Vacuum chuck for processing of aeronautical laminas

A technology of vacuum suction cups and thin plates, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of difficult control of processing accuracy and processing efficiency, and achieve the effect of small deformation, small deformation and high versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] From the perspective of fixtures, it can effectively reduce clamping deformation, avoid chattering of parts during processing, and ensure the machining accuracy and surface quality of workpieces; and one fixture can clamp multiple products, greatly reducing manufacturing costs.

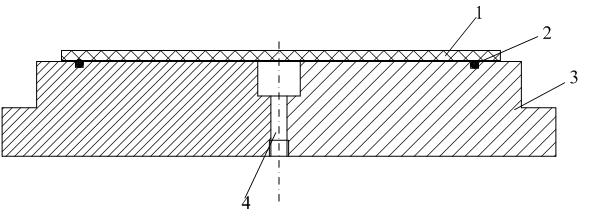

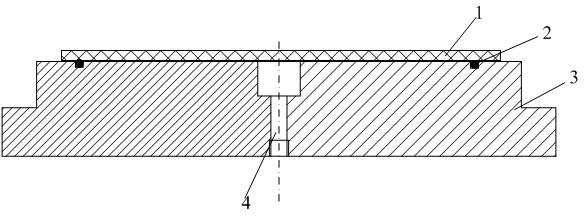

[0013] Such as figure 1 As shown, the vacuum chuck for aviation thin plate processing includes a fixture body 3 and a sealing strip 2. The upper surface of the fixture body 3 is provided with grooves at equal intervals, and the sealing strip 2 is embedded in the groove, which can be processed according to the product 1. The shape embeds the corresponding sealing strip in the groove, and the central part of the fixture body 3 is opened with a through air hole 4 in the axial direction, and the bottom end of the air hole 4 is connected to the compressed air machine through the air pipe.

[0014] In specific application, the processed product 1 is placed on the sealing strip, the compressed air mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com