Resin grinding wheel forming machine with compact structure

A resin grinding wheel with a compact structure, applied in metal processing equipment, grinding devices, grinding/polishing equipment, etc., can solve the problems of loose structure of resin grinding wheel molding machine, affecting the production quality of resin grinding wheel, poor position accuracy, etc. Easy to remove, repair, replace and install, make full and rational use of space, and have good location accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

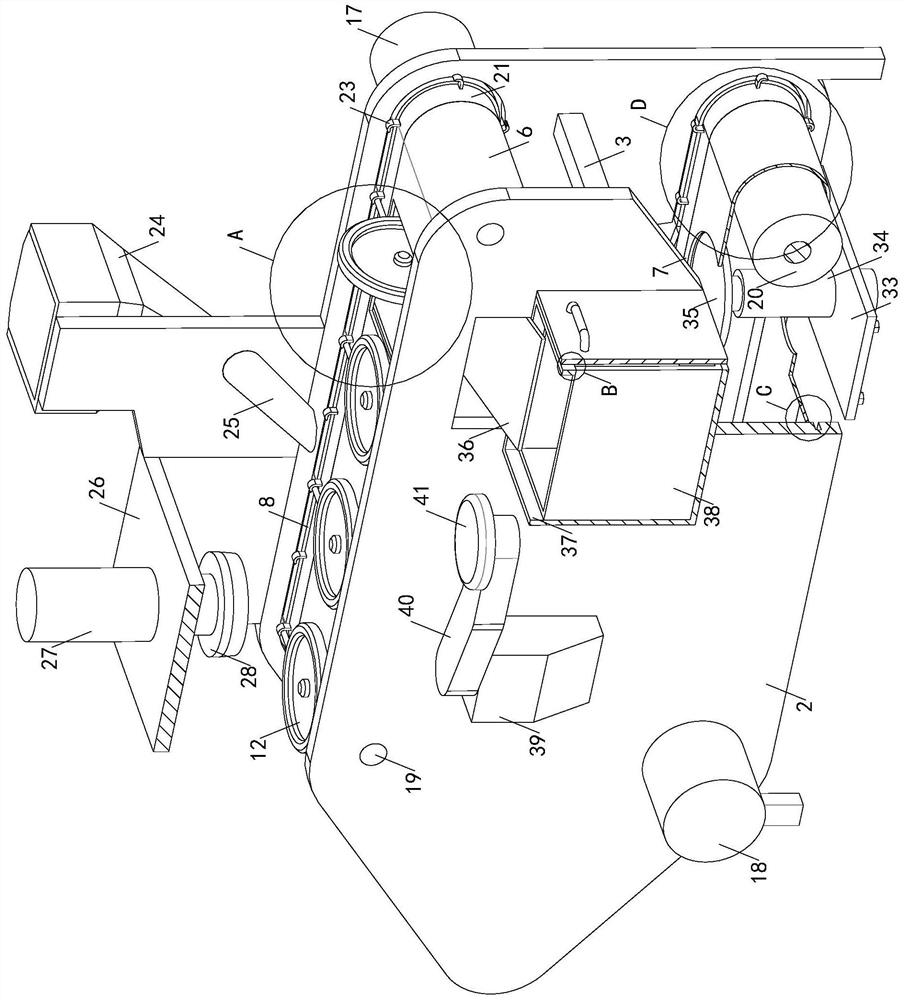

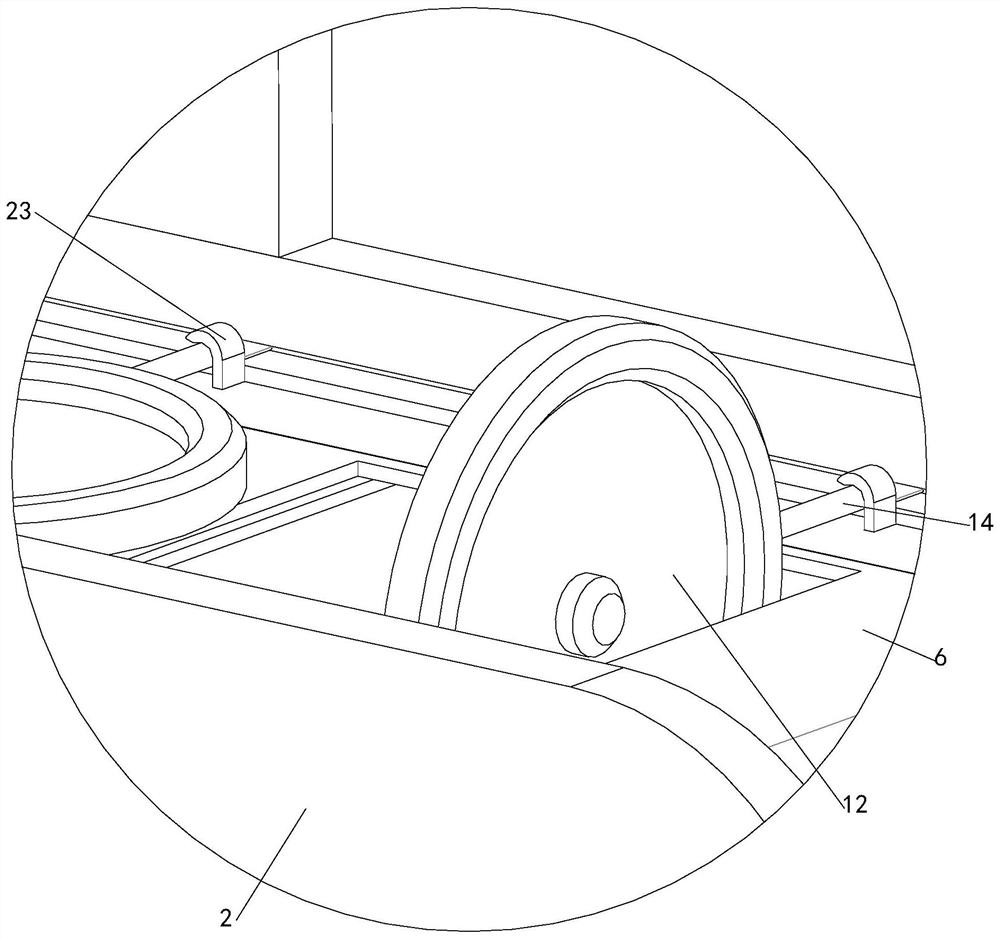

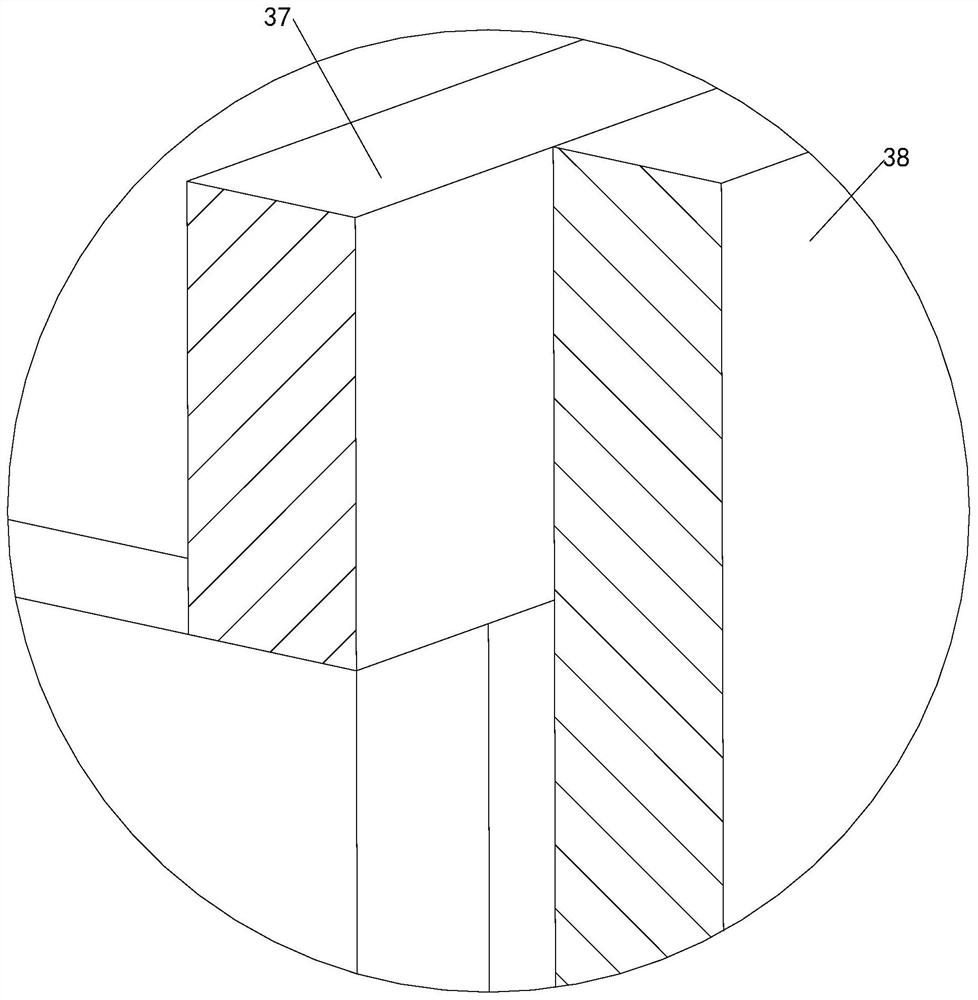

[0035] see Figure 1-9, a resin grinding wheel molding machine with compact structure, including an electromagnetic on-off valve 1, and two mounting plates 2, which are fixedly connected by a plurality of connecting rods 3, which can make full use of the space and make the structure compact The functional components of the resin grinding wheel molding machine are installed to make the overall layout more compact, which can make full and reasonable use of space, occupy a small area, and have a more beautiful appearance. The two mounting plates 2 are fixedly connected with multiple upward inclined support rods. 4 and a plurality of oblique support rods 5, a plurality of oblique support rods 4 are fixedly connected with an upper auxiliary cover 6, a plurality of oblique support rods 5 are fixedly connected with a lower auxiliary cover 7, and the upper auxiliary cover 6 is provided with a square It is more practical to assist the demoulding and unloading of the resin grinding whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com