A control method for reducing the temperature difference between the head and the tail of the continuous casting slab in the direct rolling process

A control method and continuous casting billet technology, applied in the field of direct rolling, can solve the problems of reducing the temperature difference between the head and tail of the direct rolling continuous casting billet, and achieve the advantages of convenient unloading, inspection and maintenance, convenient production and maintenance, and reducing the temperature difference between the head and the tail. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

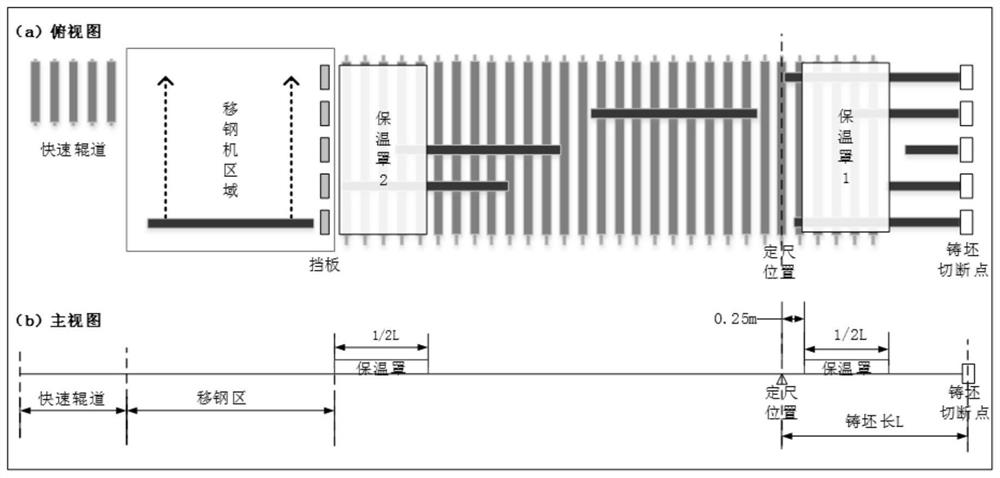

[0033] A long section production enterprise adopts the short-flow direct rolling process of electric furnace to produce HRB400 steel bars. The continuous casting slab size is 150mm×150mm, the length is 6m, the casting speed is 2.4m / min, and the mold water volume is 170m 3 / h, the casting temperature is 1530°C, and the size specification of the product is The chemical composition is shown in Table 1.

[0034] Table 1 Chemical composition of HRB400 steel bars in a factory (the balance is Fe)

[0035] Element C Si mn P S Nb V content 0.23 0.45 0.85 ≤0.04 ≤0.03 ≤0.01 0.04

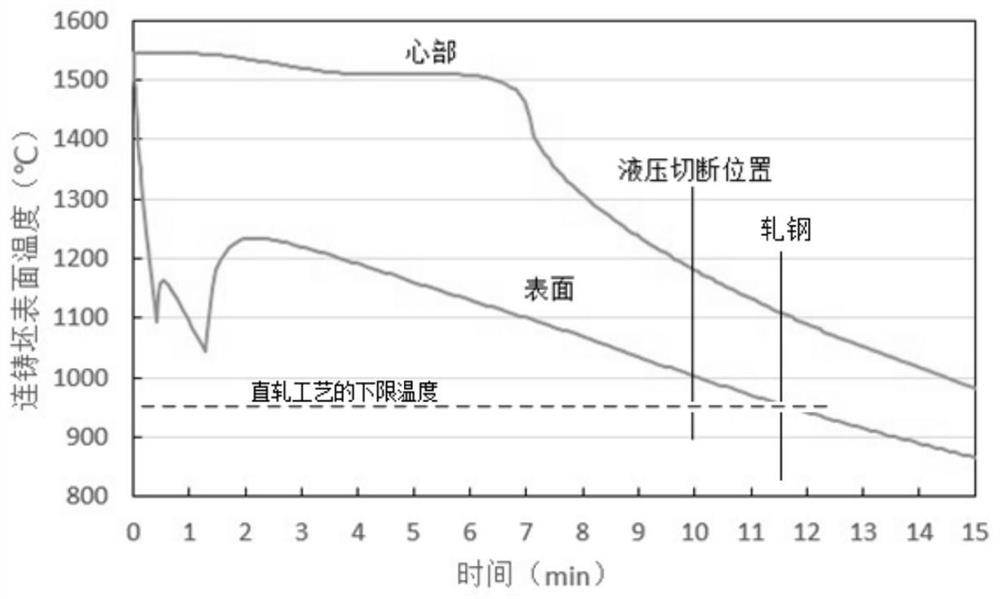

[0036] When the invention is not adopted to control the uniform temperature process, the temperature of the upper surface of the head when the slab is cut is 955°C, and the upper surface of the tail is 1035°C, and the temperature difference between the head and the tail is 80°C. After the continuous casting slab passes through the parallel flow, it enters the fast conveyin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com