Method for controlling overall-length temperature uniformity of discharged plate blank of vehicle bottom type heating furnace

A control method and technology for releasing slabs, applied in temperature control and other directions, can solve problems such as affecting temperature measurement accuracy, reducing production efficiency, splashing iron oxide scale, etc., achieving broad technology promotion prospects, improving heating quality, and reducing head-to-tail temperature differences. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

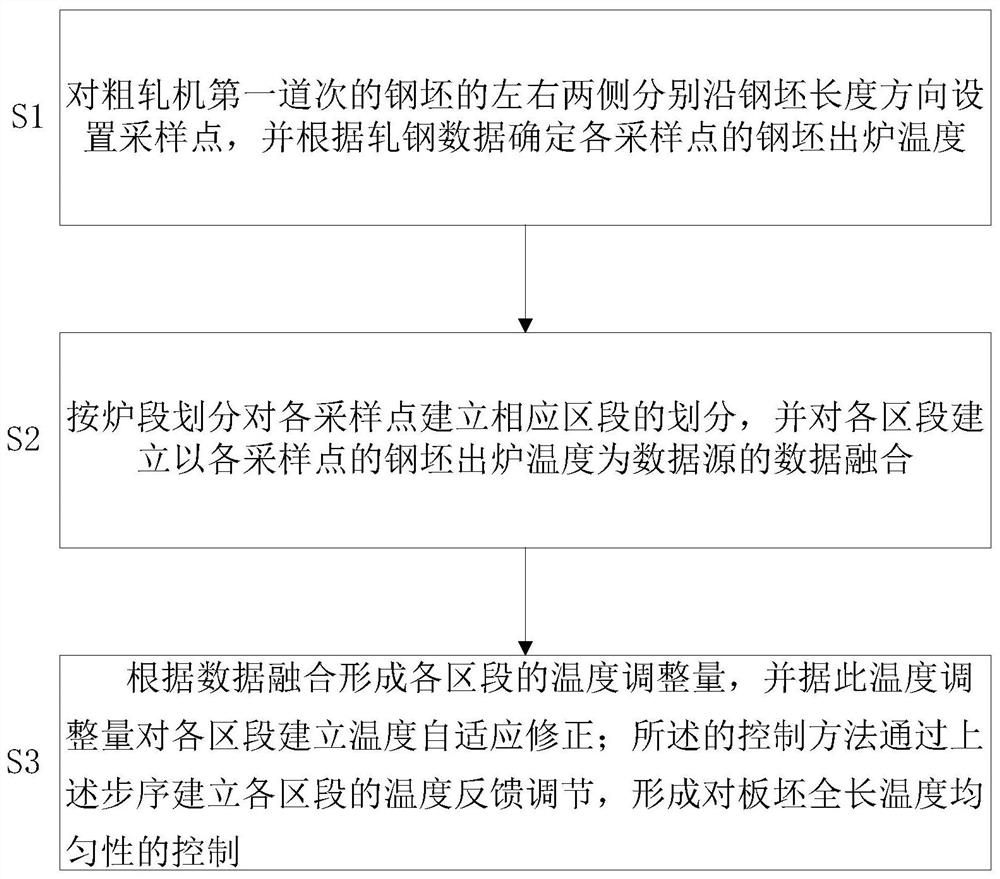

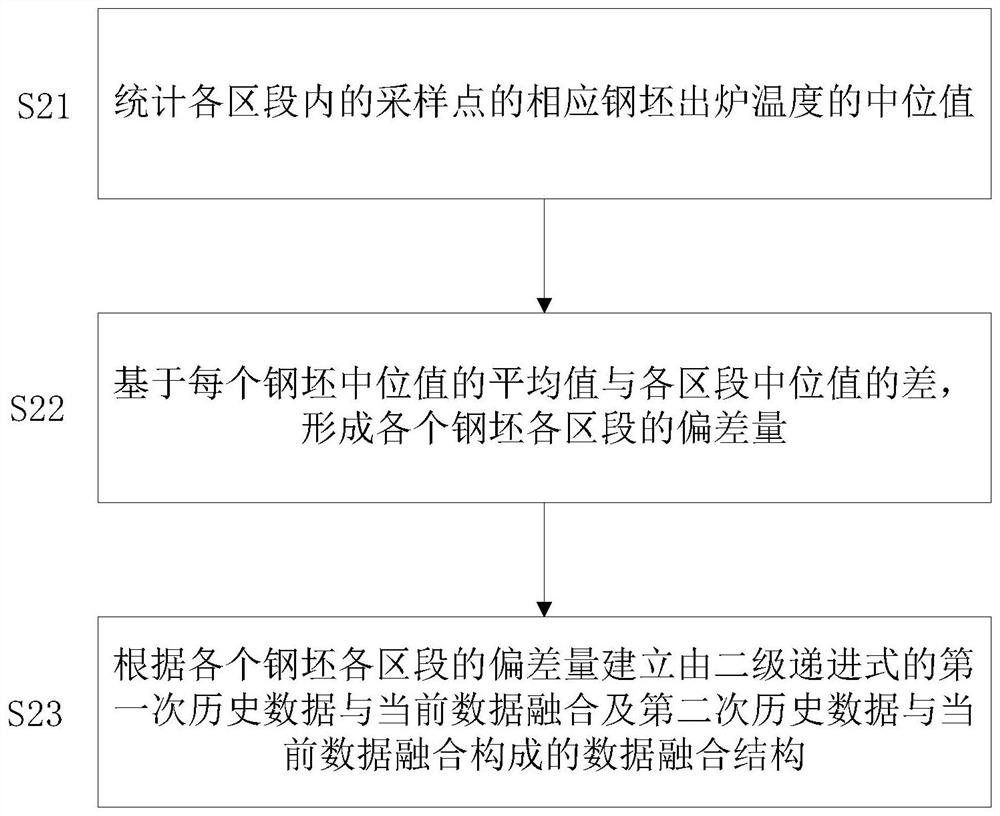

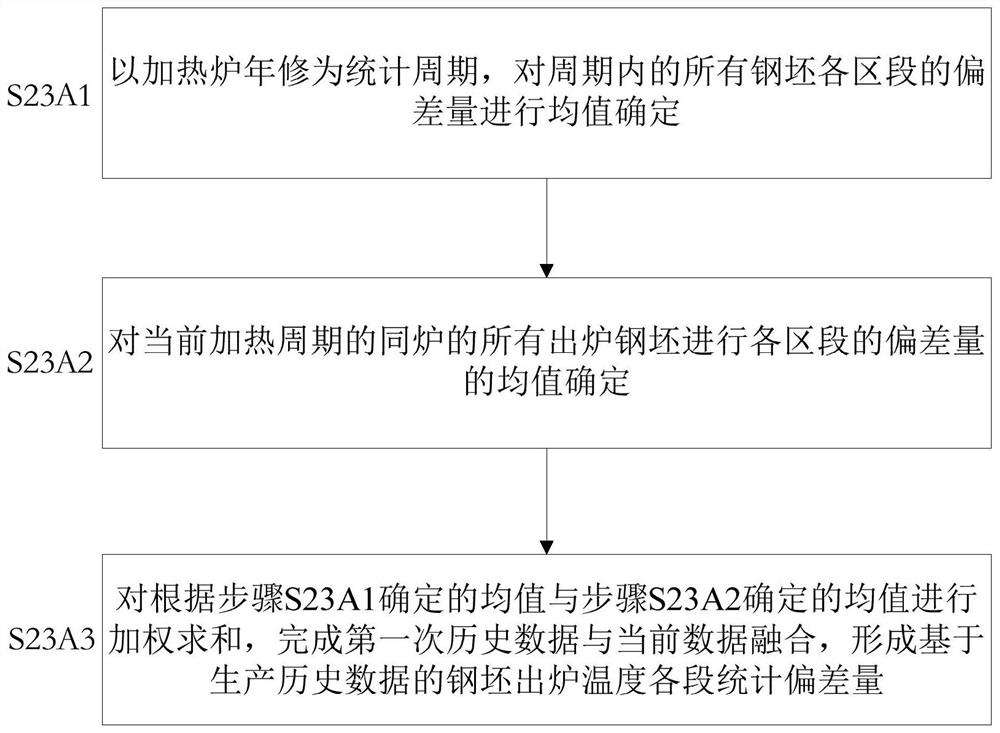

Method used

Image

Examples

Embodiment

[0201] For a plate production line with one car-bottom heating furnace, the billet heating curve number is "HP303".

[0202] The car hearth furnace is transformed into two sections from left to right, namely the left section and the right section. The left section corresponds to the tail to the middle in the length direction of the steel plate, and the right section corresponds to the middle to the head in the length direction of the steel plate.

[0203] Added temperature observer module and corresponding database in rolling mill L2 computer.

[0204] When the slab is released from the furnace, the MES system sends some information to the newly added module, including the position number of the slab in the car hearth furnace layoutNo=“L1”, the heating curve number of the slab in the car hearth furnace heatNo=“HP303”, etc. .

[0205] After the steel plate is rolled in the roughing mill, the rolling line L2 sends the rolling process information of multiple sampling points to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com