A meltblown mold

A mold and melt blown technology, applied in spinneret assemblies, textiles and papermaking, etc., can solve the problems of complex disassembly process, affecting the production process, difficult disassembly, etc., to achieve simple operation, reduce maintenance cost, and prevent damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

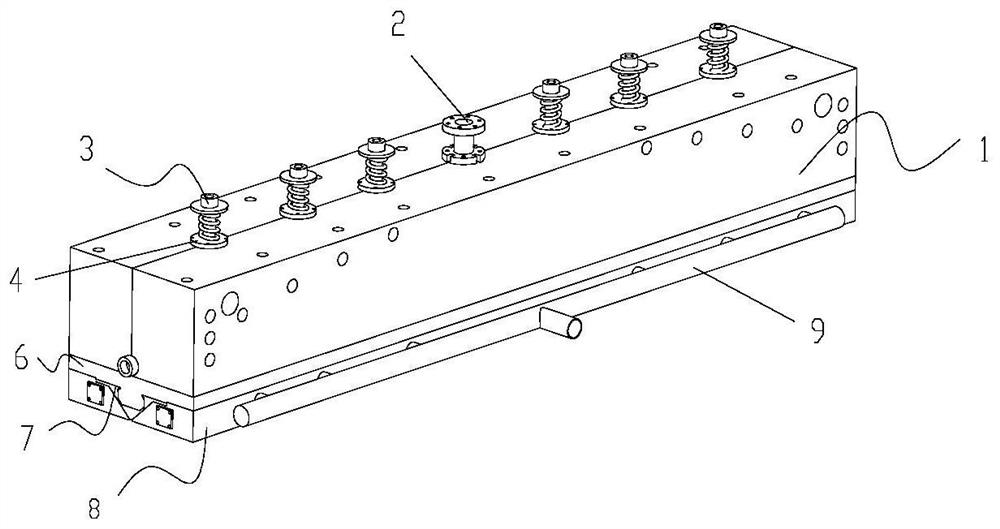

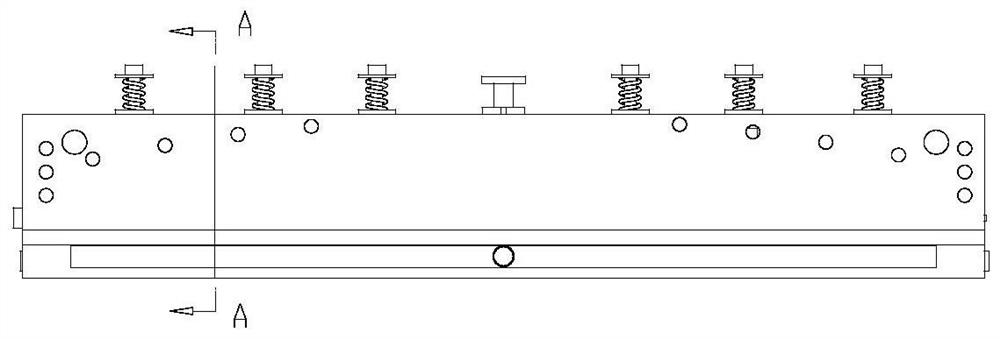

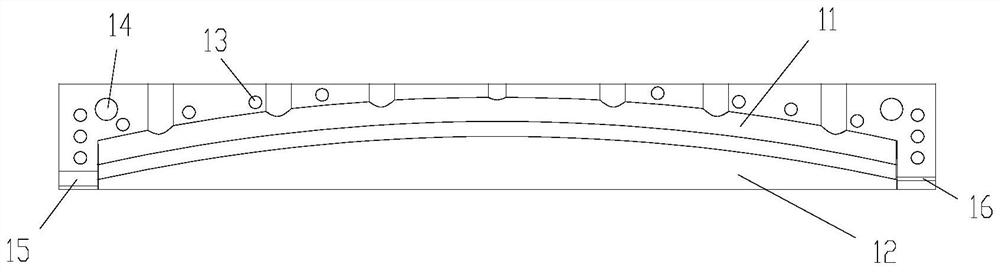

[0024] Such as Figure 1-14 As shown, a melt-blown mold includes two identical upper molds 1 symmetrically arranged, a flange 2 fixed on the upper mold, a cleaning valve 3 for cleaning the interior of the melt-blown mold, and a penetrating valve for supporting the cleaning valve. Cover 4, cleaning assembly 5 detachably inserted into the upper mold, connecting plate 6 located under the upper mold, spinneret 7, multiple air knife plates 8 located on both sides of the spinneret, and air knife plates for A plurality of air pipes 9 for inputting air flow; the cleaning assembly 5 includes a sleeve 51, a sealing cover 52 arranged at one end of the sleeve, a push rod 53 inserted in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com