Rotary six-nozzle jet flow linear spray head

A rotary, spray-head technology, applied in the field of wall-climbing robots, can solve the problem that stains cannot be effectively removed, and achieve the effect of preventing too fast rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

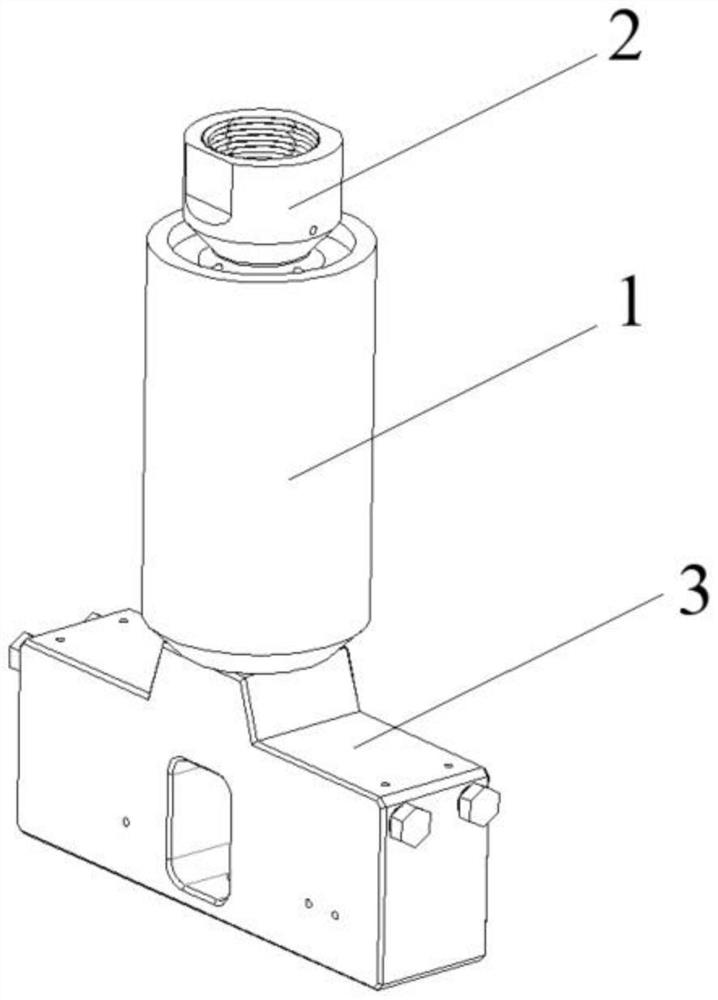

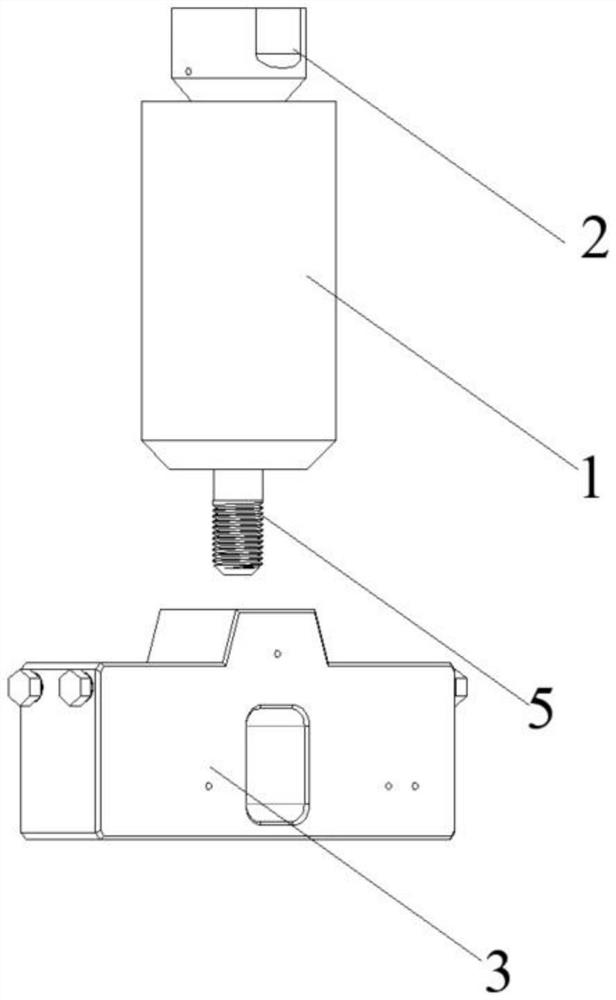

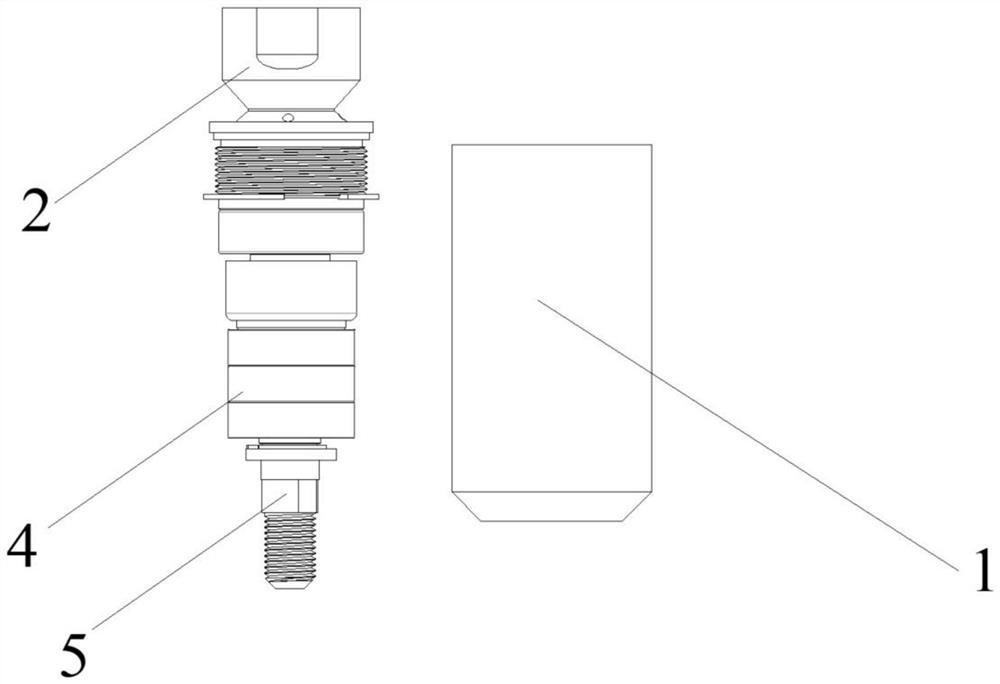

[0021] Such as Figure 1 to Figure 7 As shown, the present invention discloses a rotary 6-nozzle jet in-line sprinkler head. The technical solution adopted is to include a casing 1, a water inlet 2, a sprinkler head 3, a bearing 4 and a rotating shaft 5; the lower part of the water inlet 2 Threads are installed on the outer surface; the inside of the rotating shaft 5 is hollow, the upper end of the rotating shaft 5 is rotated and installed in the lower part of the water inlet 2, and the inside of the rotating shaft 5 communicates with the water inlet 2, External threads are installed on the lower end of the rotating shaft 5; the casing 1 is a cylindrical structure with upper and lower openings, the upper end of the casing 1 is screwed on the lower part of the water inlet 2 through internal threads, and the rotating shaft 5 passes through the bearing 4 Rotationally installed in the casing 1, the external thread at the lower end of the rotating shaft 5 is located below the casin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com