Infrared burner of domestic gas stove

A technology for infrared burners and gas stoves, which is applied in the directions of gas fuel burners, burners, household stoves/stoves, etc., can solve the problems of affecting the service life of the burners, troublesome installation and maintenance, and deformation of the stove body, and achieves a simple structure. , The effect of easy assembly and disassembly, preventing deformation and air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

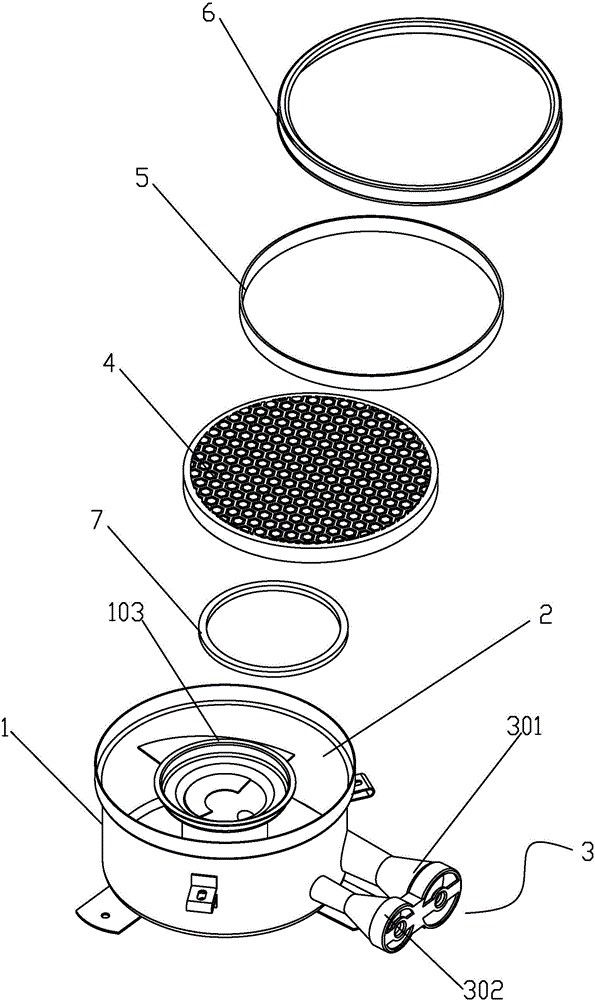

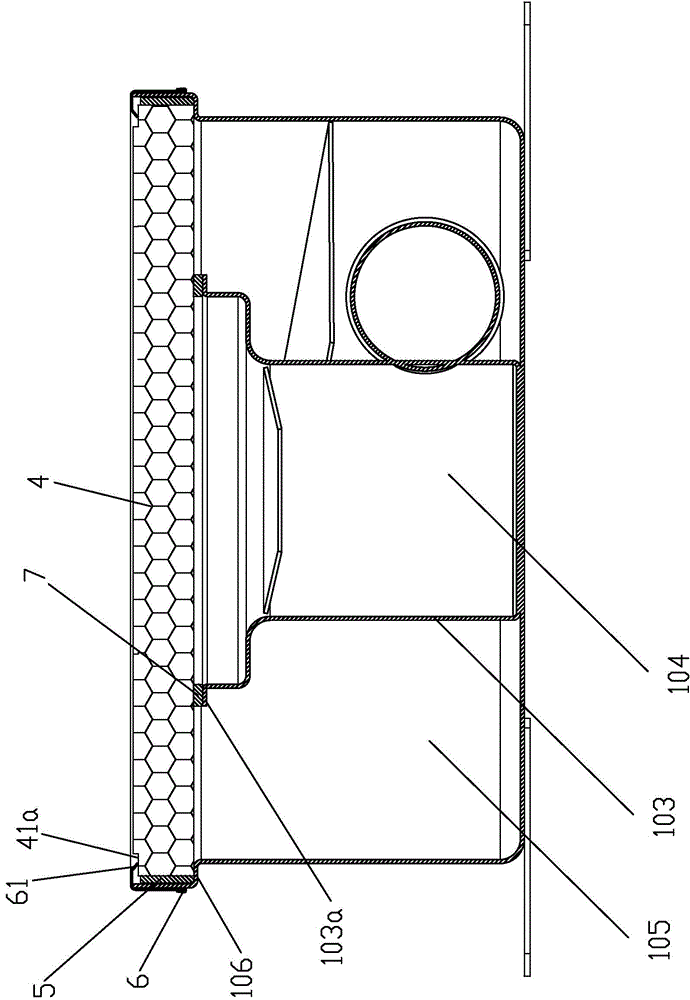

[0021] Embodiment 1: as Figure 1 to Figure 2 As shown, a kind of infrared burner of domestic gas cooker comprises furnace body 1, and described furnace body 1 is provided with furnace 2 and the injection pipe 3 that communicates with described furnace 2, and above described furnace 2 is equipped with The honeycomb structure ceramic burning disc 4 connected to the furnace body 1 is provided with a heat insulating sealing ring 5 between the periphery of the ceramic burning disc 4 and the inner wall of the furnace body 1 . The heat insulation sealing ring 5 with heat insulation and sealing function is adopted, so that the temperature at the upper end of the furnace body 1 will not be too high, and the furnace body 1 will not be deformed or leak. During the transportation of the product, since the heat insulation sealing ring 5 plays a role of shock absorption, the damage of the ceramic combustion disc 4 during transportation is avoided.

[0022] The upper inner wall of the furn...

Embodiment 2

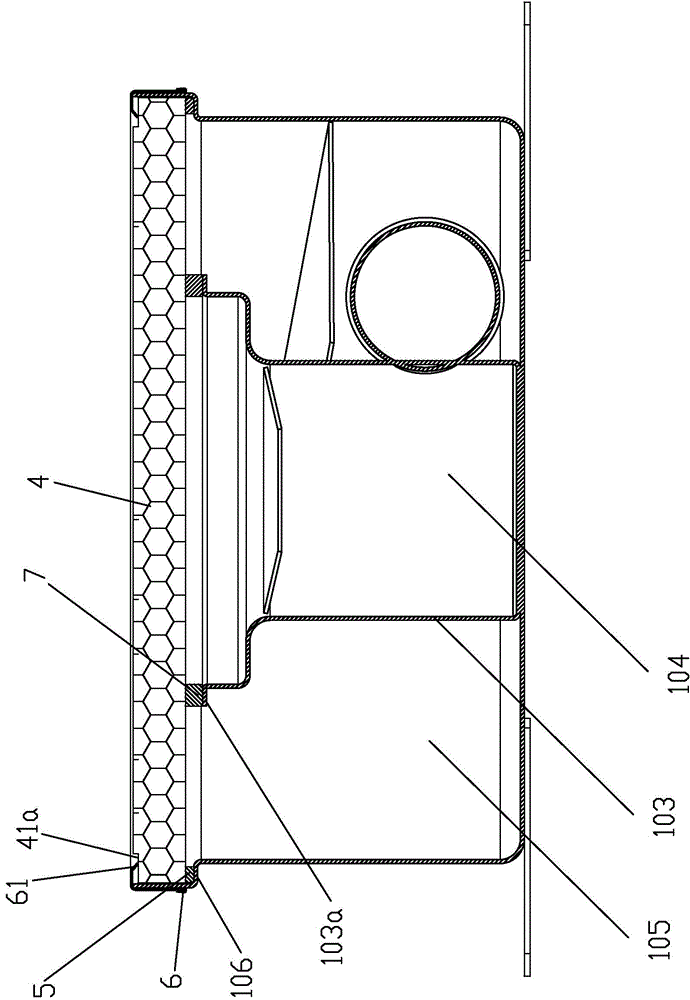

[0027] Example 2: image 3 As shown, the difference from Embodiment 1 is that the heat-insulating sealing ring 5 is installed between the annular step 106 and the bottom surface of the ceramic combustion disk 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com