Truss-type automatic punch used for pipe racks

A drilling machine and rowing frame technology, applied to portable drilling rigs, drilling/drilling equipment, workbenches, etc., can solve the problems of laborious maintenance, etc., and achieve the effect of easy climbing, easy removal and maintenance, and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

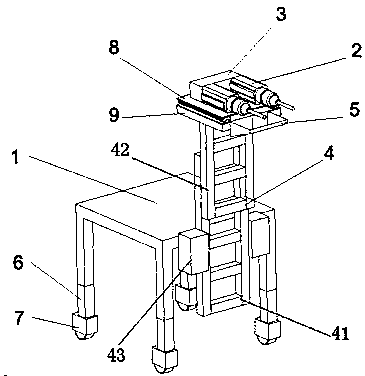

[0023] like figure 1 As shown, the rack-type automatic drilling machine for the pipe gallery includes a support platform 1, a vertical lifting ladder 4, a fixed plate 9, a propulsion device 8, a spacing adjustment device 3 and two electric drills 2.

[0024] The two electric drills 2 are arranged on the distance adjusting device 3, and the distance adjusting device 3 adjusts the distance between the two electric drills 2. The distance adjusting device 3 is arranged on the propulsion device 8, and the propulsion device 8 is used to push the two electric drills 2 forward or backward, and the propulsion device 8 is arranged on the top surface of the fixed plate 9, the bottom surface of the fixed p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com