute, an adjustable distribution stick, a movable connecting bracket, a distribution seat and a fixed connecting bracket, wherein the fixed connecting bracket and the distribution seat are fixed on the crushing box of the crushing device, the distribution chute is fixed at a discharge port of a material output belt machine head, and the distribution chute is connected with the crushing box through the movable and fixed connecting brackets. According to the large efficient screening-type double-toothed roll crusher, the problems of capital investment, equipment movement and the like of crushing equipment combined by a plurality of devices are solved fundamentally, the labor intensity of daily equipment maintenance is reduced, and the mining of surface mine materials is accelerated.

Owner:HENAN ZHENYUAN TECH

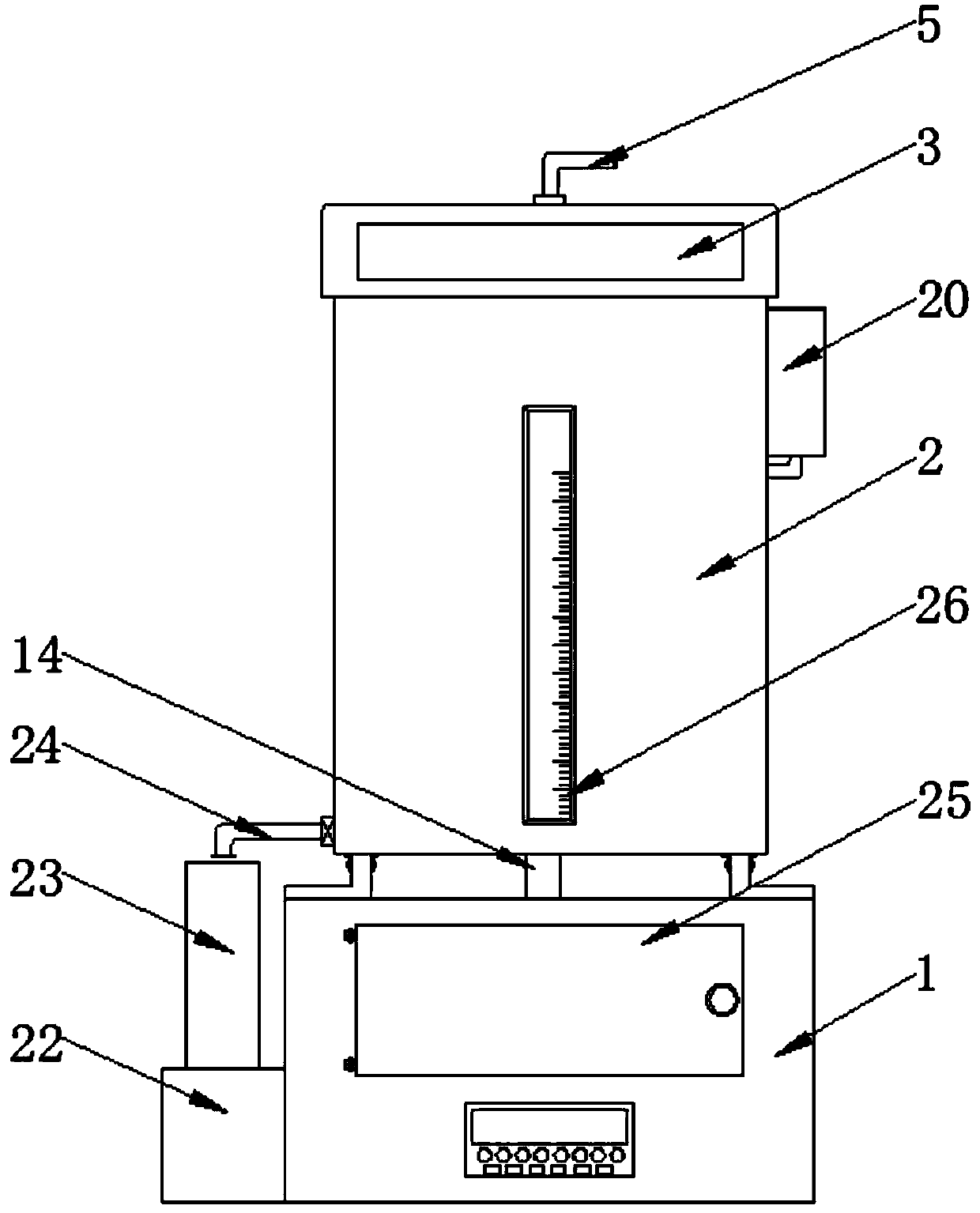

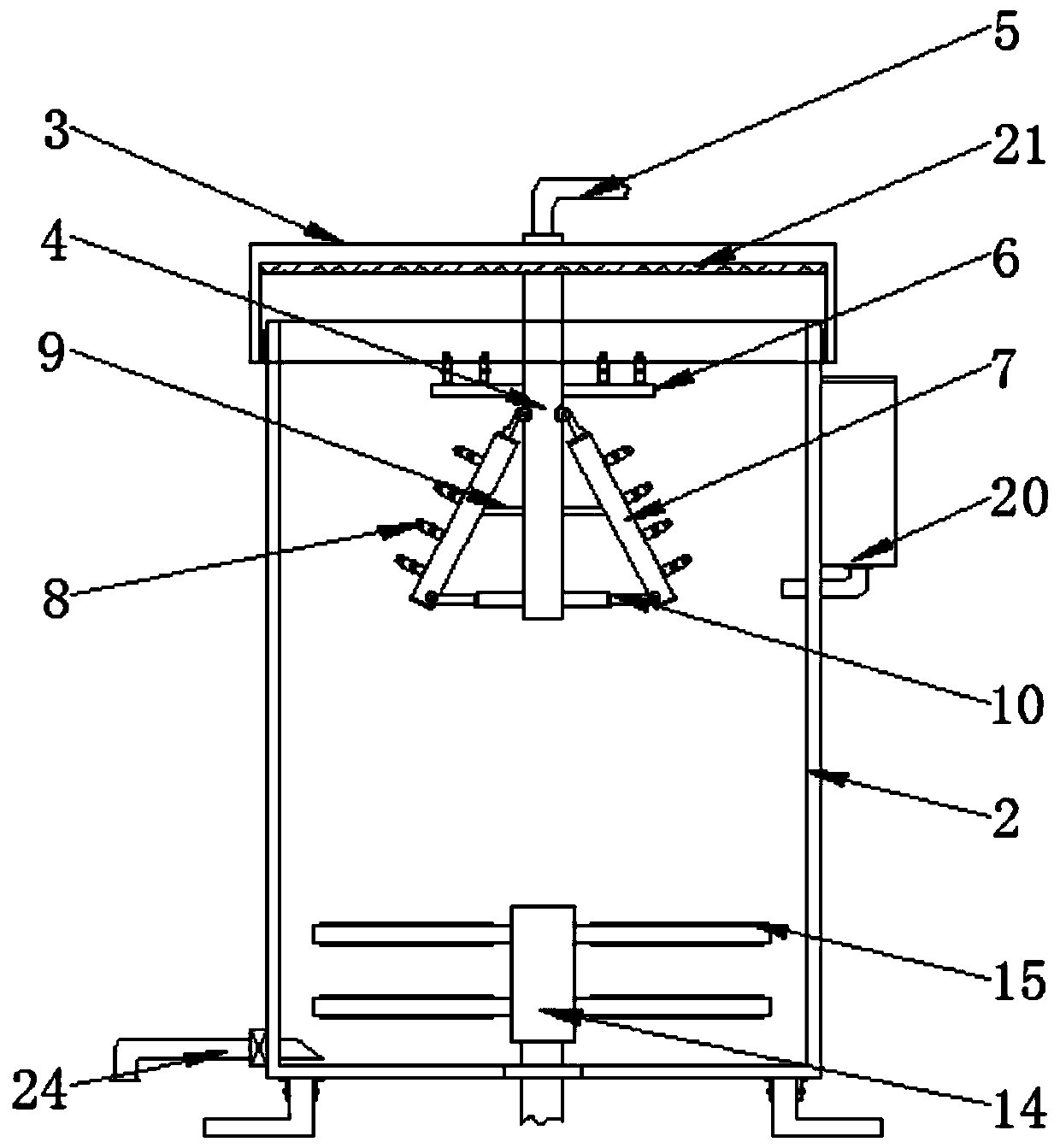

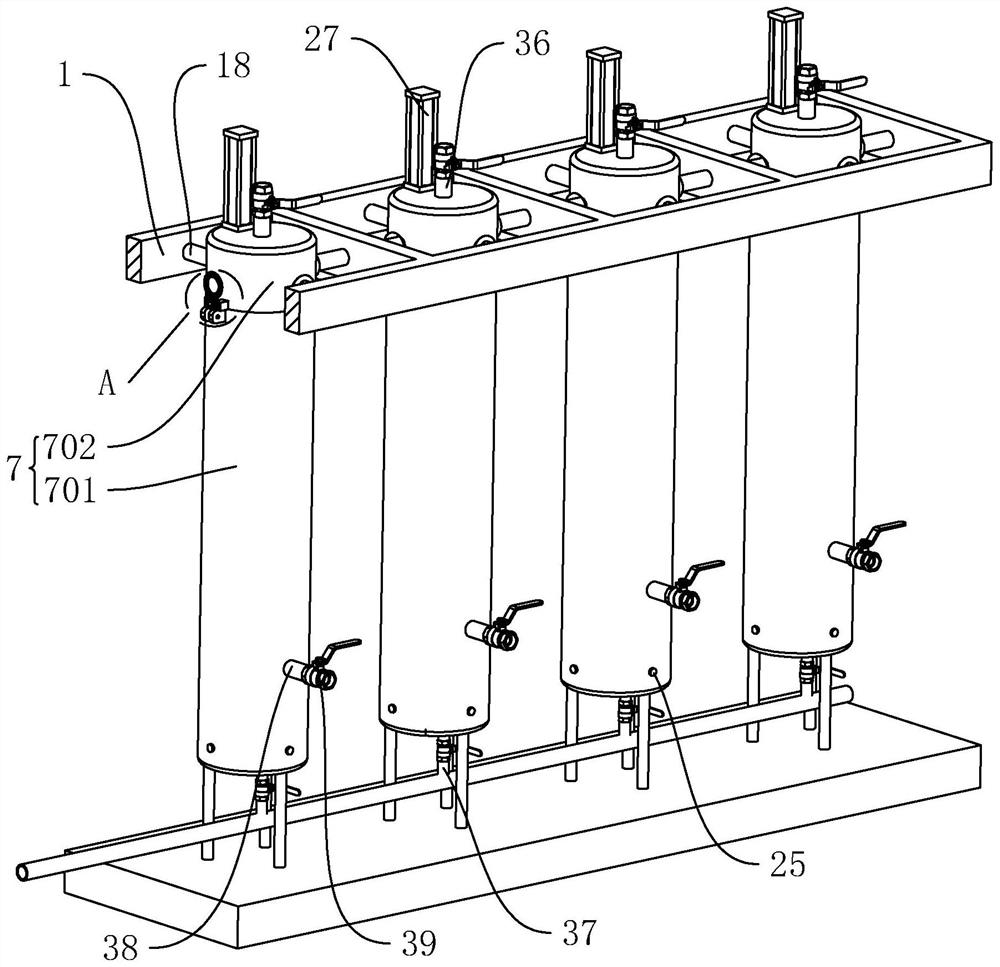

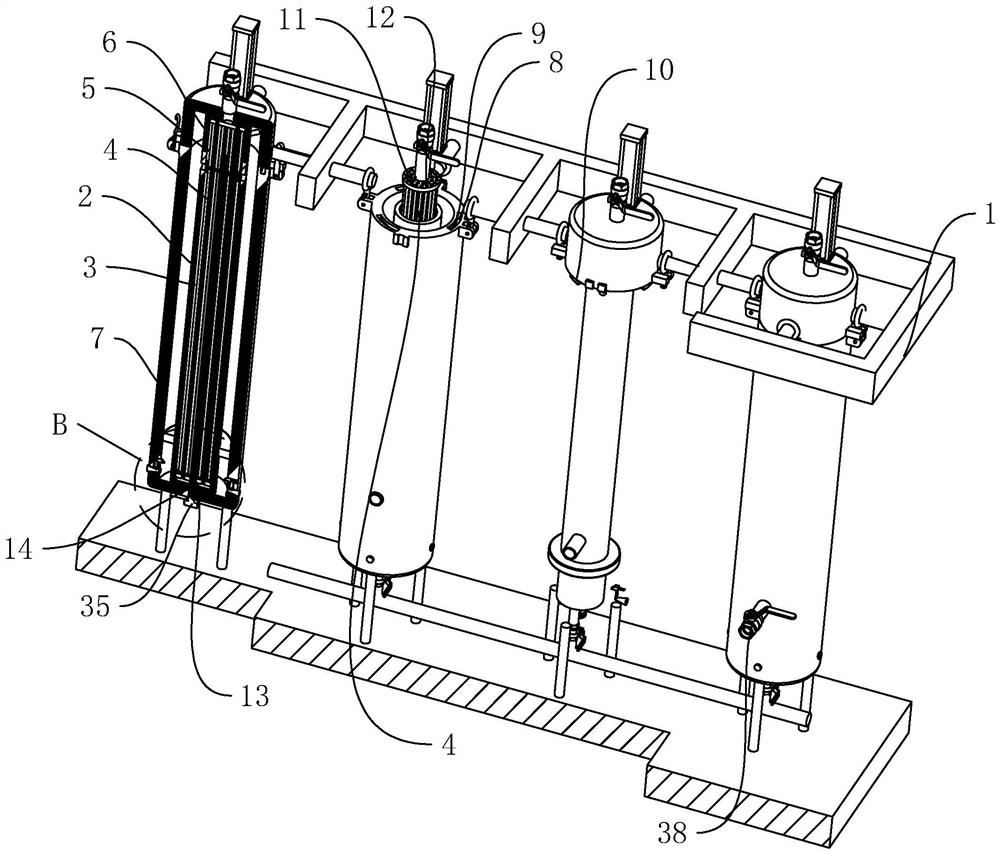

Food and drug inspection and dissolution device

InactiveCN110064325AGuaranteed SolubilityEasy to adjustRotary stirring mixersTransportation and packagingEngineeringDissolution

The invention discloses a food and drug inspection and dissolution device and relates to the technical field of food and drug inspection. The device comprises a base, a mixing box and a box cover, thebottom of the mixing box is fixedly connected with the top of the base through a bracket and screws, the surface of the top of the mixing box is in threaded connection with the interior of the box cover, the top of the box cover is fixedly connected with a water injection pipe, and the top of the water injection pipe is communicated with a water inlet pipe. According to the food and drug inspection and dissolution device, the mixing box and the box cover after dissolution can be cleaned, and the cleaning angles of high-pressure nozzles on second fixing pipes are adjusted conveniently by a user, so that the dissolution effect on food and drugs is ensured, pollution caused by residual food or drugs to dissolution in the next time is avoided, the accuracy of test results is improved to a certain extent, the overall practicality is high, to-be-tested food or drugs can be quickly dissolved, time is saved for the user, and convenience is provided for the user to carry out operation.

Owner:刘明智

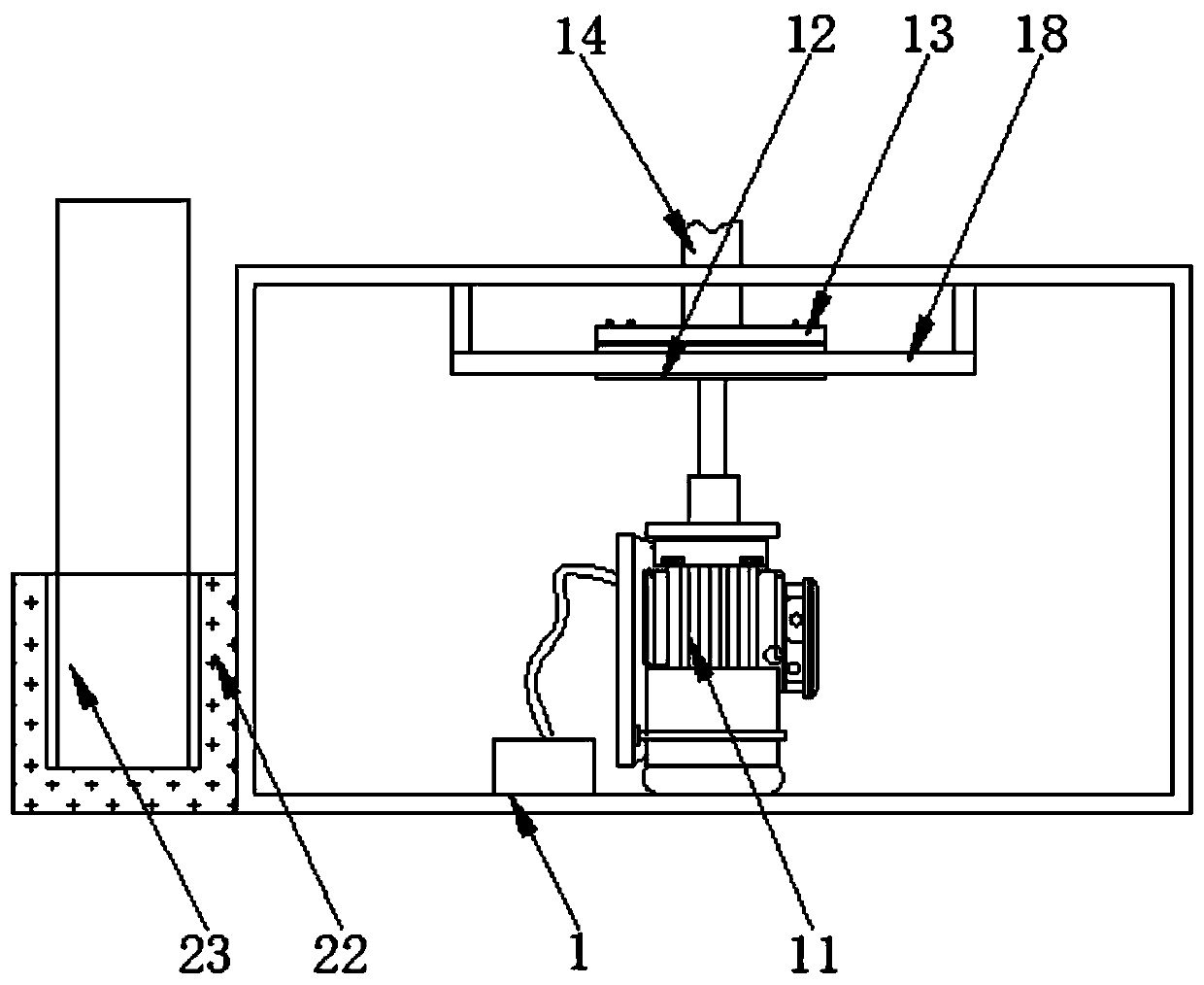

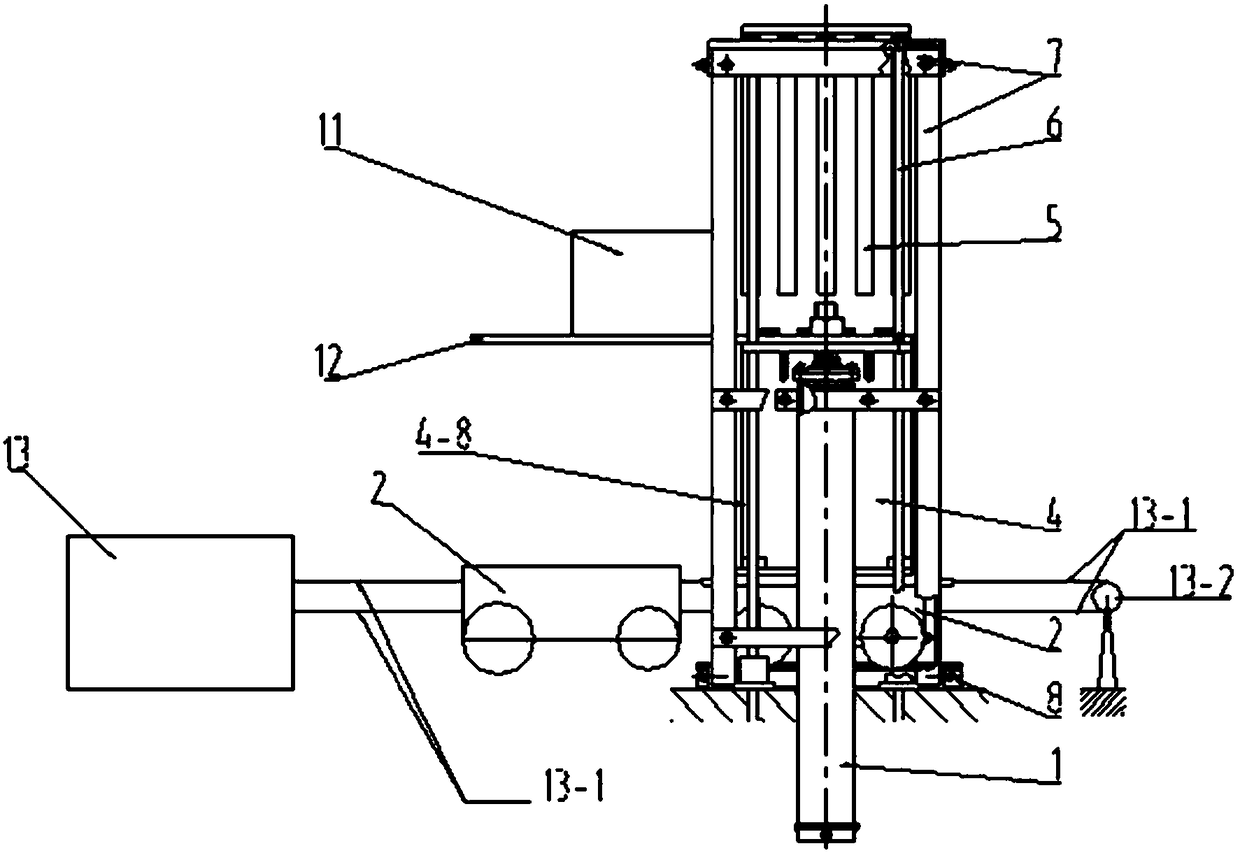

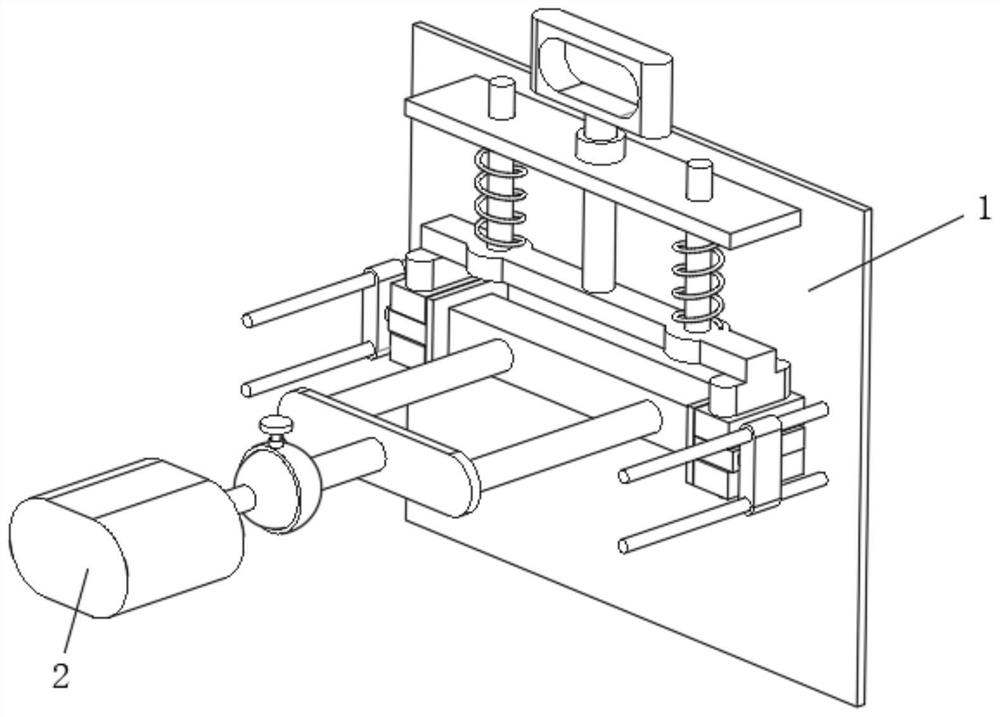

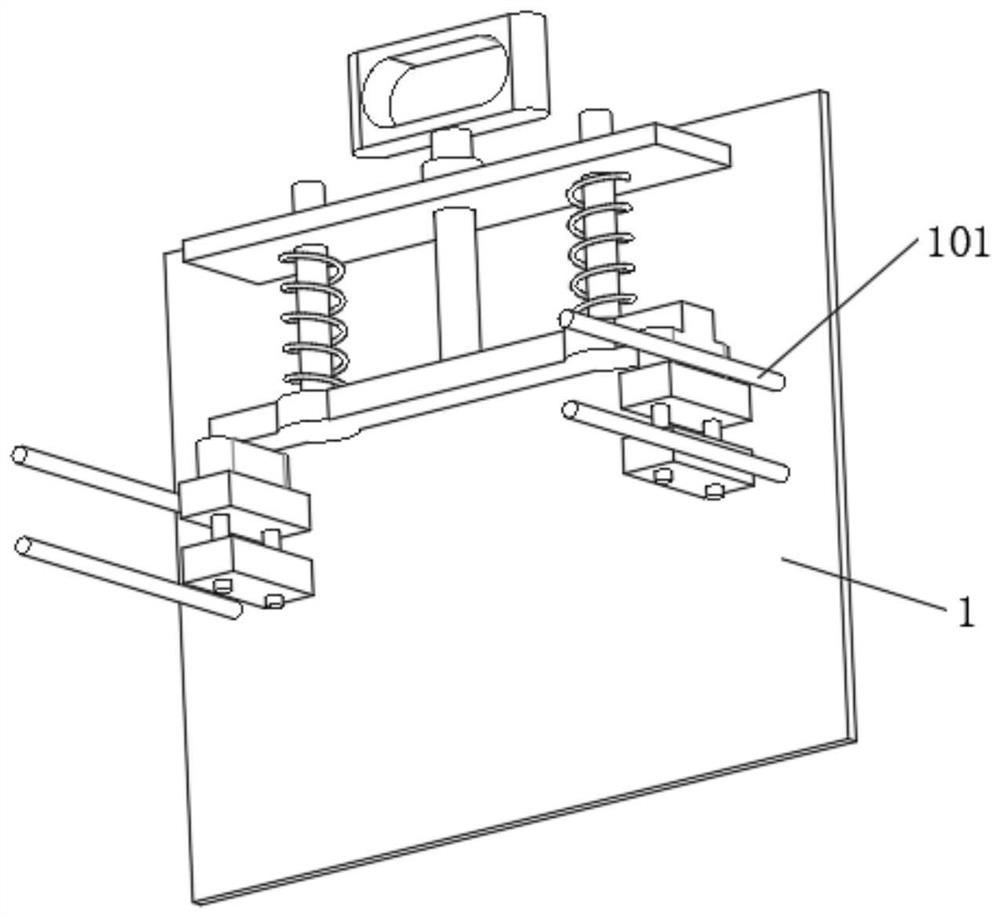

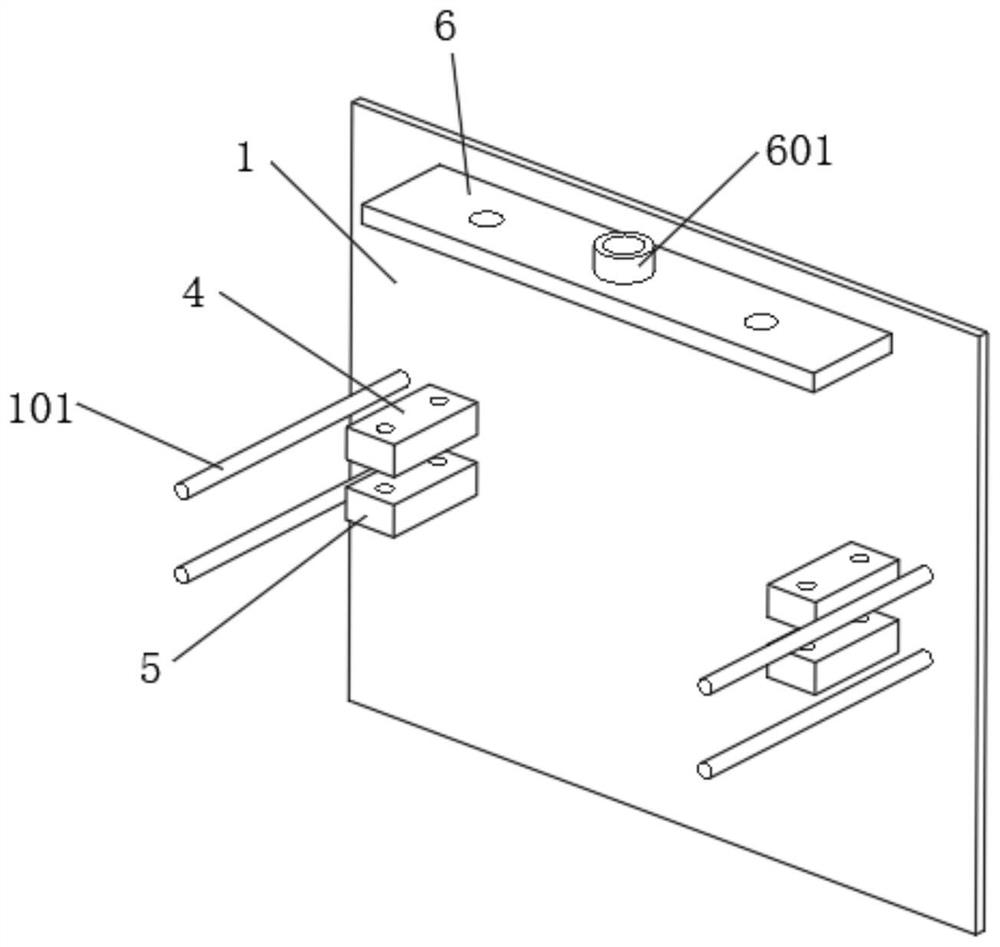

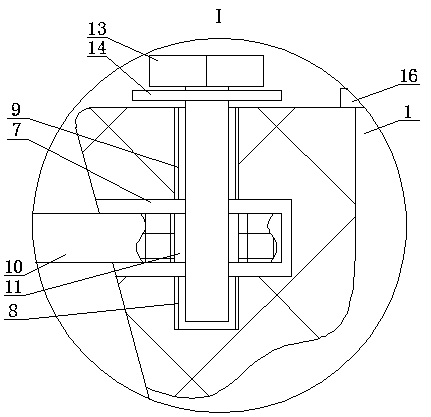

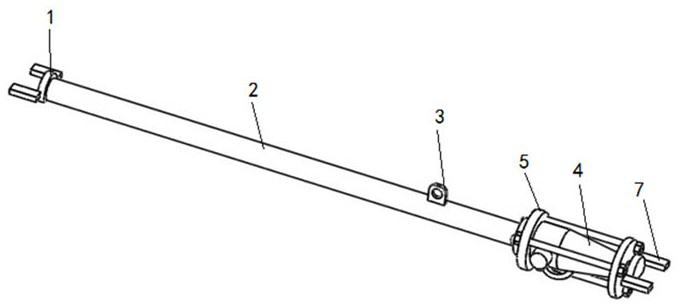

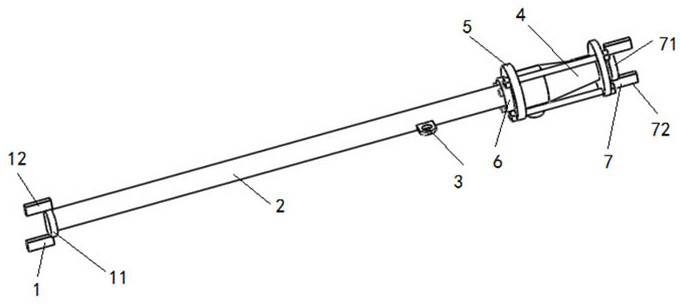

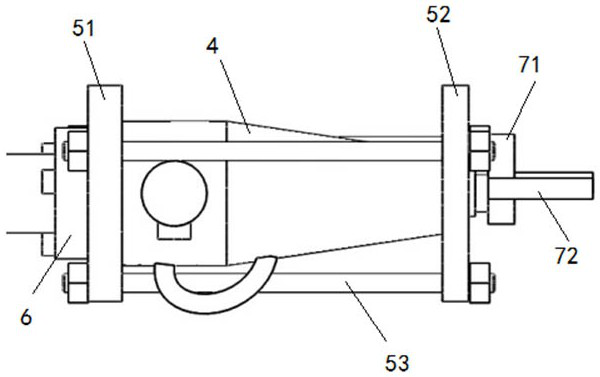

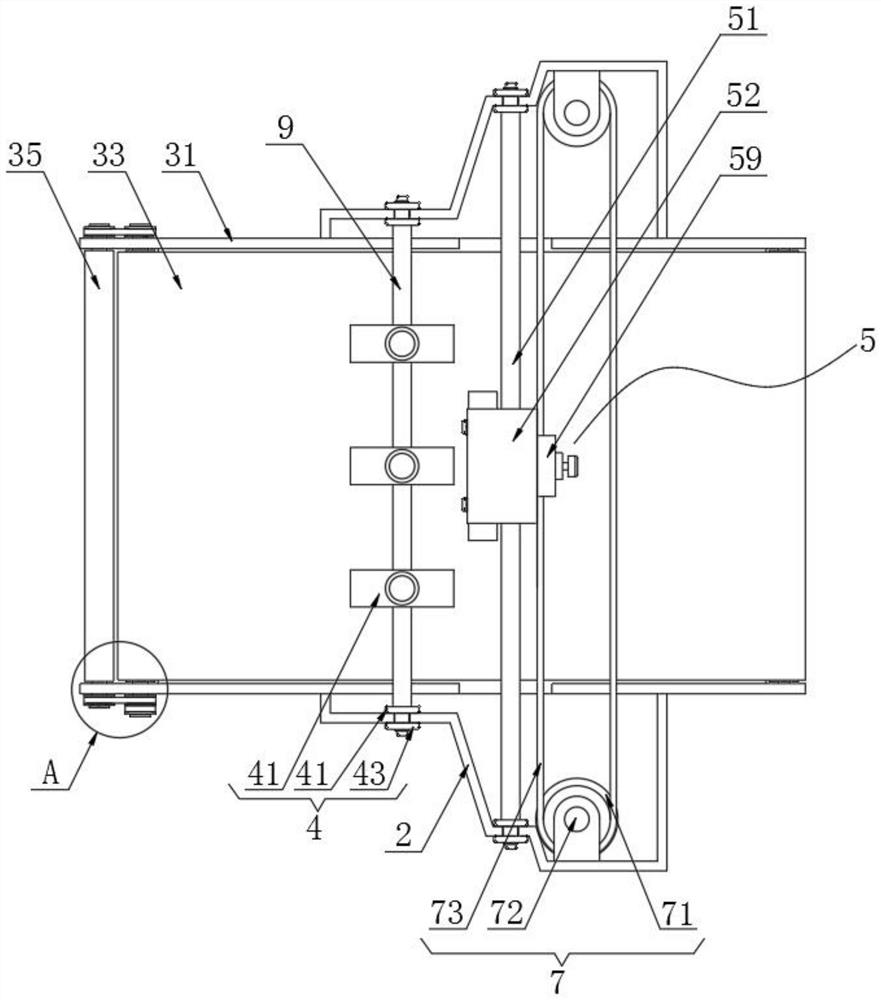

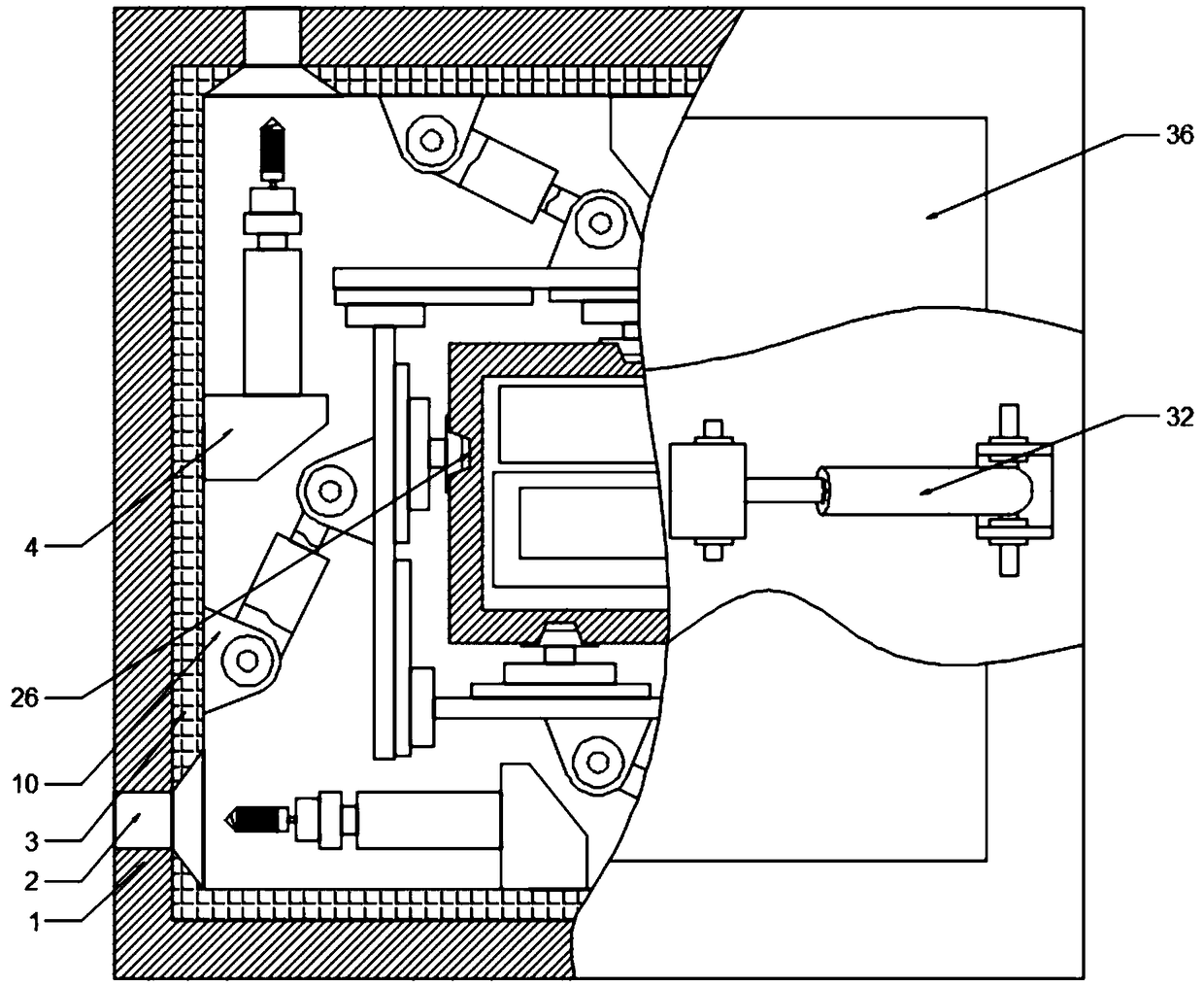

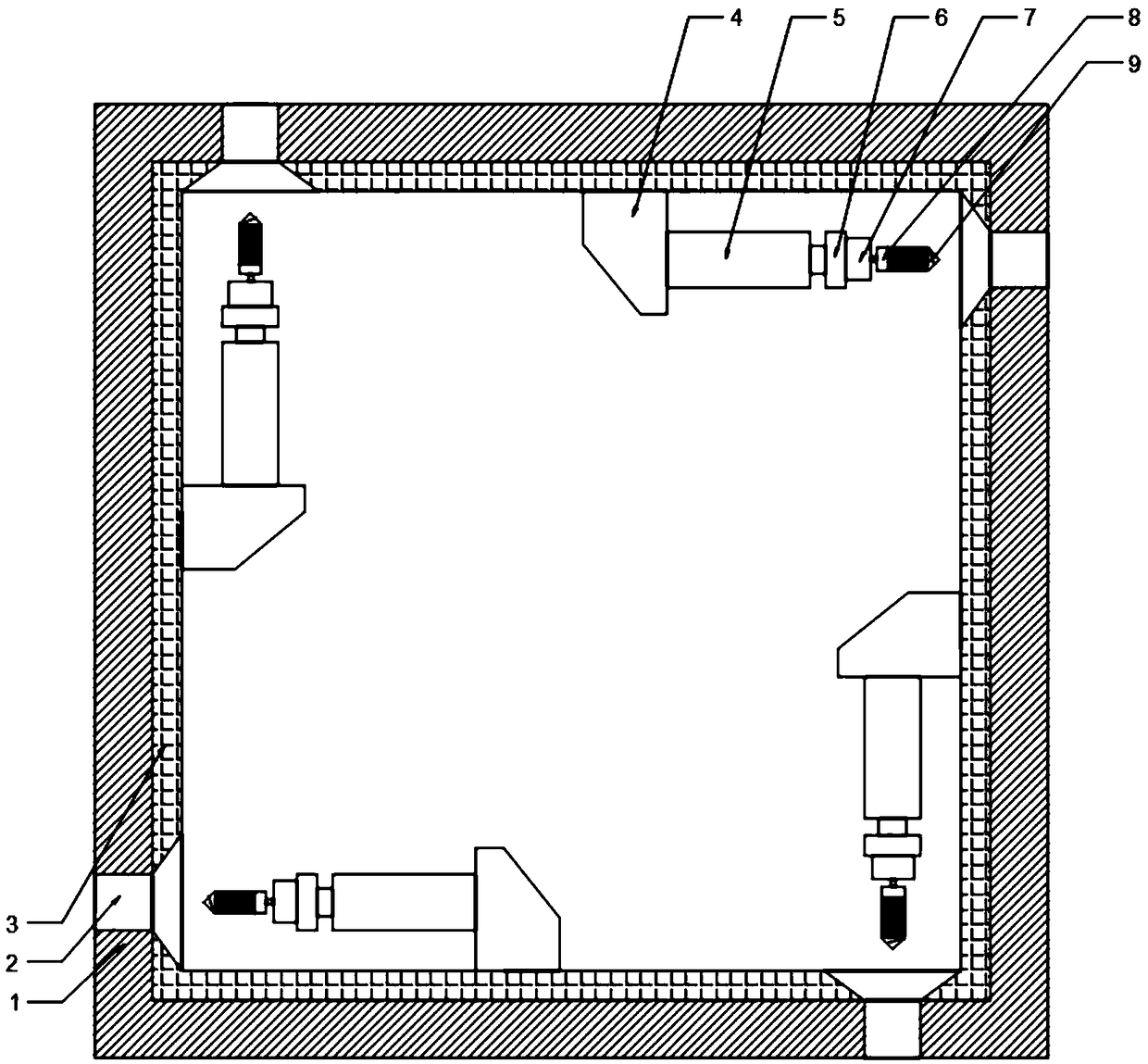

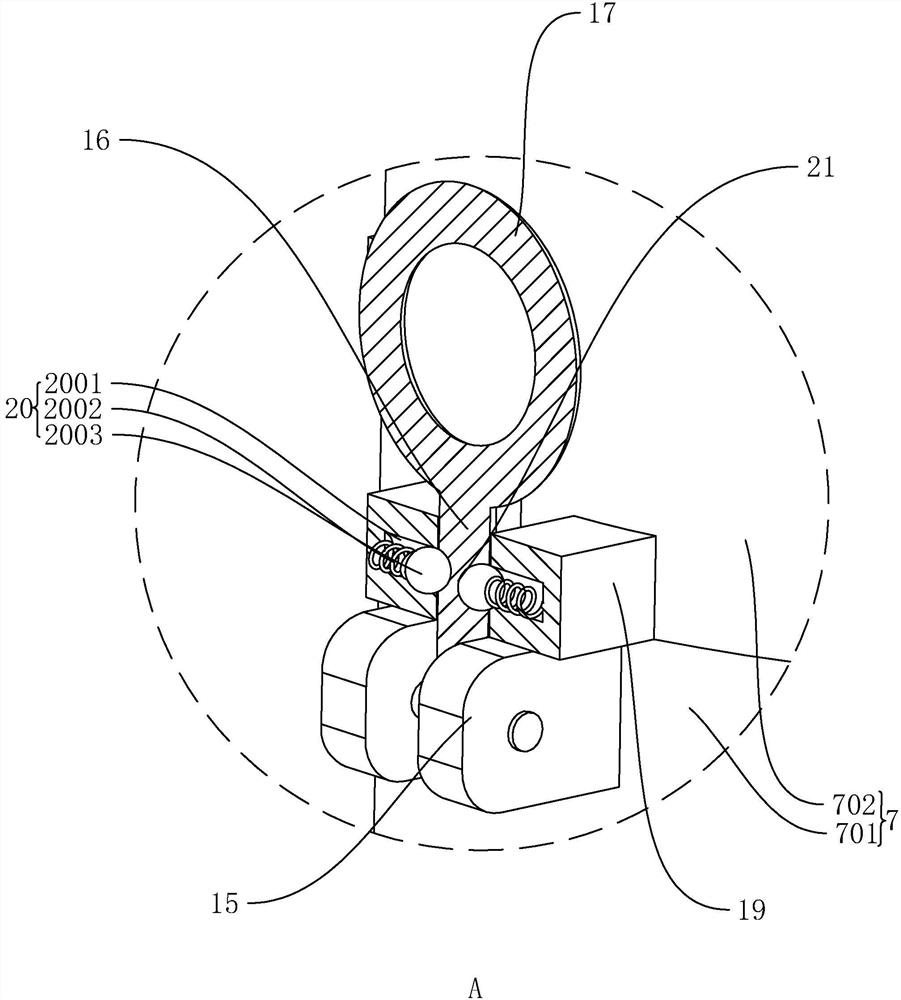

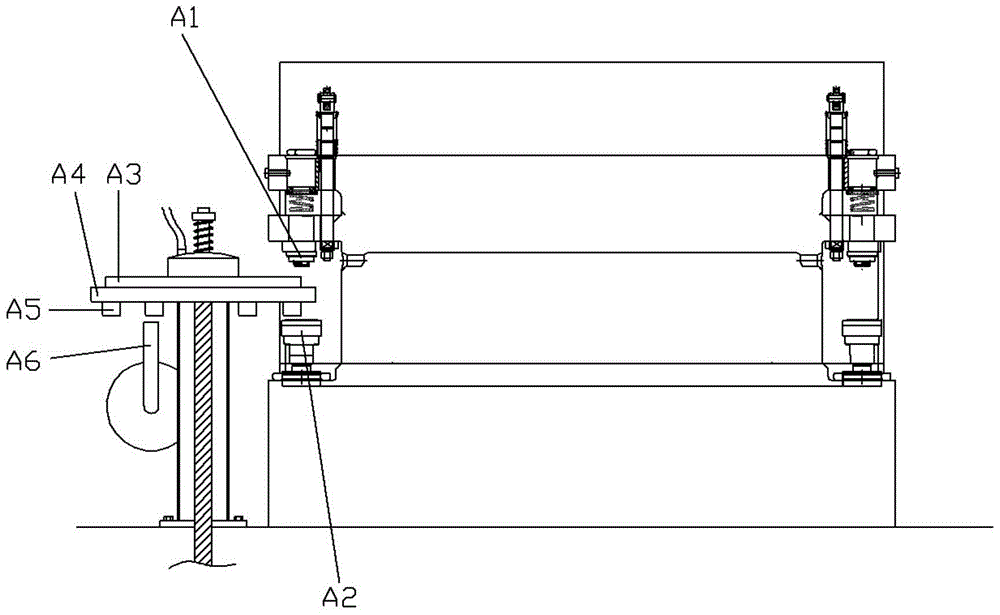

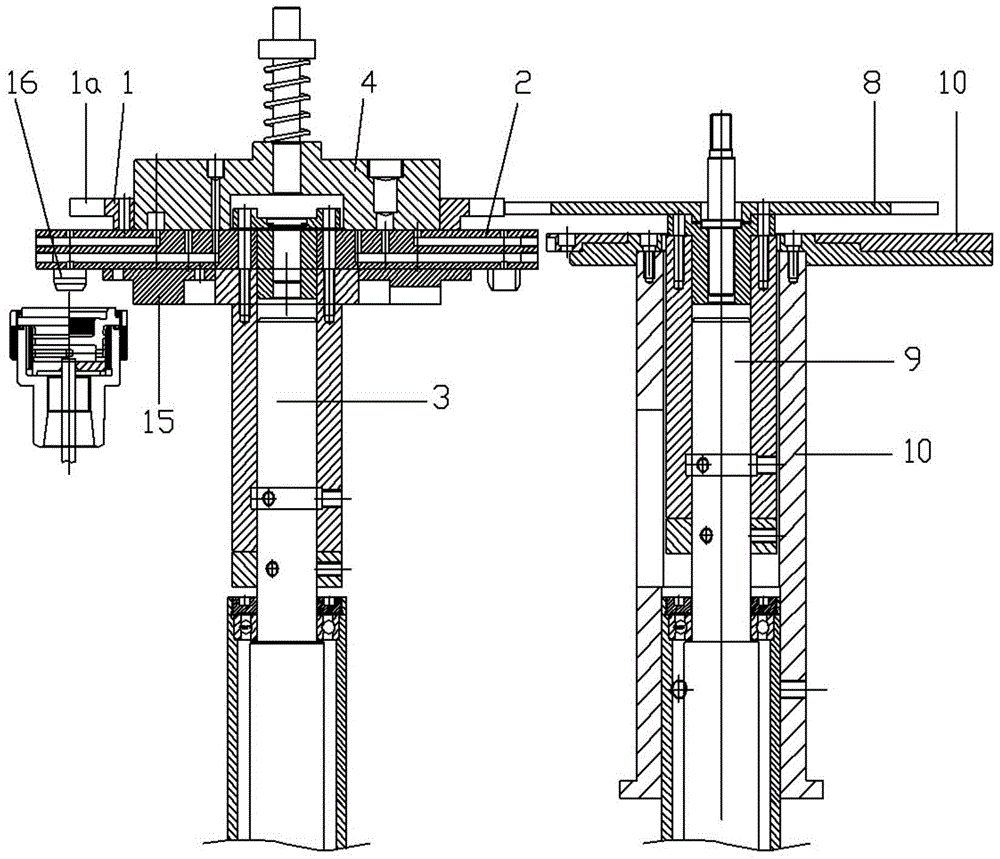

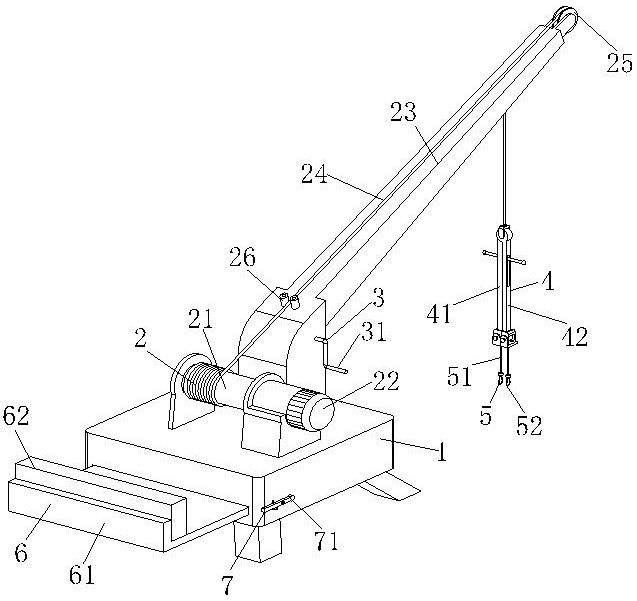

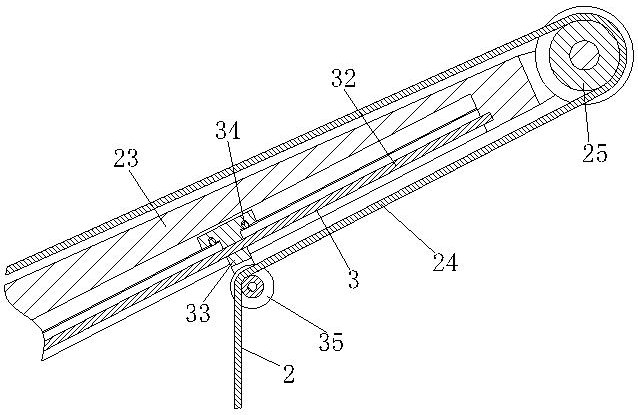

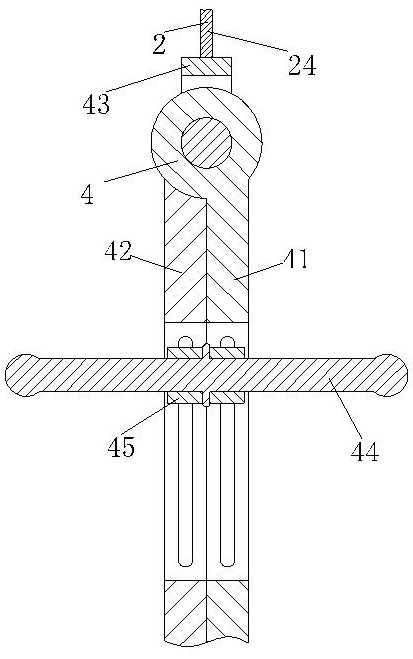

Truss-type automatic punch used for pipe racks

InactiveCN108746762AEasy to remove for maintenanceEasy to climbWork benchesPortable drilling machinesPunchingComputer engineering

The invention discloses a truss-type automatic punch used for pipe racks. The truss-type automatic punch comprises a supporting platform, a vertical lifting ladder stand, a fixed plate, a boosting device, an interval adjusting device and two electric drills, wherein the two electric drills are arranged on the interval adjusting device; the interval between the two electric drills is adjusted by the interval adjusting device; the interval adjusting device is arranged on the boosting device; the boosting device is used for pushing the two electric drills to advance or retreat; the boosting device is arranged on the top surface of the fixing plate; and the bottom surface of the fixing plate is fixedly connected with the top end of the vertical lifting ladder stand which is arranged on one side of the supporting platform. According to the truss-type automatic punch, lifting is realized through the vertical lifting ladder stand; the interval between the two electric drills is adjusted through the interval adjusting device, so that drilling positioning is realized; punching is performed through the boosting device, so that positioning is accurate, and punching efficiency is high; meanwhile, when the electric drills fail, and drill bits are stuck in a hole, a working personnel can climb conveniently through the vertical lifting ladder stand; the electric drills can be conveniently detached to be repaired; and other climbing devices are not additionally needed.

Owner:扬中奇佩智能装配科技有限公司

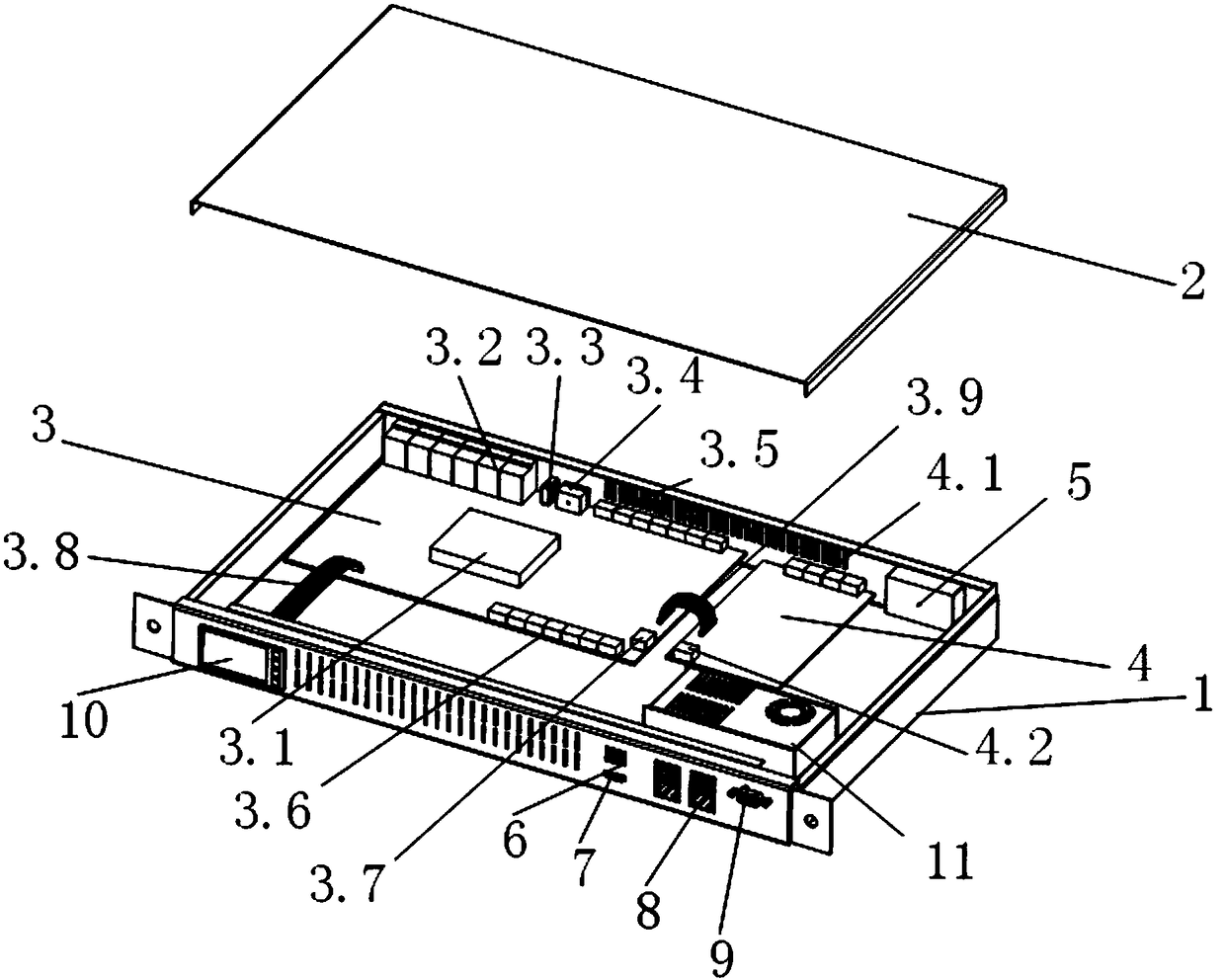

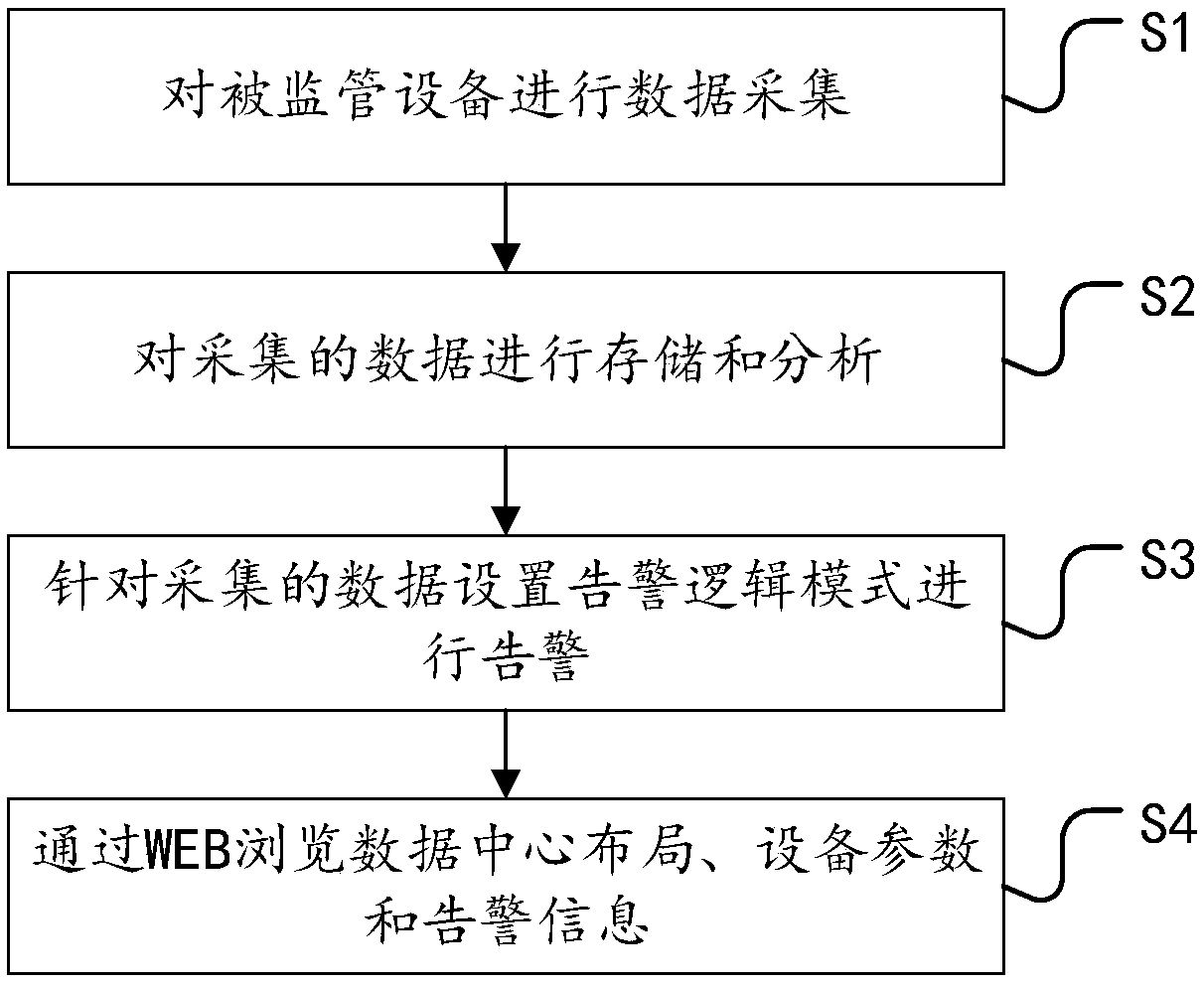

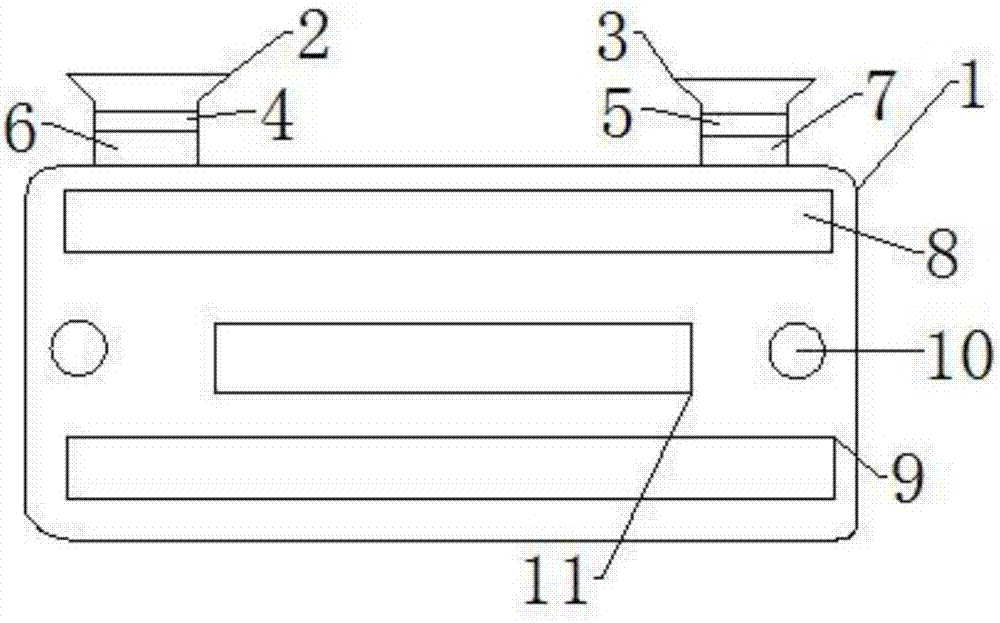

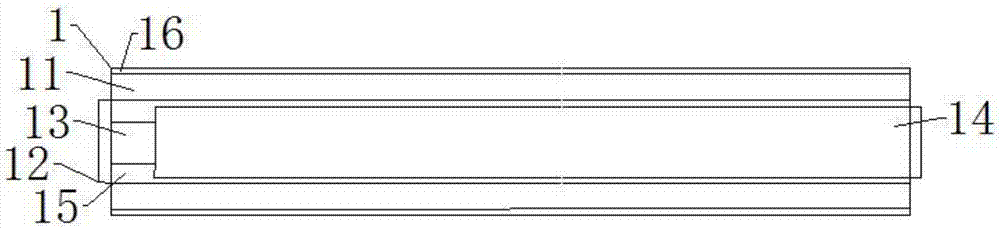

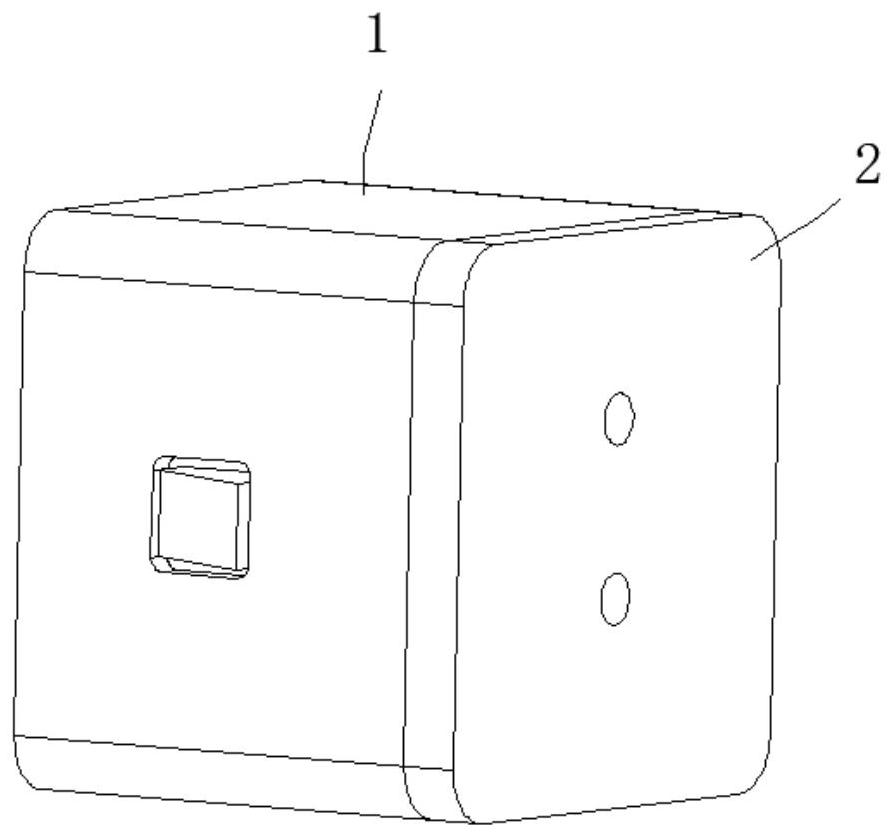

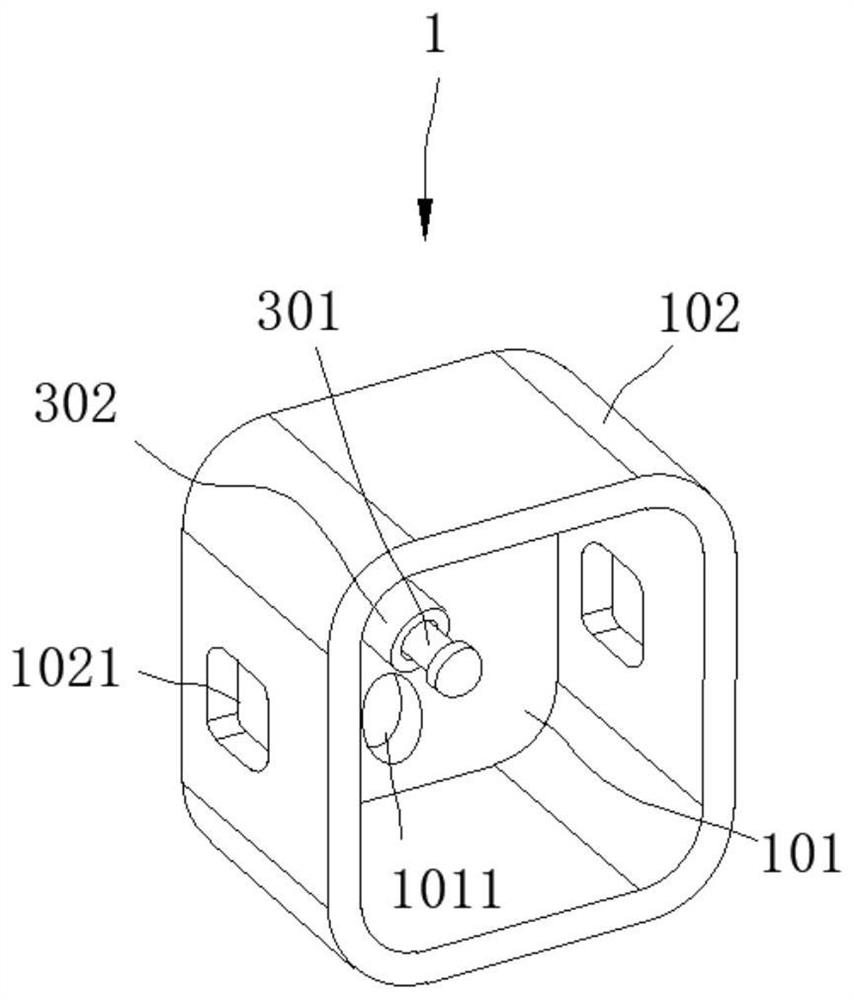

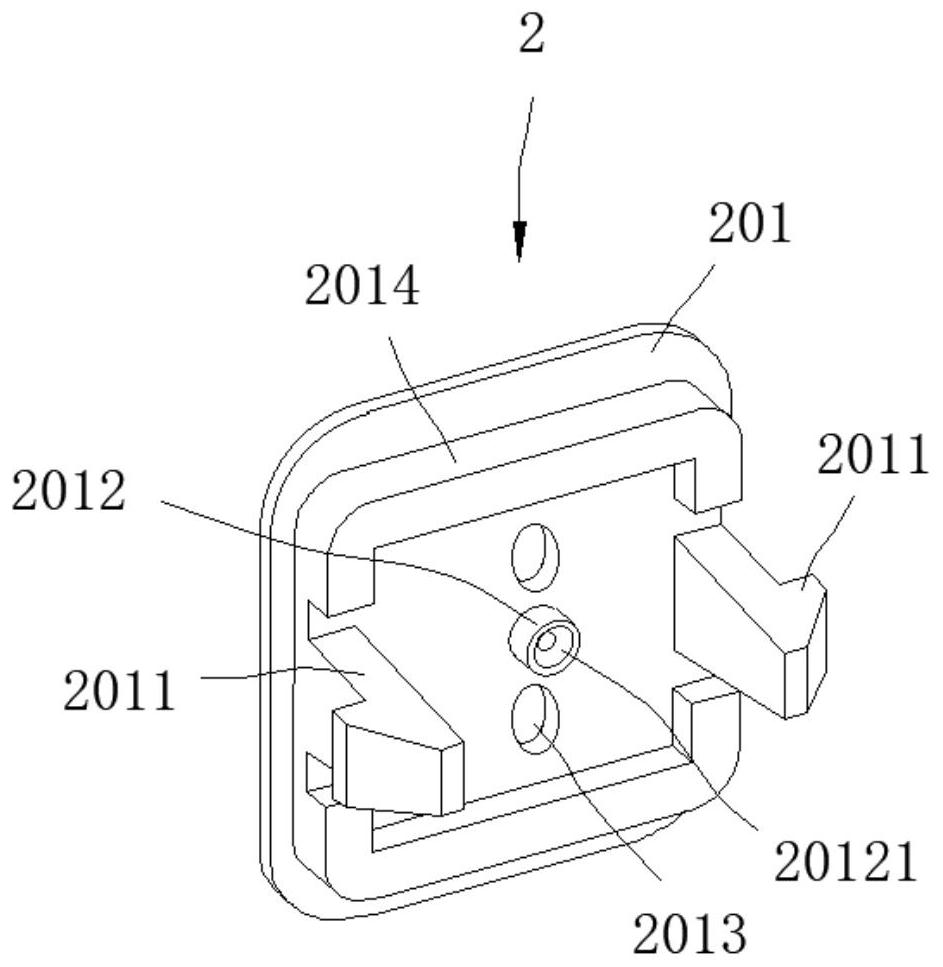

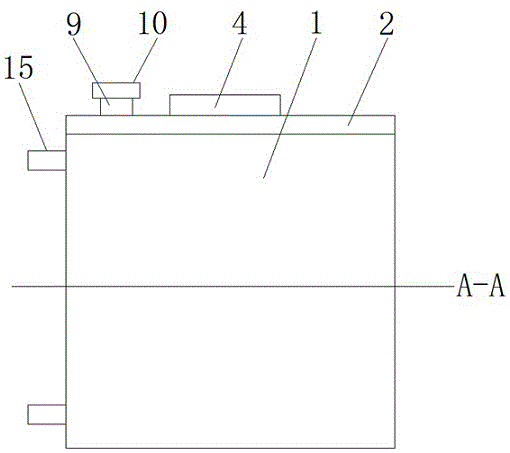

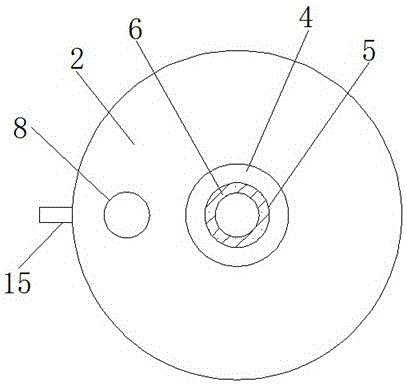

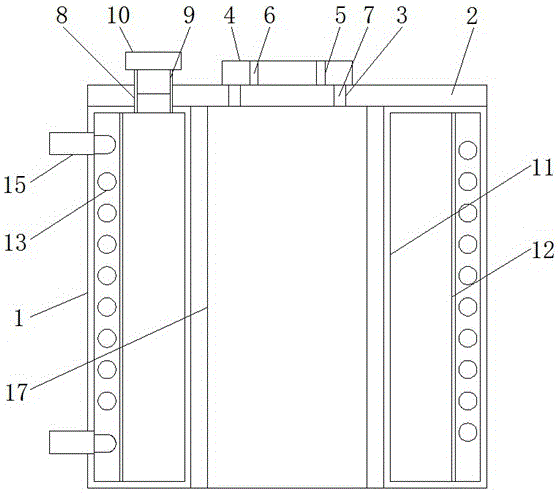

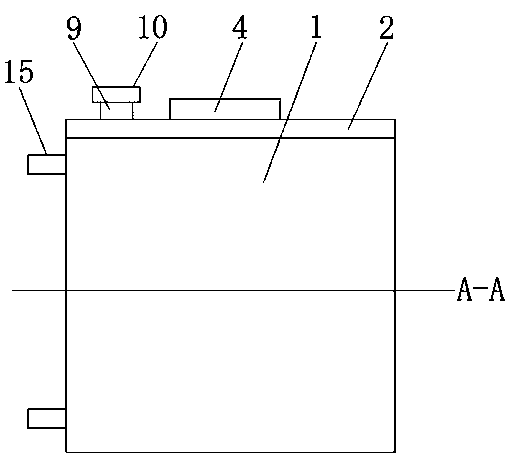

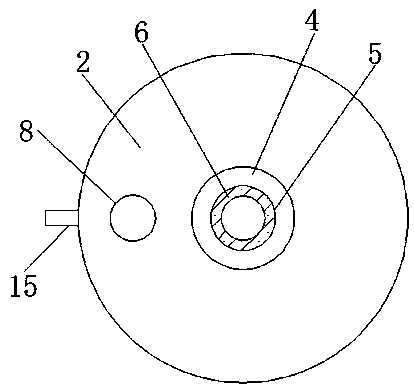

MDC-based integrated monitoring device and method

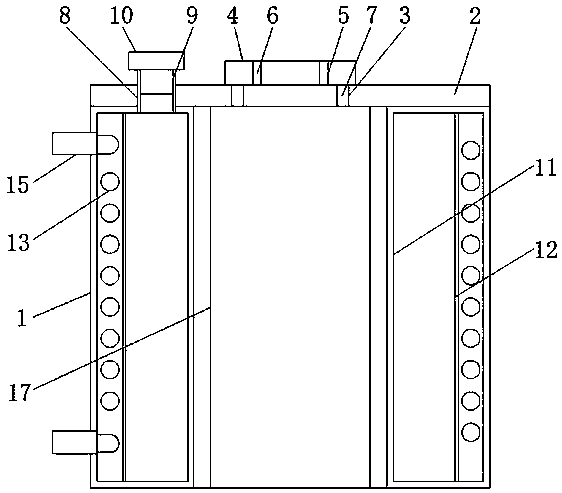

InactiveCN108401035AAchieve modularityFacilitates rack mountingData switching networksIntegrated monitoringLiquid-crystal display

The invention provides an MDC-based integrated monitoring device and a method thereof, wherein the device comprises: a mounting frame (1), an upper cover (2), a monitoring host motherboard (3), a multi-network port controller main board (4), a fan ( 5), a first USB interface (6), an HDMI high-definition interface (7), a first RJ45 network port (8), a Console debug interface (9), an LCD liquid crystal display panel (10) and a power module (11). On the basis of high availability and high reliability, the invention builds an efficient and stable integrated monitoring device, which solves the problems of complicated installation, low aesthetics, non-uniform software and high cost of current data center monitoring system, well solves many problems such as equipment installation, power distribution, cable fixing and equipment location selection, and realizes the modularization and pre-assembly of the data center integrated monitoring device.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

High-efficiency screening type large-scale double-toothed roller crusher with self-contained material distribution device

Owner:HENAN ZHENYUAN TECH

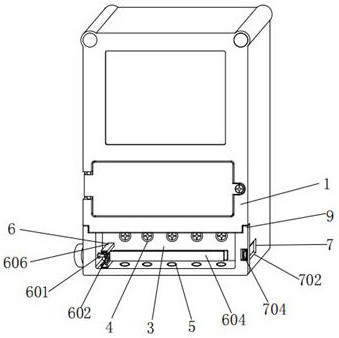

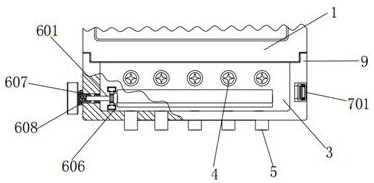

Intelligent electric meter based on Internet of Things

PendingCN113589007AImprove connection stabilityAvoid poor contactTime integral measurementInternet of ThingsElectrical and Electronics engineering

The invention discloses an intelligent electric meter based on Internet of Things. The intelligent electric meter comprises an electric meter body, an inner cavity is arranged at the lower part of the front surface of the electric meter body, and a binding mechanism is arranged in the inner cavity. According to the intelligent electric meter based on the Internet of Things, two clamping plates slide inwards and clamp and fix an external connecting wire, at the moment, a second gear and a gear block are clamped again, rotation of a round rod is limited, the external connecting wire is prevented from being accidentally separated from a wiring end during use, the connection stability is improved, poor contact is avoided, and the service life of the electric meter is prolonged. When a second rack is engaged or separated, a buckling cover can be rapidly opened and closed, the convenience of opening and closing the buckling cover is improved, the convenience of wiring or wire removing is improved, the difficulty of subsequent overhaul and maintenance is reduced, the practicability is better, when a clamping block is embedded into the clamping groove, an inner frame is fixedly connected into an outer frame, the clamping block can be driven to be separated from the clamping groove by pulling the vertical rod, and the outer frame and the inner frame can be slidably separated. The electric meter body can be quickly disassembled and assembled, the installation efficiency is improved, and the whole electric meter body can be conveniently disassembled, overhauled and maintained.

Owner:章能庆

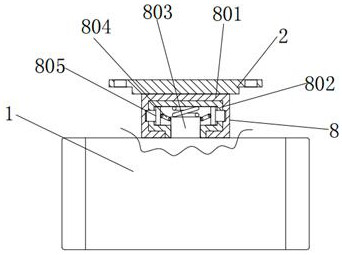

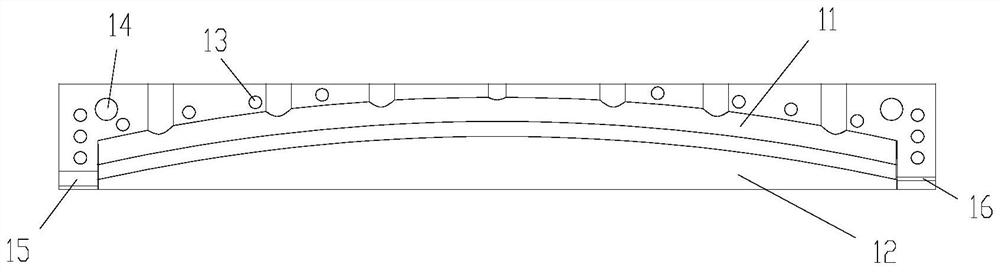

Gypsum block molding device and operation method thereof

PendingCN108908680ALower the altitudeImprove stabilityDischarging arrangementCeramic shaping plantsGypsum blockMaterials science

The invention discloses a gypsum block molding device and an operation method thereof. The gypsum block molding device comprises a hydraulic device, a mold bottom plate, a bottomless mold, ejector rods and a rack; insertion slots and insertion holes are formed in the mold bottom plate; the hydraulic device is fixedly provided with the bottomless mold; a plurality of mold cores and partition platesare arranged in a cavity of the bottomless mold at intervals; when the hydraulic device drives the bottomless mold to make contact with and match with the mold bottom plate, the partition plates areinserted in the insertion slots of the mold bottom plate, the mold cores are inserted in the insertion holes of the mold bottom plate, and the cavity of the bottomless mold can be divided into a plurality of molding cavities with lower openings being closed through the partition plates; an ejector rod fixing frame is fixedly arranged on the rack, and the multiple ejector rods are fixedly arrangedon the ejector rod fixing frame and located over the molding cavities; and when the hydraulic device drives the bottomless mold to move upwards, gypsum blocks are jacked out of the bottomless mold through the ejector rods. The gypsum block molding device has the advantages of high production efficiency, good product quality, high stability and safety and convenient repairing and maintenance.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Multifunctional air-conditioning vestibule and air conditioning method thereof

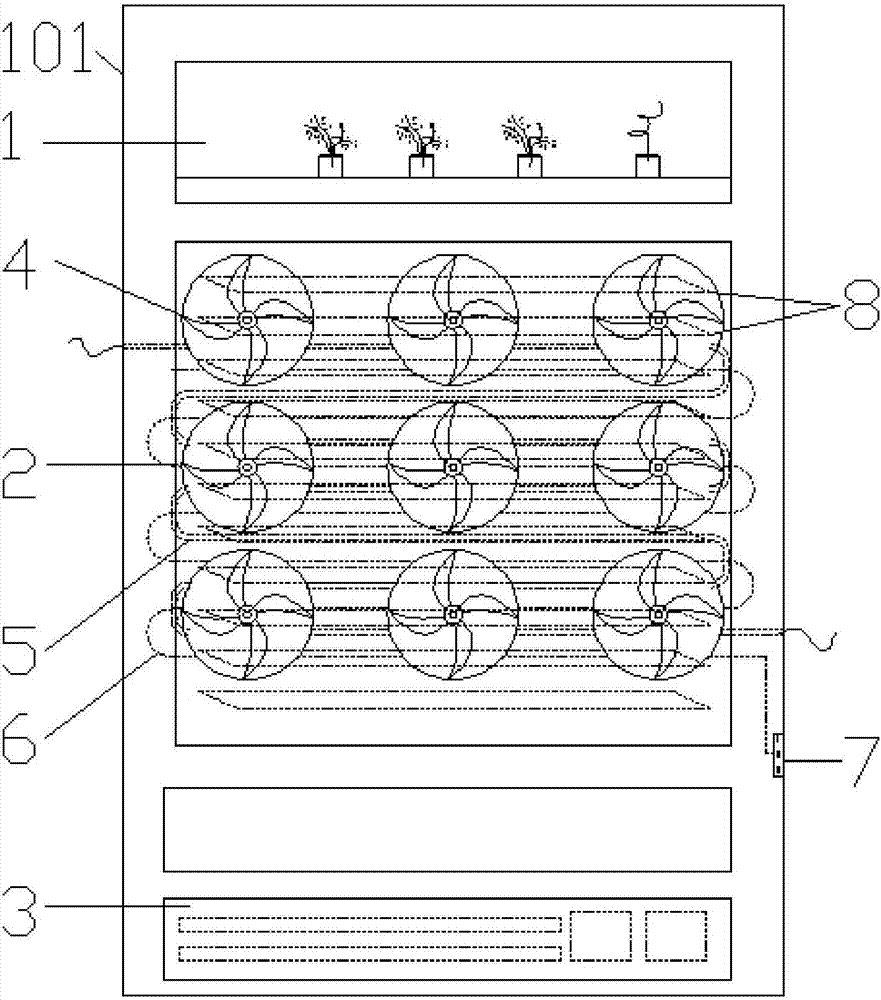

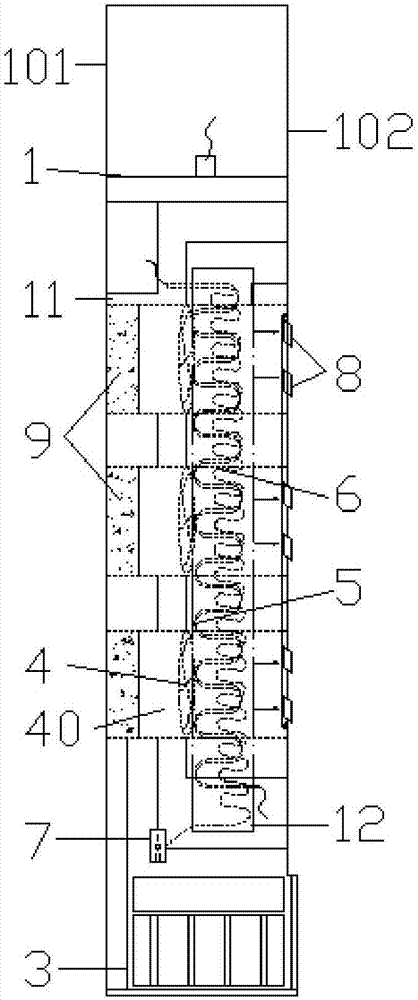

InactiveCN107467905AWith translucent effectSpeed up circulationWardrobesSpace heating and ventilation safety systemsEngineeringAir conditioning

The invention discloses a multifunctional air-conditioning vestibule and an air conditioning method thereof. The vestibule sequentially comprises a potted plant frame, an air conditioning device and a shoe cabinet from top to bottom, the side, facing a door, of the vestibule is an outer side, and the side, facing a main hall, of the vestibule is an inner side; the potted plant frame is of a through structure from the outer side of the vestibule to the inner side of the vestibule, the shoe cabinet is located at the inner side of the vestibule, and the outer side of the vestibule is separated by an opaque base plate; the air conditioning device comprises fans, a cooling pipe, an electric heating wire and an air conditioning switch; a wind port is formed in the vestibule, the fans are installed in the middle of the wind port, the electric heating wire and the cooling pipe are embedded in the vestibule, and one end of the cooling pipe is connected with a conveying pump. The multifunctional air-conditioning vestibule is ingenious in concept, low in overall energy consumption and high-grade, has the functions of refrigeration, heating and air circulation, integrates aesthetic feeling and practicality and provides good experiences for a guest.

Owner:TAICANG JINQIANG FURNITURE

Internet of Things monitoring equipment for information acquisition

PendingCN112066228AEasy to remove for maintenanceEasy to fixStands/trestlesThe InternetMonitor equipment

The invention discloses Internet of Things monitoring equipment for information acquisition. A wallboard, a monitoring equipment body and a bearing block are included, two groups of supporting columnsare fixedly connected to the front surface of the bearing block, a supporting plate is fixedly connected to the ends, far away from the bearing block, of the two groups of supporting columns, and anadjusting mechanism corresponding to the monitoring equipment body is arranged on the supporting plate. The monitoring equipment body is fixedly installed on the front face of the supporting plate, limiting plates are fixedly connected to the two sides of the bearing block, clamping blocks are fixedly connected to the sides, away from the bearing block, of the limiting plates, two sets of lockingholes are formed in the tops of the clamping blocks, and limiting blocks are fixedly connected to the sides, away from the limiting plates, of the clamping blocks. The Internet of Things monitoring equipment has the beneficial effects that when a user installs and fixes the monitoring equipment body, the operation is simple and convenient, time and labor are saved, the monitoring equipment body isconveniently disassembled and overhauled in the later period, the operation is convenient, the monitoring equipment body is disassembled and assembled multiple times, and the monitoring equipment main body is also ensured to be fixed stably and not to loosen.

Owner:金花兰

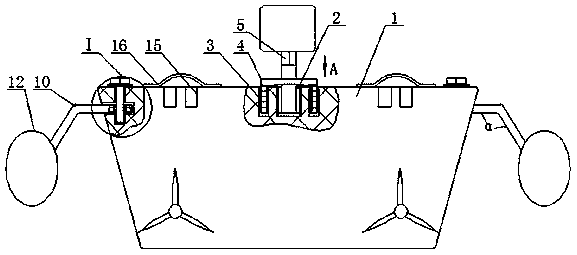

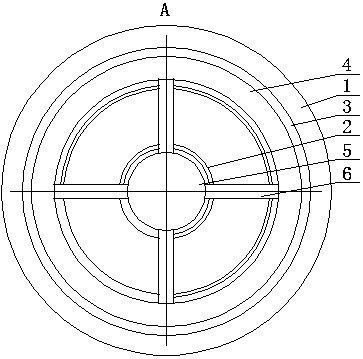

Water surface unmanned ship

PendingCN109733546AEasy to assemble and disassembleEasy to replaceNavigational aid arrangementsAntenna adaptation in movable bodiesArchitectural engineeringSatellite

The invention discloses a water surface unmanned ship, including a hull, a first screw hole is formed in the top surface of the hull; an annular groove is formed in the top surface of the hull; a first screw hole is located in the annular groove and is collinear with a center line of the annular groove, external threads are formed in the inner arc surface of the annular groove, a threaded sleeve is arranged in the annular groove, internal threads are arranged on the inner wall of the threaded sleeve and matched with the annular groove in a threaded mode, a stud is installed in the first threaded hole in a threaded mode, one ends of a plurality of connecting rods are fixedly connected to the periphery of the stud, the other ends of the connecting rods are fixedly connected with the inner wall of the threaded sleeve, and a satellite antenna is fixedly installed at the upper end of the stud. The stability of the stud can be further enhanced through the threaded fit of the threaded sleeveand the annular groove, so that the stud can bear the load of high wind on the sea surface.

Owner:天津海之星船艇科技有限公司

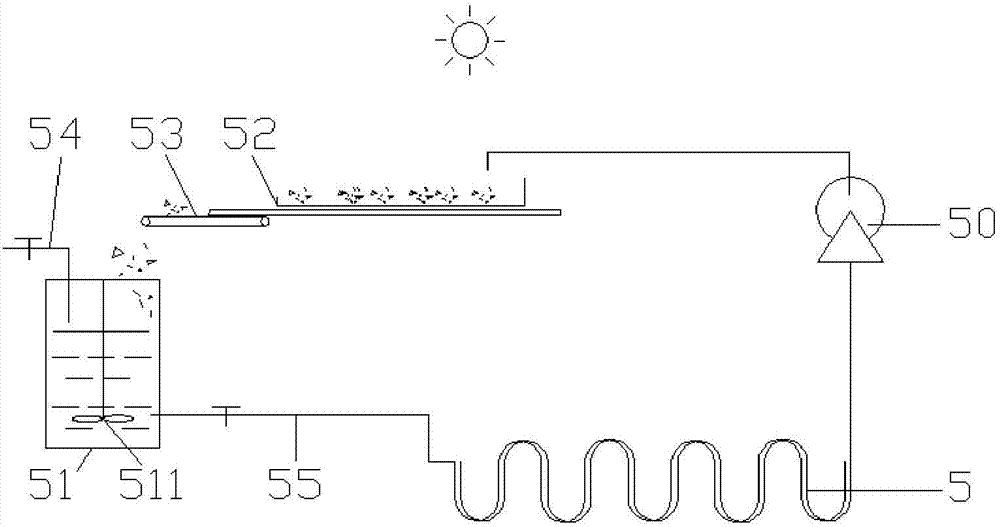

Novel solar automobile sun shield

InactiveCN107020926AInsulate from heat and noiseImprove comfortAir-treating devicesAntiglare equipmentAerospace engineeringSolar power

The invention discloses a new type of sun visor for solar vehicles, comprising a first sun visor and a second sun visor, the first sun visor is provided with an installation groove inside, the second sun visor is arranged inside the installation groove, and the second sun visor is arranged inside the installation groove. One end of the second sun visor is connected with a telescopic rod, the fixed plate is installed on the outer wall of the first sun visor, a vacuum layer is provided inside the first sun visor, a solar power generation panel is installed on the sunshade side of the first sun visor, and lighting is provided on the surface of the first sun visor For small lights, the top of the first sun visor is connected with a first connecting seat and a second connecting seat, and the first connecting seat and the second connecting seat are respectively connected with a first rotating shaft and a second rotating shaft, and the first rotating shaft The first vacuum suction cup and the second vacuum suction cup are respectively connected to the second rotating shaft. The new solar car sun visor is fixed by the vacuum suction cup. It is easy to disassemble, energy-saving and environmentally friendly, and the sun-shading area can be adjusted, and it is easy to use.

Owner:十堰坤钰渝明汽车零部件有限公司

Electric meter fixing piece and electric meter box

InactiveCN112684228AEasy to installImprove connection strengthTime integral measurementMechanical engineeringPhysics

The invention discloses an electric meter fixing piece and an electric meter box. The electric meter fixing piece comprises a first fixing piece and a second fixing piece which are matched with each other, the first fixing piece is provided with a first connecting piece, the second fixing piece is provided with a second connecting piece which is detachably matched with the first connecting piece, and the first fixing piece is provided with an elastic piece; when the first connecting piece and the second connecting piece are connected in a matched mode, the elastic piece abuts against the second fixing piece, and the elastic piece always has the trend of driving the second connecting piece and the first connecting piece to be locked. By arranging the first fixing piece and the second fixing piece which are detachably connected and matched, when the electric energy meter breaks down, the electric energy meter can be conveniently detached from the electric energy meter box to be maintained; by arranging the elastic piece, the first connecting piece and the second connecting piece can be driven to be locked, the connecting strength between the first fixing piece and the second fixing piece is improved, and the electric energy meter can be stably installed in the electric meter box.

Owner:GUANGDONG POWER GRID CO LTD +1

Vehicle-mounted device convenient to overhaul, disassemble and assemble

InactiveCN113581088AEasy to replaceMany applicable situationsVehicle componentsIn vehicleMechanical engineering

Owner:广西梦科智联信息技术有限公司

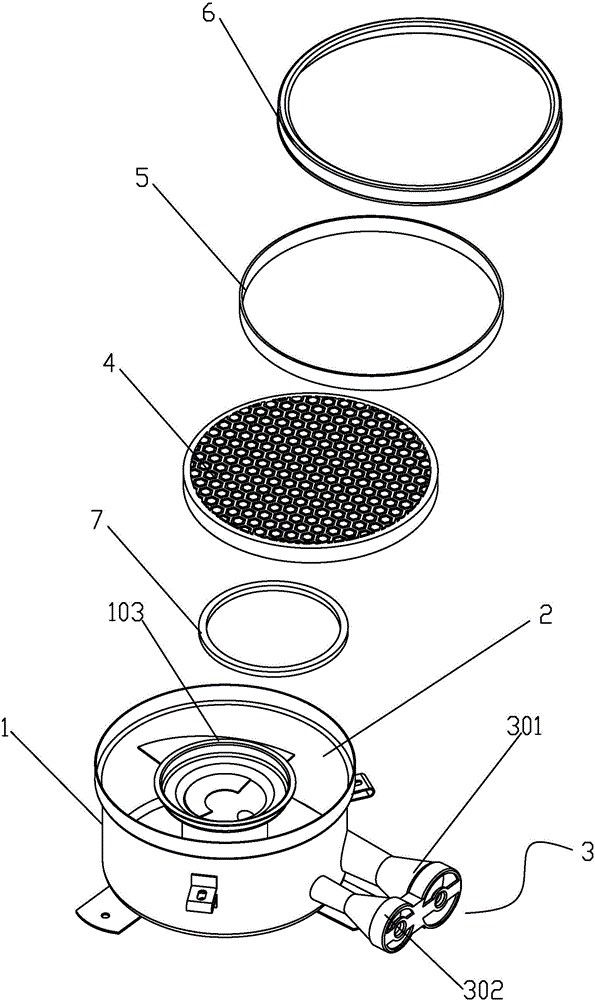

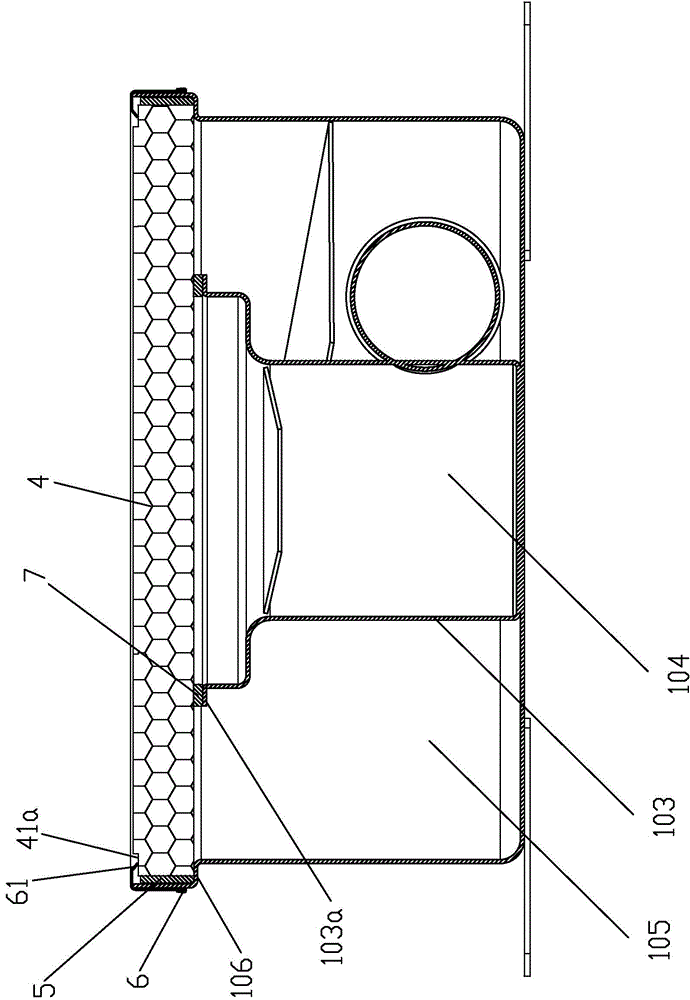

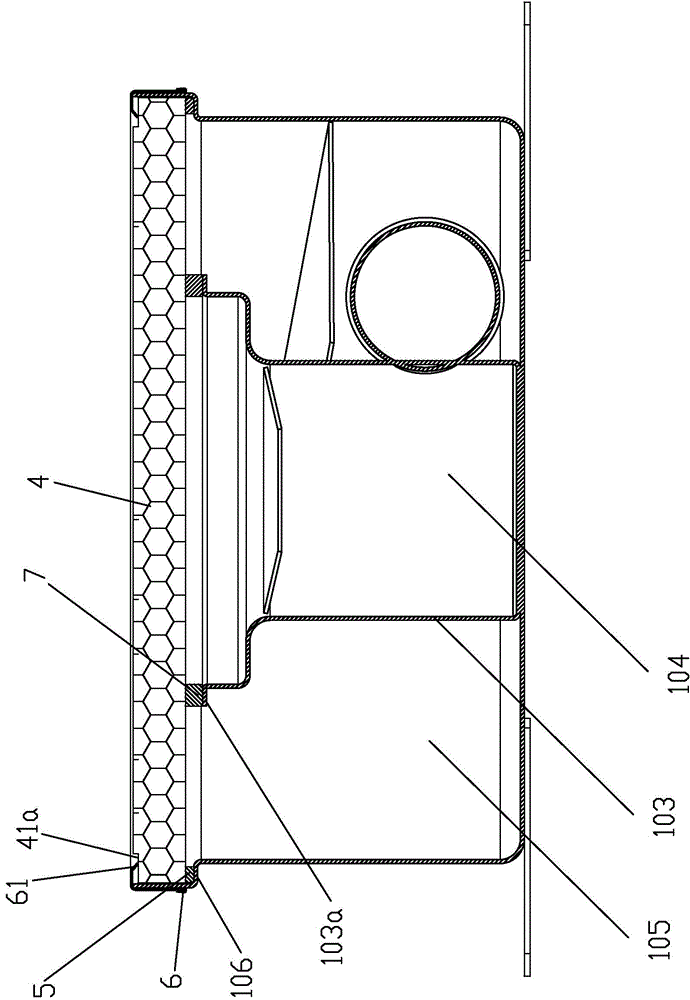

Infrared burner of domestic gas stove

InactiveCN105737155ASimple structureEasy to assemble and disassembleDomestic stoves or rangesGaseous fuel burnerEngineeringAbsorption effect

The invention discloses an infrared burner of a domestic gas stove. The infrared burner comprises a stove body, wherein a hearth and an ejecting tube which communicates with the hearth are arranged in the stove body; a honeycomb structure ceramic burning tray which is connected to the stove body is mounted over the hearth, and an insulating seal ring is arranged between the periphery of the ceramic burning tray and the inner wall of the stove body. The burner disclosed by the invention is simple in structure, convenient to assemble and disassemble, convenient to repair, has an insulating effect, and prevents gas leakage. The insulating seal ring further has a shock absorption effect when conveyed, so that the ceramic burning tray is prevented from being damaged.

Owner:何勤

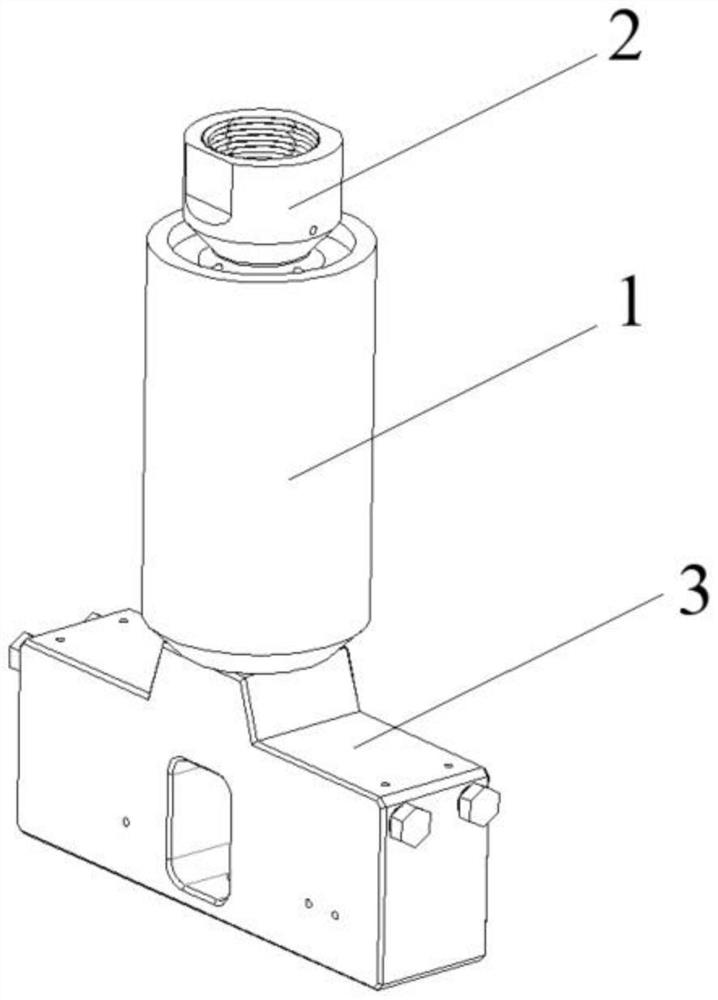

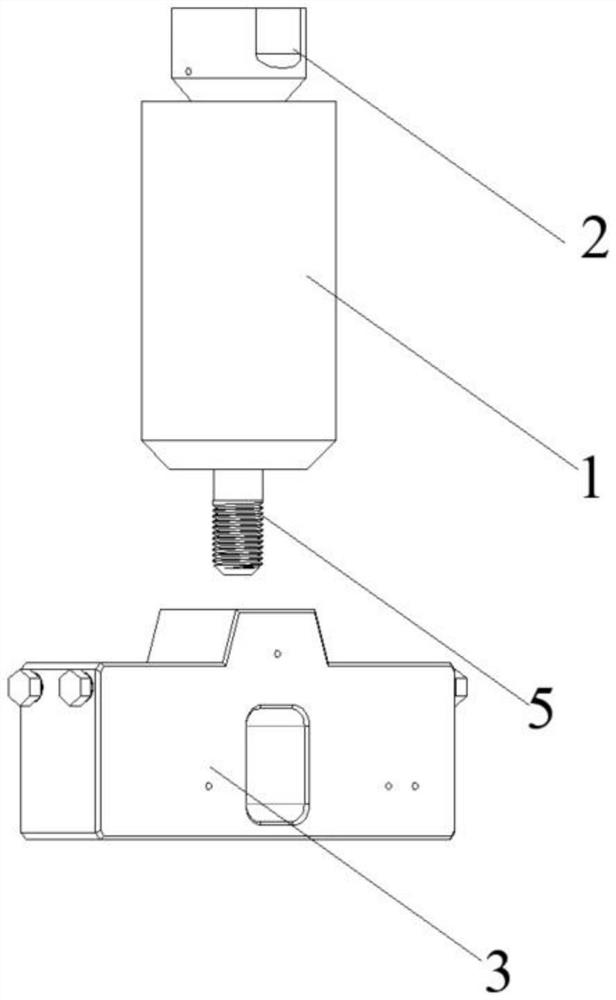

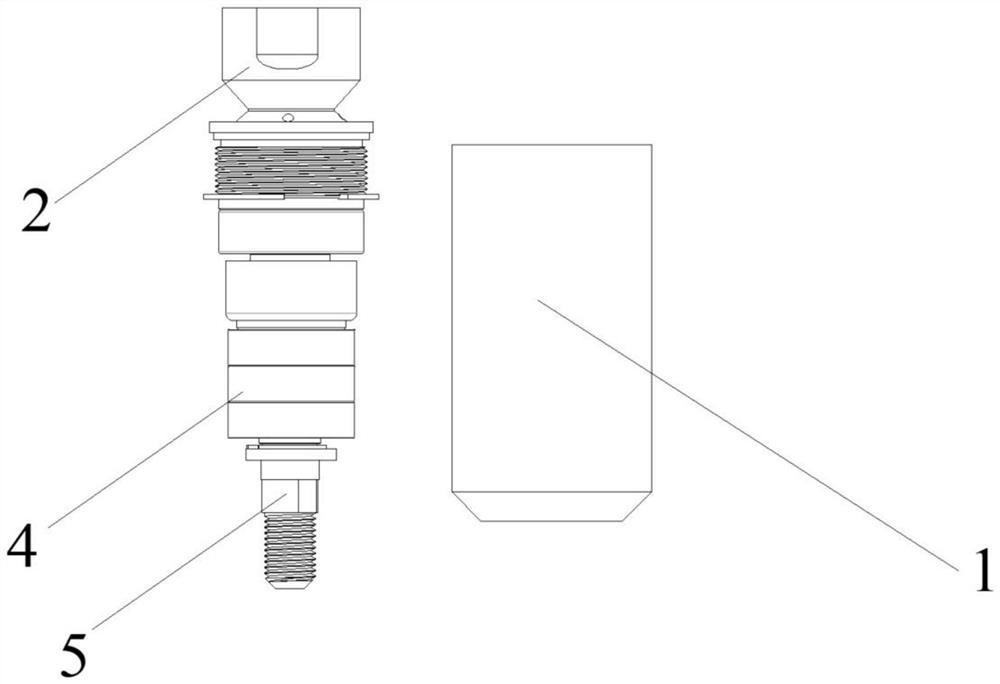

Locomotive oil tank edge correcting device

PendingCN112489973ANo sheddingEasy to remove for maintenanceTransformers/inductances coolingInductances/transformers/magnets manufactureJackscrewElectrical and Electronics engineering

The invention discloses a locomotive oil tank edge correcting device which comprises a supporting rod, a fixing base, a jack, a jack fixing device, a supporting rod quick-changing device and a movablefixing base. The fixing base is fixedly installed at one end of the supporting rod, the other end of the supporting rod is connected with the jack fixing device, and the jack is fixedly installed inthe jack fixing device. According to the designed fixed base and movable fixed base structure, an ejector rod device can be quickly fixed to the box edge and automatically generate a standard warmingarea; for an oil tank with small size difference in two directions of the tank edge, the inward bending correction of the tank edge can be realized by utilizing the telescopic change of the jack headwithout replacing the support rod. For an oil tank with large size difference in two directions of the tank edge, a supporting rod quick-changing device can be used for replacing a supporting rod witha matched size to correct the inward bending of the tank edge; the jack fixing device ensures that the jack does not fall off in the continuous force application process, and is safe and reliable; and the jack fixing device is designed to be of a detachable structure, and the jack can be conveniently detached, maintained and replaced.

Owner:HUNAN LIANCHENG TRACK EQUIP CO LTD

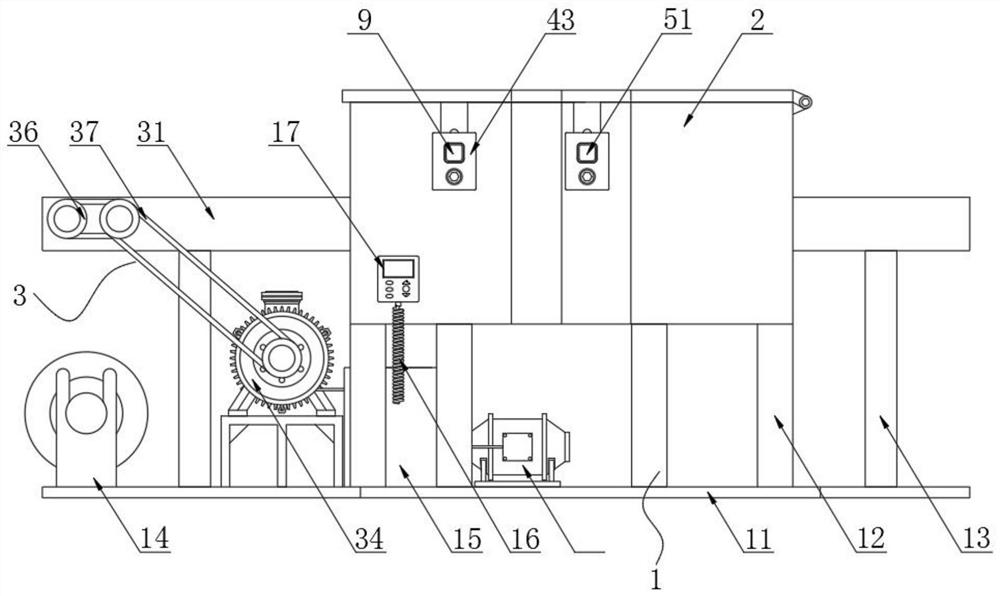

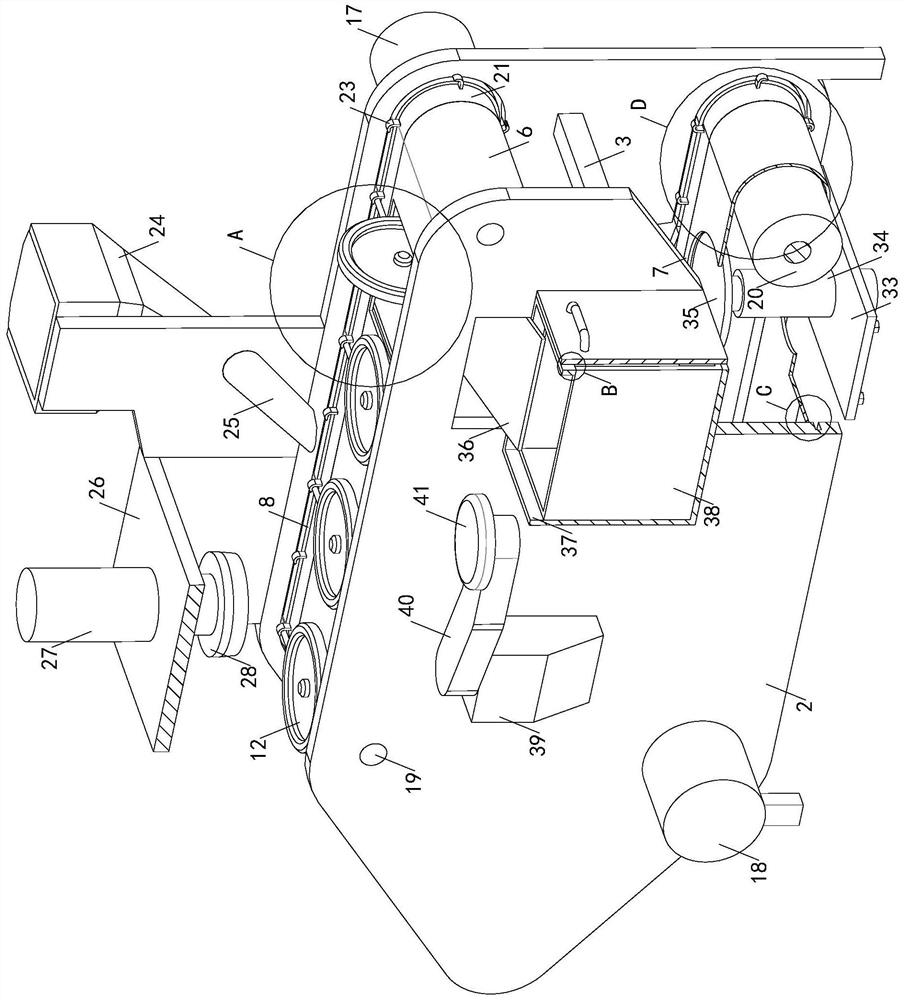

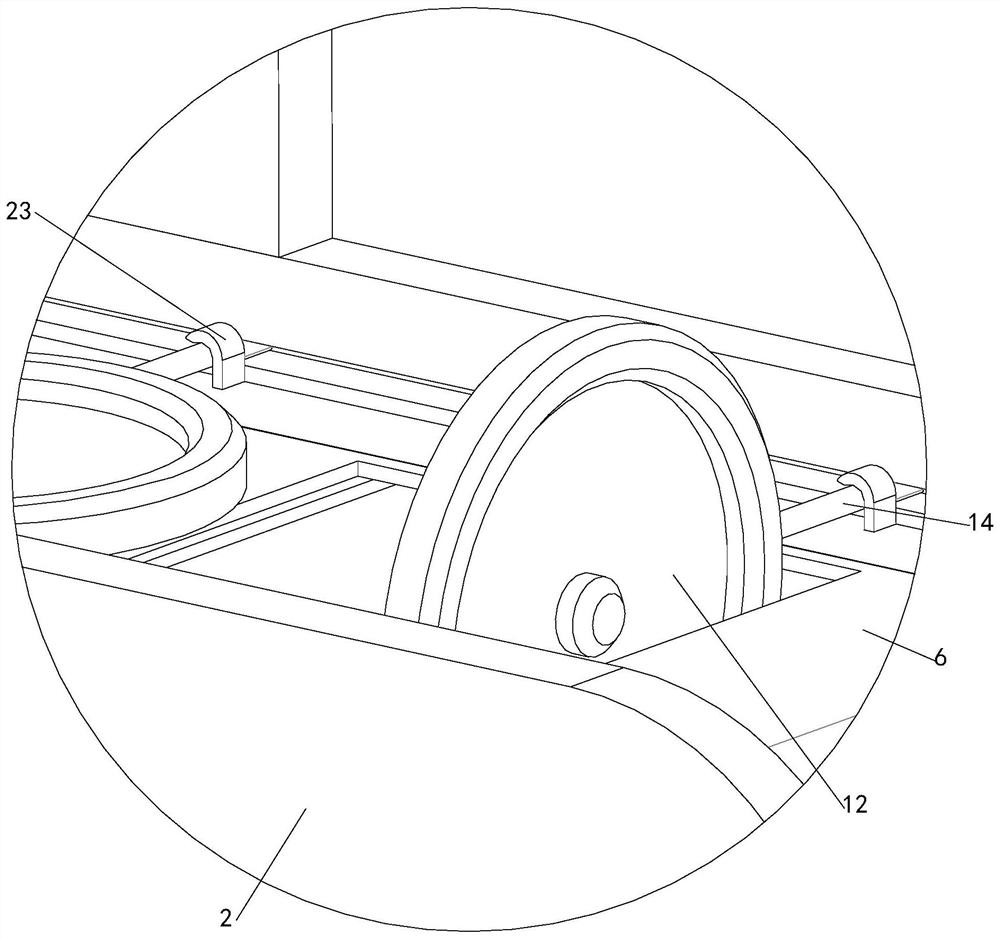

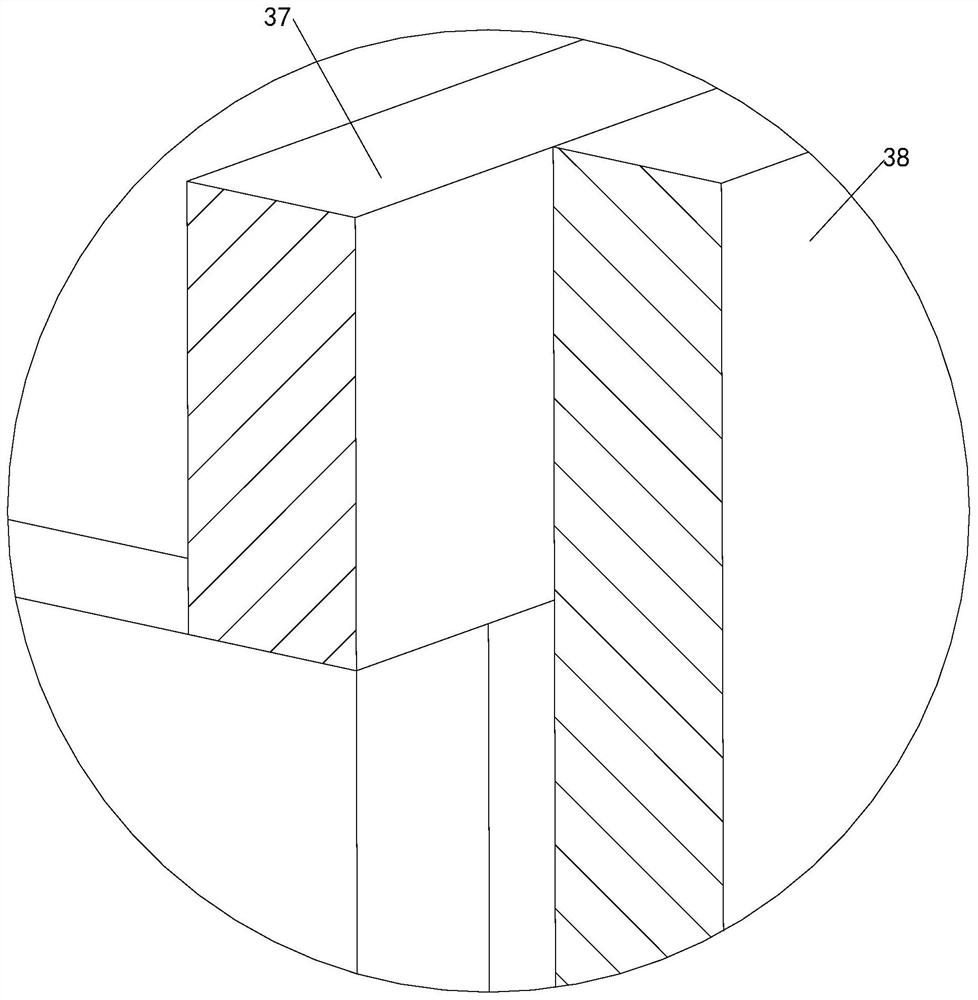

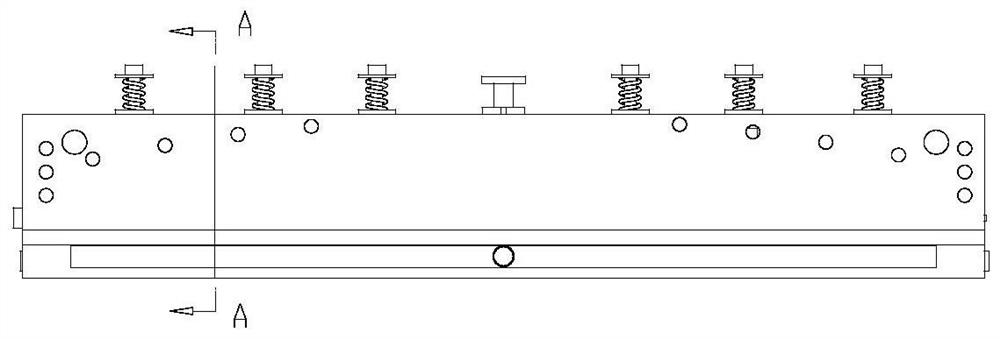

Multifunctional efficient thin film cutting machining system

The invention discloses a multifunctional efficient thin film cutting machining system, and relates to the technical field of thin film machining. The multifunctional efficient thin film cutting machining system comprises a rack, a machine box and a feeding transmission mechanism, a slitting assembly, a transverse cutting assembly, an indentation mechanism assembly and a driving mechanism are arranged inside the machine box correspondingly, and a driving assembly of the indentation mechanism assembly is arranged at the bottom of the machine box. According to the multifunctional efficient thinfilm cutting machining system, a transverse moving tool apron in the transverse cutting assembly can slide along a first sliding rod in a reciprocating mode, and with blades at the bottom of the transverse moving tool apron used in cooperation, the rapid cutting effect can be achieved, the two blades are arranged, then the problem that complete cutting off is difficult to achieve through one-timecutting can be solved through double cutting, balance weight metal blocks are arranged on the blades, with the weights of the blades used in cooperation, balanced pressure can be applied, the bottomsof the blades are round faces so that tangential cutting with the surface of a thin film can be kept all the time, the situation that the thin film is pushed to be turned up and stacked to reduce flatness is not prone to occurrence, and with a metal flattening seat used in cooperation, the flatness of a section can be kept .

Owner:李仰恩

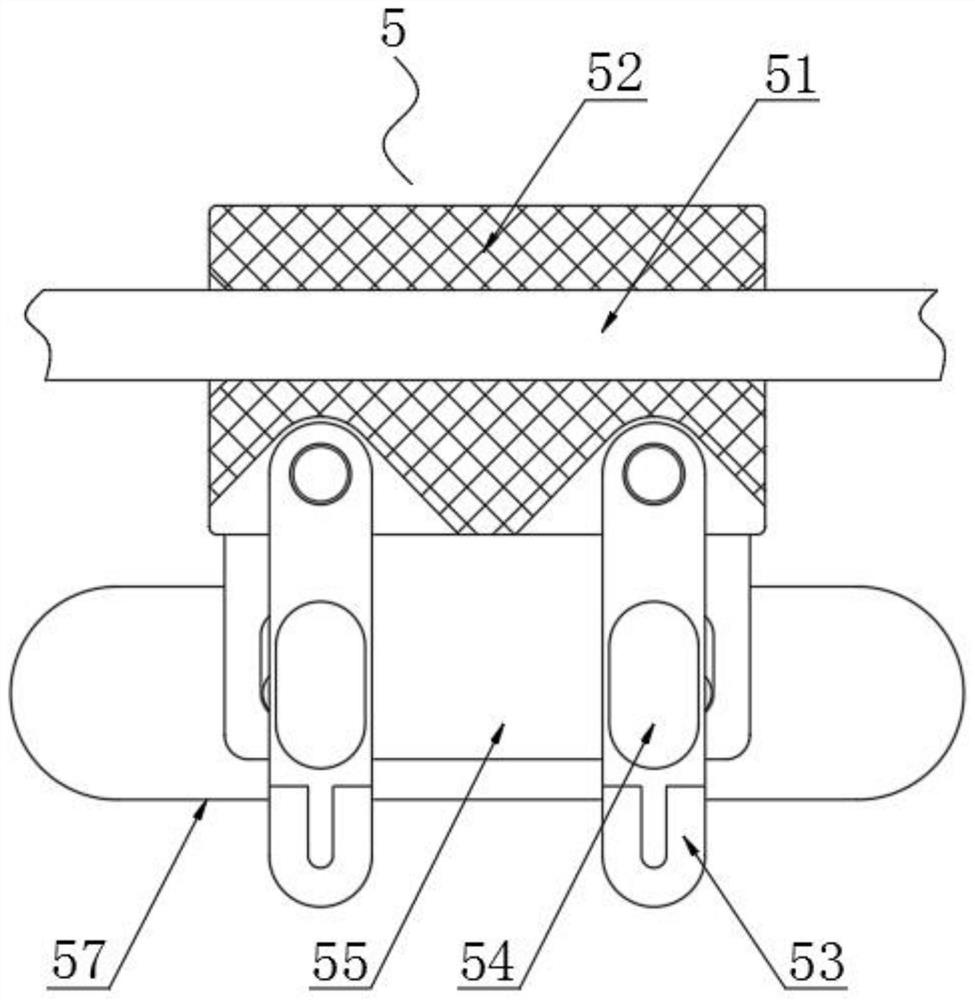

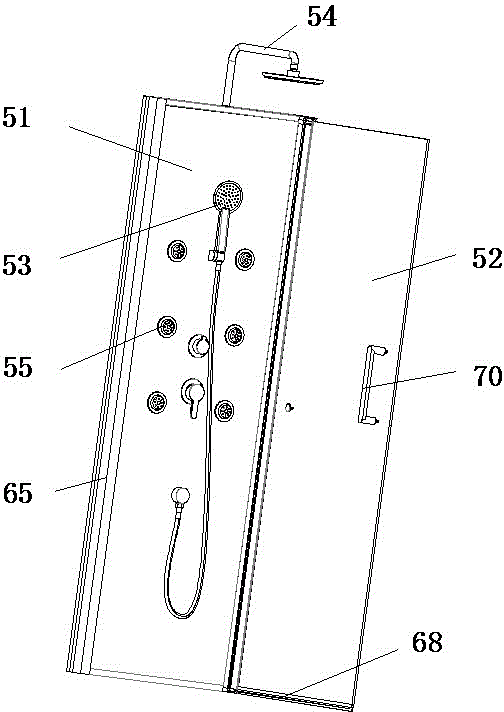

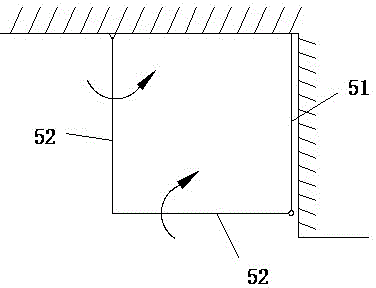

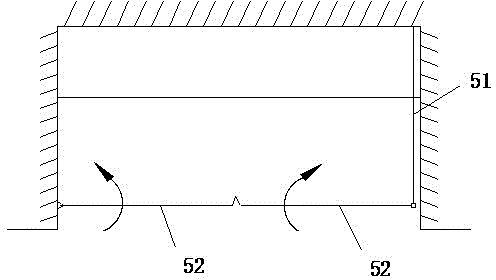

Folding type shower room

The invention discloses a folding type shower room. The folding type shower room comprises a back plate for being fixedly arranged on a wall surface and one or two side blocking doors, wherein an enclosed shower space is surrounded by the back plate, the wall surface and the side blocking doors; when one side blocking door is arranged, the side blocking door is arranged on the back plate in a rotating fit way; when two side blocking doors are arranged, the side blocking doors are respectively arranged on the back plate and the wall surface in a rotating fit way; and a spray assembly is arranged on the back plate, the spray assembly comprises a tap and a spray head assembly which are arranged on the back plate, and a connecting water pipe is arranged between the tap and the spray head assembly. According to the folding type shower room, through the arrangement of the back plate and the side blocking doors, during use, one enclosed shower space is surrounded by the back plate, the wall surface and the side blocking doors as long as the side blocking doors are opened; and after use, the side blocking doors are closed and attached with the back plate or the wall surface, and no room space is occupied. Therefore, the folding type shower room has the advantages of simple structure, convenience in use and small ground occupation area.

Owner:安徽克琳黛尔智能家居有限公司

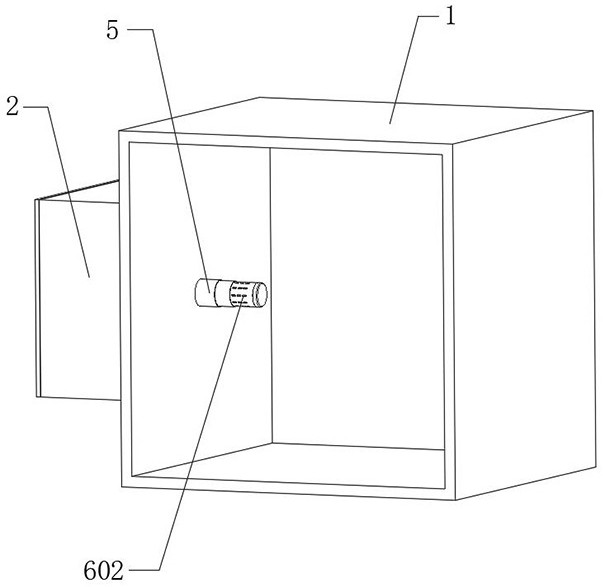

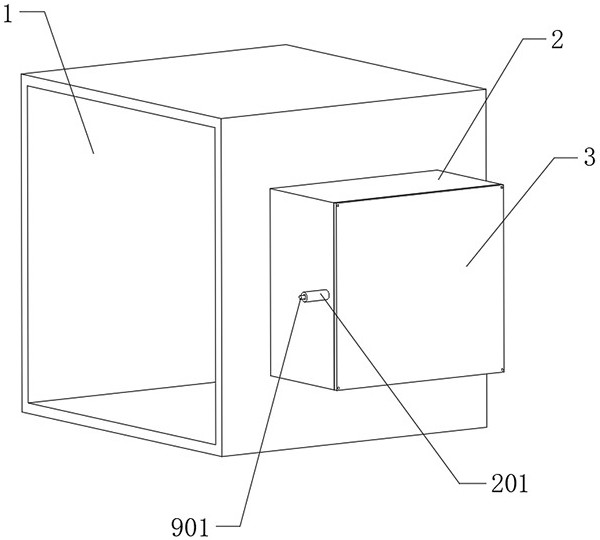

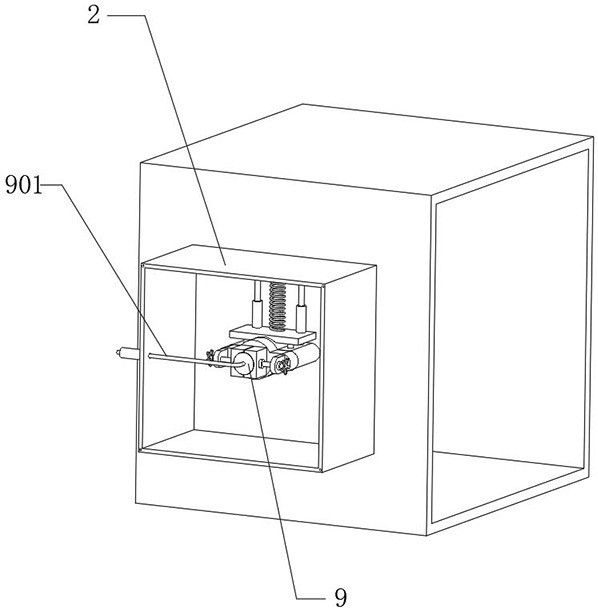

A home center console for easy disassembly and maintenance

InactiveCN109068505AEasy to installEasy to remove for maintenanceElectrical apparatus casings/cabinets/drawersLinear motorPower output

The invention discloses a home central console which is convenient to be disassembled and maintained, includes a mounting box, characterized by, the mounting box is arranged inside the wall body, A fixing mechanism is arranged in the mounting box part, A latch mechanism is arranged inside the fixing mechanism, A drive clasp mechanism is arranged inside the clasp mechanism, A telescopic mechanism of the control panel is arranged on the outer side of the transmission clasp mechanism, the power input end of the controller is electrically connected with the power output end of the battery box, thepower output end of the controller is respectively electrically connected with a linear motor, an Installing self-tapping motor, Buckle linear motor, a buckle switch and a control panel telescopic;The signal output ends of the control are respectively electrically connected with the mounting linear motor, the mounting self-tapping motor, the buckle linear motor and the control panel telescopicmechanism; The signal input end of the controller are respectively electrically connected with the buckle switch and the control panel telescopic mechanism. The invention has the advantages of simplestructure and strong practicability.

Owner:阙宇凡

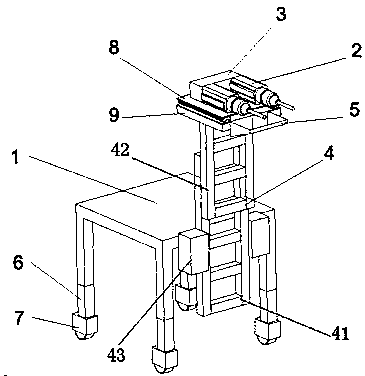

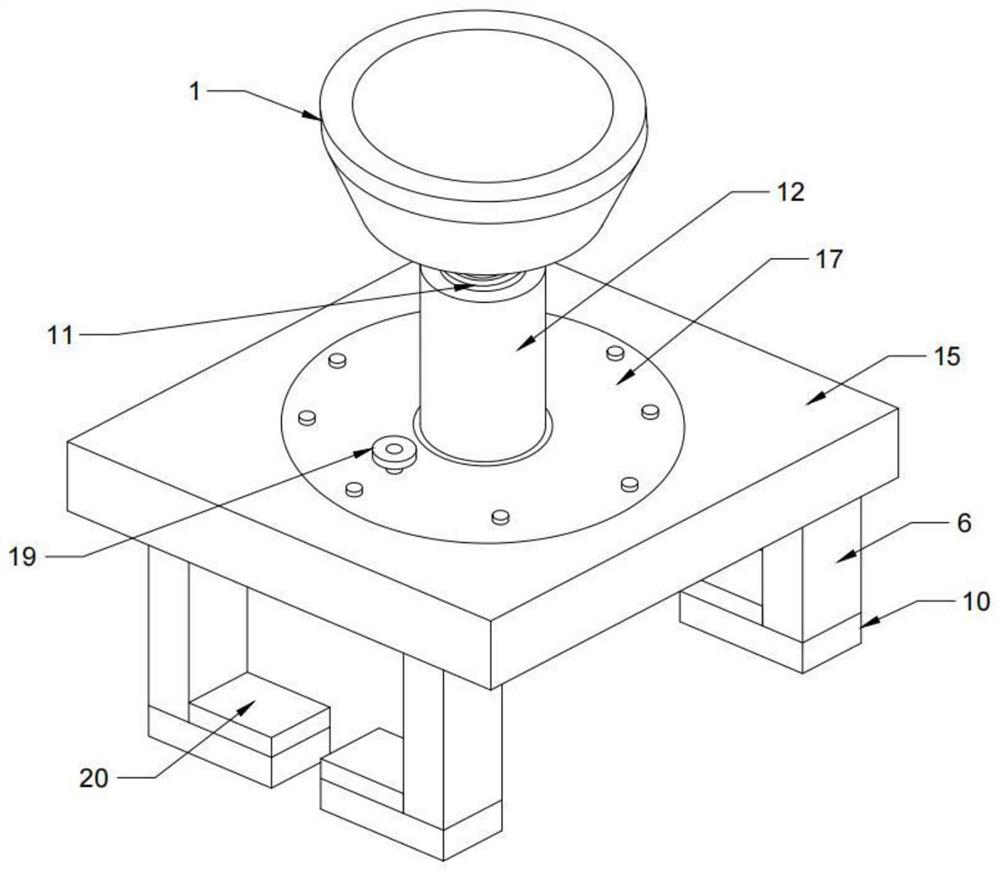

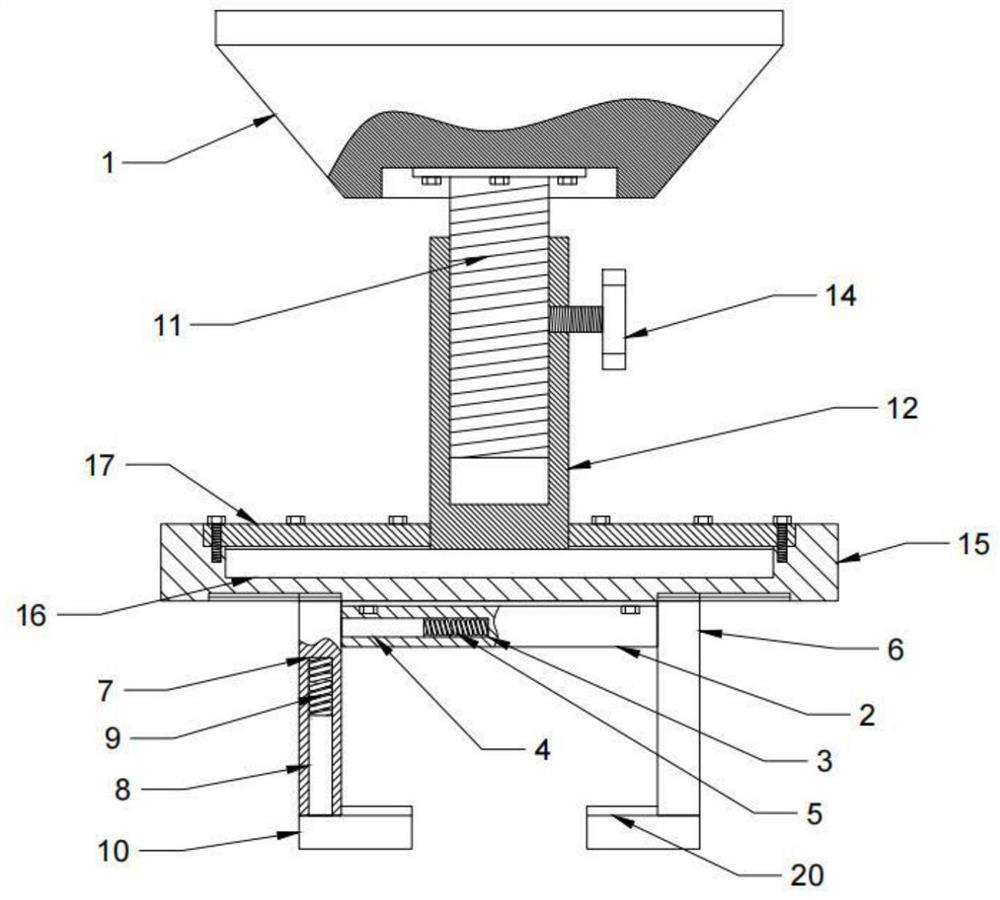

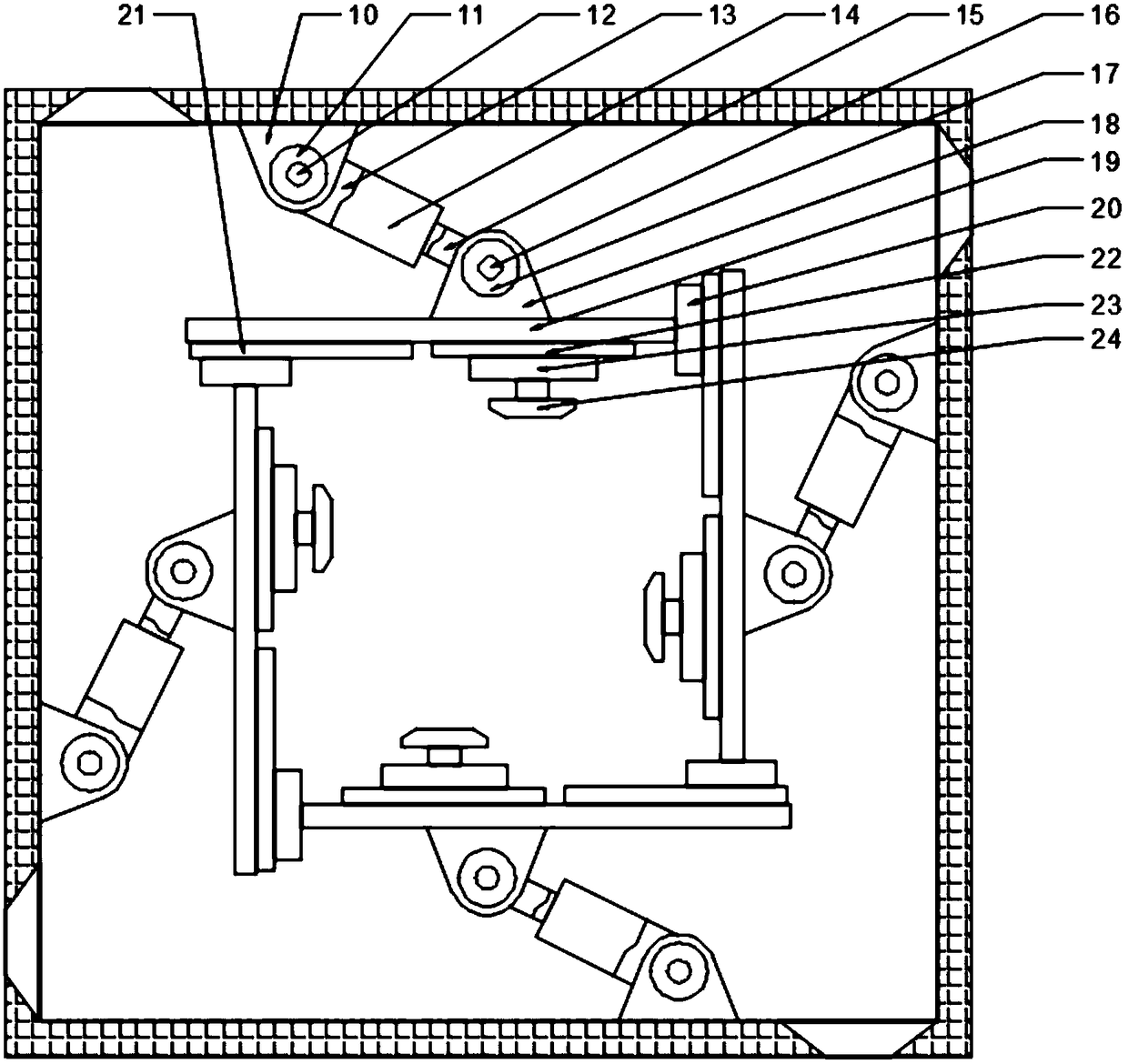

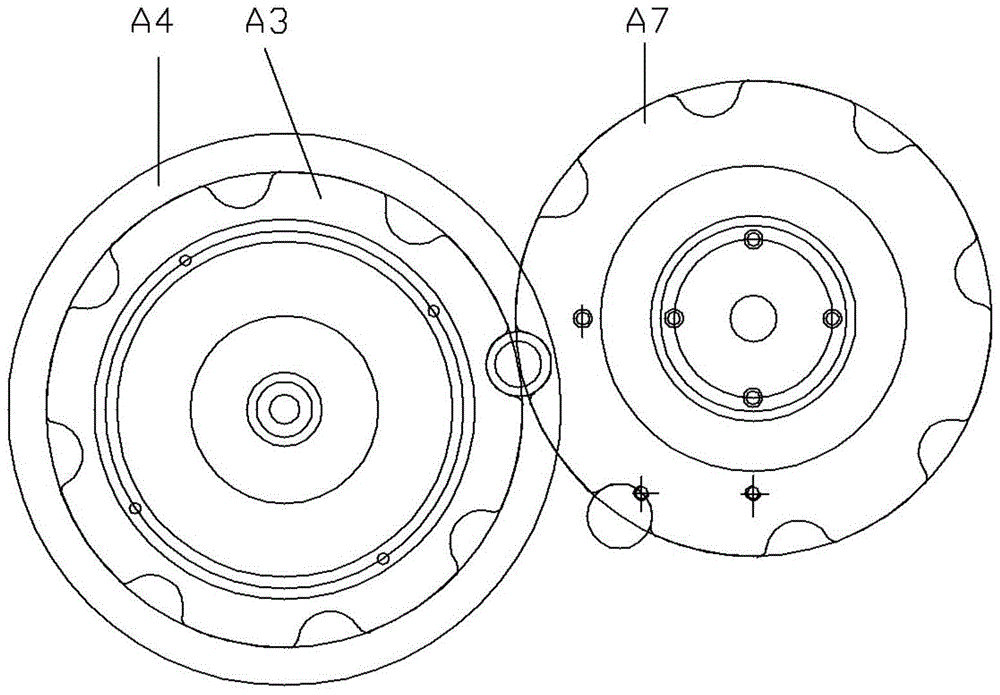

Resin grinding wheel forming machine with compact structure

InactiveCN113414719ACompact structureImprove product qualityGrinding devicesMolding machineStructural engineering

The invention relates to the technical field of resin grinding wheel forming machines, in particular to a resin grinding wheel forming machine with a compact structure. The resin grinding wheel forming machine comprises an electromagnetic on-off valve and two mounting plates, the two mounting plates are connected, a plurality of upper inclined supporting rods and a plurality of lower inclined supporting rods are connected to the two mounting plates, the upper inclined supporting rods are connected with upper auxiliary sleeves, the lower inclined supporting rods are connected with lower auxiliary sleeves, the upper auxiliary sleeves are provided with square openings, the lower auxiliary sleeves are provided with two round openings, the two mounting plates are provided with rail system grooves, a plurality of mold assemblies are mounted between the two rail system grooves, an upper auxiliary moving assembly and a lower auxiliary moving assembly are mounted between the two mounting plates, a feeding hopper assembly is mounted on the mounting plate close to the rear side, and the electromagnetic on-off valve is mounted on the feeding hopper assembly. The production quality is relatively stable, the operation stability is relatively good, the mold assembly is relatively convenient to replace, the overall layout is relatively compact, the occupied area is relatively small, the appearance is relatively attractive, and the practicability is relatively good.

Owner:河北双羊砂轮制造有限公司

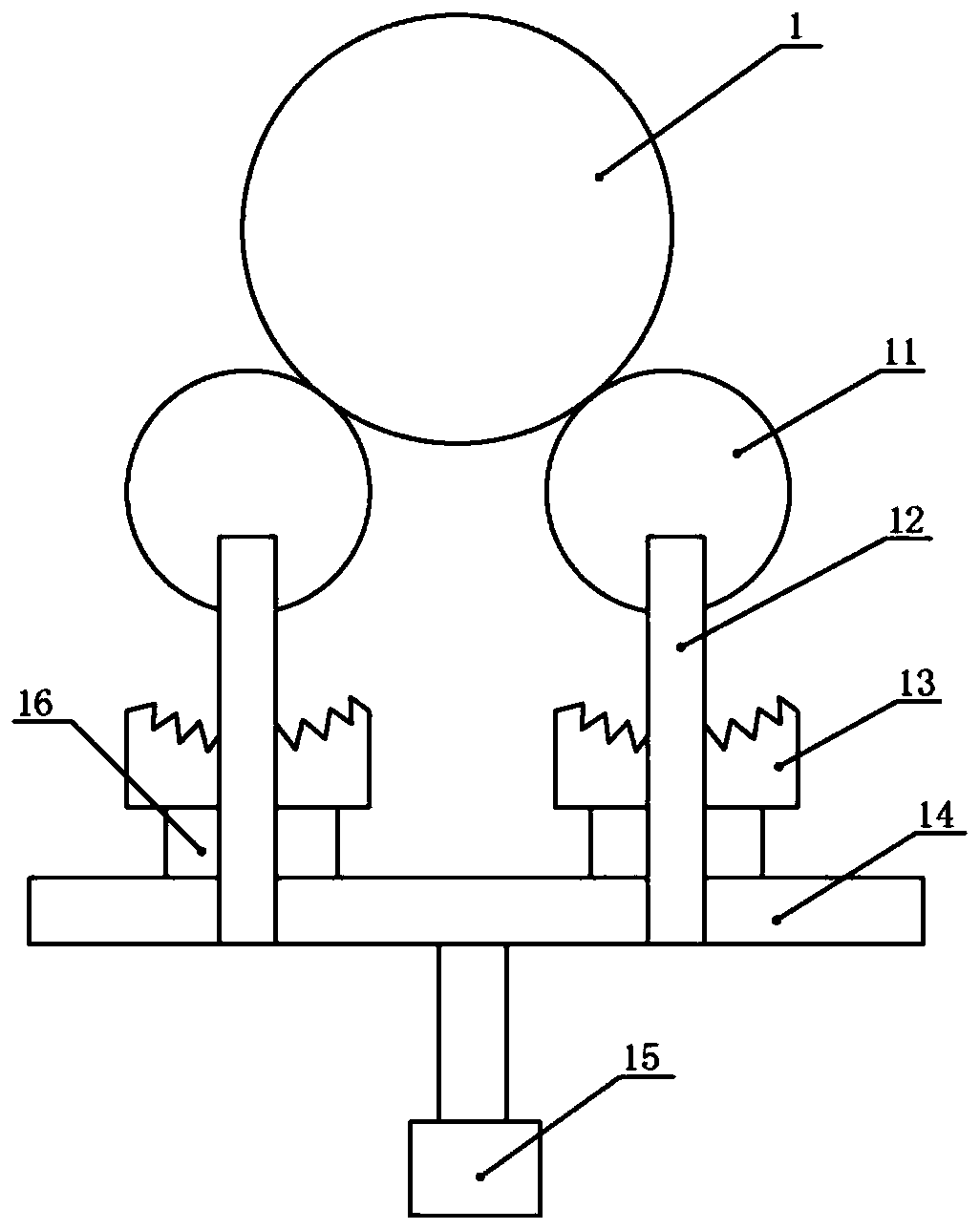

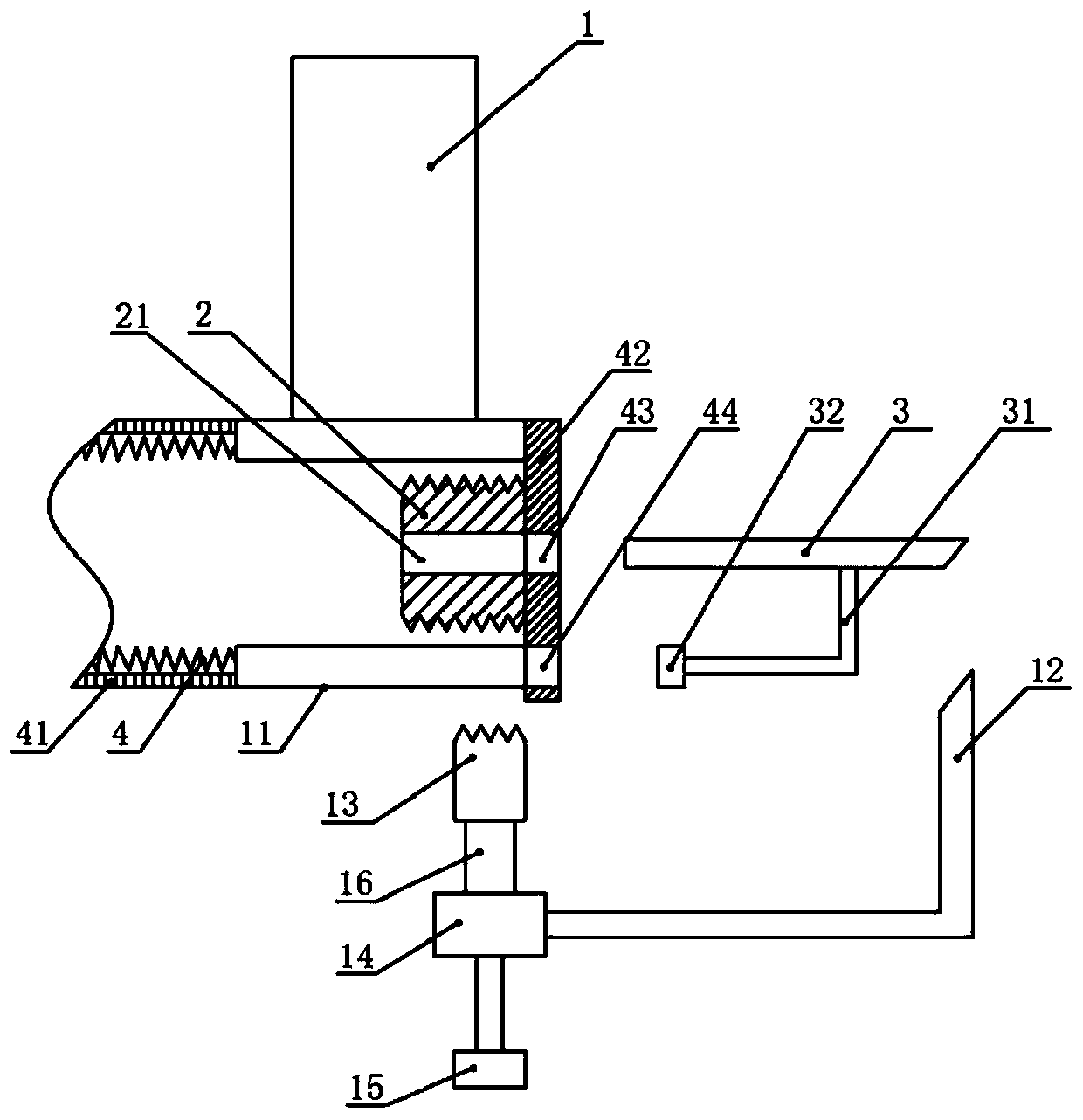

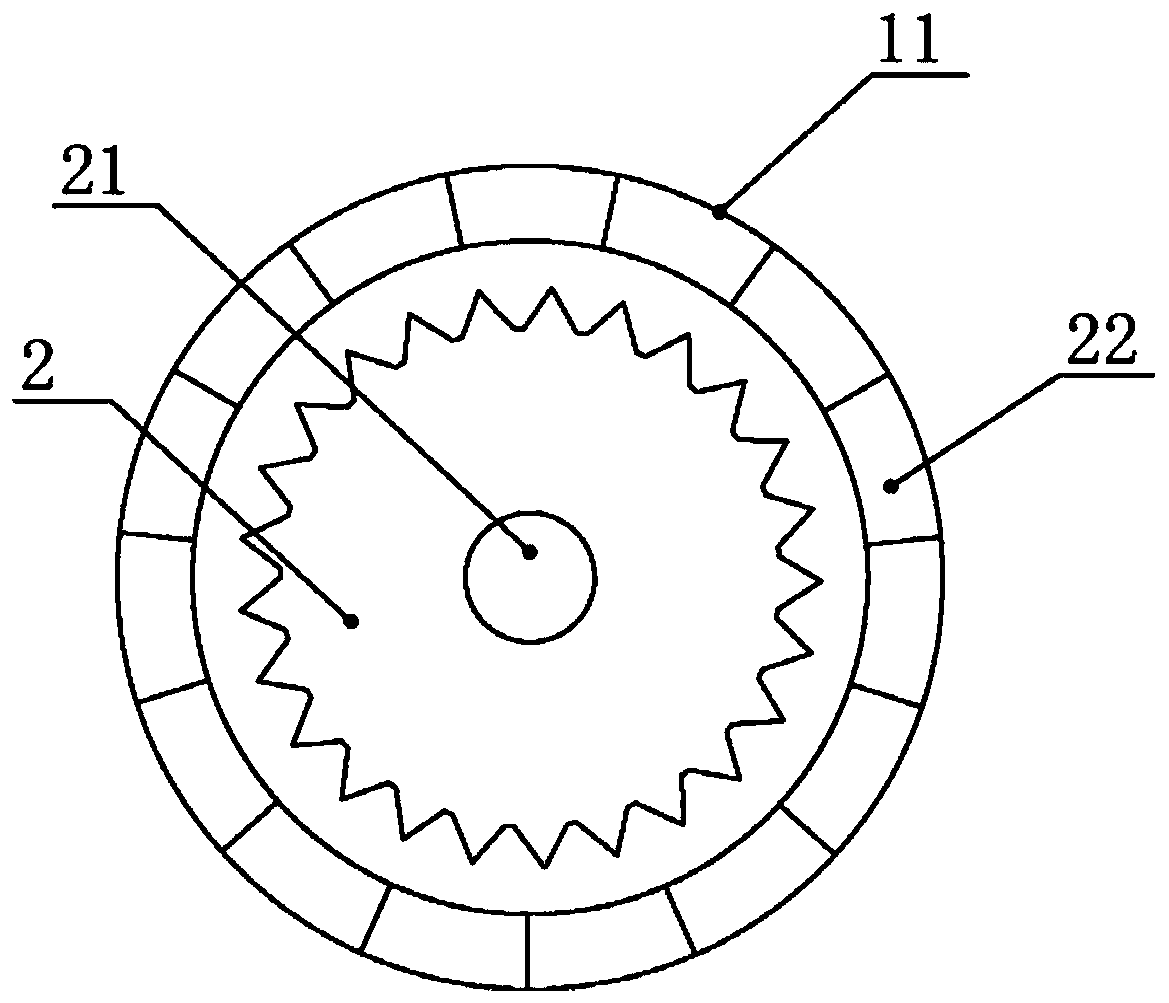

Speed table brake device

The invention relates to the technical field of vehicle detection, in particular to a speedometer test bench braking device, comprising a support frame. A driving mechanism is connected to the bottomof the support frame; a toothed plate is arranged on the support frame, a roller is arranged above the toothed plate, a toothed ring is concentrically arranged in the roller, the idle of the toothed ring is provided with a first through hole, the roller is formed by enclosing a plurality of slide plates, one end of the roller is provided with a retaining plate, a spring is connected between the retaining plate and each slide plate, a wedged rod is perpendicularly connected to one side of the support frame, a push rod is arranged above the wedged rod, one end of the push rod is provided with awedged face matching with the wedged rod, a push plate is arranged below the push rod, the push plate is in arc shape matching with the roller, each side of the push rod is connected with an L-shapedconnection rod, the other ends of the connection rods are connected with the two ends of the push plate respectively. The problem that the prior art has poor braking effect is solved.

Owner:郎溪品旭科技发展有限公司

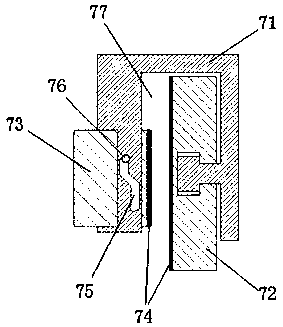

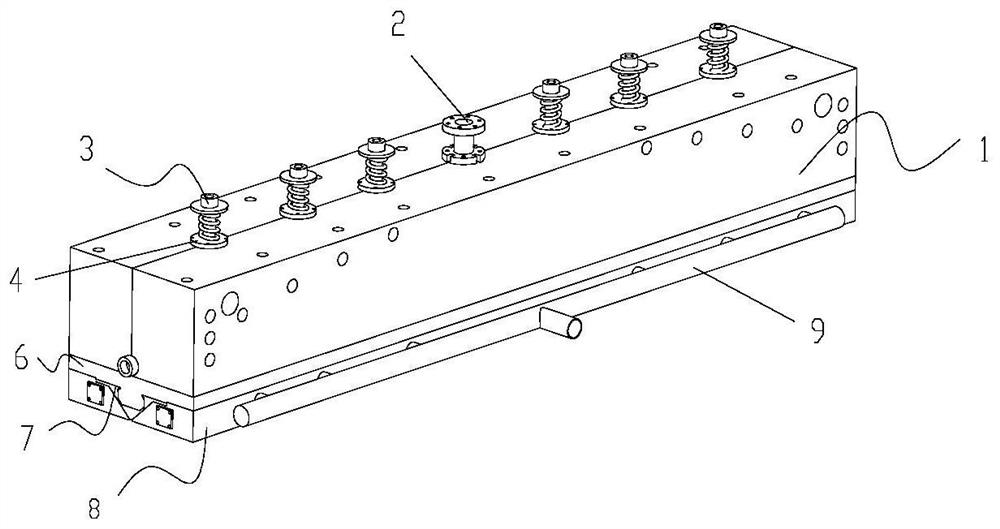

A meltblown mold

The invention discloses a meltblown mold, which includes two upper molds, flanges, cleaning valves, transparent covers, cleaning components, connecting plates, spinnerets, multiple air knife plates, and multiple air pipes; the cleaning components include Sleeve, sealing cover, push rod, multiple connecting rods, hollow cylinder, cleaning head; the first spring is set on the cleaning head; one end of the cleaning head is in contact with the hollow cylinder, and a convex There is no fixed connection between the spinneret, the upper die and the connecting plate of the present invention, which is convenient for the spinneret to be removed and maintained separately, so that the spinneret can be replaced quickly and the downtime is reduced; at the same time, a cleaning component is provided, through which the working , in daily maintenance, you only need to put the sleeve into the meltblown mold and adjust the push rod and cleaning head to quickly clean up the internal residues without disassembling the meltblown mold for separate cleaning. The operation is simple and the maintenance difficulty is reduced. The time required for maintenance or cleaning can prevent the mold from being damaged by repeated manual disassembly and assembly, and reduce maintenance costs.

Owner:肇庆市众通无纺布有限公司

External detachable suspension type membrane bioreactor device with moisturizing function

ActiveCN114275878AReduces the chance of drying outEasy to remove for maintenanceSemi-permeable membranesBiological water/sewage treatmentStructural engineeringMechanical engineering

The invention relates to an external detachable suspension type membrane bioreactor device with a moisturizing function, which comprises a membrane frame and a plurality of membrane columns vertically arranged on the membrane frame along the height direction of the membrane frame, a cavity is formed in each membrane column, a plurality of membrane wires for filtration are arranged in each cavity, a plurality of mounting blocks are uniformly arranged on the outer wall of each membrane column along the circumferential direction, and the mounting blocks are arranged on the outer wall of each membrane column. The mounting block is rotationally provided with a connecting rod, a hanging ring is arranged at one end, far away from the mounting block, of the connecting rod, the membrane frame is provided with a hanging rod, the hanging ring is hooked on the hanging rod, the membrane columns are hung on the membrane frame through the hanging ring, and when a single membrane column needs to be overhauled, the membrane columns are taken down from the membrane frame, so that the probability of mutual interference between the membrane columns is reduced. The device has the function of conveniently overhauling or cleaning the membrane column.

Owner:HANGZHOU KAIJIE MEMBRANE SEPARATION TECH

Safe-to-use heater for diesel oil filter

InactiveCN106382175AEasy to useEasy to remove for maintenanceStorage heatersMachines/enginesEngineeringWater baths

The invention discloses a safe-to-use heater for a diesel oil filter. The safe-to-use heater comprises a ring block, wherein the lower surface of a fixed disc is welded at top of the ring block; a first through hole is formed in the middle of the fixed disc; a fixed cover is arranged at top of the fixed disc; a second through hole is formed in the middle of the fixed cover; the lower surface of the fixed cover is fixedly connected with top of a fixed ring; outer surface of the fixed ring is in threaded connection with the inner surface of the first through hole; and a third through hole is further formed in the fixed disc and is formed in one side of the first through hole. According to the safe-to-use heater for the diesel oil filter, the fixed disc is welded at top of the ring block, the first through hole is formed in the middle of the fixed disc, the diesel oil filter can be inserted in the ring block, a heating component is not in direct contact with diesel oil, the heater is connected onto the diesel oil filter in a sleeving manner, heating in water bath is adopted to enable heating to be more uniform and safer, and the safe-to-use effect is realized.

Owner:JIANGYIN CITY TIANRUN MACHINERY

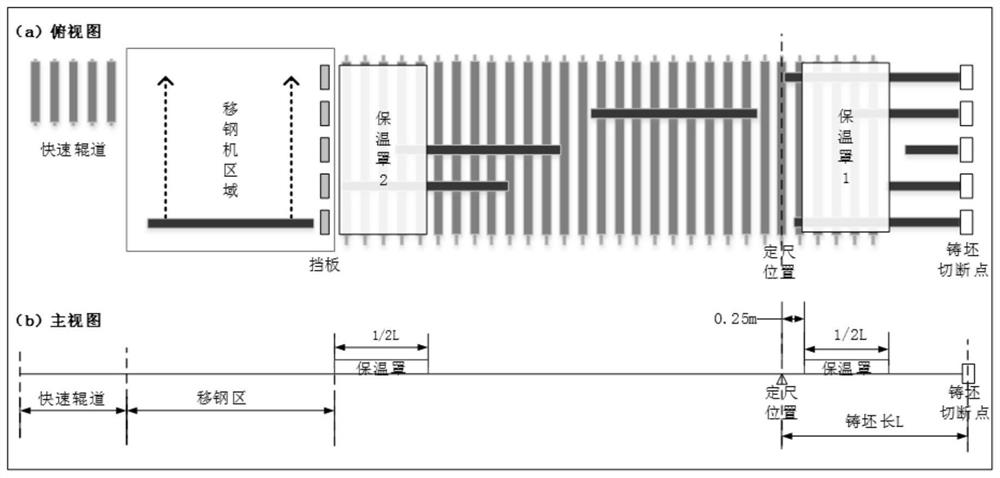

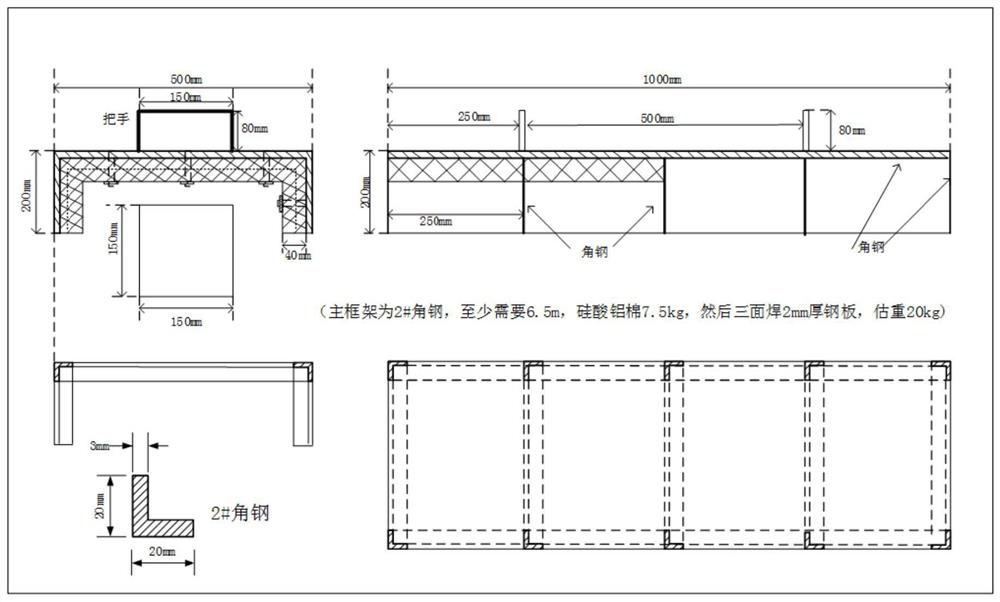

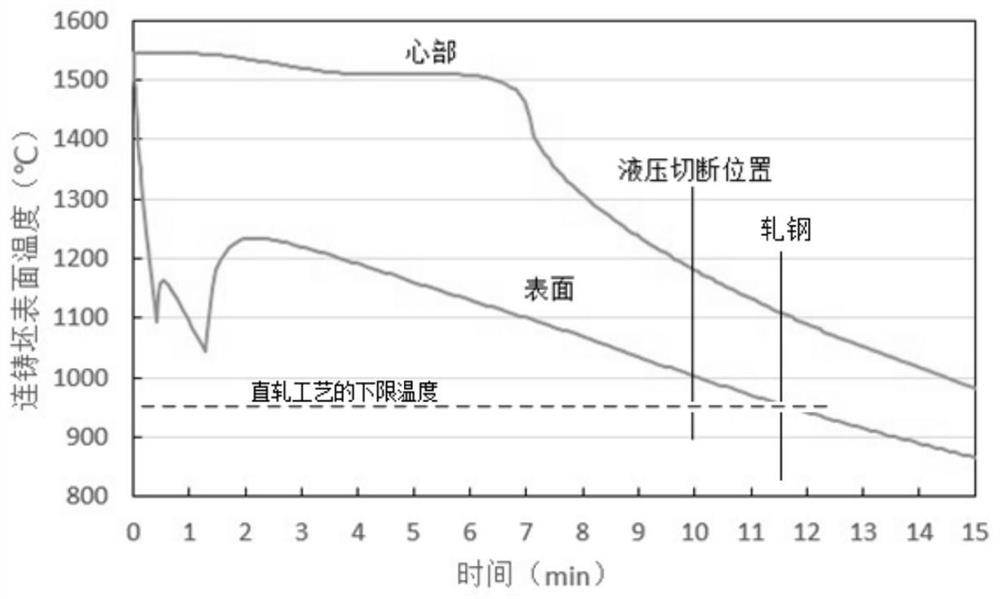

A control method for reducing the temperature difference between the head and the tail of the continuous casting slab in the direct rolling process

ActiveCN109530646BReduce head-to-tail temperature differenceLess investmentFront edgeUltimate tensile strength

The invention discloses a control method for reducing temperature difference between head and tail before continuous casting billet rolling in direct rolling process and belongs to the technical fieldof direct rolling. The control method for reducing temperature difference between head and tail before continuous casting billet rolling in direct rolling process includes the steps that two heat reservation covers are additionally arranged on a conveying roller of each path of a continuous casting machine, wherein one of the heat reservation covers is additionally arranged between the casting blanking cutting position and the sizing position, the length of the heat reservation cover is half of the sizing length of a casting blank, and the start point of the heat reservation cover is 0.25 m to the monitoring point of the sizing head; and the other heat reservation cover is additionally arranged on the conveying roller before the casting blank moves to the steel transfer zone, the length of the heat revervation cover is half of the sizing length of the casting blank, and the start point of the heat revervation cover is at the front edge of the steel transfer zone. Before each path of the casting blank moves to the steel transfer zone for combination, the casting blank needs to hold heat on the continuous casting conveying roller for 0.5-1.5 minutes, and the time of heat holding canbe technically adjusted according to pulling speed of the continuous casting machine. The advantages of the control method for reducing temperature difference between head and tail before continuouscasting billet rolling in direct rolling process are that an effect of reducing casting bank temperature difference between the head and the tail is achieved, and less investment and quick results areachived. The control method for reducing temperature difference between head and tail before continuous casting billet rolling in direct rolling process meets strength requirement and is light in weight and convenient for on-site workers to remove for examination, repair and maintenance at any time.

Owner:CENT IRON & STEEL RES INST

A working face air regulating device for underground excavation

ActiveCN113323707BEasy to remove for maintenanceEasy maintenanceMining devicesTunnel/mines ventillationArchitectural engineeringMechanical engineering

Owner:东营高航技术有限公司

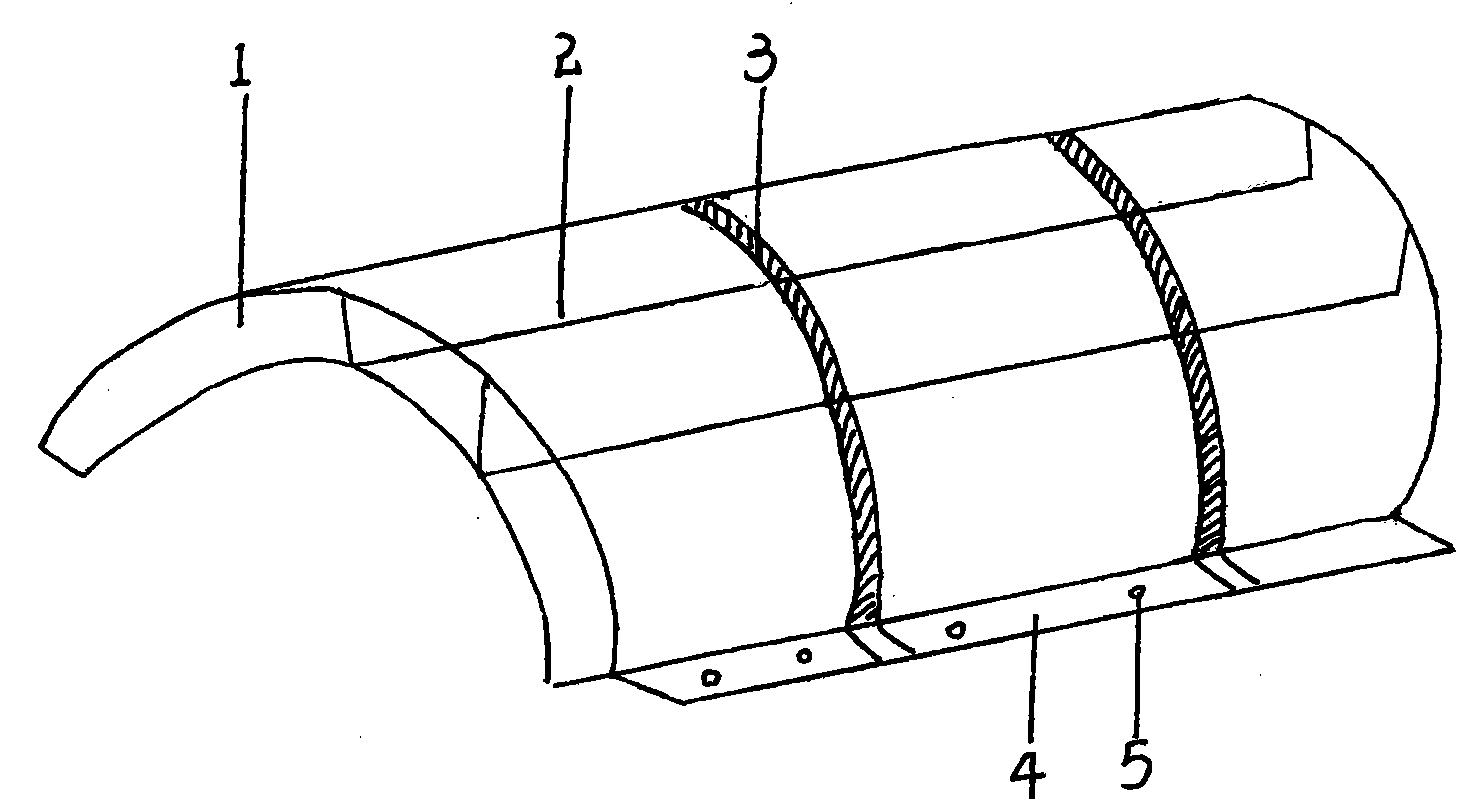

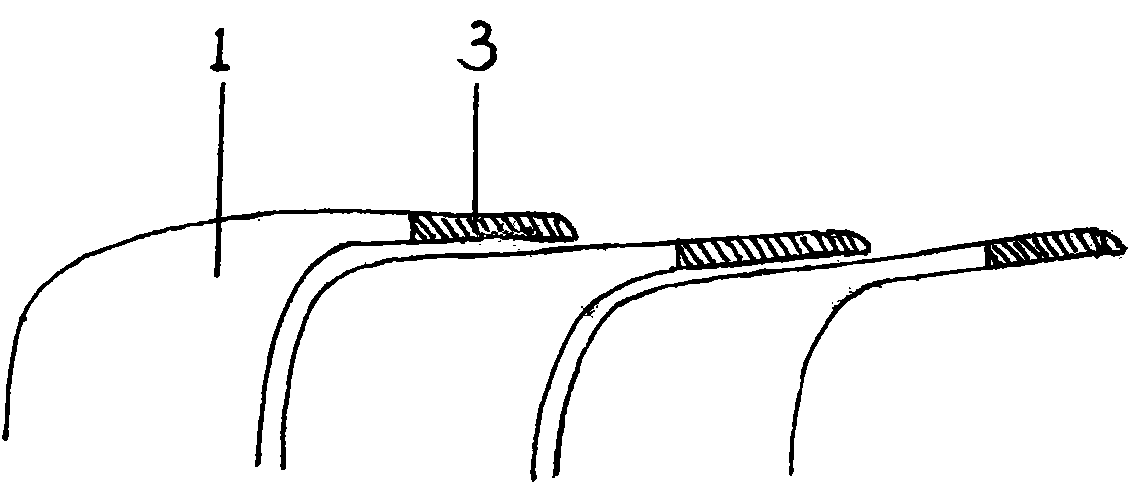

Combined air-inflation arched greenhouse

InactiveCN103548622AEnhanced protective measuresEasy to remove for maintenanceClimate change adaptationGreenhouse cultivationEngineeringGreenhouse

The invention discloses a combined air-inflation arched greenhouse which comprises 1-10 air-inflation layers, a supporting frame, pressing parts, a connecting bar and fixing bolts. The air-inflation layers are supported by the supporting frame under the air-inflation layers, the fixing bolts are arranged at two tail ends of each air-inflation layer and fixed on the connecting bar, the pressing parts are arranged on the air-inflation layers, and the air-inflation layers are sequentially buckled through the pressing parts. A plurality of air-inflation layers are overlapped and buckled, and combined lengthening of the air-inflation layers is achieved. In addition, due to the fact that the pressing parts are added, protective heat-preservation measures are strengthened, the number of the air-inflation layers is multiple, dismounting and maintenance of individual air-inflation layers are facilitated, and the service life of the air-inflation layers is prolonged.

Owner:SHUOZHOU DEV ZONE QIYUAN AGRI TECH

Rotary six-nozzle jet flow linear spray head

PendingCN113560055ATurn fasterEasy to remove for maintenanceMovable spraying apparatusRotational axisHigh pressure water

The invention discloses a rotary six-nozzle jet flow linear spray head. The rotary six-nozzle jet flow linear spray head comprises a shell, a water inlet, a water spraying spray head, a bearing and a rotating shaft, wherein a thread is installed on the outer side face of the lower portion of the water inlet. According to the rotary six-nozzle jet flow linear spray head, the water inlet communicates with an external water pipe, the internal structure of the rotary six-nozzle jet flow linear spray head is protected through the shell, and meanwhile the rotating position of the rotating shaft is limited; cleaning water is conveyed to the water spraying spray head through the rotating shaft, and high-pressure water used for cleaning is sprayed out through the water spraying spray head; the water spraying spray head connected through the thread is convenient to take down for maintenance or replacement; the inner wall of a cleaning disc of a wall-climbing robot can be self-cleaned through openings in the two ends of an X-shaped pipeline; the left end and the right end of the X-shaped pipeline can be rapidly opened or closed through sealing screws; the high-pressure water is sprayed out through a straight spray opening, a guide spray opening and an oblique spray opening; striking rust removal is conducted through the straight spray opening; the water spraying spray head is driven to rotate through the guide spray opening; and auxiliary rotating and oblique cleaning are conducted through the oblique spray opening.

Owner:浙江澎湃智能装备有限公司

A heater for safe diesel oil filter

InactiveCN106382175BEasy to useEasy to remove for maintenanceStorage heatersMachines/enginesWater bathsEngineering

The invention discloses a safe-to-use heater for a diesel oil filter. The safe-to-use heater comprises a ring block, wherein the lower surface of a fixed disc is welded at top of the ring block; a first through hole is formed in the middle of the fixed disc; a fixed cover is arranged at top of the fixed disc; a second through hole is formed in the middle of the fixed cover; the lower surface of the fixed cover is fixedly connected with top of a fixed ring; outer surface of the fixed ring is in threaded connection with the inner surface of the first through hole; and a third through hole is further formed in the fixed disc and is formed in one side of the first through hole. According to the safe-to-use heater for the diesel oil filter, the fixed disc is welded at top of the ring block, the first through hole is formed in the middle of the fixed disc, the diesel oil filter can be inserted in the ring block, a heating component is not in direct contact with diesel oil, the heater is connected onto the diesel oil filter in a sleeving manner, heating in water bath is adopted to enable heating to be more uniform and safer, and the safe-to-use effect is realized.

Owner:JIANGYIN CITY TIANRUN MACHINERY

Feeding and unloading device for anti-jump bottle cap molding machine

ActiveCN104339514BDon't let damageReduce manufacturing costDomestic articlesMolding machineHeat sink

The invention discloses a feeding and discharging device of a bottle cover moulding press for preventing bottom covers from jumping. A suction channel for preventing bottom covers from jumping is moulded on a feeding disc, a suction hole for preventing bottom covers from jumping is formed in the suction channel and positioned below a center of circle of a bottle cover discharging semicircular notch, a second suction nozzle is moulded on a ventilating block and communicated and connected with the suction channel for preventing bottom covers from jumping; a blowing pipe bracket is fixedly arranged on a cover feeding disc rotating shaft bracket, an S-shaped blowing pipe is fixedly arranged on the blowing pipe bracket, a small blowing hole is moulded in the lower part of the blowing pipe and faces towards suction holes for preventing bottom covers from jumping; a blowing nozzle is moulded on the ventilating block, and communicated and connected with the suction channel; a heat-radiating sheet is fixedly arranged at the lower part of the feeding disc. According to the feeding and discharging device, demoulded bottle covers can be kept on correct positions without being damaged; sizing materials are cooled by adopting a heat-radiating disc, thus the production cost is saved; the sizing materials all accurately fall in a lower mould of the bottle cover moulding press, and a scraping nozzle is assembled, disassembled and maintained very conveniently at the same time.

Owner:SHAOXING HUANGGUAN MACHINERY

Building construction crane

InactiveCN113443568APrevent disengagementPrevent prolapseBase supporting structuresBraking devices for hoisting equipmentsArchitectural engineeringSteel rope

The invention relates to the technical field of craning machinery, and specifically relates to a building construction crane. The building construction crane comprises a base, wherein a traction structure is installed on the base; a telescopic structure is arranged in the traction structure; a hoisting structure is arranged at the end part of the traction structure; the hoisting structure is connected with a hanger structure; a winding structure is arranged between the hanger structure and the hoisting structure; a counterweight structure is arranged in the base; and a locating structure is arranged between the counterweight structure and the base. An object can be dragged and lifted through the traction structure, a cable is prevented from being separated, the lifted object can be conveniently taken down through the telescopic structure, a clamping distance can be adjusted as needed through the hoisting structure, scattered plates can be conveniently bound and fixed through the hanger structure, and the stability in the lifting process is ensured; and the releasing length of a steel rope can be controlled through the winding structure, arrangement for a counterweight can be properly adjusted through the counterweight structure, fixing for the position of the counterweight can be ensured through the locating structure, and the stability is ensured.

Owner:余北京

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com