Multi-station brush-making rotating platform

A technology of rotating platform and station system, which is applied in the direction of brushes, brush bodies, household appliances, etc., can solve the problems of strong dependence on cheap labor, low degree of automation of equipment, and increase of labor capital, so as to reduce clamping and unloading The effect of reducing the number of times, reducing costs, and reducing production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

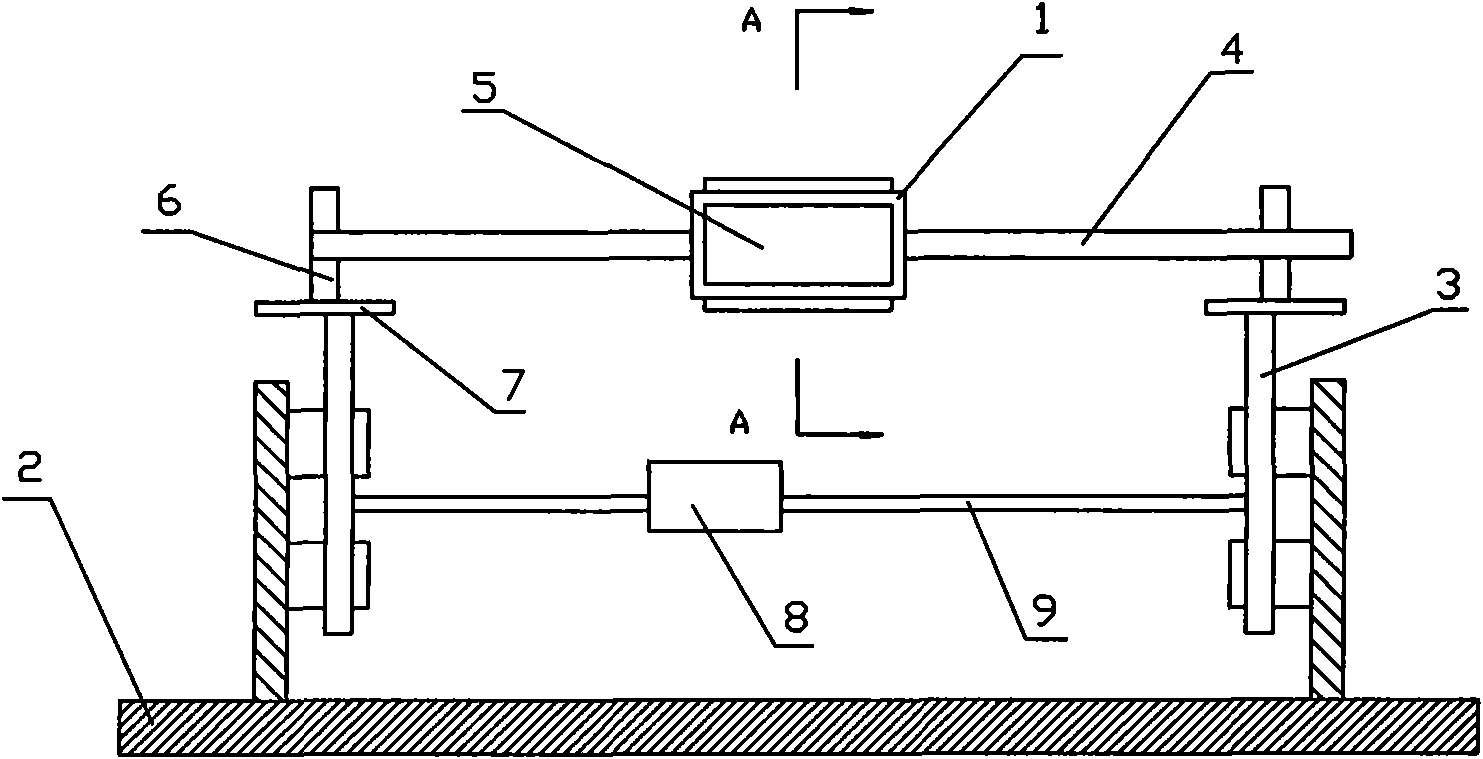

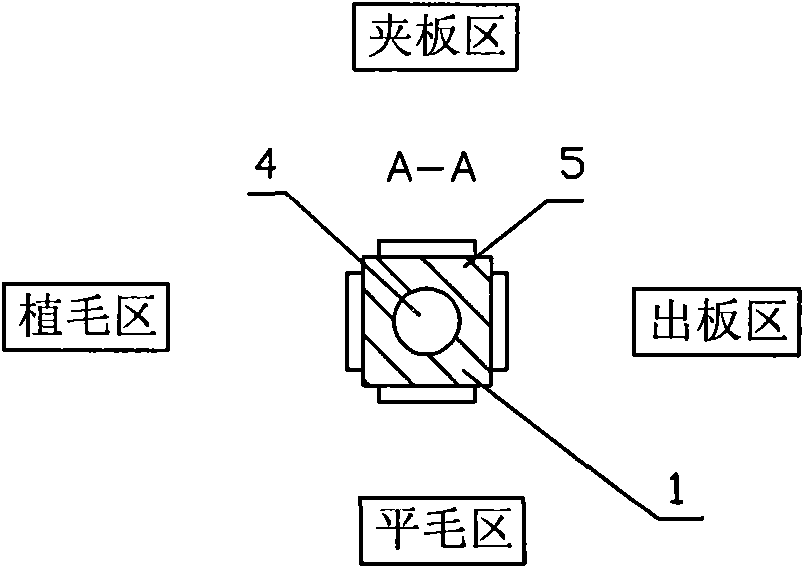

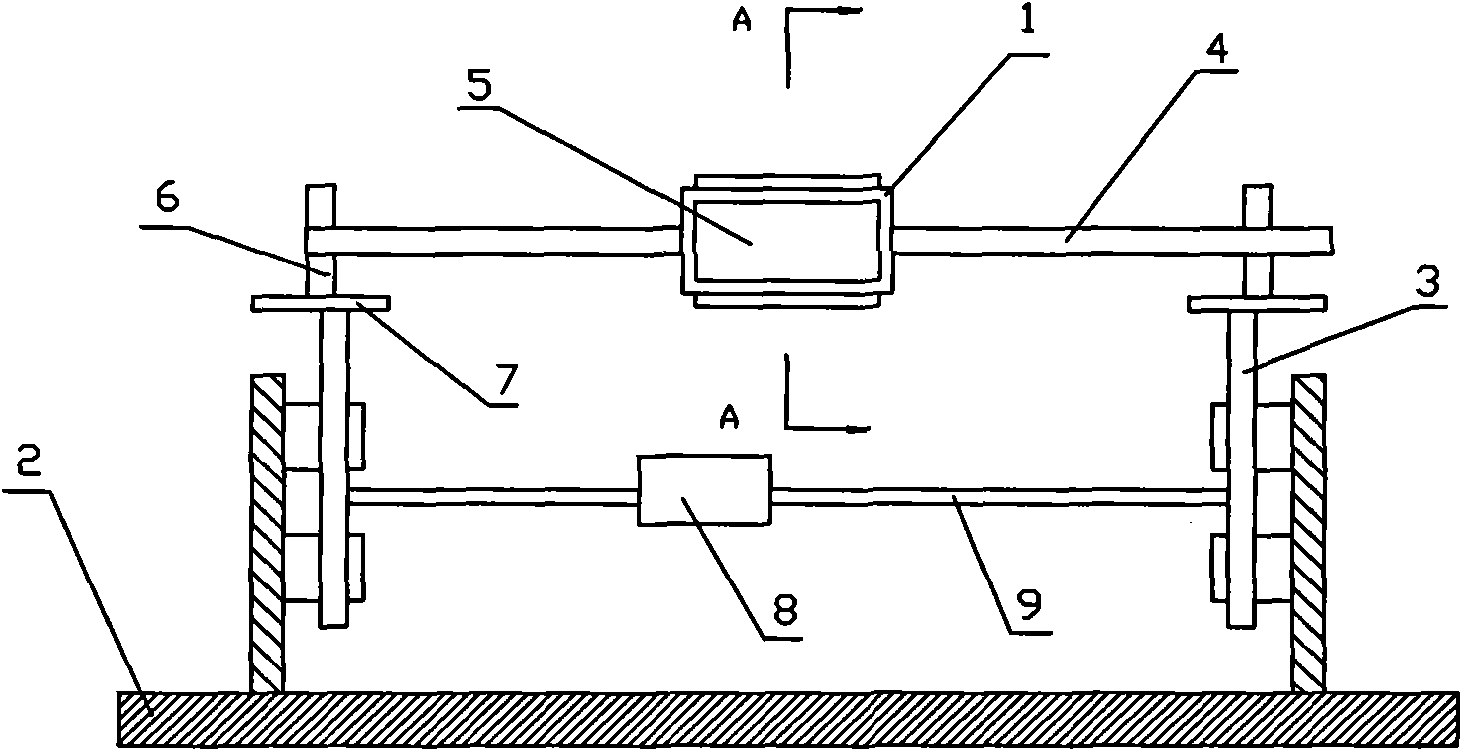

[0011] A multi-station brush-making rotary platform, including a rotary platform 1, a bottom plate 2, a lifting rod 3, a rotary shaft 4, a clamp 5, a bracket 6, a connecting plate 7, and a connecting rod 9. The longitudinal section of the rotary platform 1 is a square, Each side of the square section is provided with a fixture 5, and the rotary platform 1 has four stations, which are respectively upper, left, lower and right four stations, wherein the upper station is the plywood area, and the left station is the The hair planting area, the lower station is the flat wool area, and the right station is the plate output area. The rotating shaft 4 traverses through the center of the square section and is installed on the bracket 6. The bracket 6 is connected with the lifting rod 3 through the connecting plate 7. The rotating platform 1 can move left and right, and can move up and down with the lifting rod 3, clamp a brush plate on the fixture 5 of the upper station, turn on the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com