Patents

Literature

340results about How to "Automatic replacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Battery charging and replacing station for electric vehicles

ActiveCN102064578AAutomatic replacementWith charging monitoringBatteries circuit arrangementsElectric powerBattery chargeElectrical battery

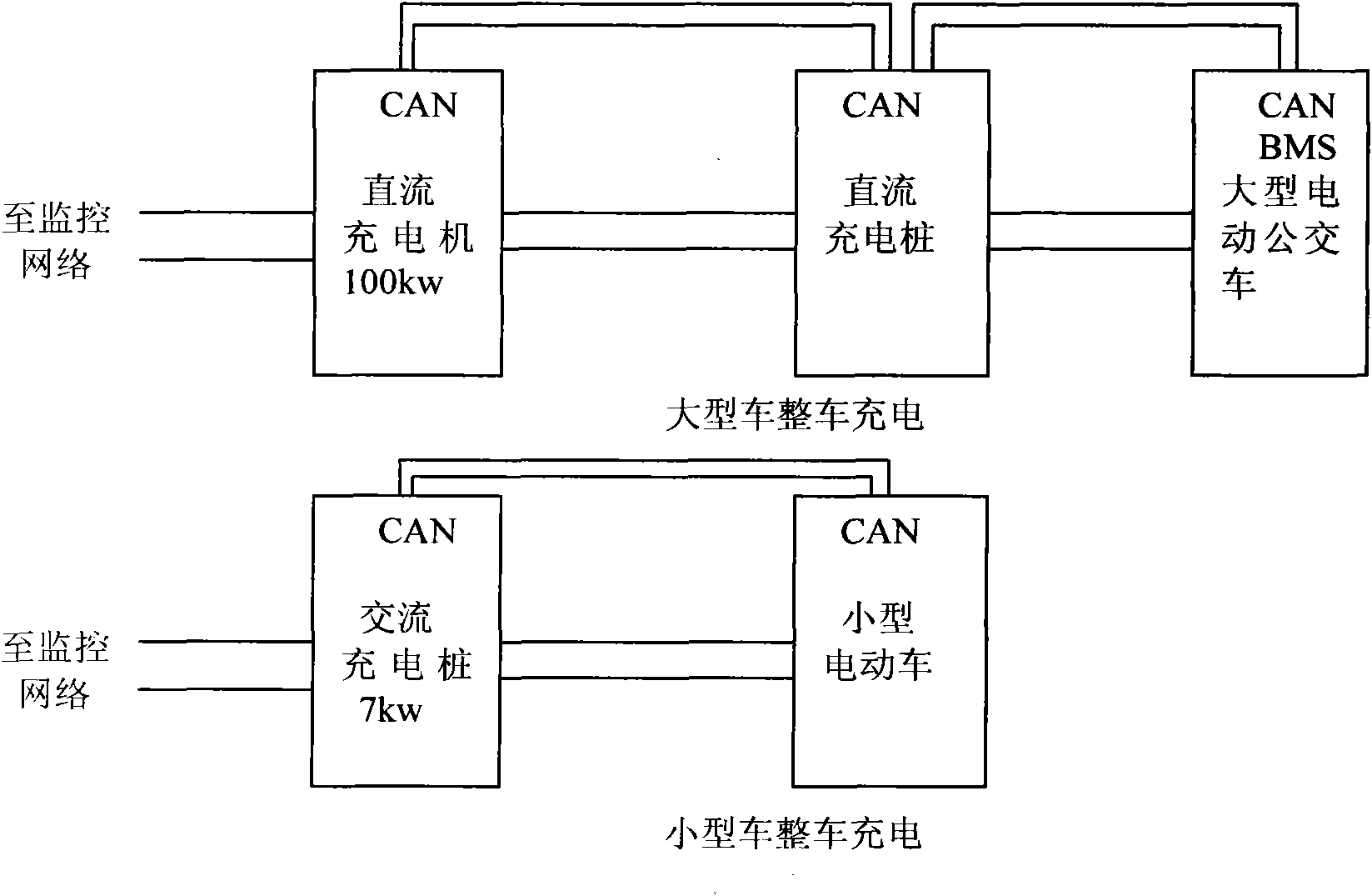

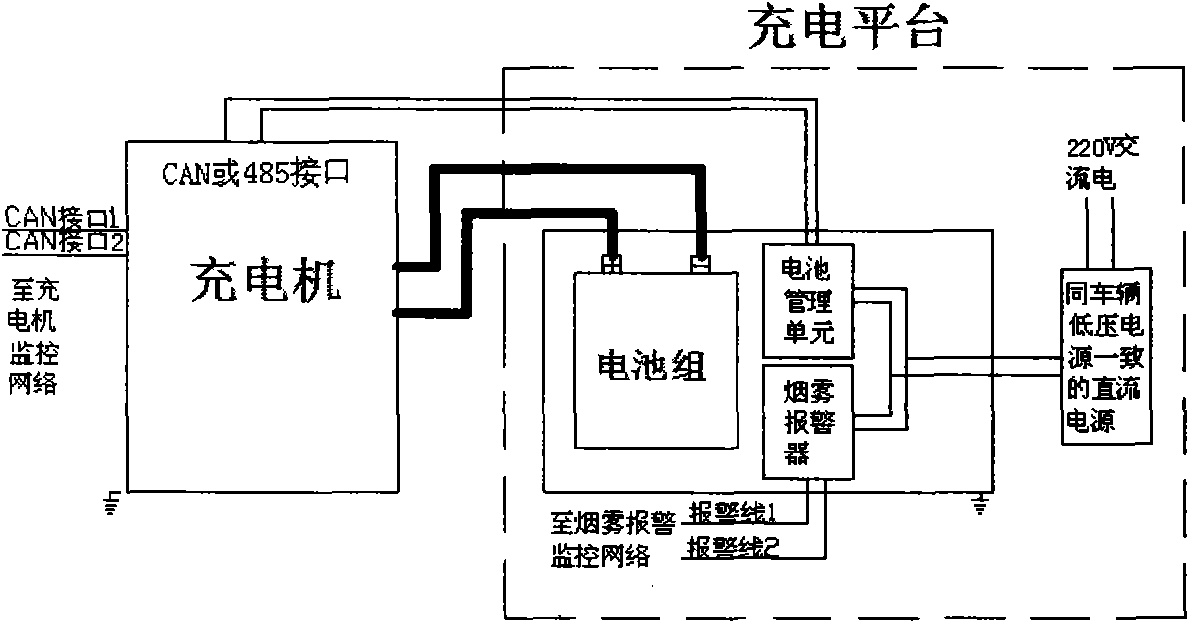

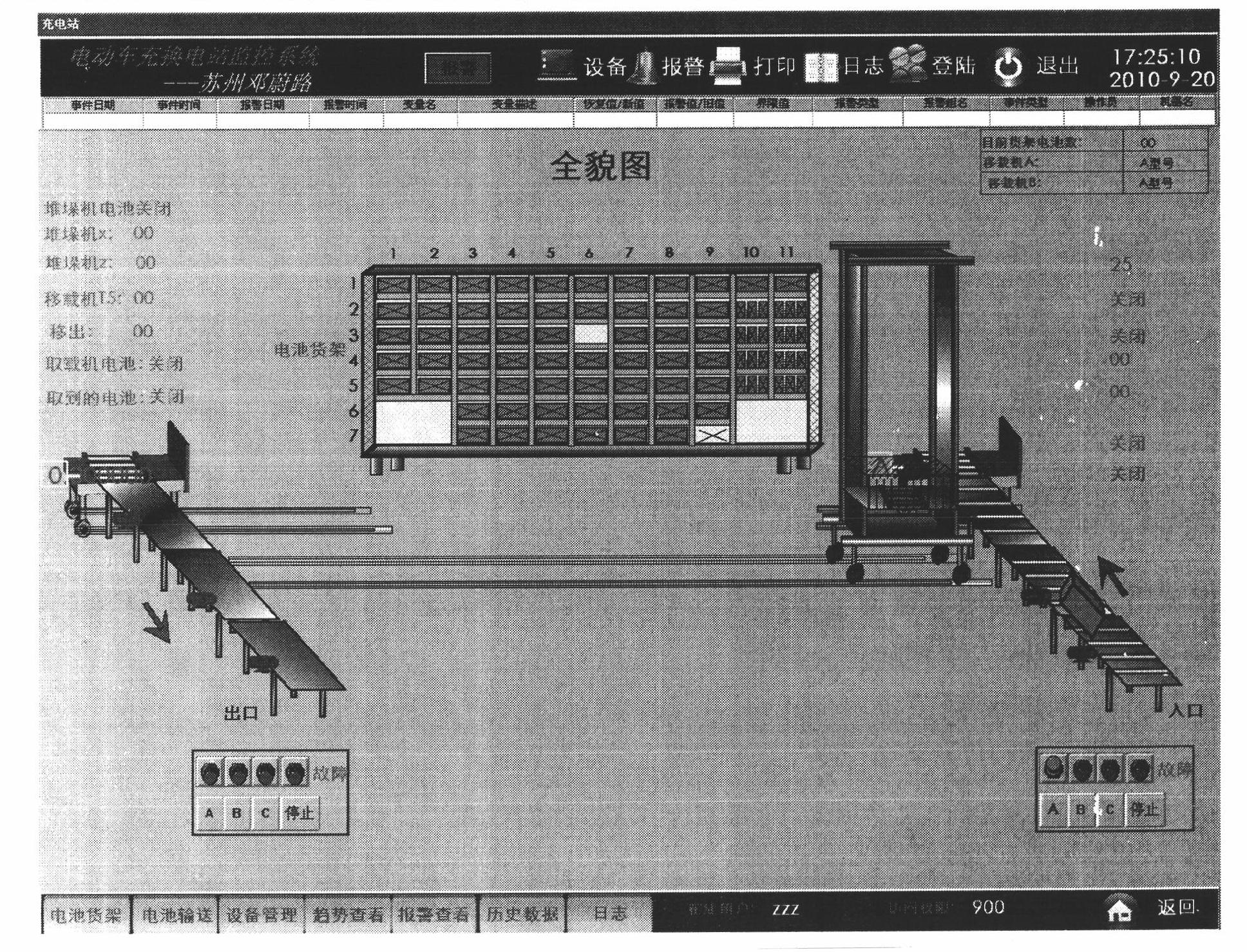

The invention belong to the technical fields of low-voltage power distribution and power electronics, and relates to a battery charging and replacing station for electric vehicles. In the battery charging and replacing station for the electric vehicles, battery replacement and separated-box charging take the priority and entire vehicle charging takes the secondary. The battery charging and replacing station can satisfy the requirement of replenishing electric energy for large-size commercial vehicles and small-size passenger vehicles. In addition, a warehousing type automatic battery replacing system is adopted so that the functions of automatic battery replacement and automatic warehousing in / out management are achieved, and a separated-box charging system can be used for charging the batteries.

Owner:CHINA ELECTRIC POWER RES INST +1

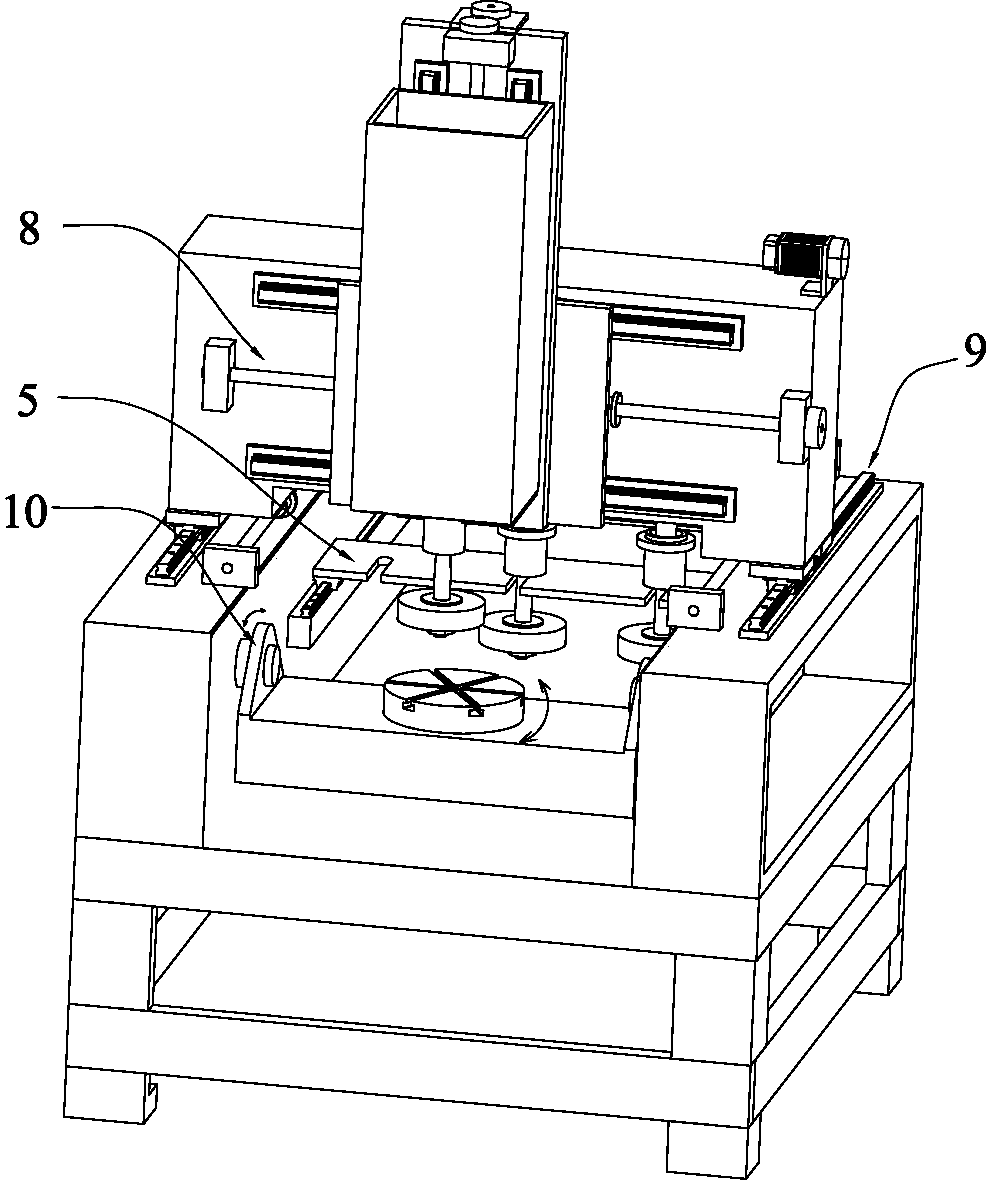

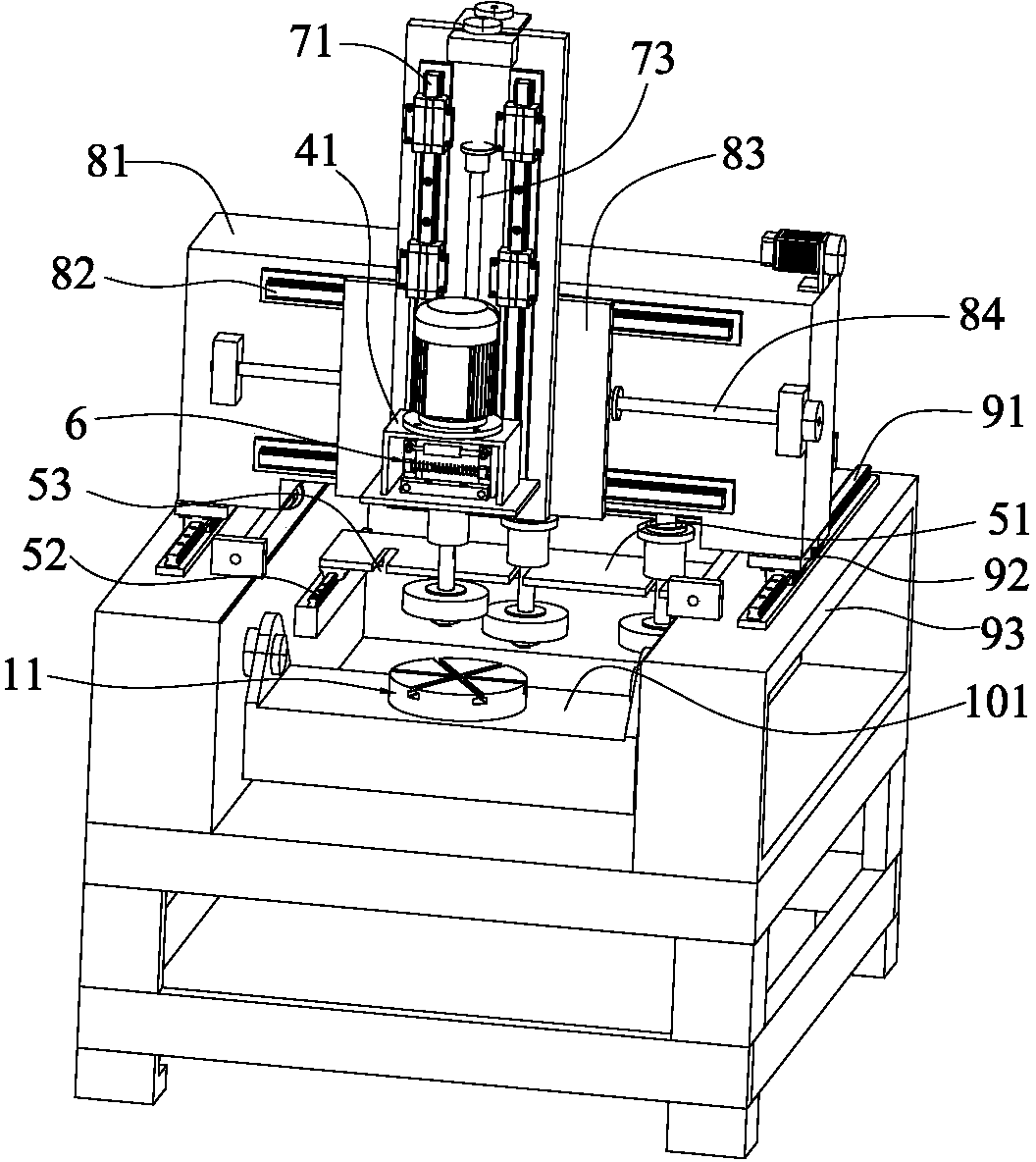

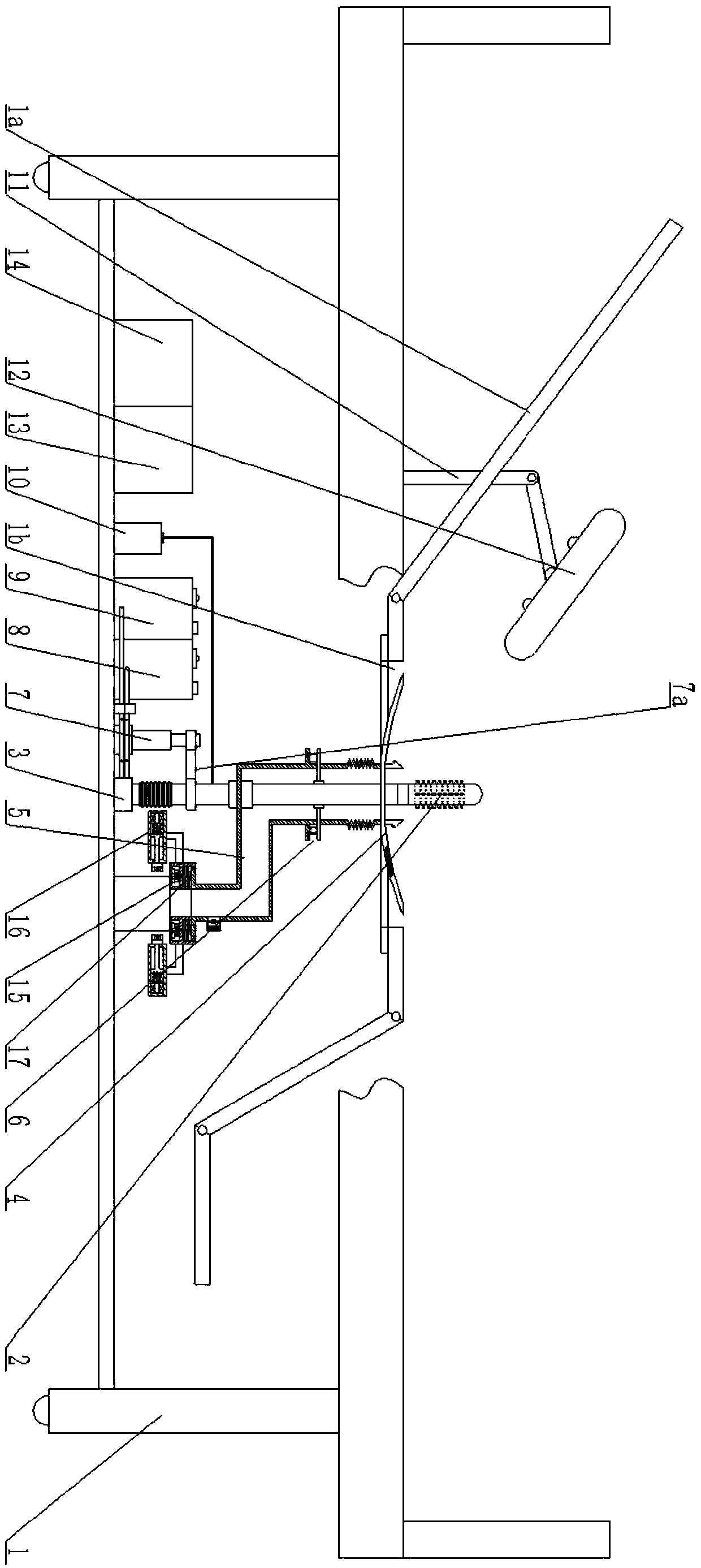

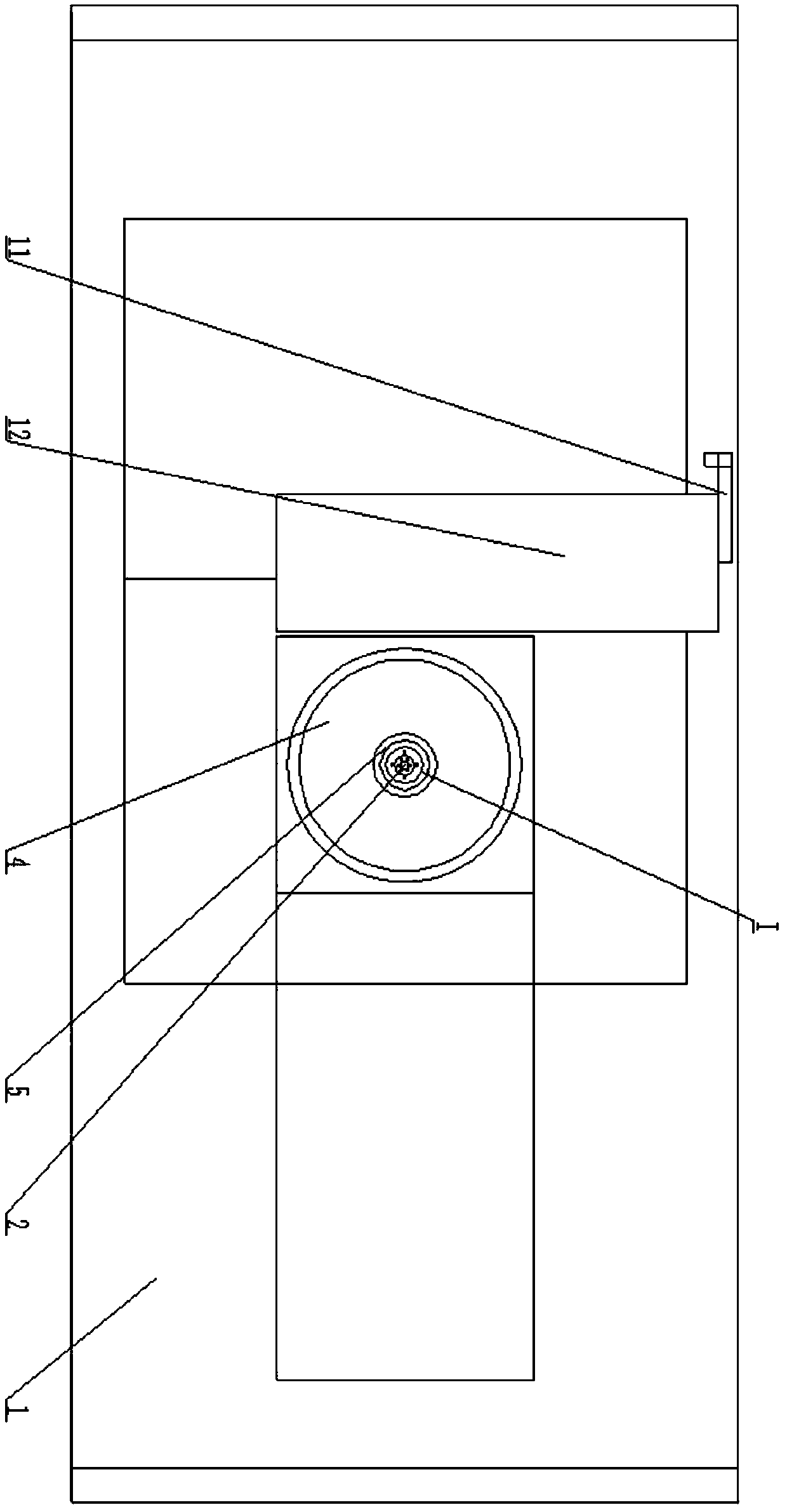

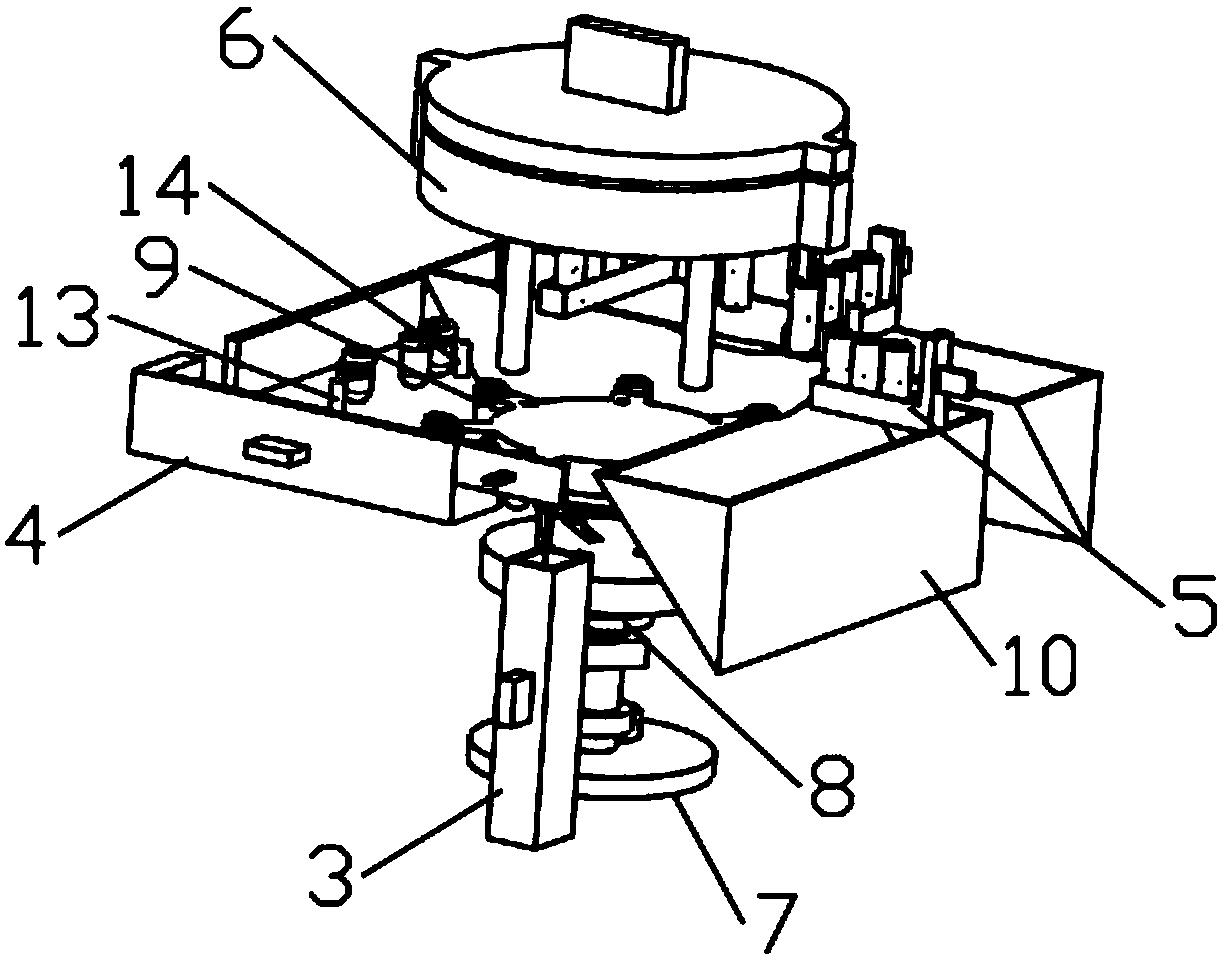

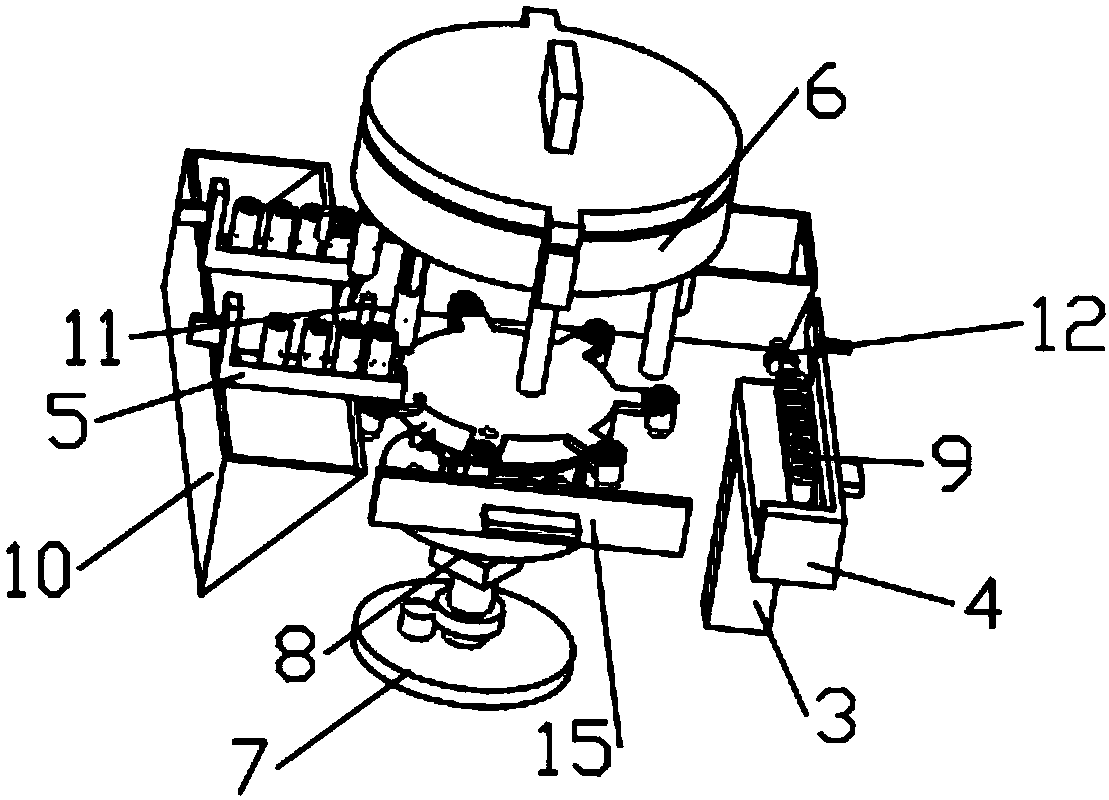

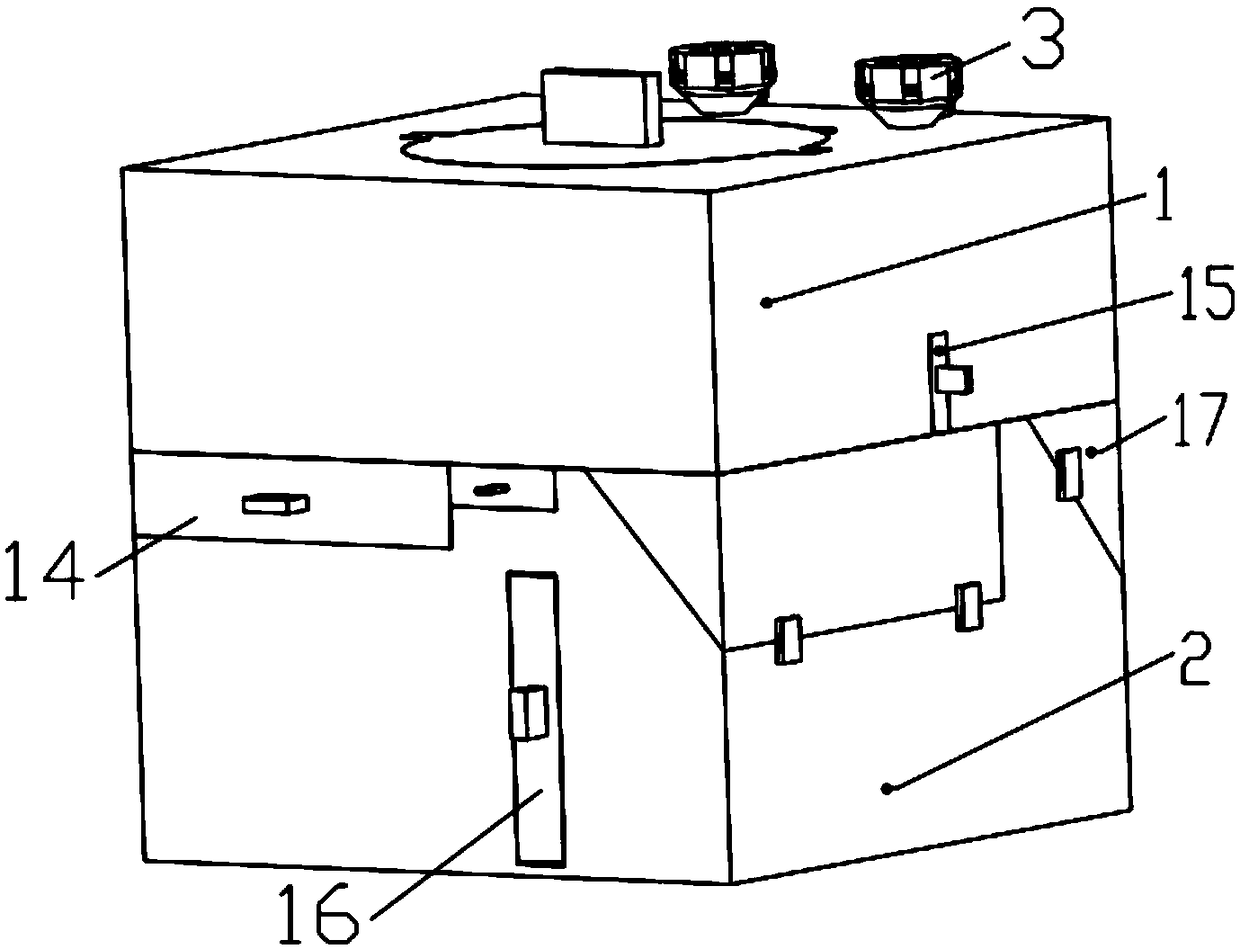

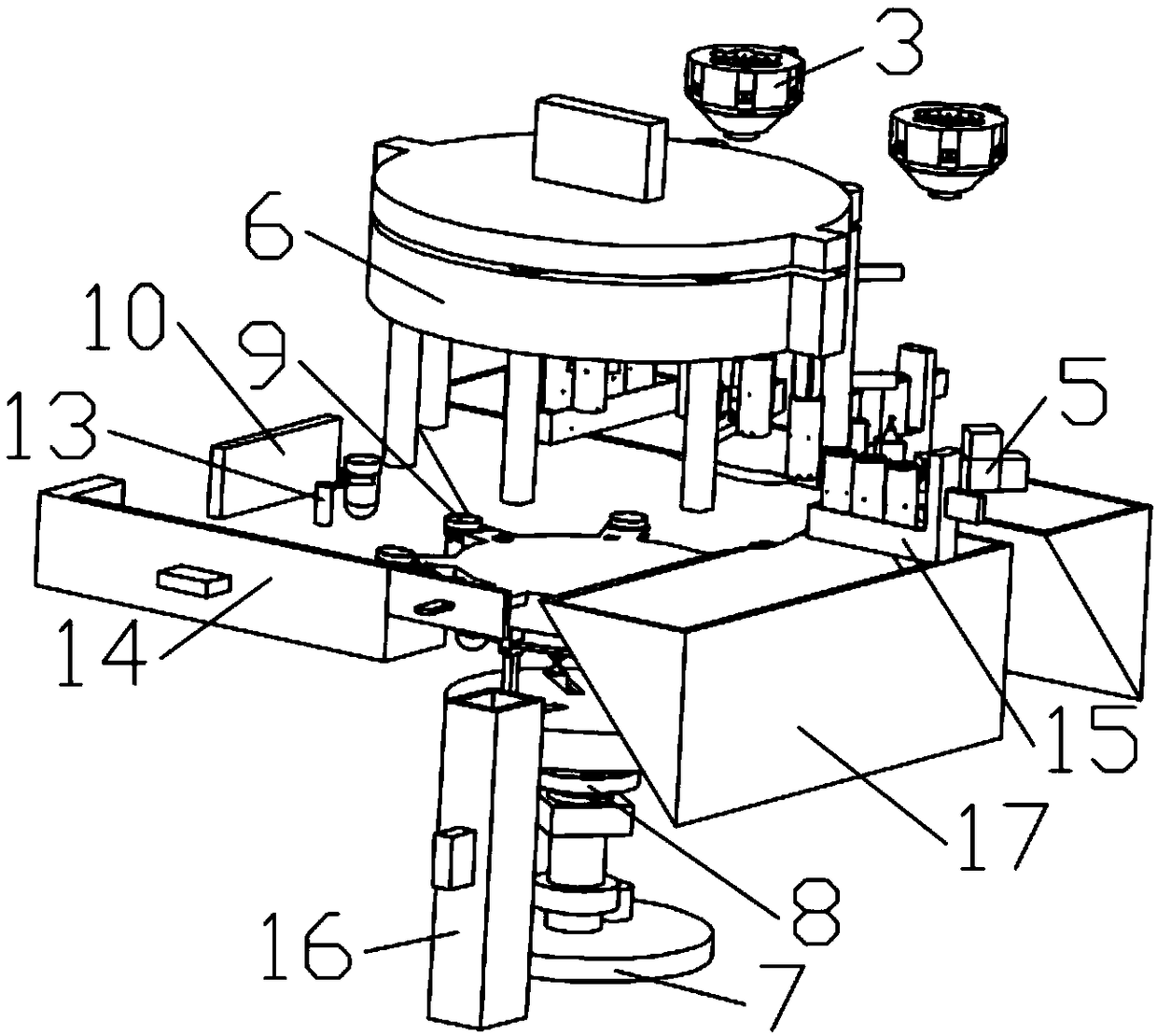

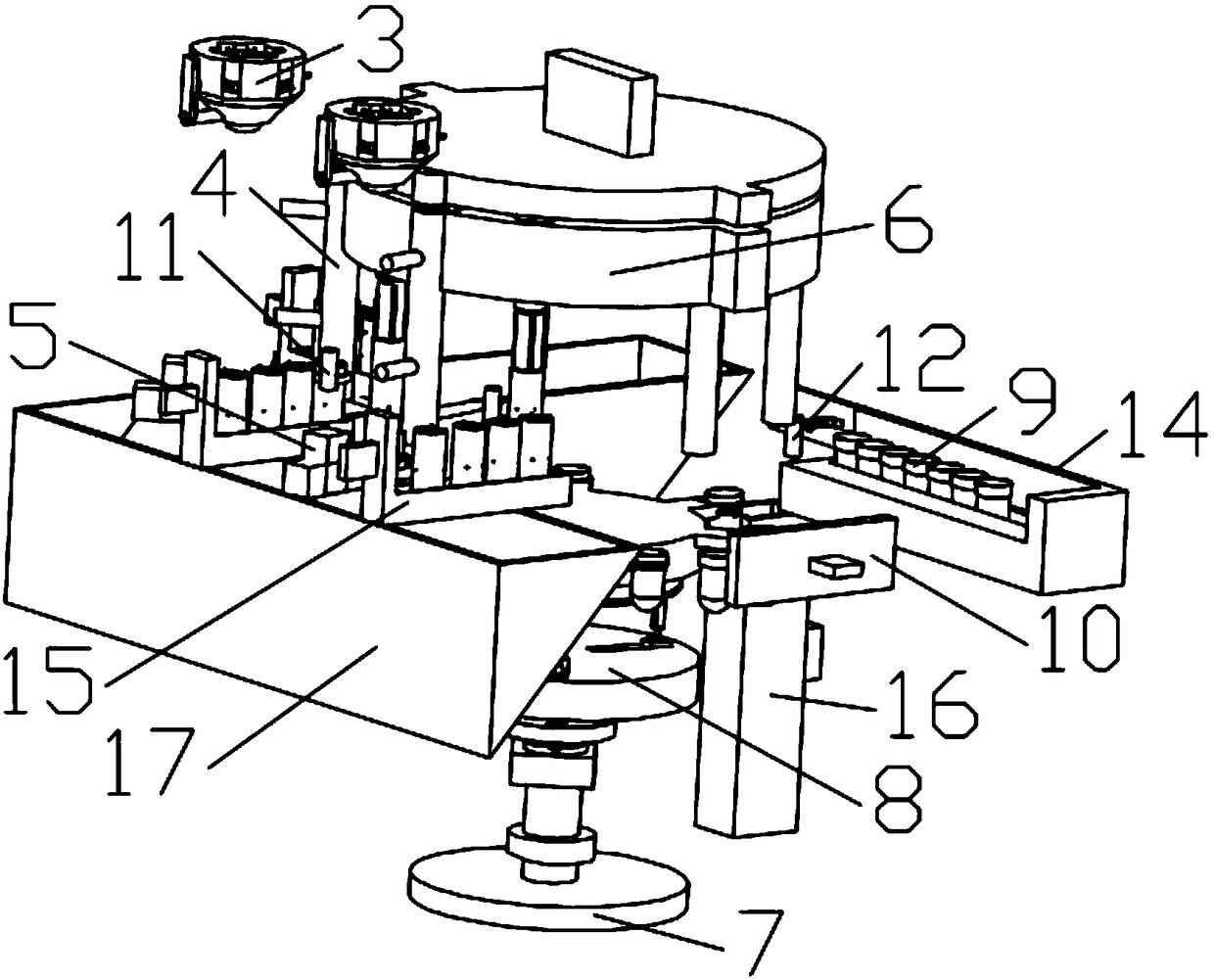

Five-axis numerical control polishing machine capable of changing grinding heads automatically

InactiveCN103465145AAutomatic replacementReduce labor intensityPolishing machinesNumerical controlCurve shape

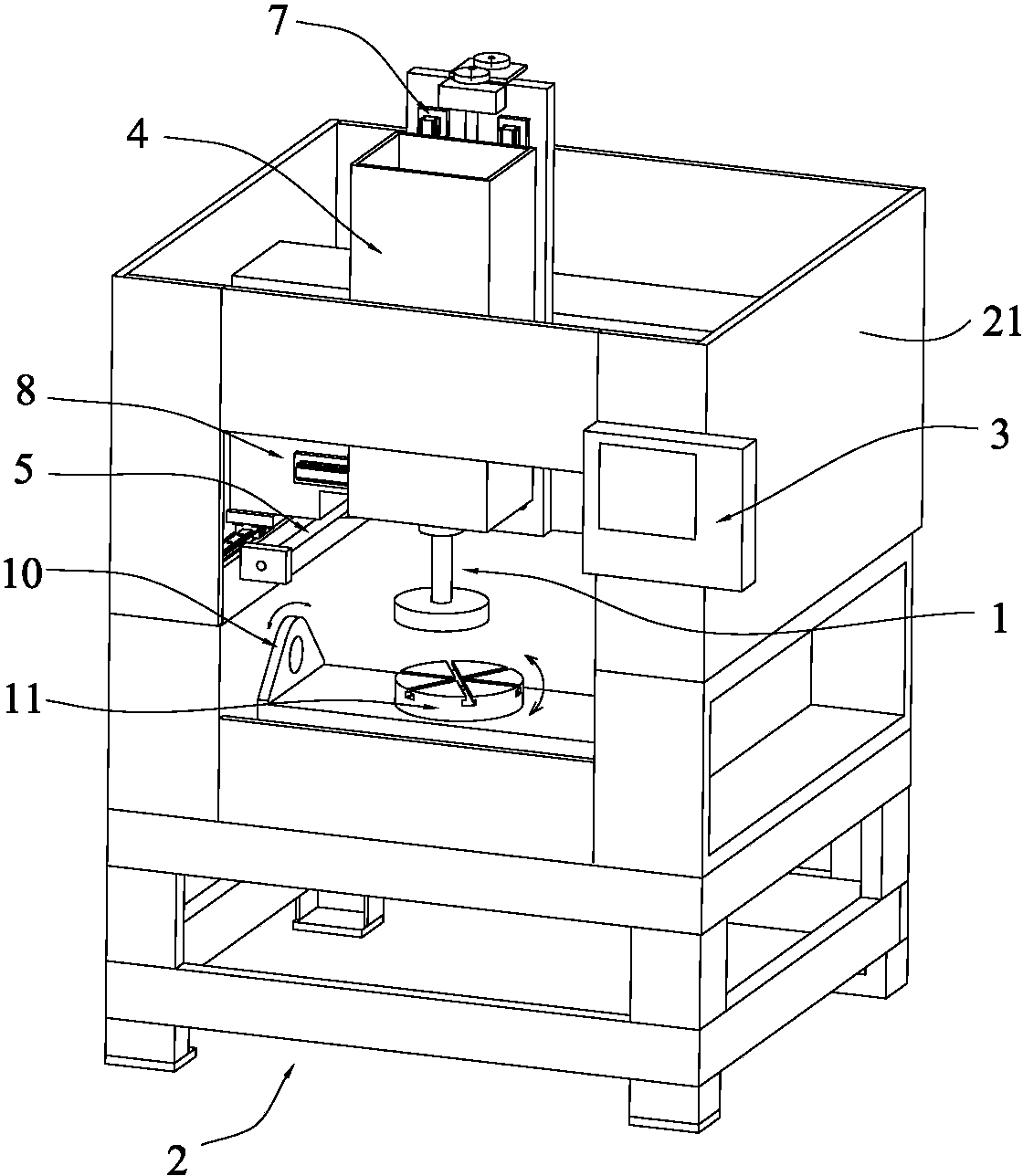

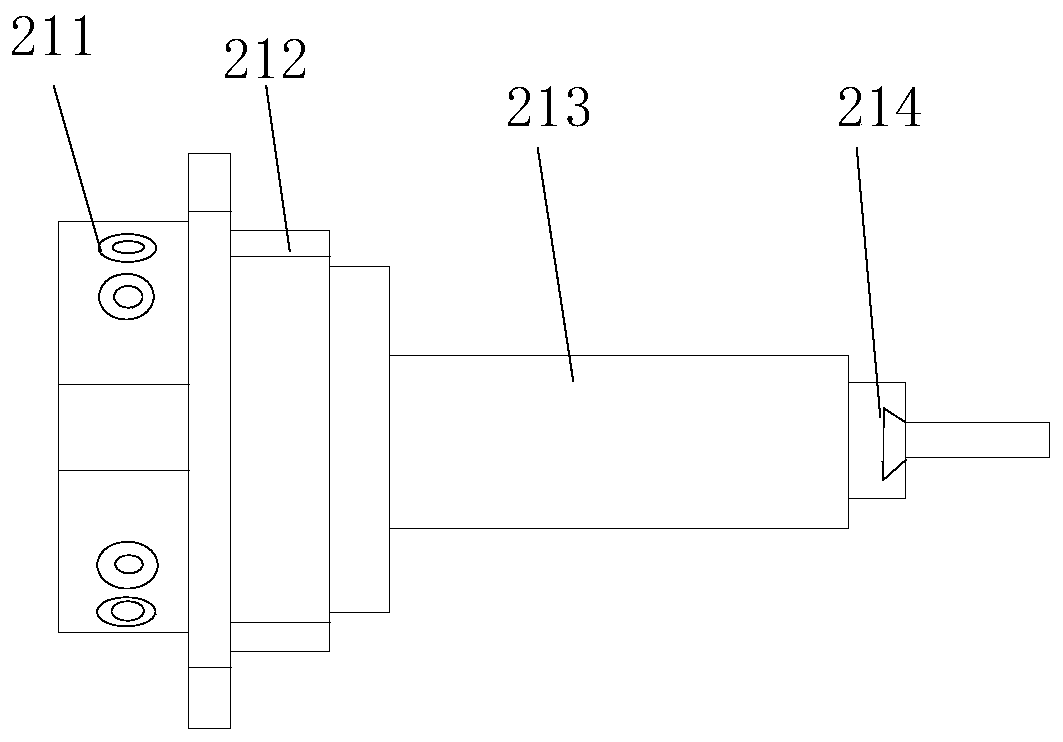

The invention discloses a five-axis numerical control polishing machine capable of changing grinding heads automatically. The five-axis numerical control polishing machine comprises a plurality of semi-axis grinding heads, a machine body frame, a controller, a polishing head, a grinding head supply mechanism, a spindle clamping device, a Z-axis drive mechanism, an X-axis drive mechanism, a Y-axis drive mechanism, an A-axis rotary workbench and a C-axis rotating mechanism. The polishing head, the grinding head supply mechanism, the spindle clamping device, the Z-axis drive mechanism, the X-axis drive mechanism, the Y-axis drive mechanism, the A-axis rotary workbench and the C-axis rotating mechanism are respectively connected with the controlled and controlled by the same. The five-axis numerical control polishing machine capable of changing grinding heads automatically has the advantages that the polishing machine is ingenious and reasonable in structural design, high in automation level, convenient and fast to operate, high in flexibility by the five-axis linkage structure, and widely applicable; multiple polishing procedures such as rough polishing, fine polishing and mirror polishing can be completed at one-step clamping, clamping time is saved, machining efficiency and precision are increased greatly, polishing effect is guaranteed, work efficiency is increased, labor intensity of workers is lowered, enterprise competitiveness is increased effectively, and polishing of surfaces of complex curve shapes can be achieved.

Owner:东莞市钜铧机械有限公司

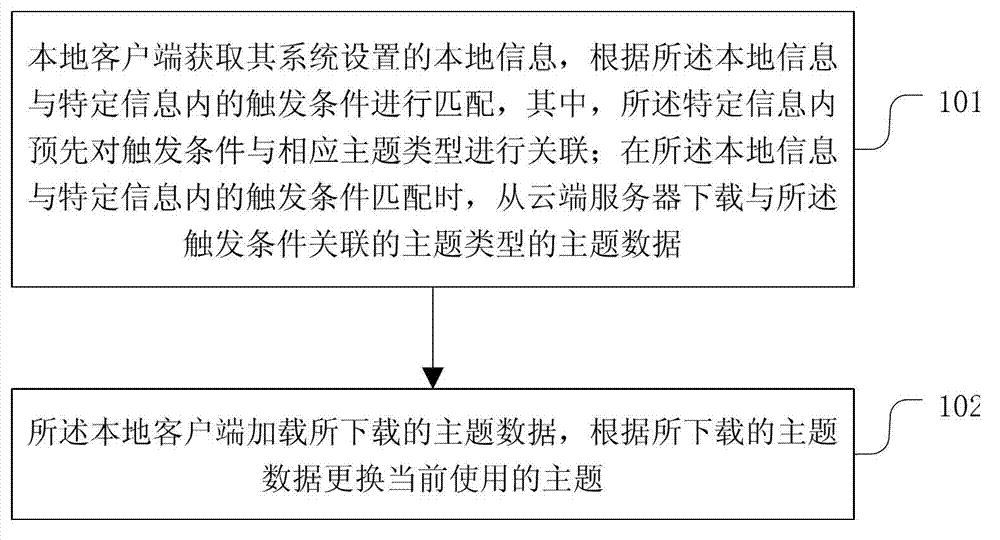

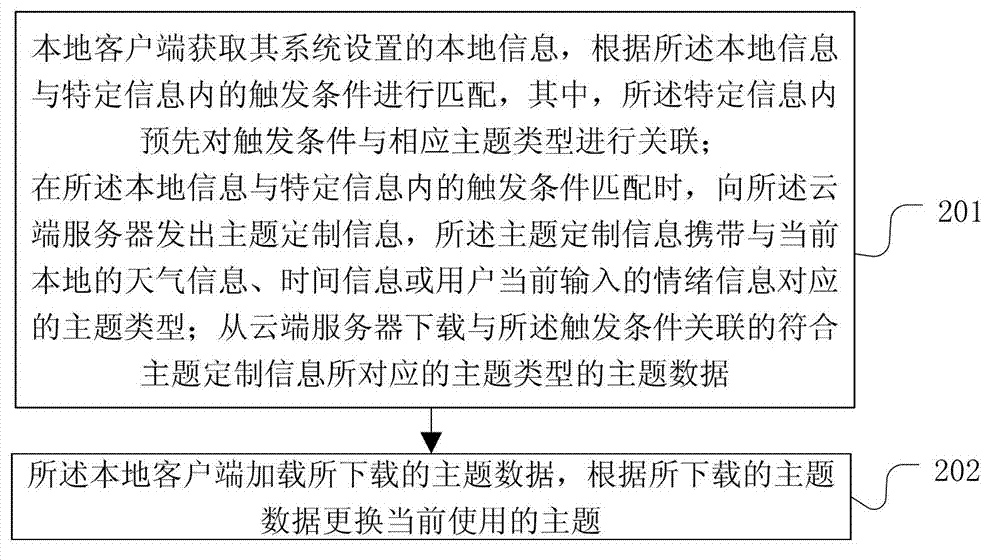

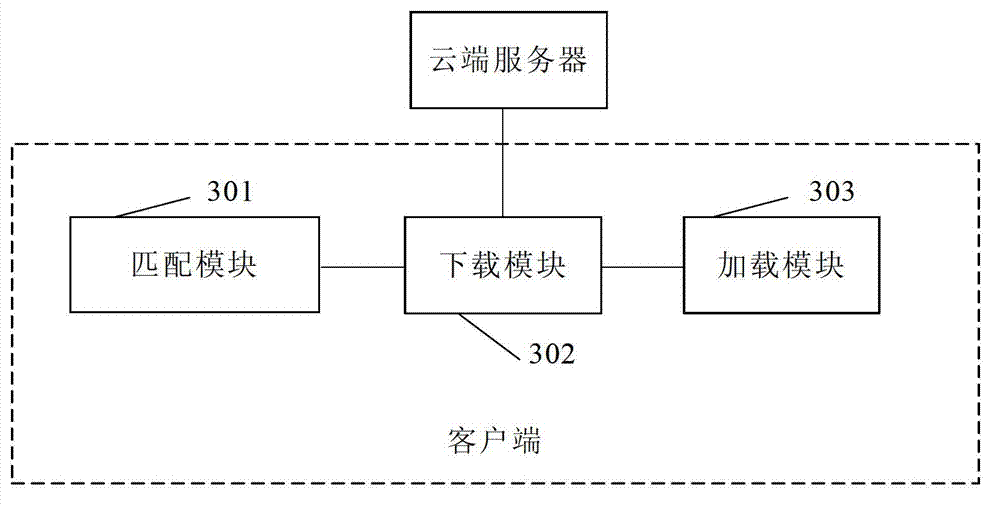

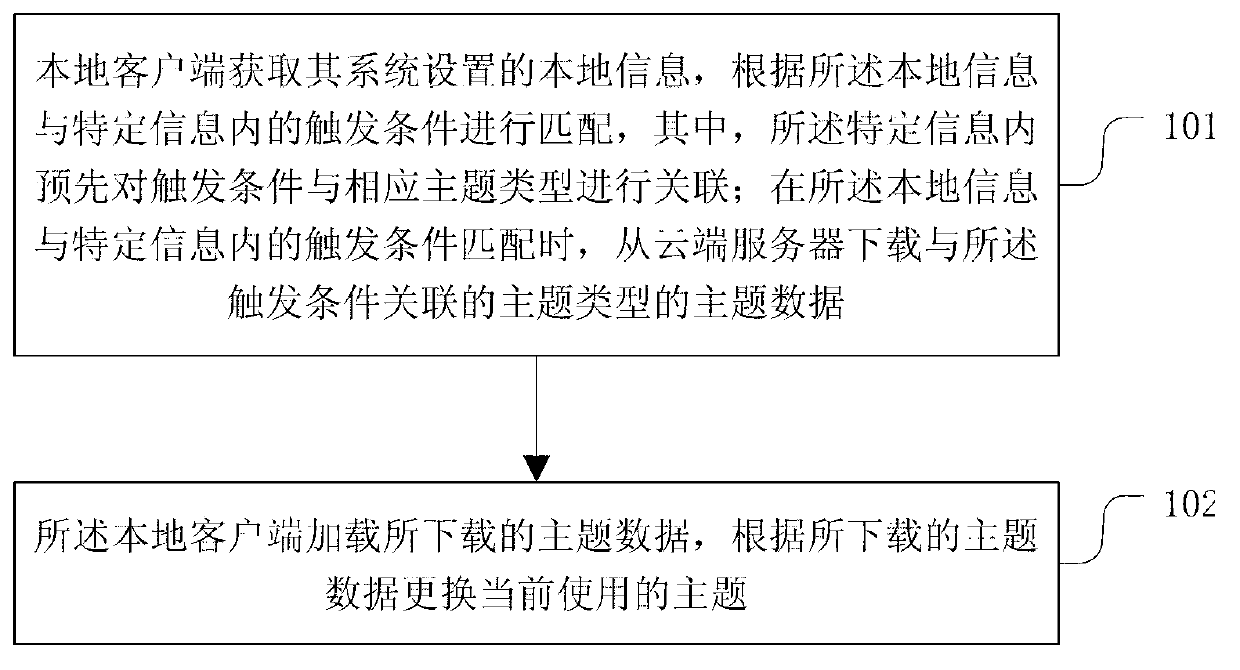

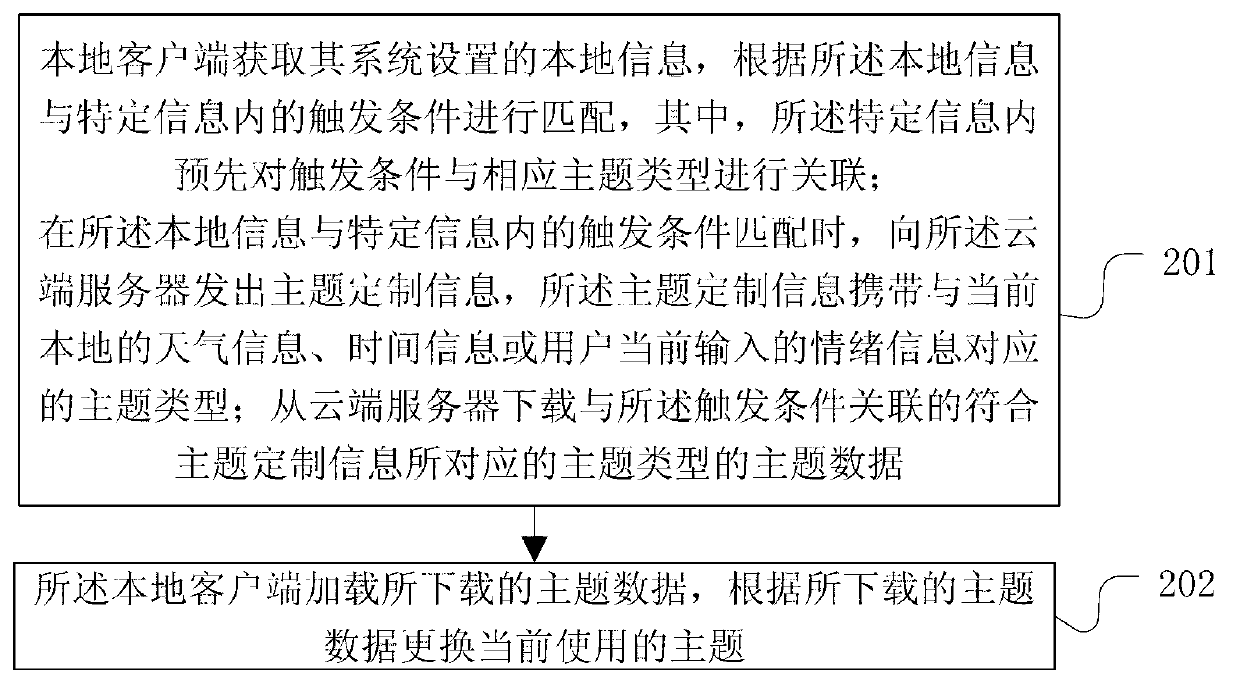

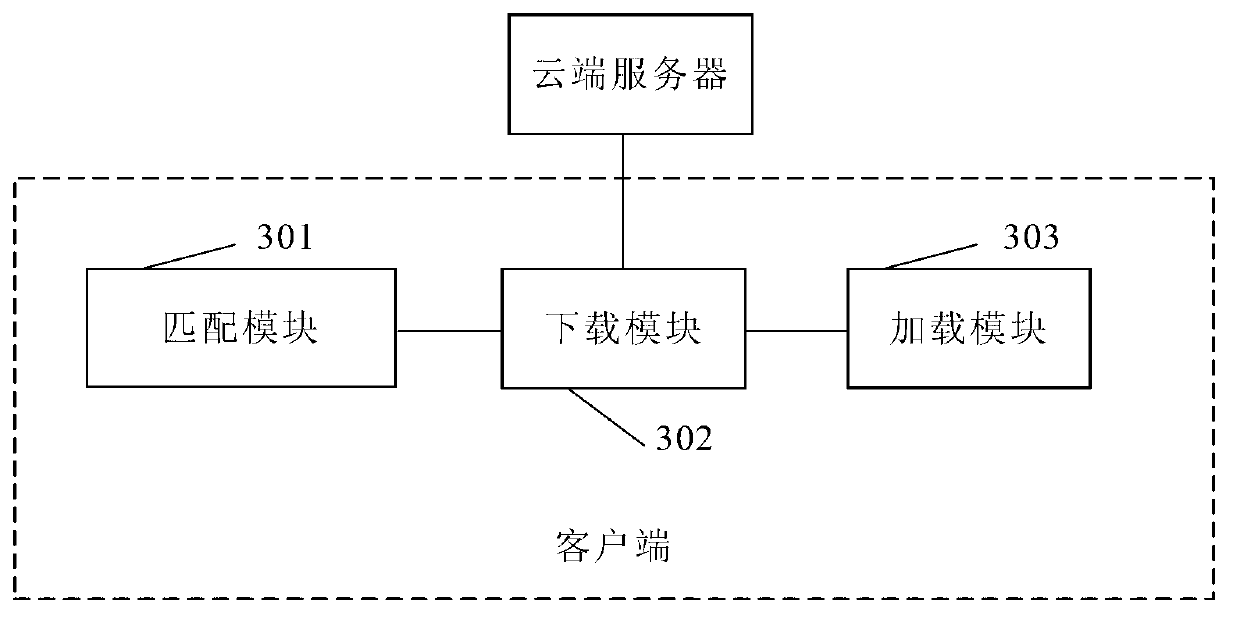

Method for automatically changing subject and client

InactiveCN102970364AAutomatic replacementSmart and automatic replacementTransmissionNetwork communicationClient-side

The invention discloses a method for automatically changing a subject and a client, and belongs to the technical field of network communication. The client comprises a matching module, a downloading module and a loading module, wherein the matching module is used for acquiring local information set by a system and matching the local information with a triggering condition in specific information, wherein the triggering condition is pre-associated with a corresponding subject type in the specific information; the downloading module is used for downloading subject data of the subject type corresponding to the triggering condition from a cloud-end server when the local information is matched with the triggering condition in the specific information; and the loading module is used for loading the downloaded subject data, and changing the subject which is currently used according to the downloaded subject data. According to the method disclosed by the invention, the subject is automatically changed according to a strategy pre-set by the server or in a mode set by a user.

Owner:BEIJING QIHOO TECH CO LTD +1

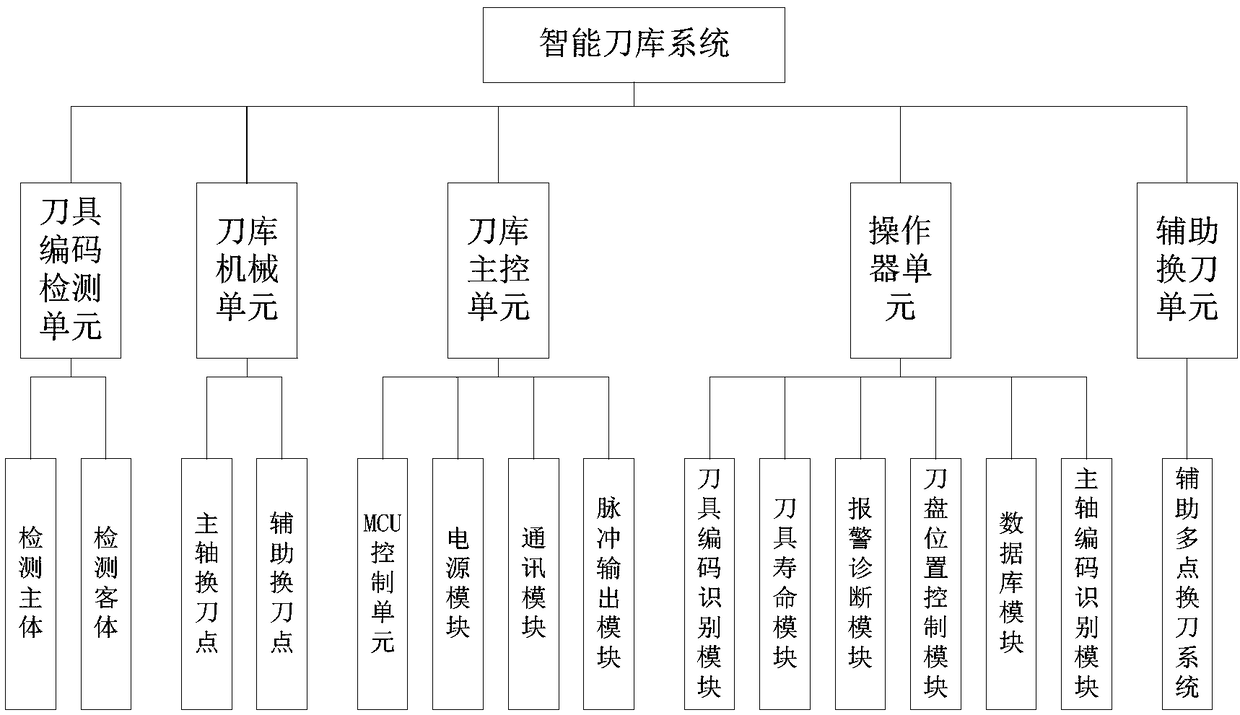

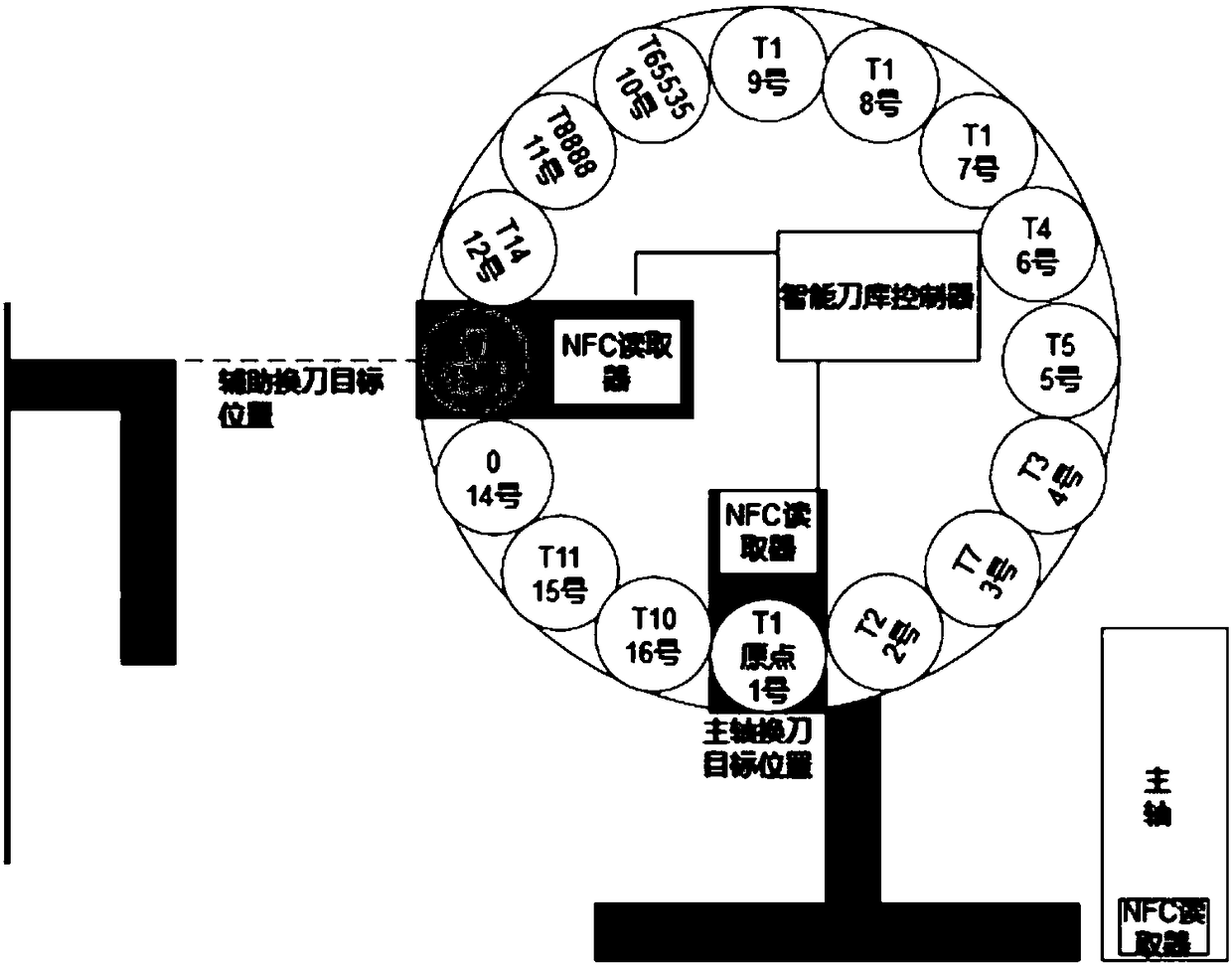

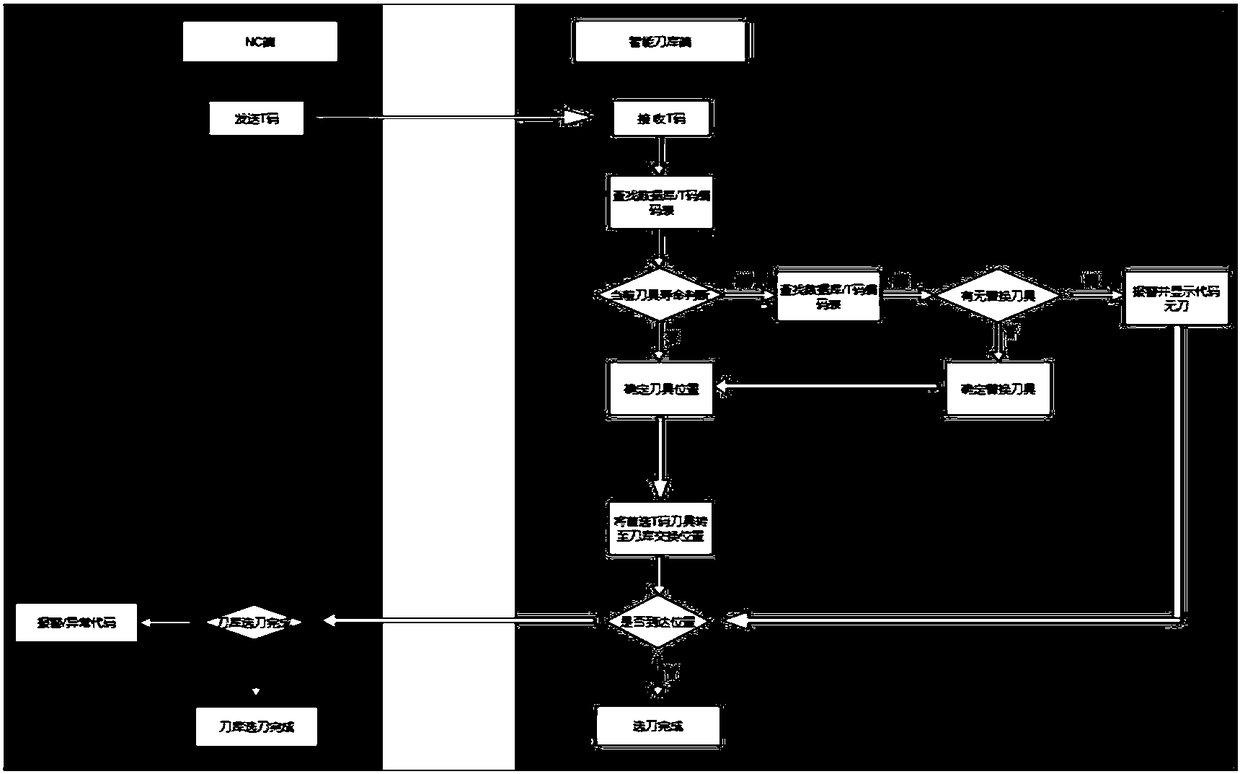

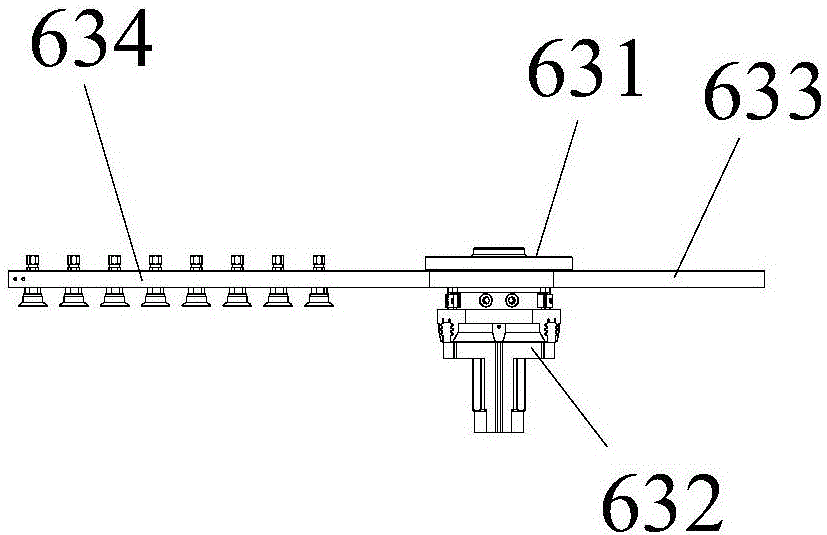

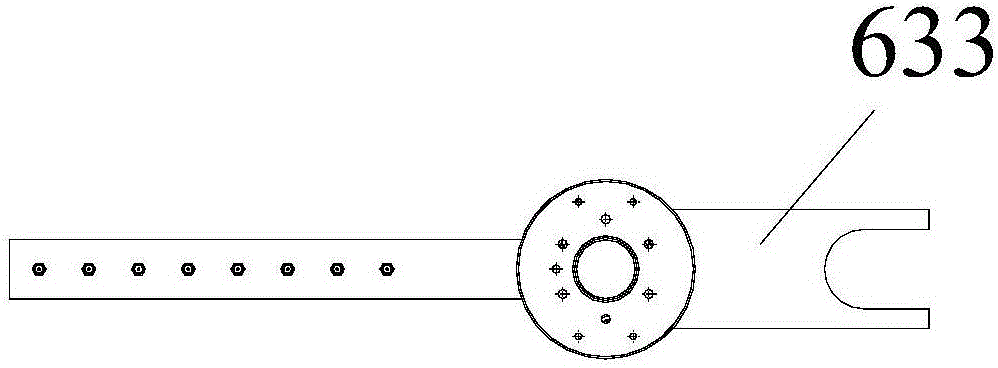

Intelligent tool magazine system suitable for numerical control machine tool and control method of intelligent tool magazine

ActiveCN108393724ARealize automatic error correctionImplement tool magazine system requirementsPositioning apparatusMetal working apparatusNumerical controlProcess study

The invention provides an intelligent tool magazine system suitable for a numerical control machine tool. The intelligent tool magazine system comprises a tool encoding detection unit, a tool magazinemachinery unit, a tool magazine master control unit, an auxiliary tool changing unit and a manipulator unit. The invention also provides a control method of the intelligent tool magazine suitable forthe numerical control machine. The control method comprises the following steps: providing the intelligent tool magazine system, performing code initialization on the intelligent tool magazine system, and re-building a real-time encoding database; and searching for empty tool spacings, tools with insufficient service life and damaged tools in the intelligent tool magazine system by retrieving a database with a retrieval command, performing tool selection control, and examining the tools at an NC end and programs after tool changing. The control method has the following advantages: initialization of tool magazines with repeated tool numbers and searching of the empty tool spacings, tools with insufficient service life and damaged tools can be realized, and the standby tools can be automatically changed in real time during machining. Meanwhile, classification of process tools and process studies on the tools can be achieved. A one-step one-tool-number process is realized.

Owner:颜芳俊

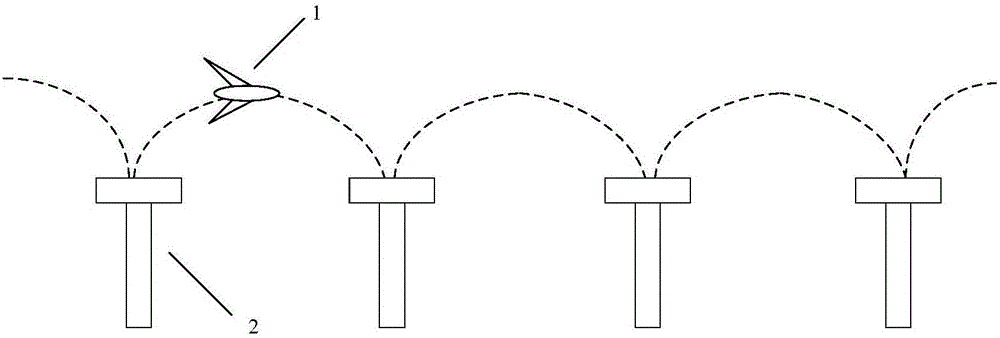

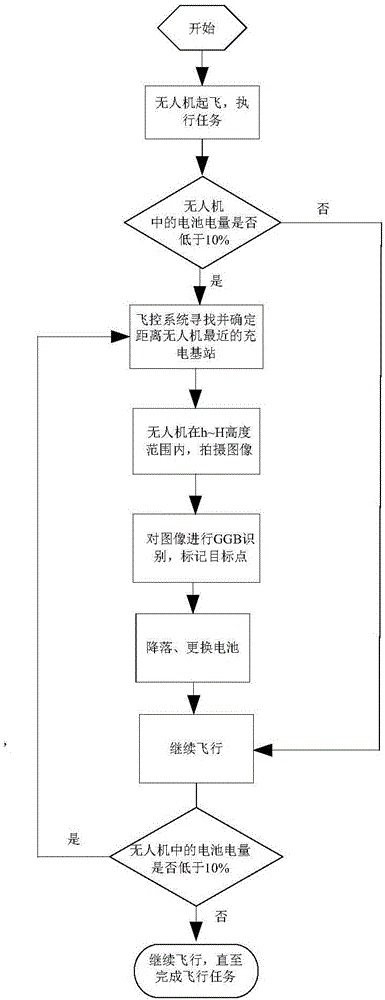

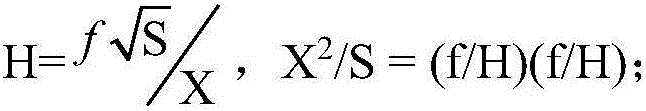

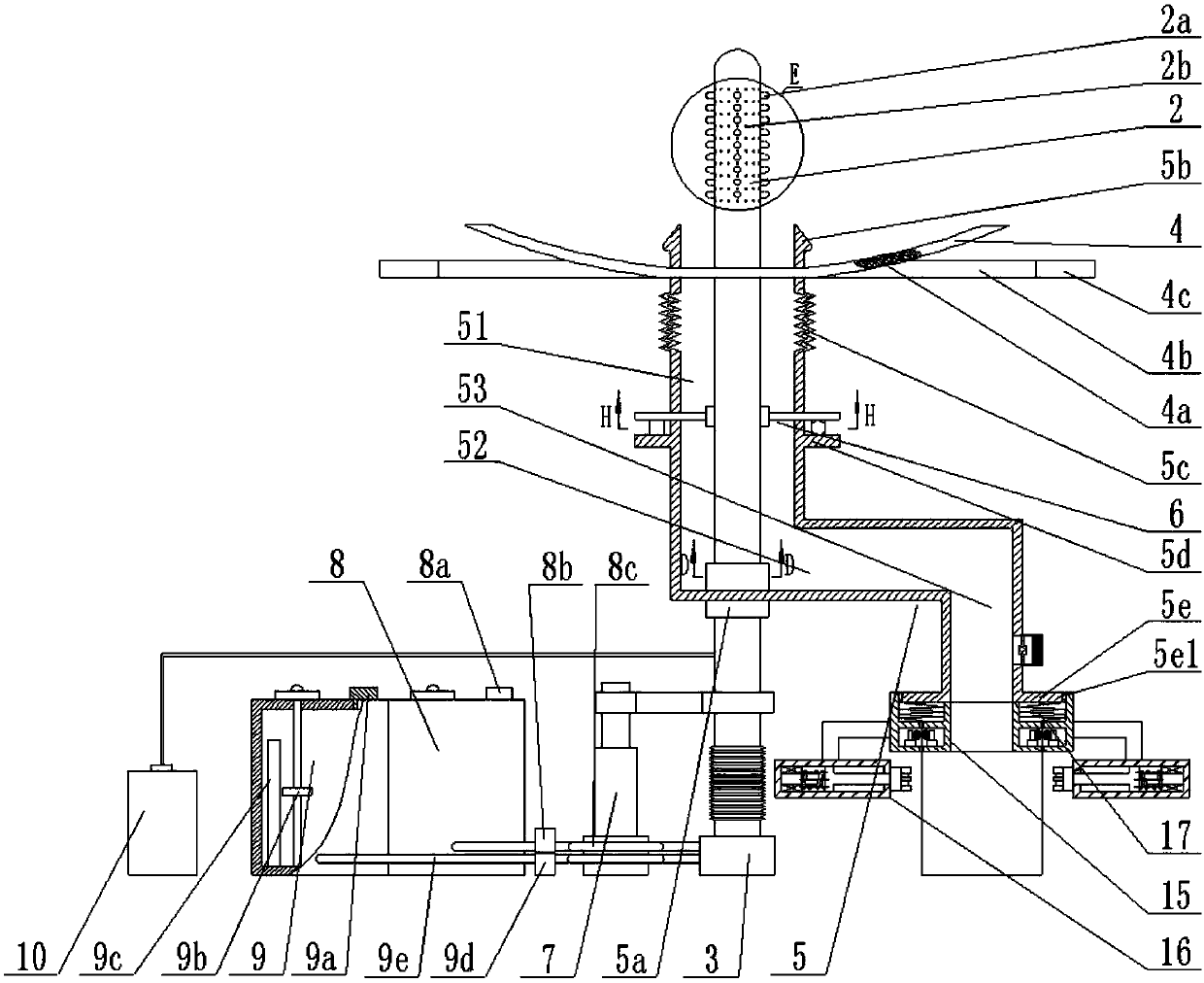

Complete autonomous super remote distance flight system for unmanned plane, and control method thereof

ActiveCN106527472AAchieve ultra-long-distance flightReal-time power monitoringElectrical testingPosition/course control in three dimensionsControl systemUncrewed vehicle

The invention discloses a complete autonomous super remote distance flight system for an unmanned plane, and a control method thereof. The complete autonomous super remote distance flight system for an unmanned plane includes an unmanned plane and a plurality of charging base stations. The control method of the complete autonomous super remote distance flight system includes the steps: 1) when battery capacity is less than 10%, a flight control system determines the charging base station being nearest to the unmanned plane; 2) the flight control system controls the vertical height between the unmanned plane and the charging base station within the range of h-H meter, and a camera shoots the charging base station; 3) the flight control system performs RGB identification on the shot image, and capturing a landing point; 4) the flight control system controls the unmanned plane to land, and exchanges the battery, and then controls the unmanned plane to take off again; and 5) the step 1 to the step 4 are repeated until super remote distance flight is completed. During the flying process of the unmanned plane, the flight control system monitors the battery capacity in real time, and when the battery capacity is less than 10%, the unmanned plane selects the nearest charging base station to land, and then the battery is exchanged so that super remote distance flight of the unmanned plane is realized. For the complete autonomous super remote distance flight system for an unmanned plane and the control method thereof, a solar cell panel is utilized to charge the battery, so that the complete autonomous super remote distance flight system for an unmanned plane and the control method thereof use green energy and are environmentally friendly.

Owner:南京奇蛙智能科技有限公司

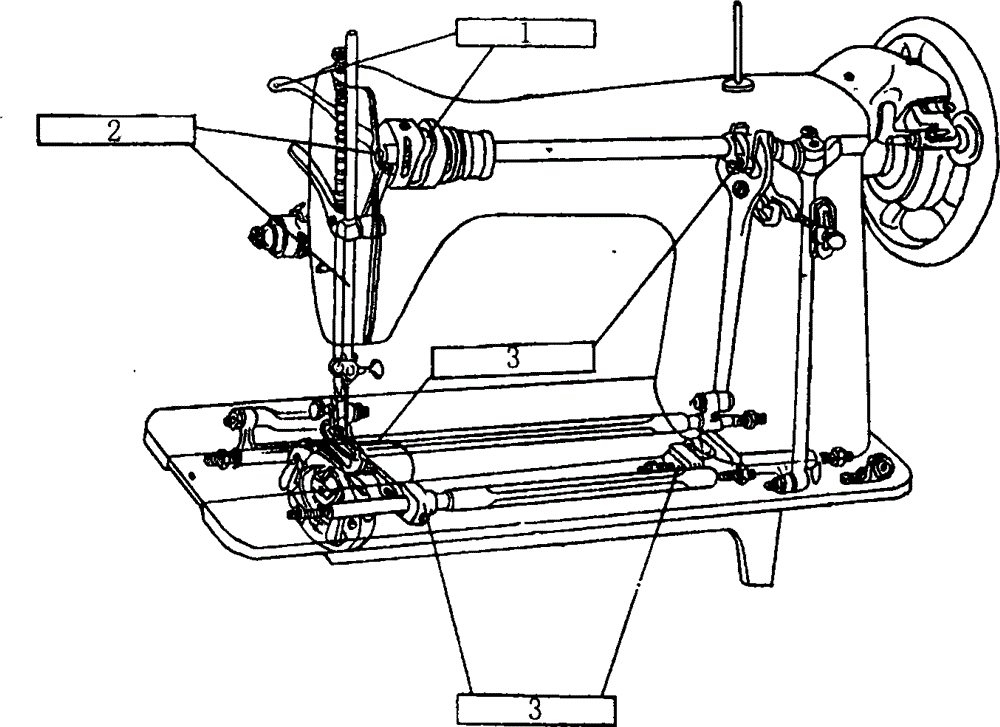

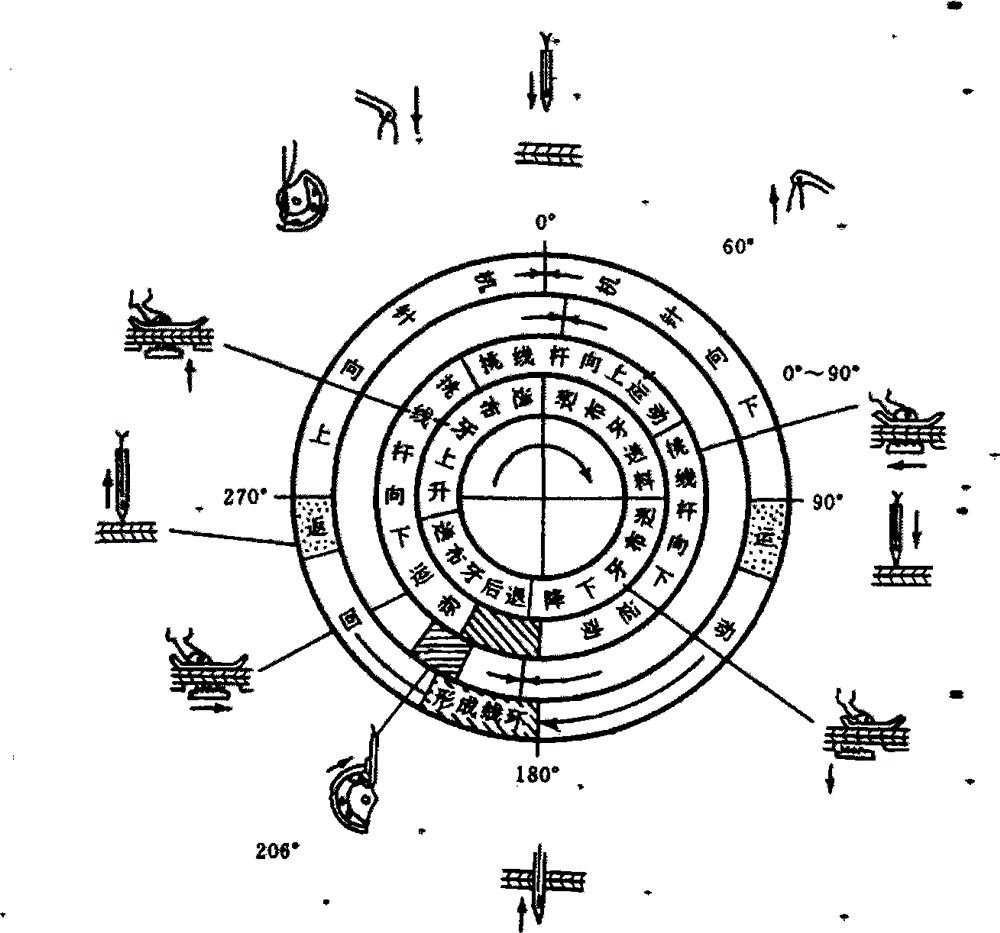

Thick stuff sewing machine

InactiveCN102943352ALarge capacityAutomatic replacementNeedle severing devicesSewing-machine control devicesClutchManipulator

The invention provides a thick stuff sewing machine which mainly comprises a needle bar mechanism, a thread hooking mechanism, a take-up mechanism and a feeding mechanism. A base thread detection device is mounted on a rotating shuttle; a sensor, a controller and a manipulator are arranged in the base thread detection device; the sensor is used for sensing the stock of base threads; the controller controls the manipulator to replace a bobbin; a lifting mechanism is mounted on a needle bar; the needle bar is connected with a draw bar through the lifting mechanism; a clutch I is arranged between the draw bar and the needle bar through the lifting mechanism; a clutch II is arranged between the needle bar and a needle bar crank connecting rod mechanism; a linkage curved bar is arranged between the clutch I and the clutch II; a servo control system is arranged on the thick stuff sewing machine; and a power module, a control module, a drive module and a servo motor are arranged in the servo control system. Through the invention, the structure and the control system are optimized, and the production efficiency is improved.

Owner:苏磊 +1

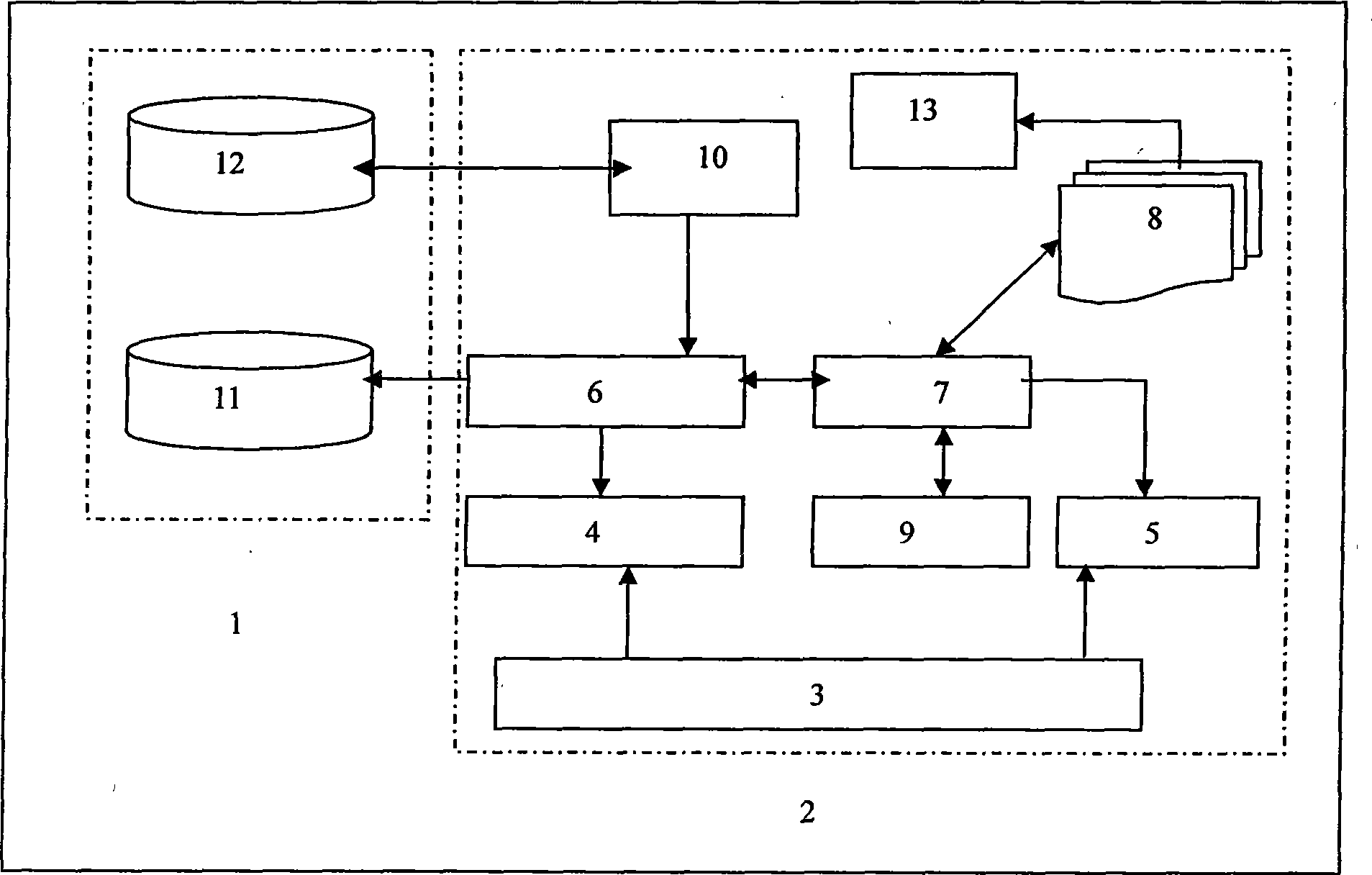

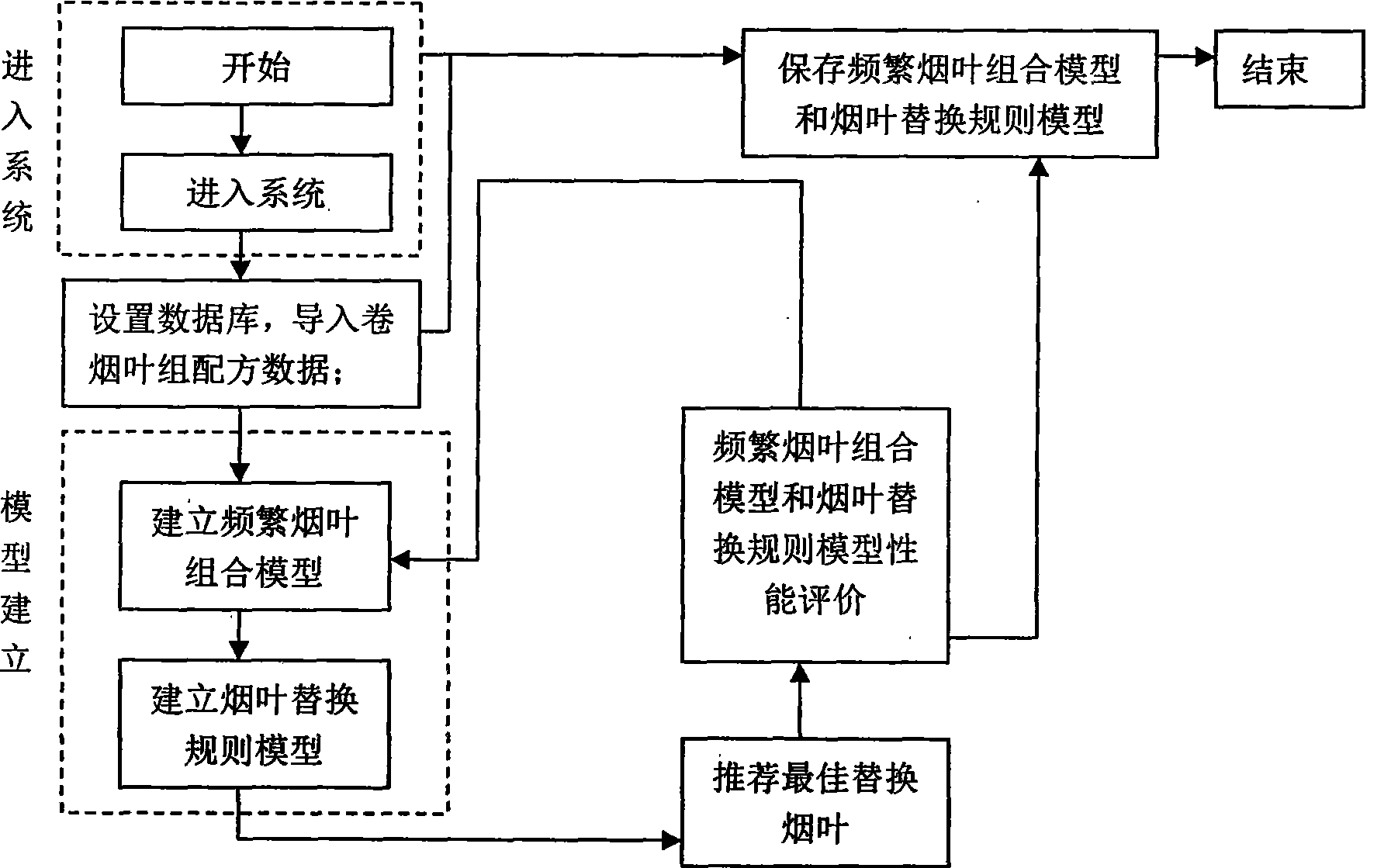

Cigarette composition maintenance action digging system based on associations ruler and method thereof

ActiveCN101419627AAutomatic replacementAchieve substitutionSpecial data processing applicationsData connectionPassword

The invention discloses a cigarette formulating maintenance behavior mining system based on association roles and a method thereof. The cigarette formulating maintenance behavior mining system comprises a database server and a data mining client, wherein, the data mining client comprises a visual displaying tool which is connected with a data displaying and processing module and a result displaying module; the data displaying and processing module is connected with a data connecting module which provides connection of data sources with different data type formats, a database generating a mining algorithm and also interfaces through which a data object performs accessing; the result displaying module is connected with a mining and processing module which is respectively connected with a pattern storage module, a pattern evaluating module and a data connecting module; the data connecting module is connected with the data resources in an authentication processing module and the database server, and simultaneously, the authentication processing module is connected with a permission database in the database server, and the authentication processing module verifies the user validity through a user name and a password.

Owner:CHINA TOBACCO SHANDONG IND +1

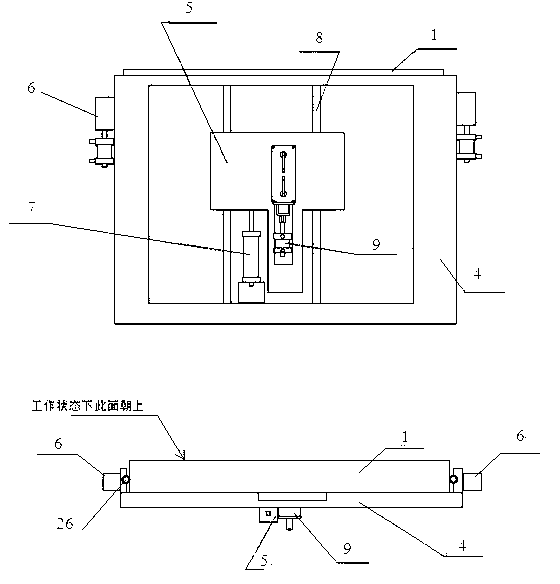

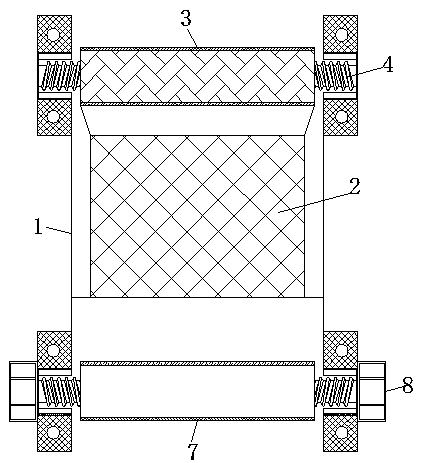

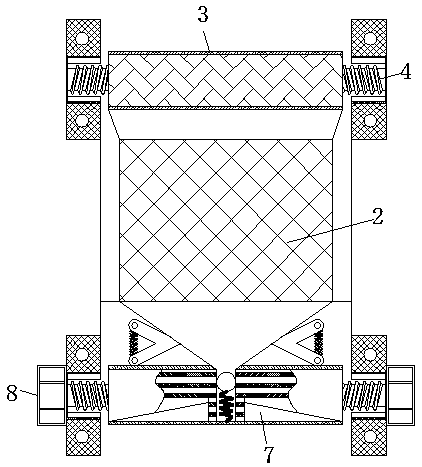

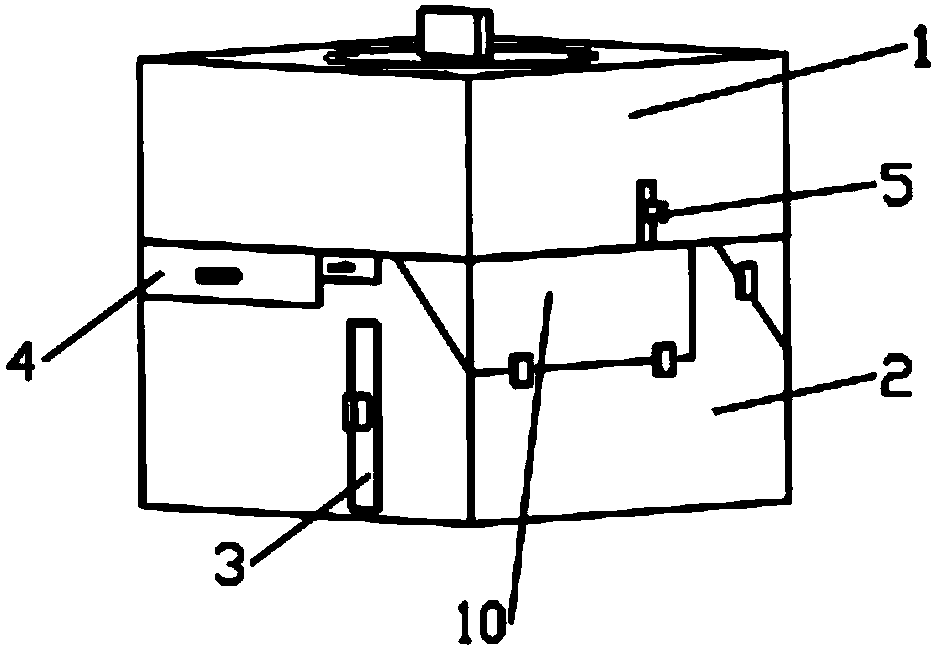

Battery box locking maintaining structure

ActiveCN103253243AAutomatic replacementImprove securityElectric propulsion mountingElectric/fluid circuitPower batteryEngineering

A battery box locking maintaining structure is used in battery assembling and disassembling of a power battery automatic quick replacing battery box system of a pure electro-mobile. The power battery automatic quick replacing battery box system of the pure electro-mobile comprises a battery outer box, a battery inner box, a battery assembling and disassembling mechanism and battery box locking maintaining mechanisms. The battery inner box is placed inside the battery outer box, two sides of the battery inner box are provided with locking holes matched with the battery outer box, and locking pin holes which are matched with the assembling and disassembling mechanism are formed in the bottom of the battery inner box. The battery outer box is of a framework structure. The battery box locking maintaining mechanisms are arranged on two side frames of the battery outer box and power is provided to the battery box locking maintaining mechanisms by a locking air cylinder.

Owner:BIT HUACHUANG ELECTRIC VEHICLE TECH

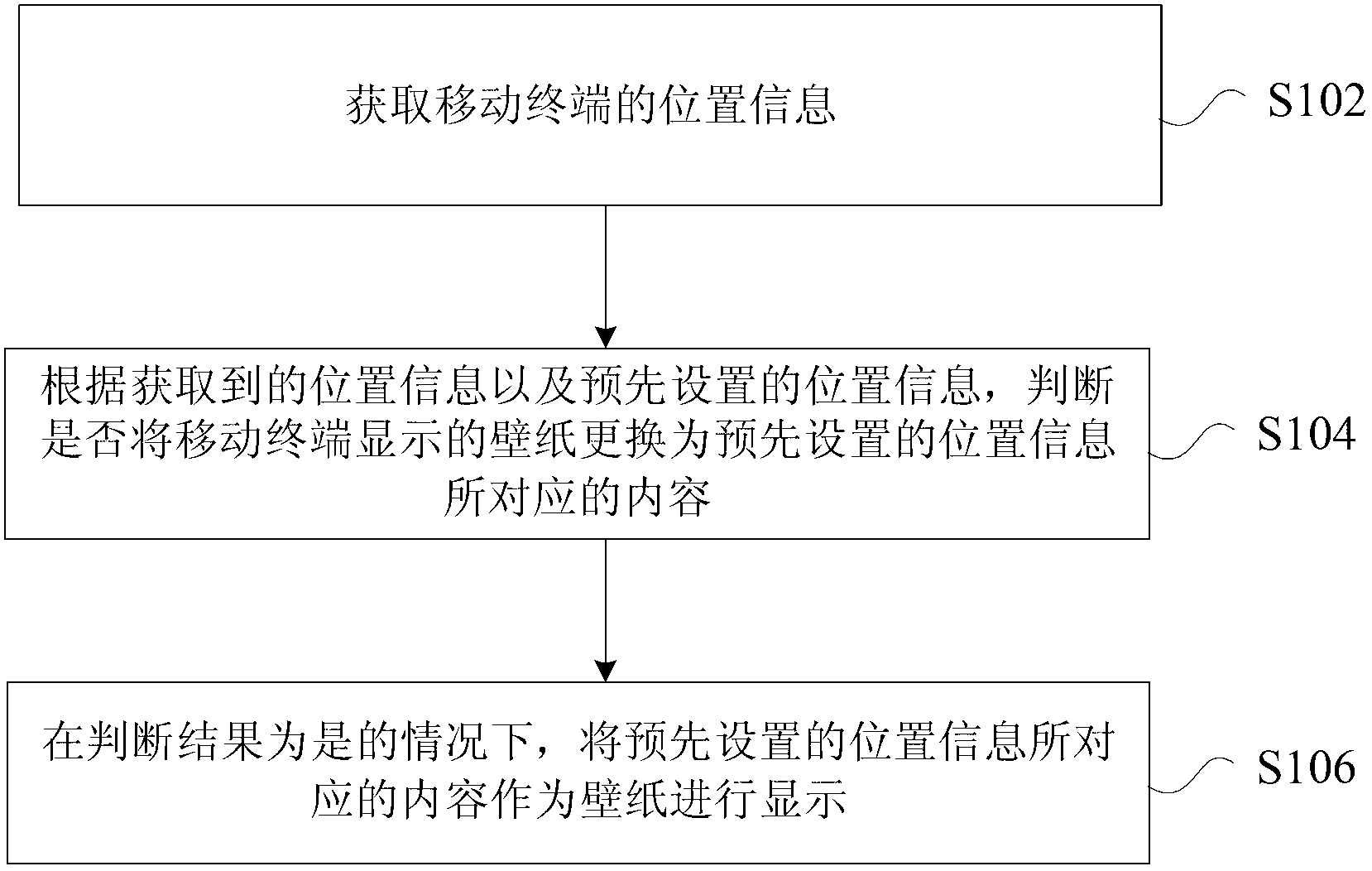

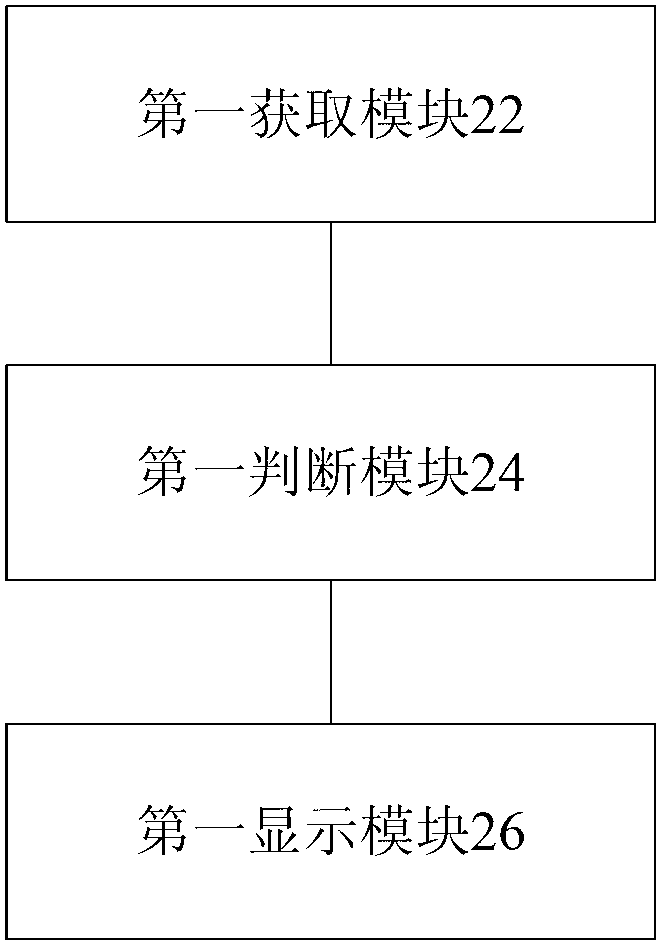

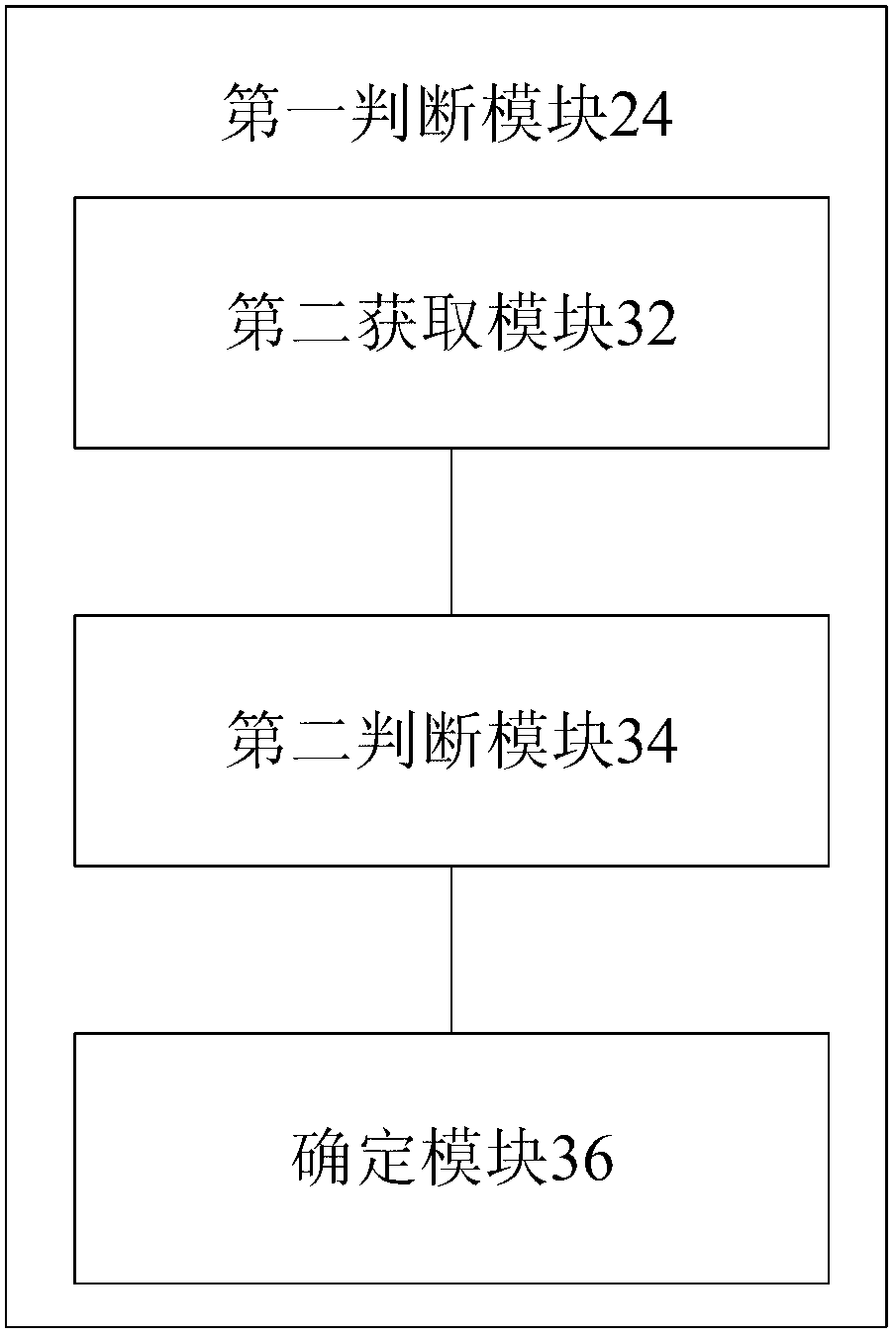

Wallpaper treatment method and device

InactiveCN102711039AAutomatic replacementRich requirementsTexturing/coloringTelephone sets with user guidance/featuresPersonalizationComputer engineering

The invention provides a wallpaper processing method and a device. The method comprises the steps of obtaining position information of a mobile terminal, judging whether to change wallpaper displayed through the mobile terminal into contents corresponding to preset position information according to the obtained position information and the preset position information, and taking the contents corresponding to the preset position information as wallpaper to be displayed if the wallpaper is judged to be changed. According to the method, the problem that the user experience is bad when a mobile terminal user uses wallpaper or a theme in the prior art is solved, and further the effects that the method not only can automatically realize wallpaper changing, but also meets the requirements on diversification and individuation of users are achieved.

Owner:ZTE CORP

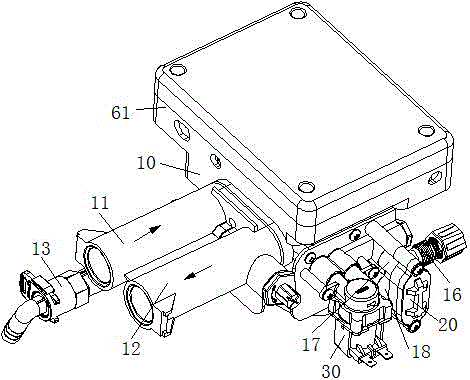

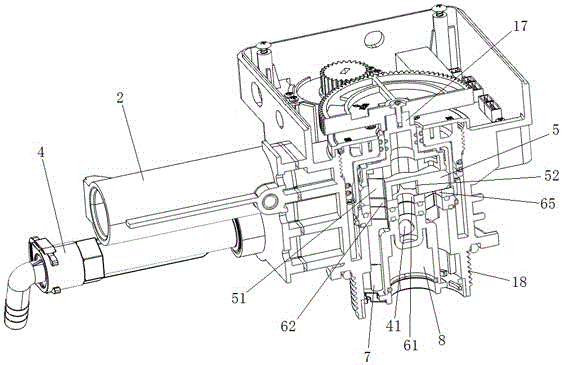

Water softener control valve and control method thereof

ActiveCN105927758AAutomatic replacementSimple structureWater treatment parameter controlOperating means/releasing devices for valvesMagnetic valveSewage

Owner:XIAMEN BAILIN WATER PURIFICATION TECH CO LTD

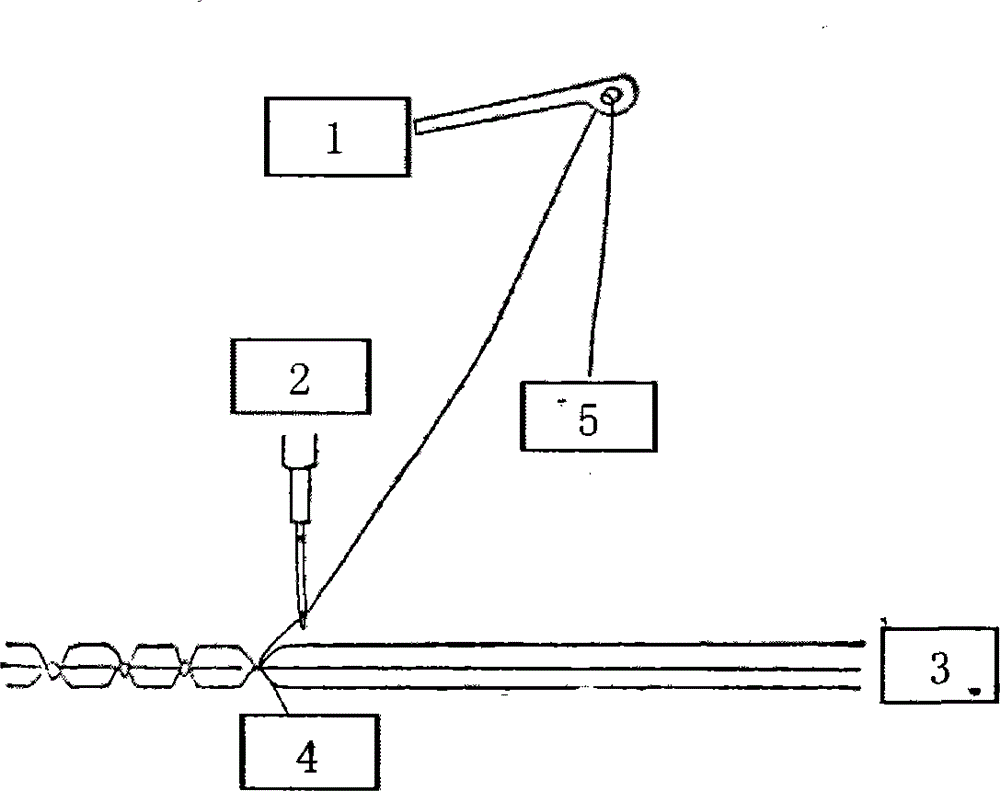

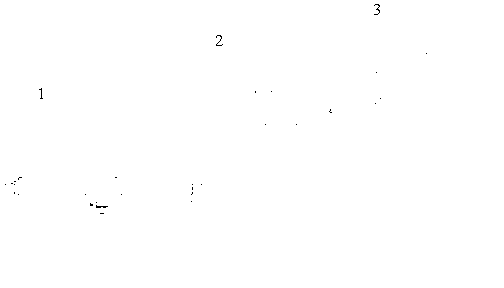

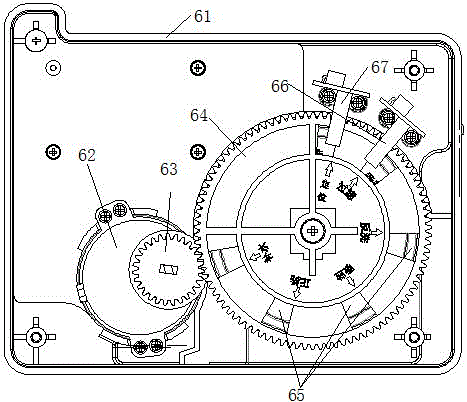

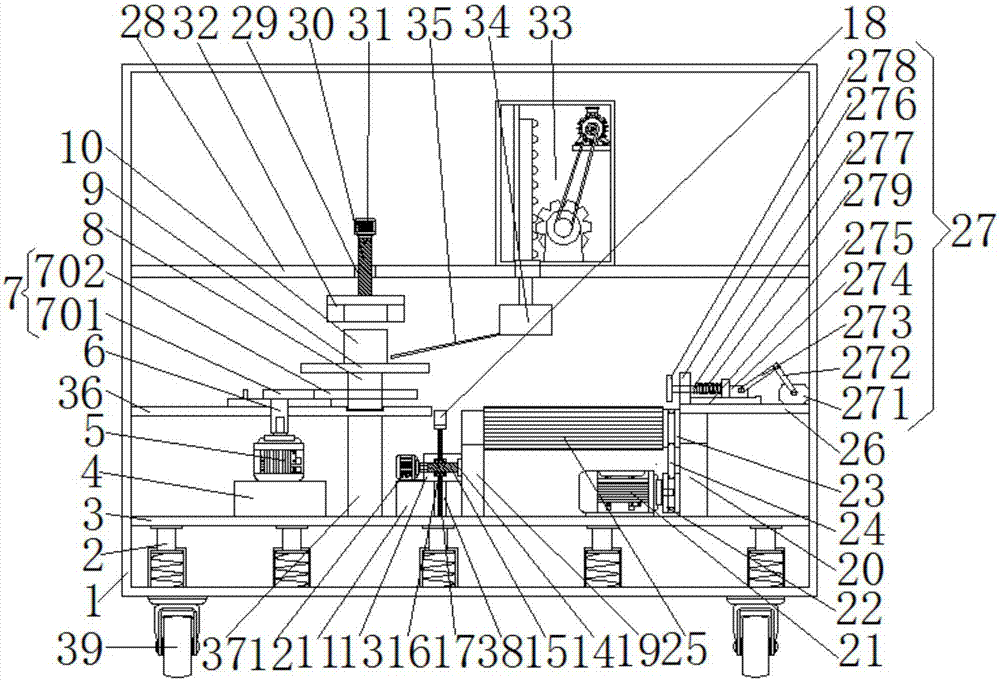

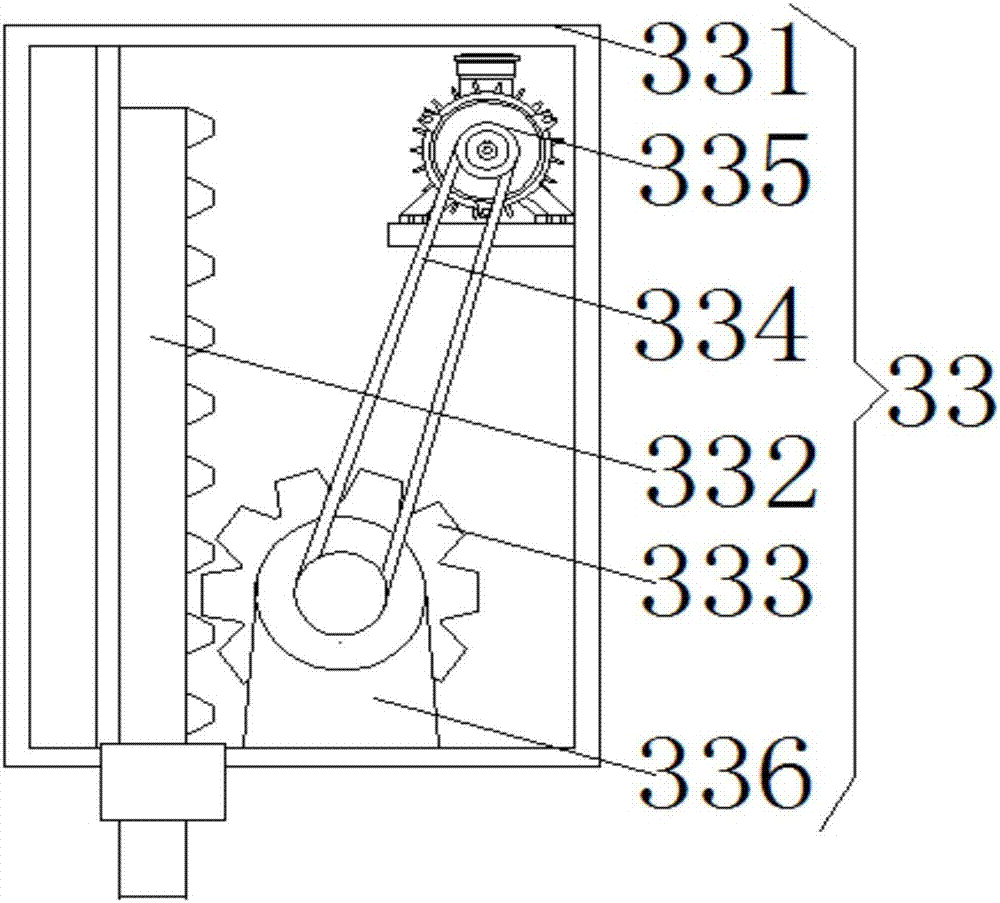

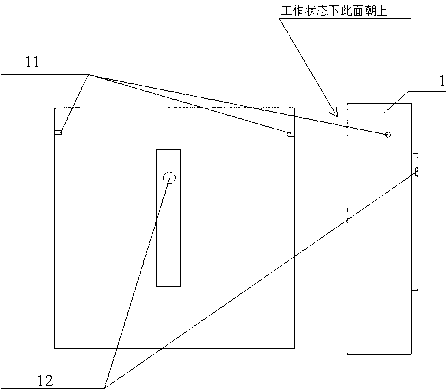

Base welding device for swivel chair

InactiveCN107398663AProtection securityRealize automatic feedingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringThreaded rod

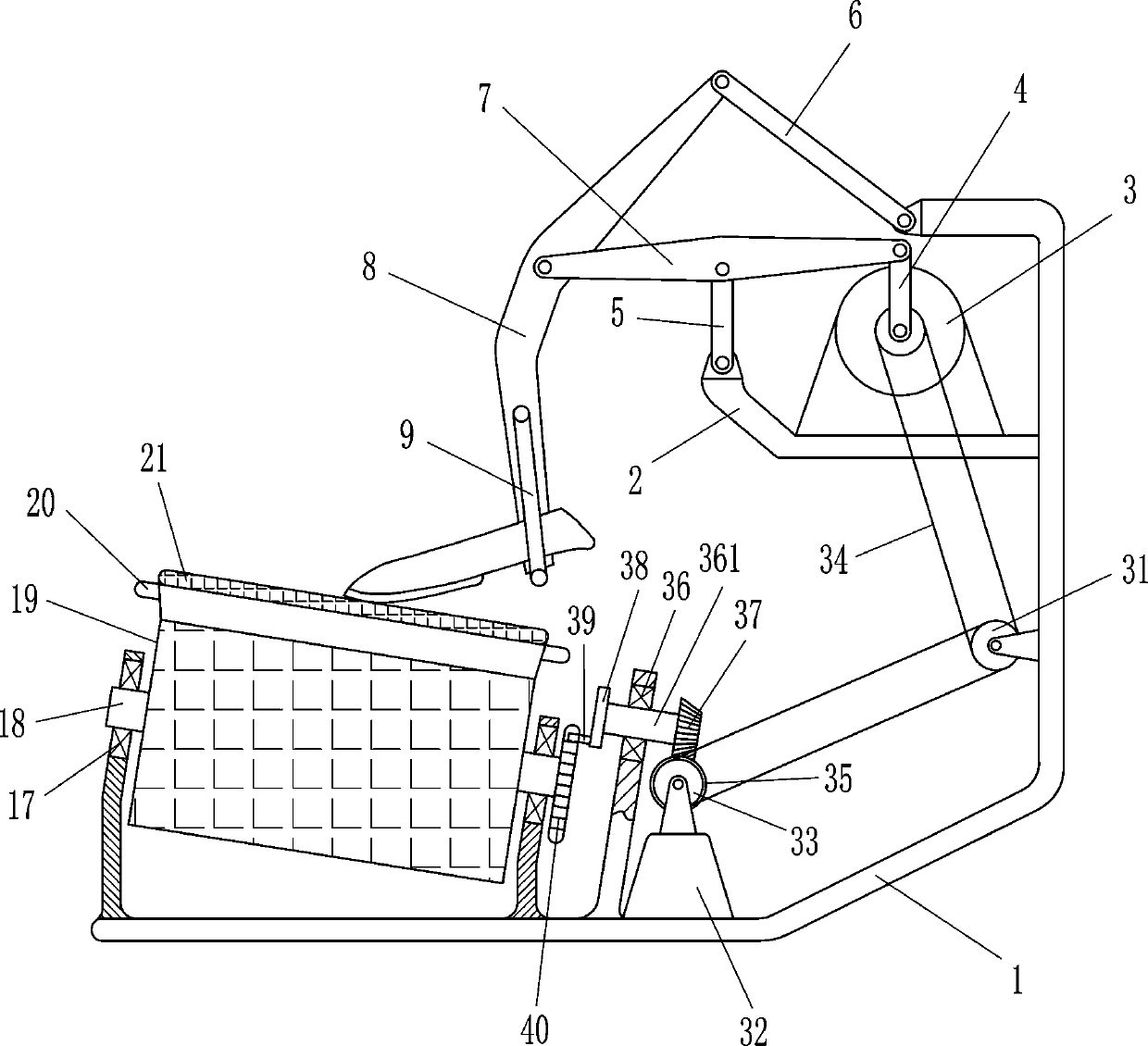

A base welding device for a swivel chair, comprising a box body, a plurality of shock absorbing devices are fixedly connected to the bottom of the inner wall of the bottom box, the output shaft of the first motor is connected to a sheave device through a shaft coupling and rotated through a first rotating shaft, and the The side of the sheave device away from the first rotating shaft is fixedly connected with the loading platform through the second rotating shaft, and the side of the second pulley away from the second support column is rotationally connected with the first support column through a conveyor belt, and the second support column The top is fixedly connected with a first horizontal plate, the top of the first horizontal plate is fixedly connected with a crank slider device, the bottom of the vertical lifting device is fixedly connected with a welding box, and the top of the first threaded rod is fixedly connected with a U-shaped support , The present invention relates to the technical field of processing equipment for swivel chair parts. The device automatically replaces the welding points, completely welds the five legs of the base, fixes the welding position of the legs and the intermediate shaft, prevents mistakes, realizes automatic feeding, avoids manual operation, and protects personal safety.

Owner:安吉天剑电器科技有限公司

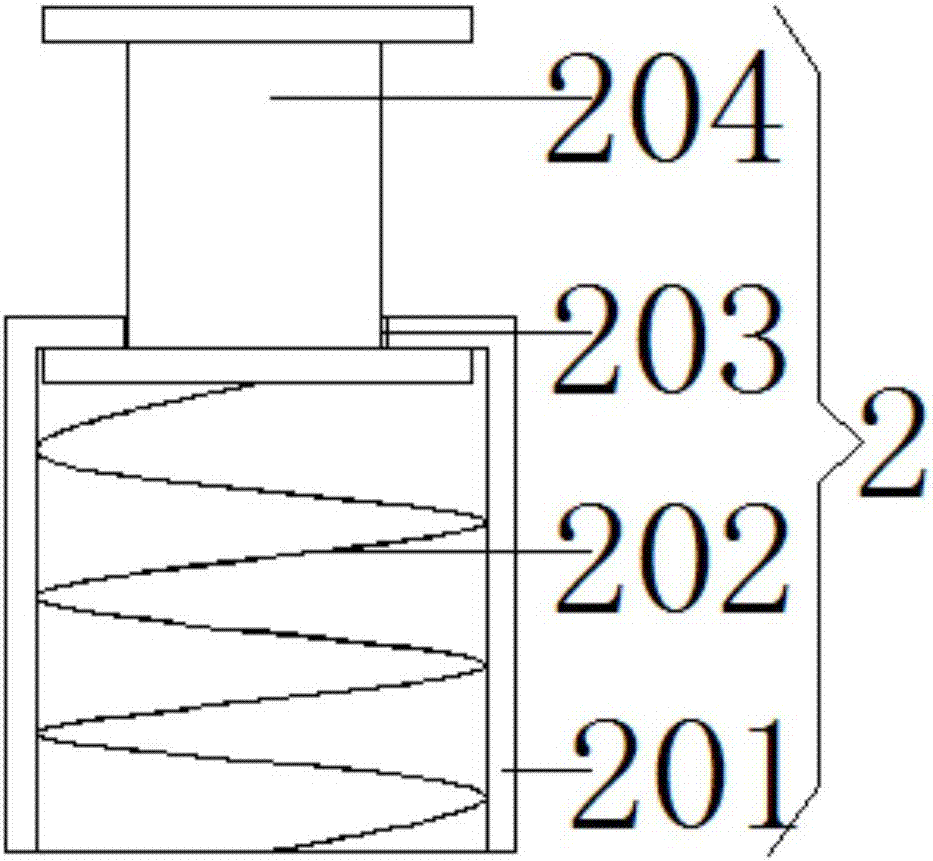

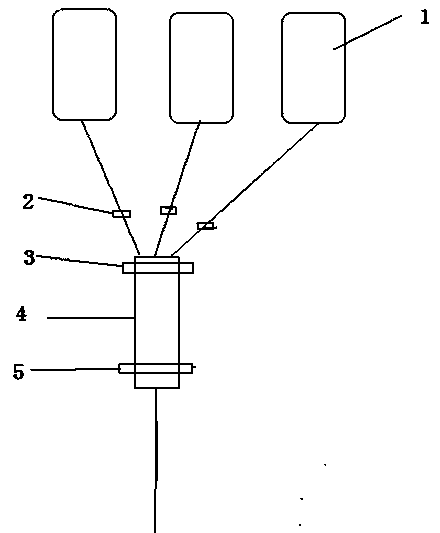

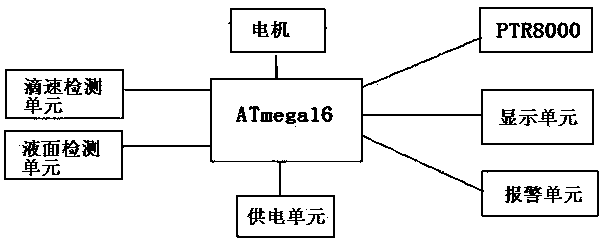

Monitoring system on basis of full-automatic infusion set

The invention discloses a monitoring system on the basis of a full-automatic infusion set. The monitoring system comprises infusion bottles, an infusion pump and infusion valves; an infusion controller is arranged on the infusion pump; a control module simultaneously controls a motor to regulate the infusion valves to control infusion rates and switch the infusion bottles by an infusion rate control module; and a micro control module uploads data to medical personnel by a communication module. The monitoring system not only is convenient to operate, is visual to display and has an alarm function, but also can automatically replace infusion liquor, can effectively avoid a medical accident caused by blood return in the infusion process, can effectively reduce workload of nursing personnel and gives a better working environment for the medical personnel.

Owner:SUZHOU YOURUI TESTING TECH

Method and device for replacing theme

InactiveCN103002025AAutomatic replacementSmart and automatic replacementTransmissionSpecial data processing applicationsNetwork communicationClient-side

The invention belongs to the technical field of network communication and discloses a method and a device for replacing a theme. The method includes a local client acquiring local information set by a system, matching according to the local information and a trigger condition in specific information, wherein the trigger condition associates with a corresponding theme type in the specific information in advance; when the local information and the trigger condition in the specific information are matched, downloading theme data of the theme type associated with the trigger condition from a cloud server; and loading the downloaded theme data according to the local client, determining whether the downloaded theme data is consistent with a currently used theme, and if no, replacing the currently used theme with the downloaded theme data. According to the method and the device, theme replacement can be performed automatically according to strategies preset by the server or modes set by users.

Owner:BEIJING QIHOO TECH CO LTD +1

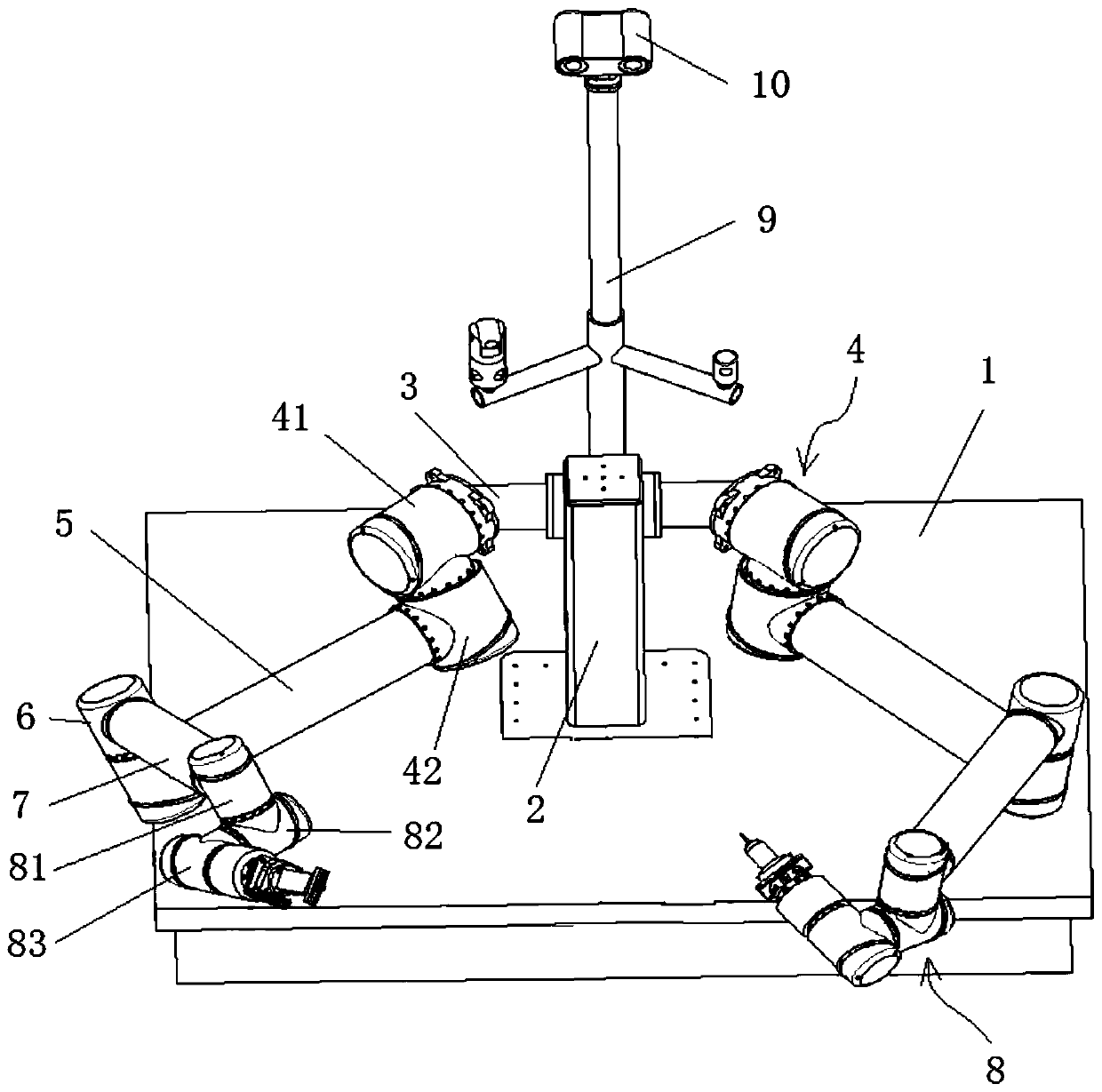

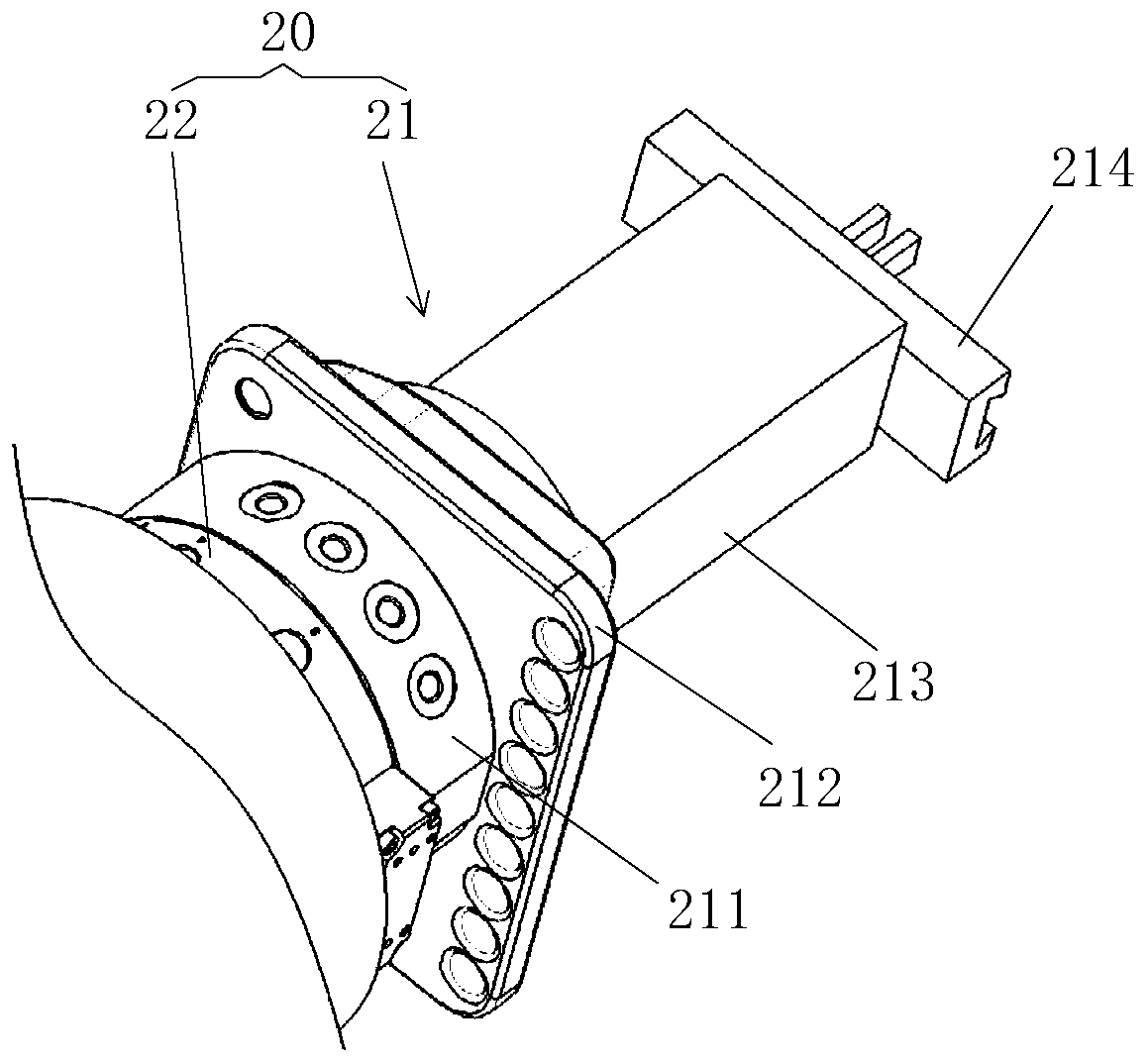

Distribution network hot-line work robot with automatic quick-change work tool system

InactiveCN110421546AEnhance automatic operation abilityAutomatic replacementProgramme-controlled manipulatorJointsWrist jointsLive-line working

The invention discloses a distribution network hot-line work robot with an automatic quick-change work tool system. The robot comprises a workbench, a stand column, a cross rod, a first mechanical arm, a second mechanical arm, a telescopic rod and a binocular vision camera, wherein the first mechanical arm and the second mechanical arm are symmetrically arranged on both ends of the cross rod; thefirst mechanical arm comprises a shoulder joint, a large arm, an elbow joint, a wrist joint, a mechanical arm end quick-change joint and a plurality of quick-change work tools; the shoulder joint is composed of two joint motors; the elbow joint is composed of a joint motor; the wrist joint is composed of three joint motors; the rotation central axes of the first joint motors of the first mechanical arm and the second mechanical arm are in an splayed arrangement; the quick-change work tools comprise a tool end quick-change joint, a quick-change frame, an insulation mounting seat and an operation tool; and the tool end quick-change joint, the quick-change frame, the insulation mounting seat and the operation tool are sequentially connected. The distribution network hot-line work robot is adaptable to the requirements of distribution network live-line work, has the characteristics of miniaturization, light weight, standard interfaces and the like, and is capable of automatically and quickly replacing the work tools.

Owner:STATE GRID ANHUI ELECTRIC POWER CO LTD HUAINAN POWER SUPPLY CO +3

Surgical operating knife blade sharpness qualification detection device

InactiveCN109596449AReduce workloadAutomatic replacementInvestigating machinabilityEmbedded systemKnife blades

The invention relates to a sharpness qualification detection device, in particular to a surgical operating knife blade sharpness qualification detection device, and aims at the technical problem of providing a surgical operating knife blade sharpness qualification detection device which is more accurate in test result and more convenient in record and test process. According to the technical scheme, the surgical operating knife blade sharpness qualification detection device comprises an installation rack, an L-shaped connecting rod, a motor, a first connecting rod, a second connecting rod, a third connecting rod, a fourth connecting rod, an arc-shaped connecting rod, a first pressing rod and the like; and the L-shaped connecting rod is arranged on the upper surface of the left side of theinstallation rack, and the motor is arranged on the right side of the top of the L-shaped connecting rod. According to the surgical operating knife blade sharpness qualification detection device, detection personnel control the motor to rotate to drive an operating knife blade to downwards make a knife mark, and then the sharpness of the operating knife blade can be clearly measured by observing and recording the displacement size of the operating knife blade; and by arranging a pressing wheel, the detection personnel can avoid the phenomenon that due to the fact that too many skin-like materials are discharged in the process of replacing the skin-like materials, a detection result is not precise.

Owner:钟卿

Battery replacement charging system of unmanned aerial vehicle

ActiveCN108528745AImprove fault toleranceReduced precision requirementsCharging stationsCurrent conducting connectionsUncrewed vehicleEngineering

The invention discloses a battery replacement charging system, and belongs to the technical field of machinery. The battery replacement charging system of an unmanned aerial vehicle comprises a detachable battery and a detachable battery replacement charging device. The system has the advantages that the use efficiency of the unmanned aerial vehicle is improved, the overall battery life of the unmanned aerial vehicle is prolonged, the application range is wide, the development period is short, the difficulty is moderate, and the cost is low.

Owner:JIANGNAN UNIV

Automatic bag changing defecation nursing bed using method

The invention relates to an automatic bag changing defecation nursing bed using method. The automatic bag changing defecation nursing bed comprises a foldable nursing bed, a defecation bar, a distribution block, a tray, a defecation pipe, an automatic bag discharging box, a bag opening sealing partition device, a control device, a power supply device and the like, wherein the tray is arranged atthe hip opening position of the foldable nursing bed; the defecation pipe is arranged in the middle of the tray; the automatic bag discharging box and the bag opening sealing partition device are arranged at the tail end of the defecation pipe; the defecation bar is arranged in the middle of the defecation pipe; the tail end of the defecation bar is connected with the distribution block through the defecation pipe; and a massager is arranged at the head of the foldable nursing bed. The bed is simple to operate, can realize intelligent control, not only has a good cleaning effect on constipation, but also can clean residual excrement in rectal folds; after cleaning, probiotic solution is sprayed on the inner wall of the rectum, so that the bed is helpful for improving intestinal microecological environment and enhancing gastric motility.

Owner:李昱儒

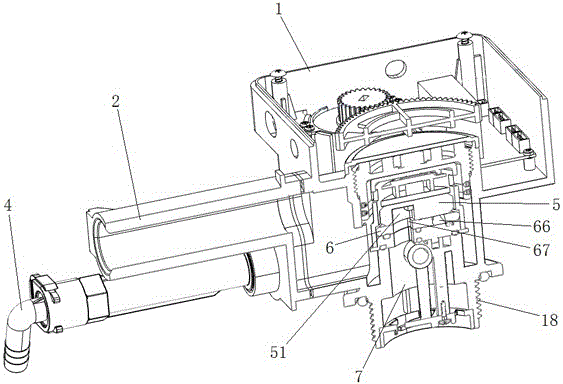

Water purifier control valve and method of using same

InactiveCN105889568AAutomatic replacementSimple structureWater treatment parameter controlOperating means/releasing devices for valvesEngineeringControl valves

The invention relates to a water purifier control valve and a method of using the same. The water purifier control valve comprises a valve body and a valve cover; a water inlet pipe connected with a water inlet pipeline, a water outlet pipe connected with a faucet, a blow-off pipe, a filter element outside port and a filter element inside port are arranged on the valve body; a moving valve block and a fixed valve block which are stacked upon each other are arranged inside the valve body; the fixed valve block is driven by a driving mechanism to rotate around the axial center; a first through hole communicated with the blow-off pipe is formed at the central part of the fixed valve block; a second through hole, a third through hole, a fourth through hole, a fifth through hole, a sixth through hole and a seventh through hole are evenly distributed beside the first through hole in a radial pattern; the fourth through hole and the sixth through hole are closed; the second through hole, the fifth through hole and the seventh through hole are respectively communicated with the filter element outside port; the third through hole is communicated with the filter element inside port. The water purifier control valve realizes the automatic shift between the filter mode, the front washing mode and the back washing mode of a water purifier, and has the advantages of being simple in structure, and stable and reliable in performance.

Owner:XIAMEN BAILIN WATER PURIFICATION TECH CO LTD

Rotary sewage treatment device

InactiveCN105776517AExtended duty cycleAutomatic replacementTreatment using aerobic processesTreatment involving filtrationWork cycleEngineering

The invention belongs to the field of water treatment equipment, and particularly relates to a rotary sewage treatment device.The rotary sewage treatment device comprises a barrel.The barrel is cylindrical.At least two filter plates are installed in the barrel in a radial mode, connecting parts of the filter plates are connected through a rotating shaft, and the rotating shaft is connected with an output shaft of a motor.A water inlet and a water outlet are formed in the barrel.An arc baffle is arranged between the water inlet and the water outlet, one end of the arc baffle is rotationally connected to the inner wall of the barrel, and the radian of the arc baffle is equal to that of the barrel, so that the arc baffle is attached to the inner wall of the barrel.The linear distance between the two ends of the arc baffle is equal to the width of the filter plates.According to the rotary sewage treatment device, the filter plates can be automatically replaced, and thus the work cycle can be prolonged.

Owner:TIANJIN ZHUOSHENG TECH DEV CO LTD

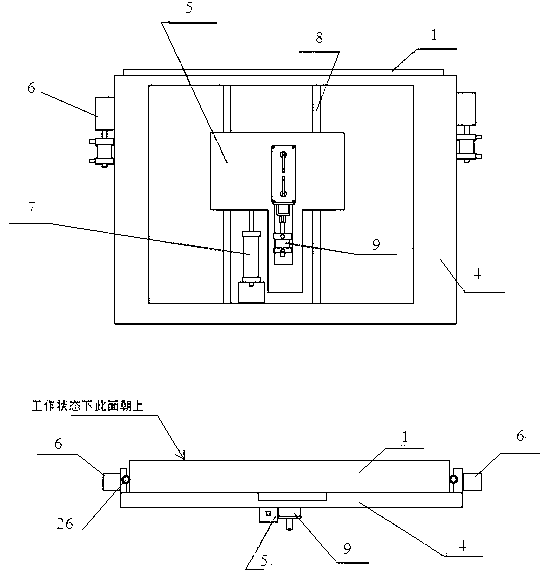

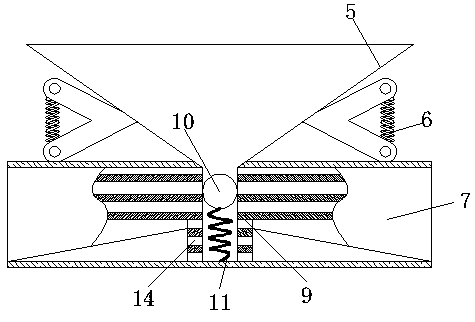

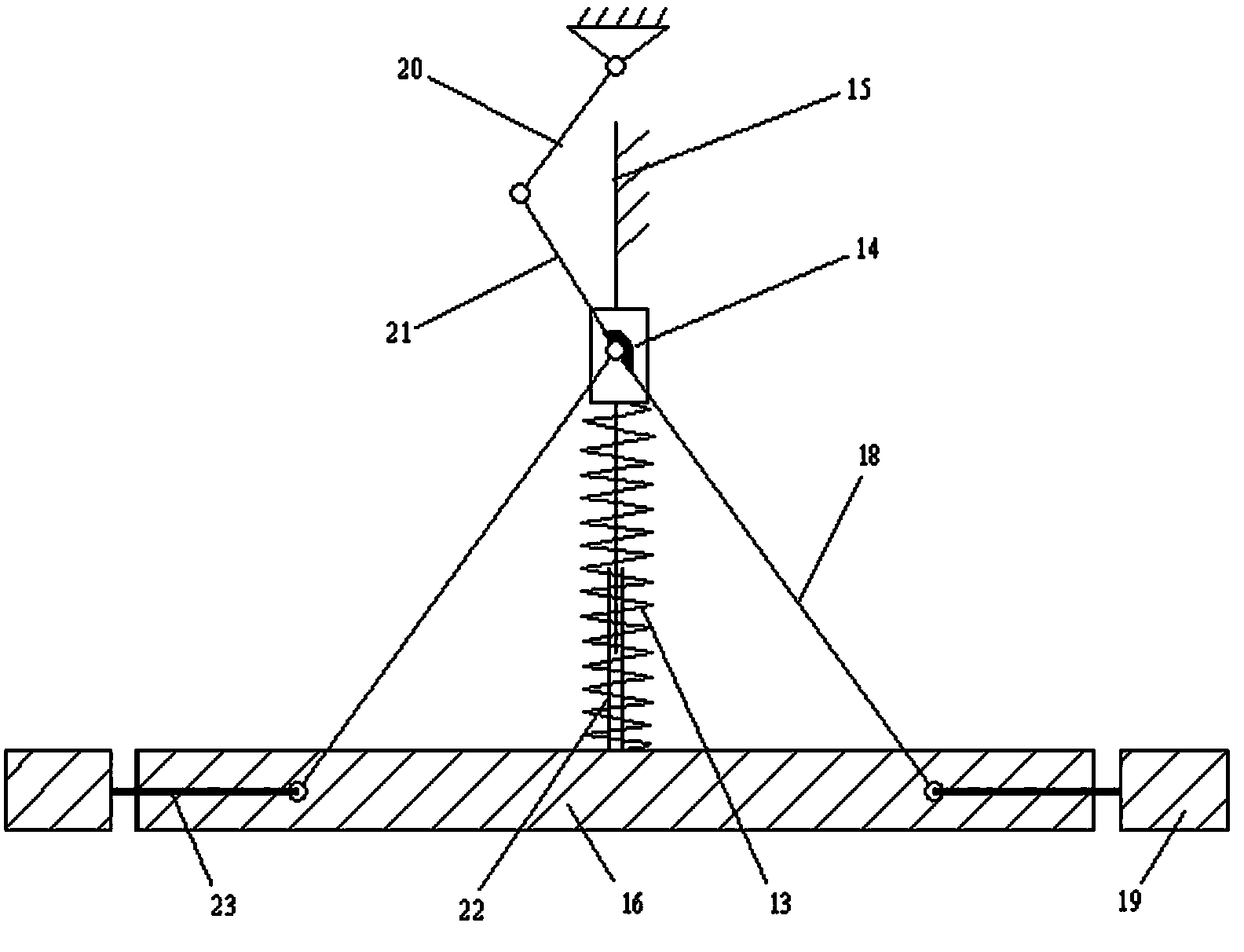

Mounting and dismounting mechanism for electrombile battery and mounting and dismounting method thereof

ActiveCN103223926AAutomatic replacementNo need to increase the size of the buildingElectric propulsion mountingElectric/fluid circuitPower batteryControl system

The invention discloses a mounting and dismounting mechanism for an electrombile battery and a mounting and dismounting method thereof. An automatic fast-replacing battery box system of the pure electrombile power battery comprises a battery outer box, a battery inner box and a battery mounting and dismounting mechanism, wherein the battery inner box is placed inside the battery outer box; the battery outer box adopts a frame structure; a guide rail is arranged in the middle of the bottom casing of the battery outer box; a sliding structure matched with the guide rail is correspondingly arranged at the bottom of the battery inner box; the battery mounting and dismounting mechanism comprises a straining cylinder and a linkage mechanism; the straining cylinder is fixedly connected with the frame on one side of the battery outer box; the end part of a straining piston rod of the straining cylinder is connected with the corresponding position at the bottom of the battery inner box through an electromagnet; the straining cylinder is connected with the cylinder control system through an air channel control electromagnetic valve, and supplies power through the straining cylinder; the battery inner box can move along the guide rail; and the linkage mechanism is fixedly arranged at the bottom casing of the battery outer box, and moves in response to the movement of the straining cylinder.

Owner:BIT HUACHUANG ELECTRIC VEHICLE TECH

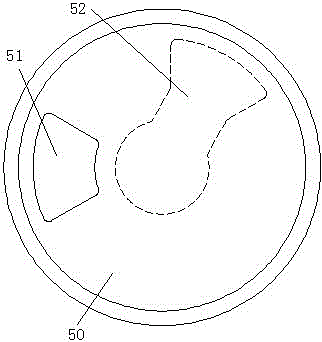

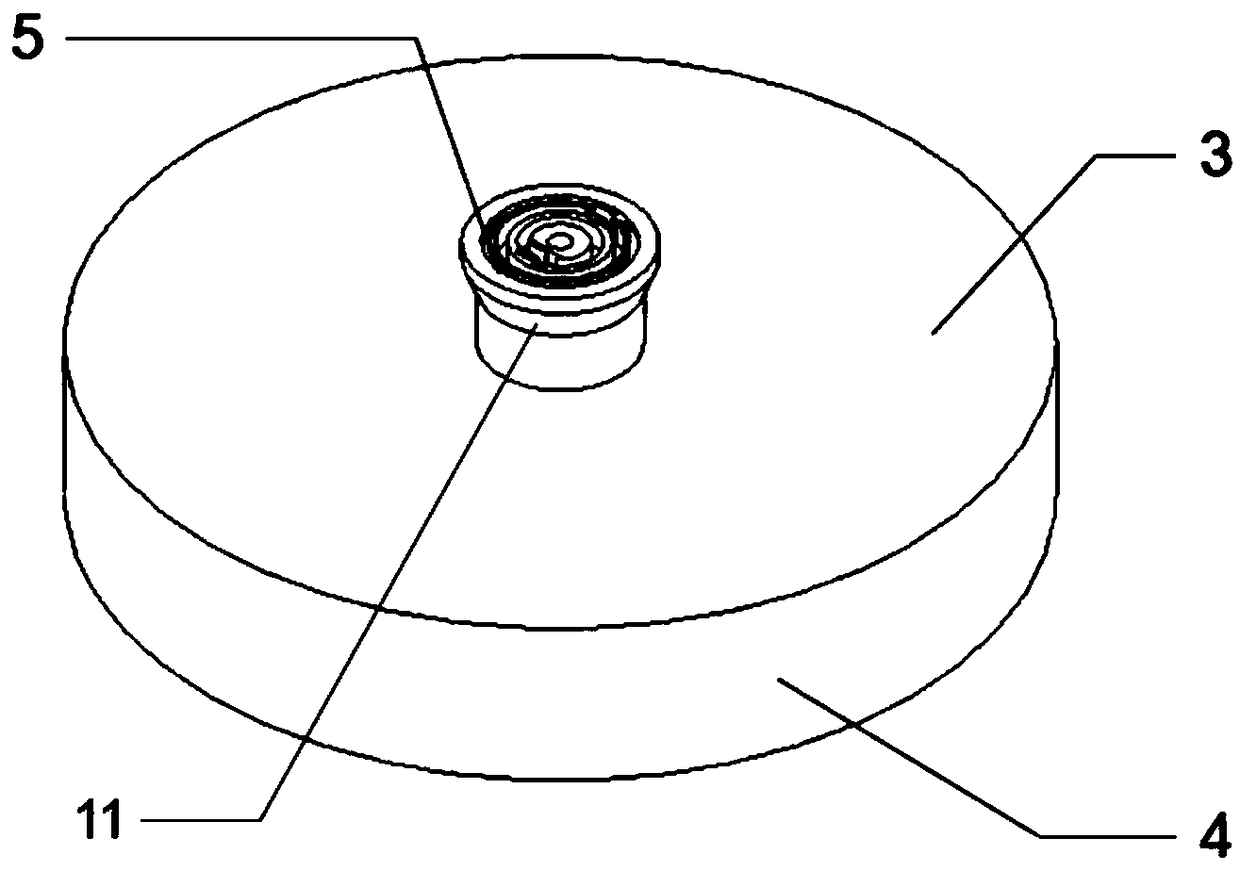

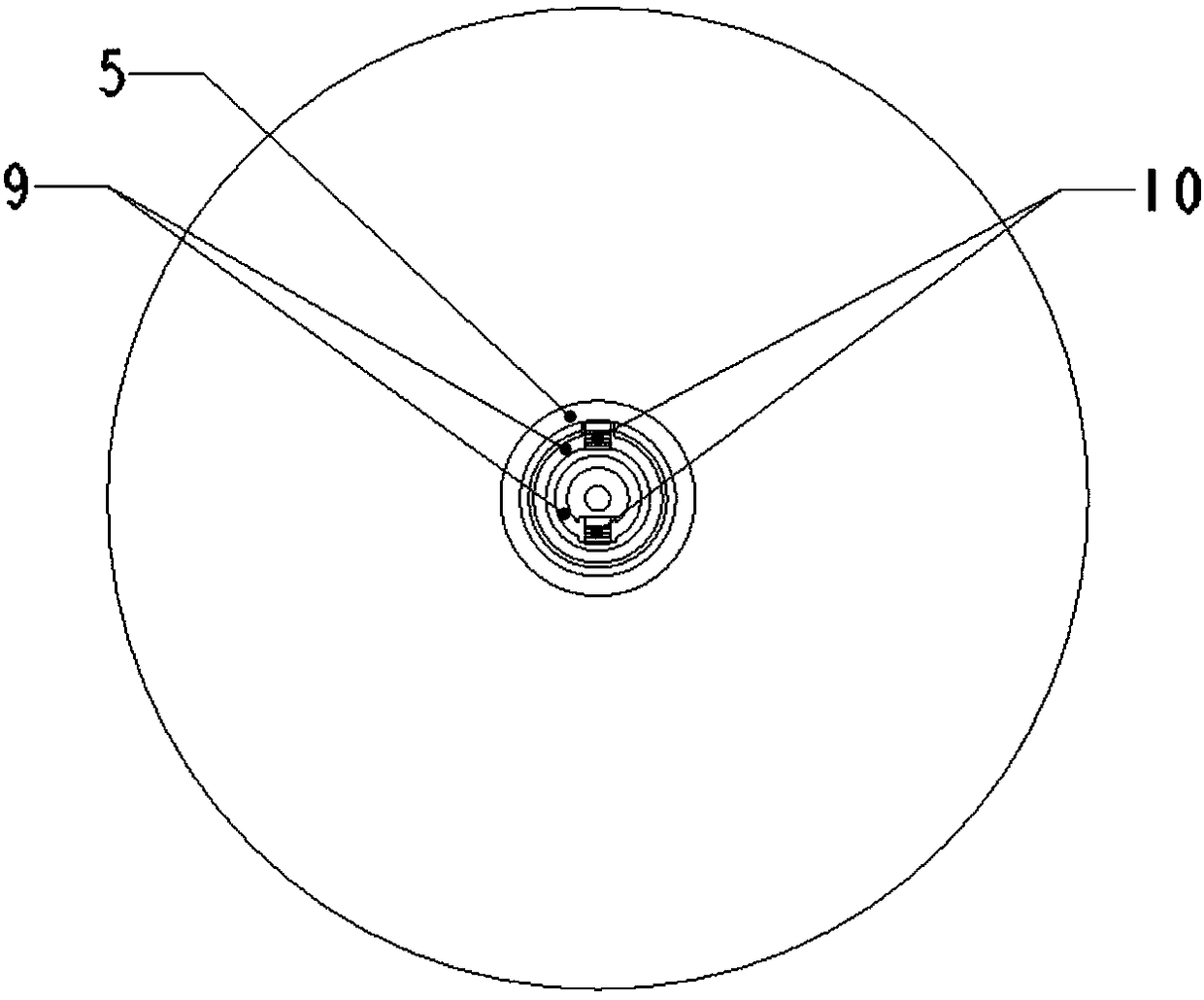

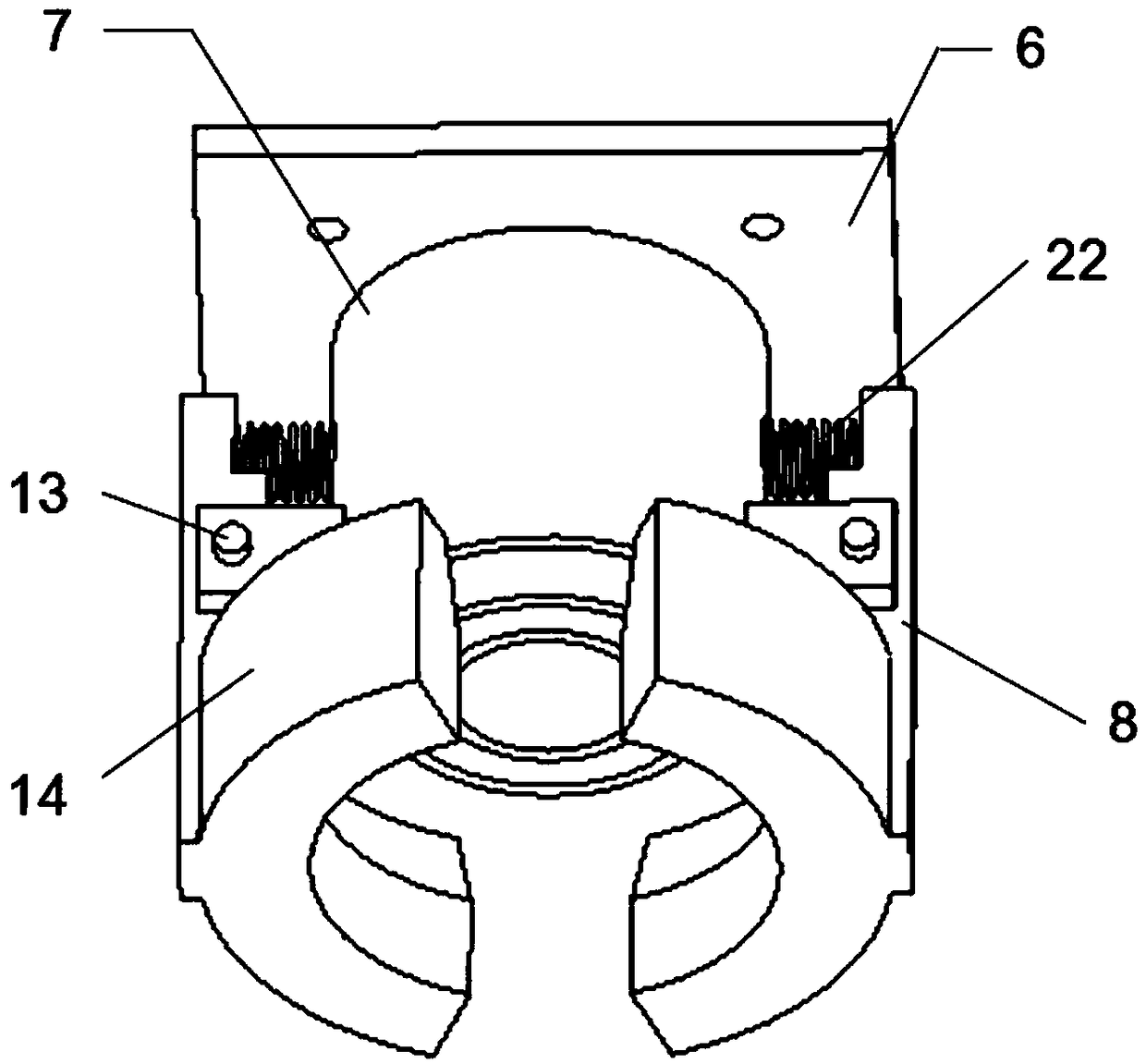

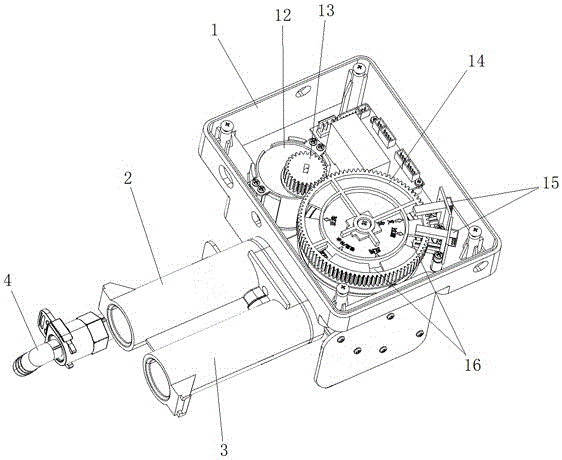

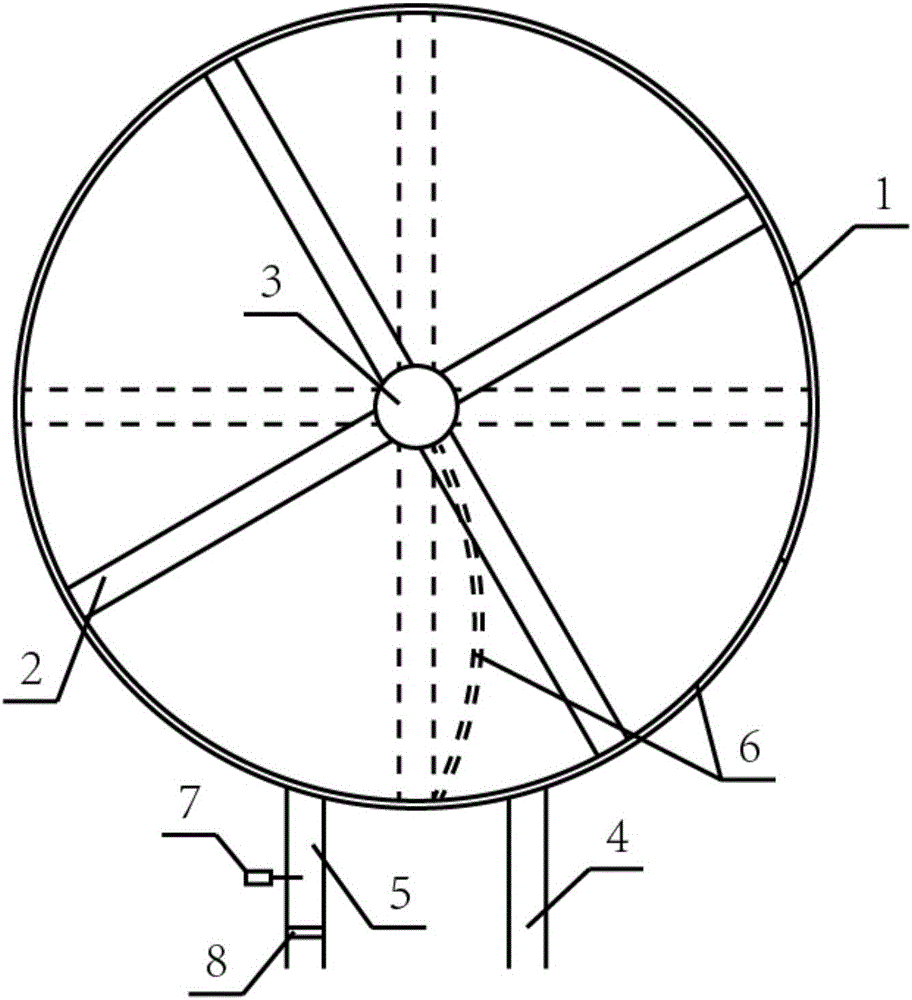

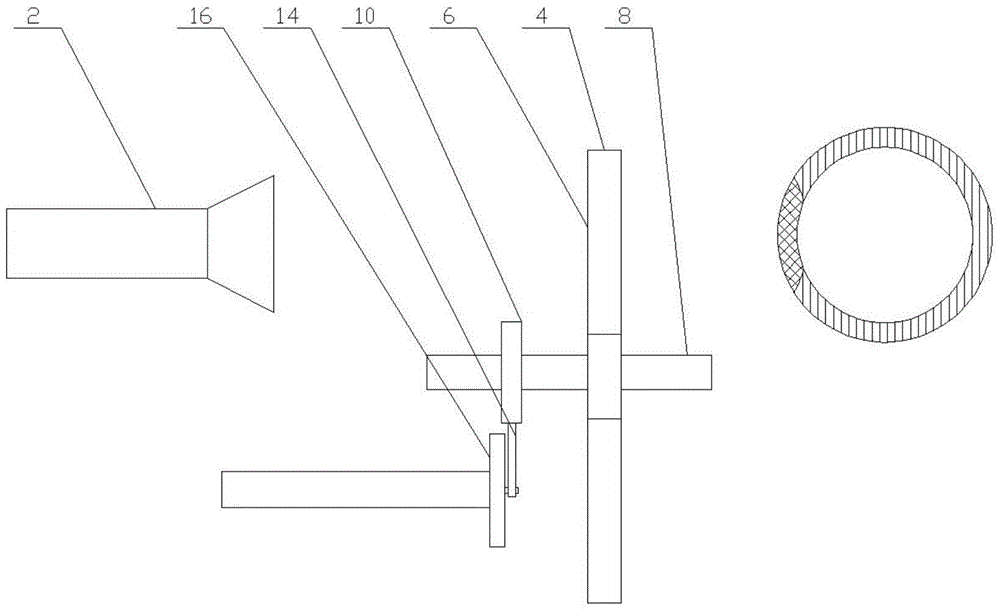

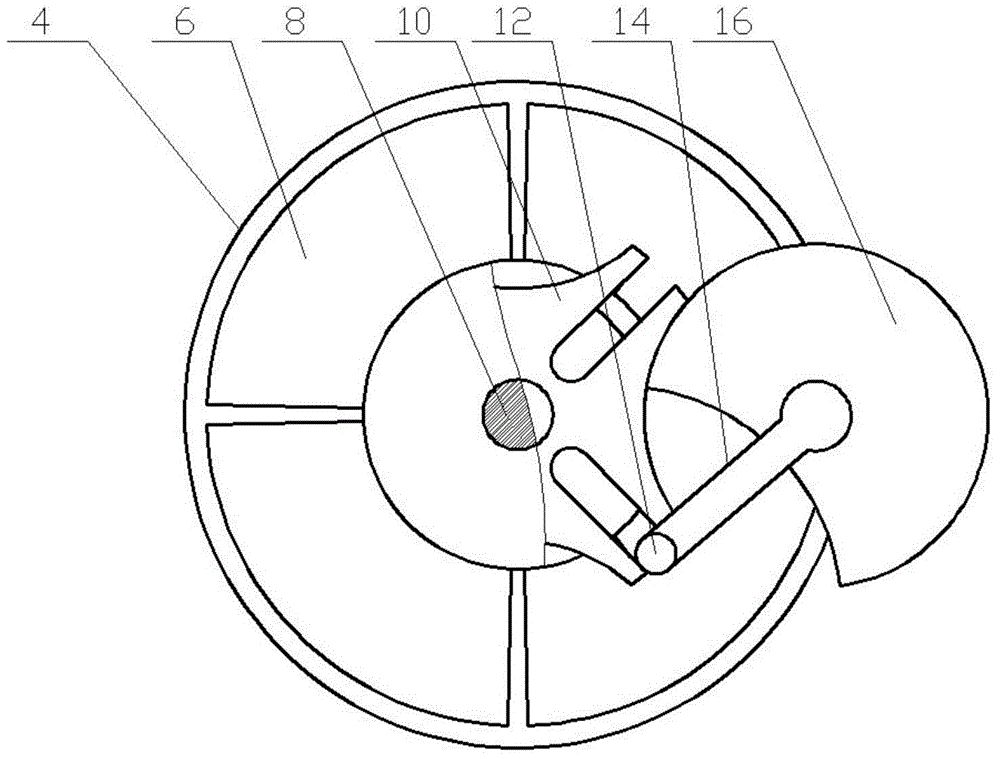

Device for analyzing fluid through optics

InactiveCN105021537AAutomatic replacementSimple structureColor/spectral properties measurementsOptical pathHuman power

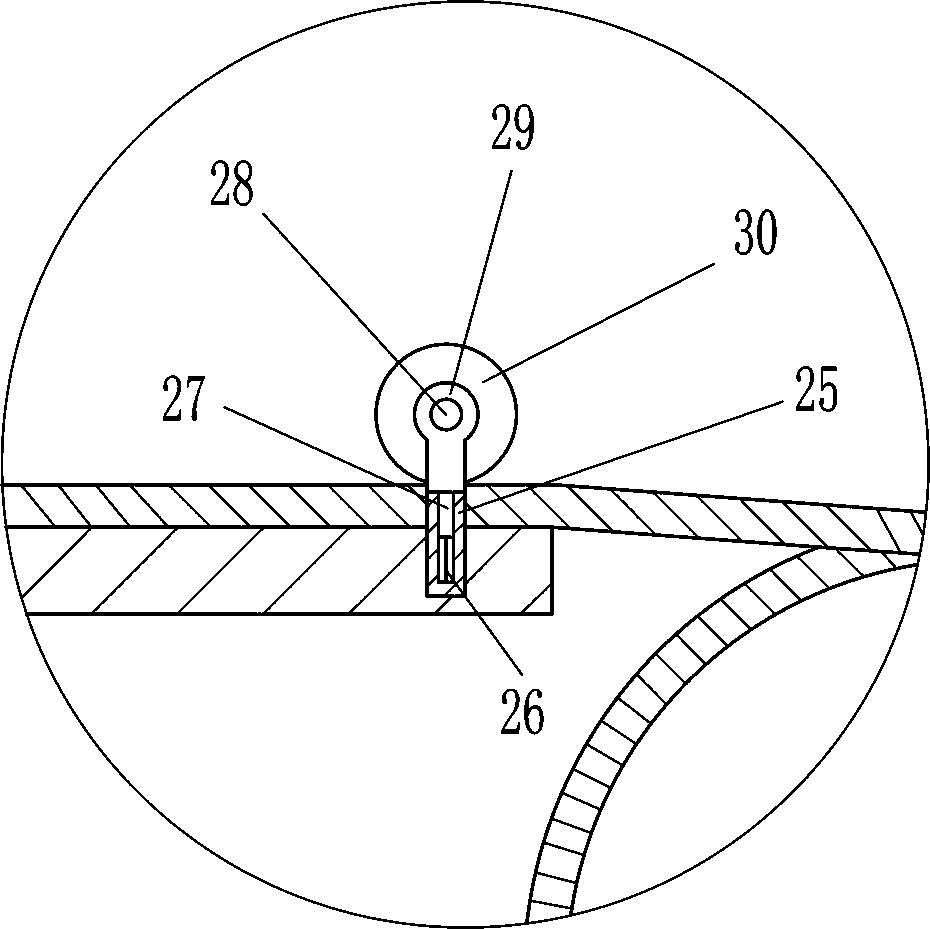

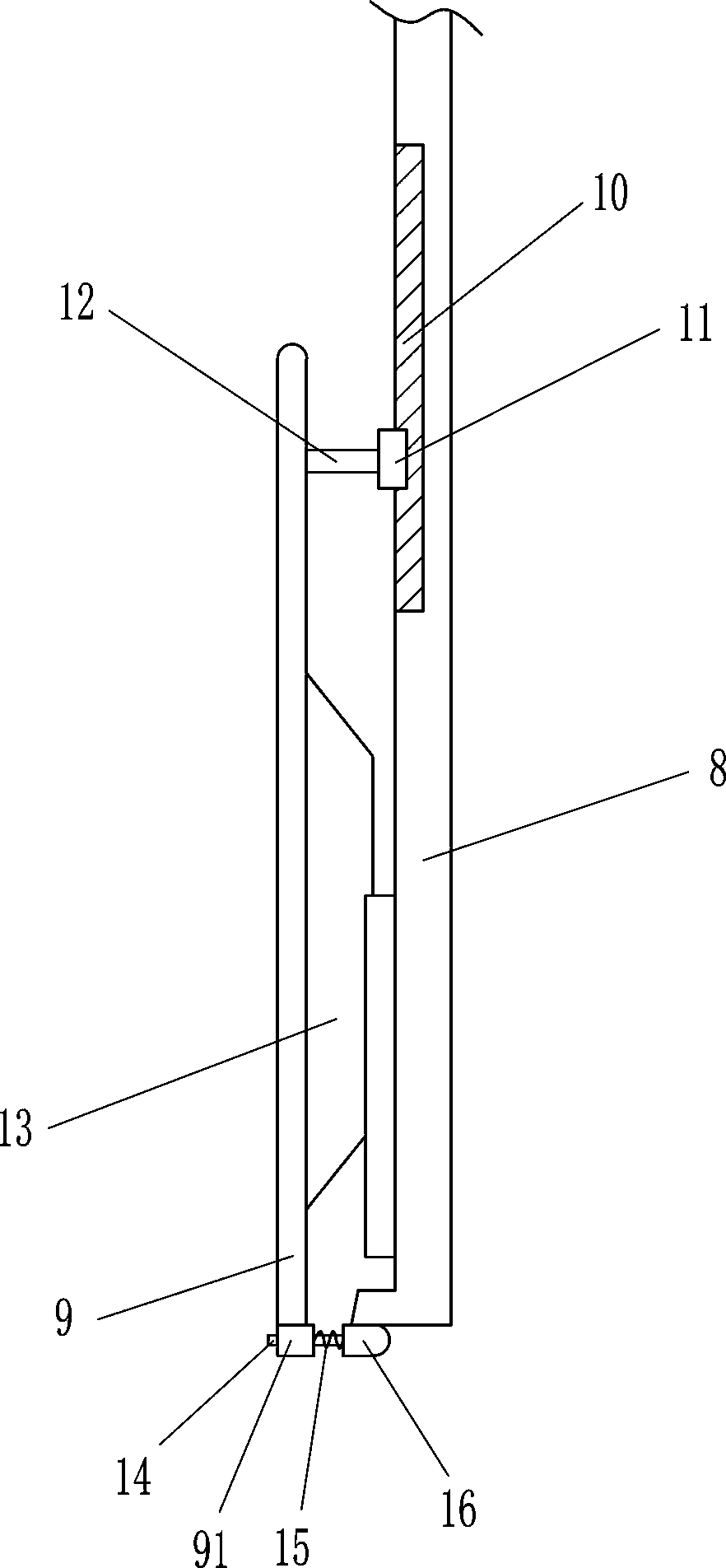

The invention discloses a device for analyzing fluid through optics. The device comprises a light source (2) capable of irradiating into fluid to be detected, and an optical processing mechanism located on the light path of the light source (2). The device is characterized in that the optical processing mechanism comprises a color wheel (4), a drive shaft (8), a grooved pulley (10) and a cylindrical pin (12), the color wheel (4) is of a circular disc structure and is composed of a plurality of optical filters (6), the drive shaft (8) is concentric with the color wheel (4), the grooved pulley (10) is concentrically connected to the drive shaft (8), and the cylindrical pin (12) can be driven by a power device to do eccentric circular movement. The device solves the problems in the prior art, the spectrum analysis principle is adopted, the light source (2) directly irradiates into the fluid through conversion of the optical filters, and all physical parameters of reflected light are analyzed through the spectrum of the reflected light. The mode is simple in structure and convenient to use, the optical filters (6) can be arranged on the same color wheel (4) and are automatically replaced through an intermittent movement mechanism of the grooved pulley (10), the automation degree is improved, the production cost is reduced, and manpower and material resources are reduced.

Owner:SUZHOU EUROPOD PRECISION INSTR TECH CO LTD

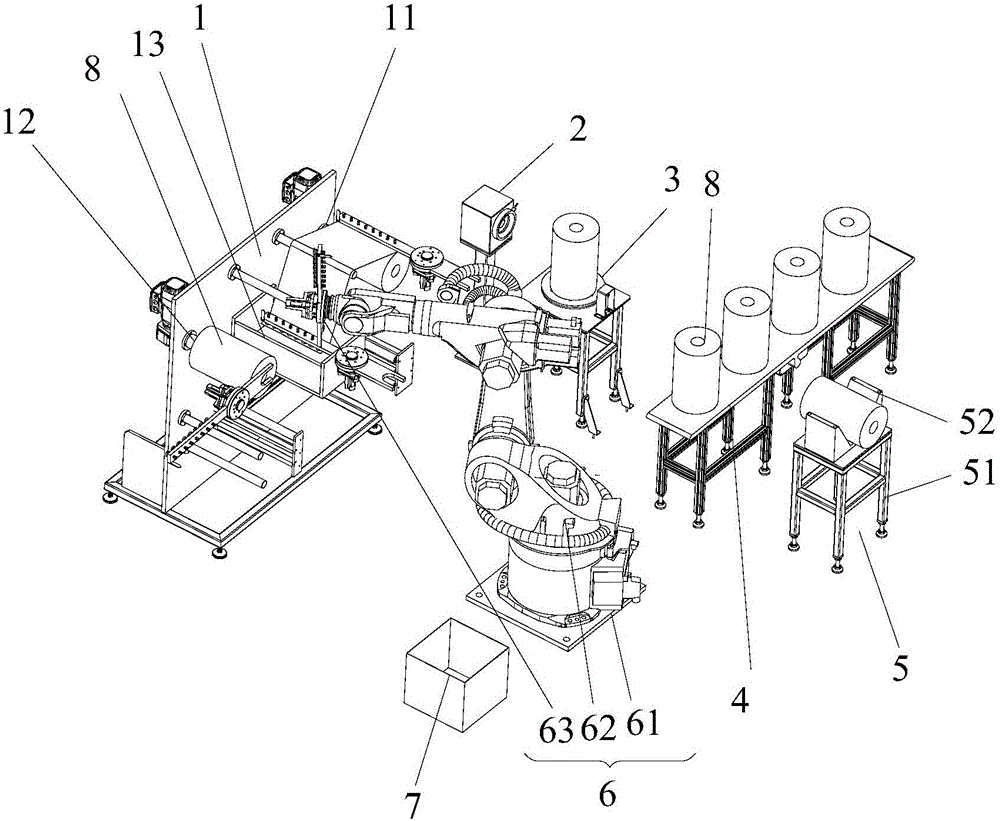

Automatic film connection system for plastic films

ActiveCN106144711ARealize automatic feeding processImprove automationPackagingWebs handlingProduction linePlastic film

The invention discloses an automatic film connection system for plastic films. The automatic film connection system for the plastic films comprises a film connection machine used for bearing plastic film rolls, unfolding the plastic film rolls and conveying the plastic film rolls to a packaging machine for online packaging operation. The film connection machine is provided with a first winding shaft, a second winding shaft and a film combining mechanism, wherein the first winding shaft and the second winding shaft are used for bearing the plastic film rolls correspondingly, and the film combining mechanism is used for seamless connection of the plastic films, on the first winding shaft and the second winding shaft, of the unfolded plastic film rolls. The system further comprises a conveying device and an industrial robot, wherein the conveying device is used for supplying a standby plastic film roll online; and the industrial robot is used for transferring the standby plastic film roll on the conveying device to the first winding shaft or the second winding shaft, in an idling state, on the film connection machine, so that automatic feeding of the film connection machine is achieved. The real sense of continuous product packaging and unmanned production are achieved, the automation and intelligence level of the automatic film connection system is improved, the system is particularly suitable for packaging of dangerous articles, safety accidents of production of the dangerous articles is reduced, and accordingly safety and reliability of packaging and production are improved, and efficiency of a production line is also effectively improved.

Owner:湖南静悦创业投资管理合伙企业(有限合伙)

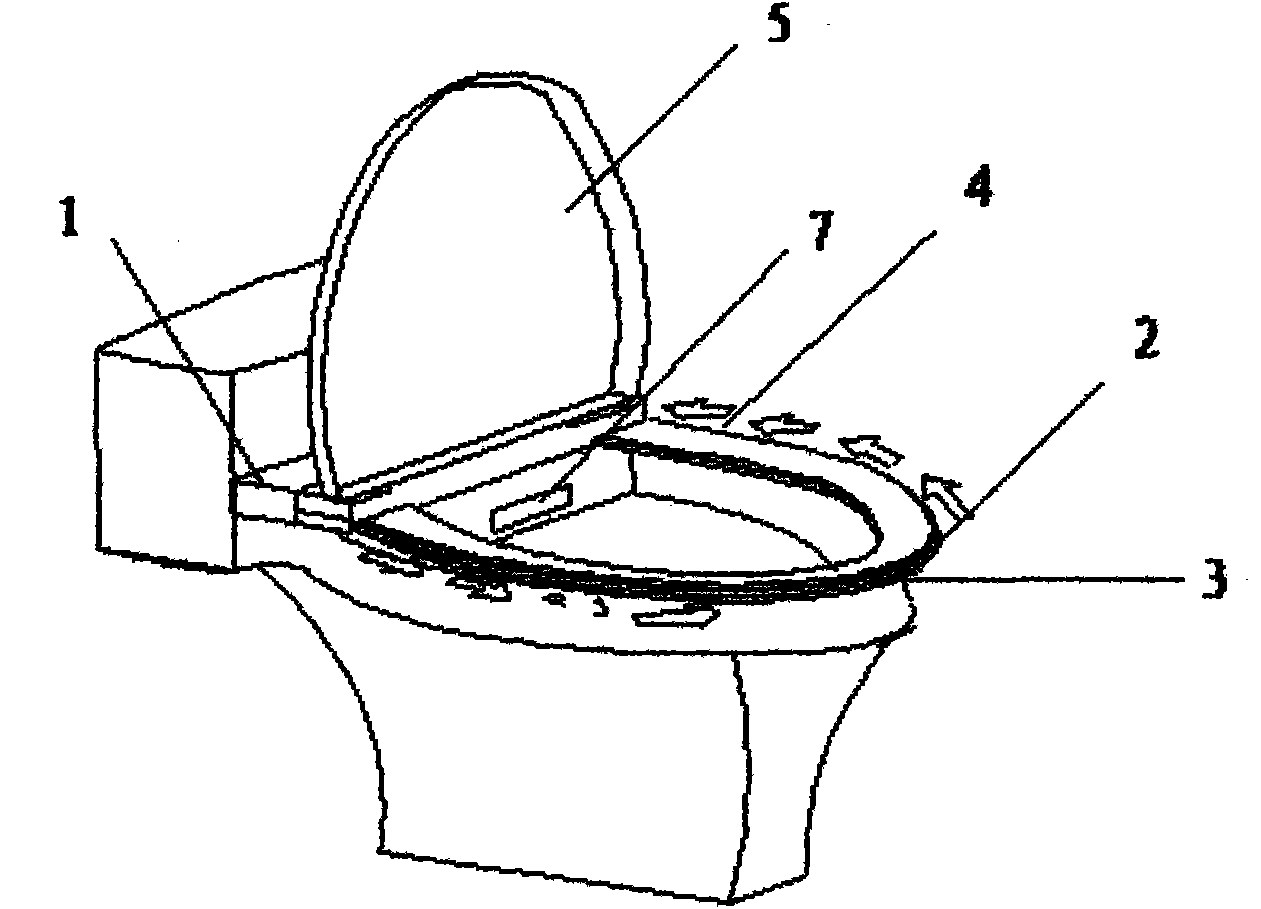

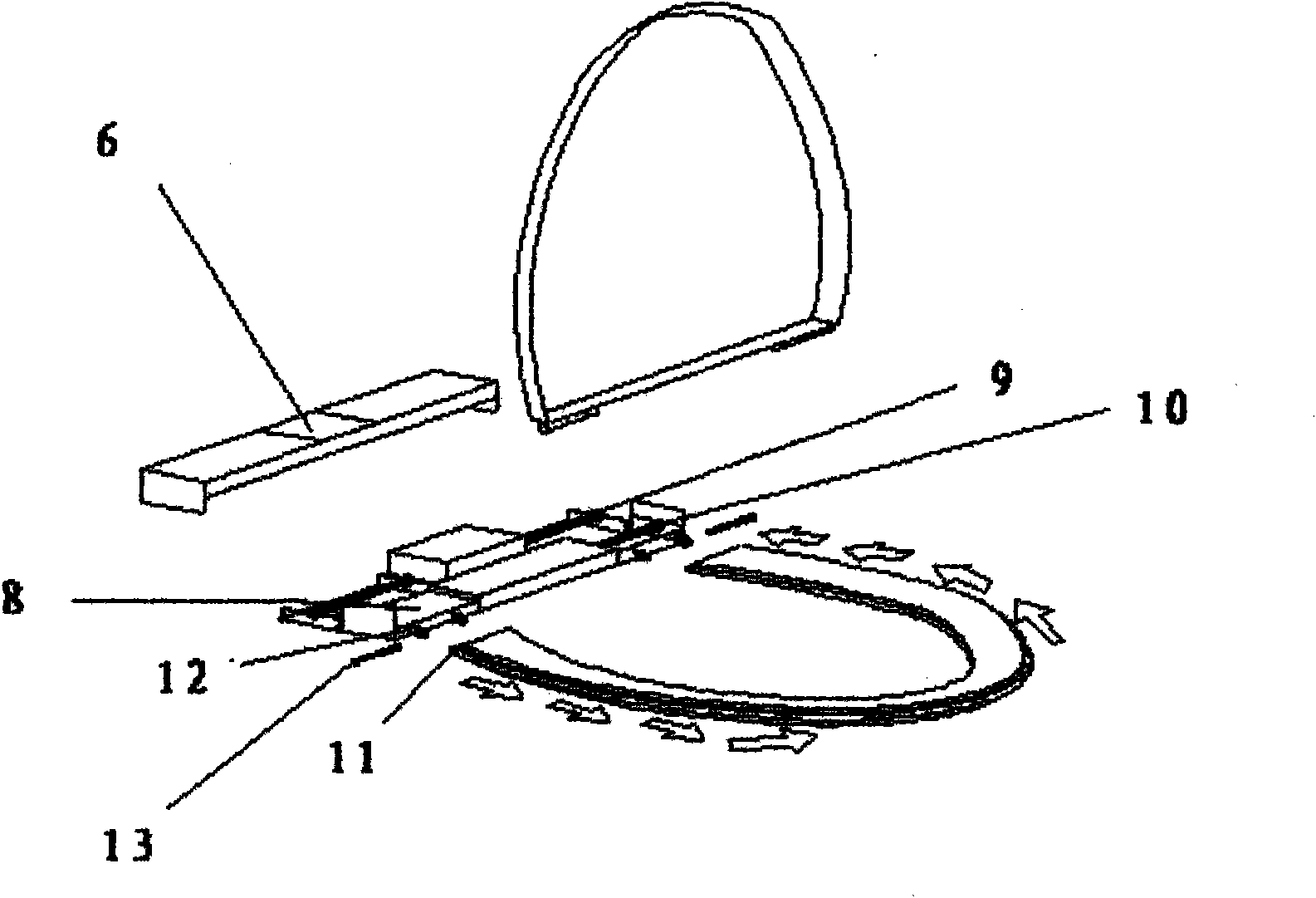

Intelligent toilet pad

InactiveCN101836839AAvoid cross infectionImprove stabilityBathroom coversOhmic-resistance heating detailsEngineeringToilet

The invention discloses an intelligent toilet pad. A heating plate is arranged above a toilet base; a clean sleeve is arranged above the heating plate; a control box 1 is arranged at the connection part of the toilet base and the toilet cover and is connected with an automatic clean sleeve replacing mechanism by a connecting piece; the control box is provided with a heating controller, a odor removal controller and a fragrance releasing controller; and an inductive switch is arranged above the control box. The intelligent toilet pad can realize full intellectualization, automatic heating at constant temperature, automatic replacement of the clean sleeve, automatic release of fragrance, and automatic odor removal and sterilization.

Owner:孙建伟

Sludge treatment filter press with function of easily replacing filter cloth

InactiveCN110314429AAccurately control usageAutomatic replacementSludge treatmentFiltration separationSludgeGravity center

The invention relates to the technical field of replacement of filter cloth of filter press, relates to a sludge treatment filter press with a function of easily replacing filter cloth. The filter press comprises a supporting rack, a press plate is fixedly connected in the supporting rack, the upper portion of the pressure plate is movably connected with a roller, the two sides of the roller are movably connected with a rotary shaft, a flow guide plate is movably connected to the portion, on the lower potion of the press plate, in the supporting rack, the two sides of the flow guide plate aremovably connected with spring blades, and the side, away from the press plate, of the flow guide plate is movably connected with a rolling body. Due to the action of an oblique plate arranged on the bottom, the gravity center of the rolling body is changed, so that the rolling body rotates; due to rotation, the filter cloth can be separated from the surface of the roller, while the filter cloth ispulled, the surface of the filter cloth can be scratched by the spring blades, when the rolling body rolls to the side away from the flow guide plate, water and sludge in a hollow channel can be separated out due to the action of gravity, and therefore, the effects that the using condition of the filter cloth is precisely controlled and the filter cloth is automatically replaced are achieved.

Owner:湖北华耀生物科技有限公司

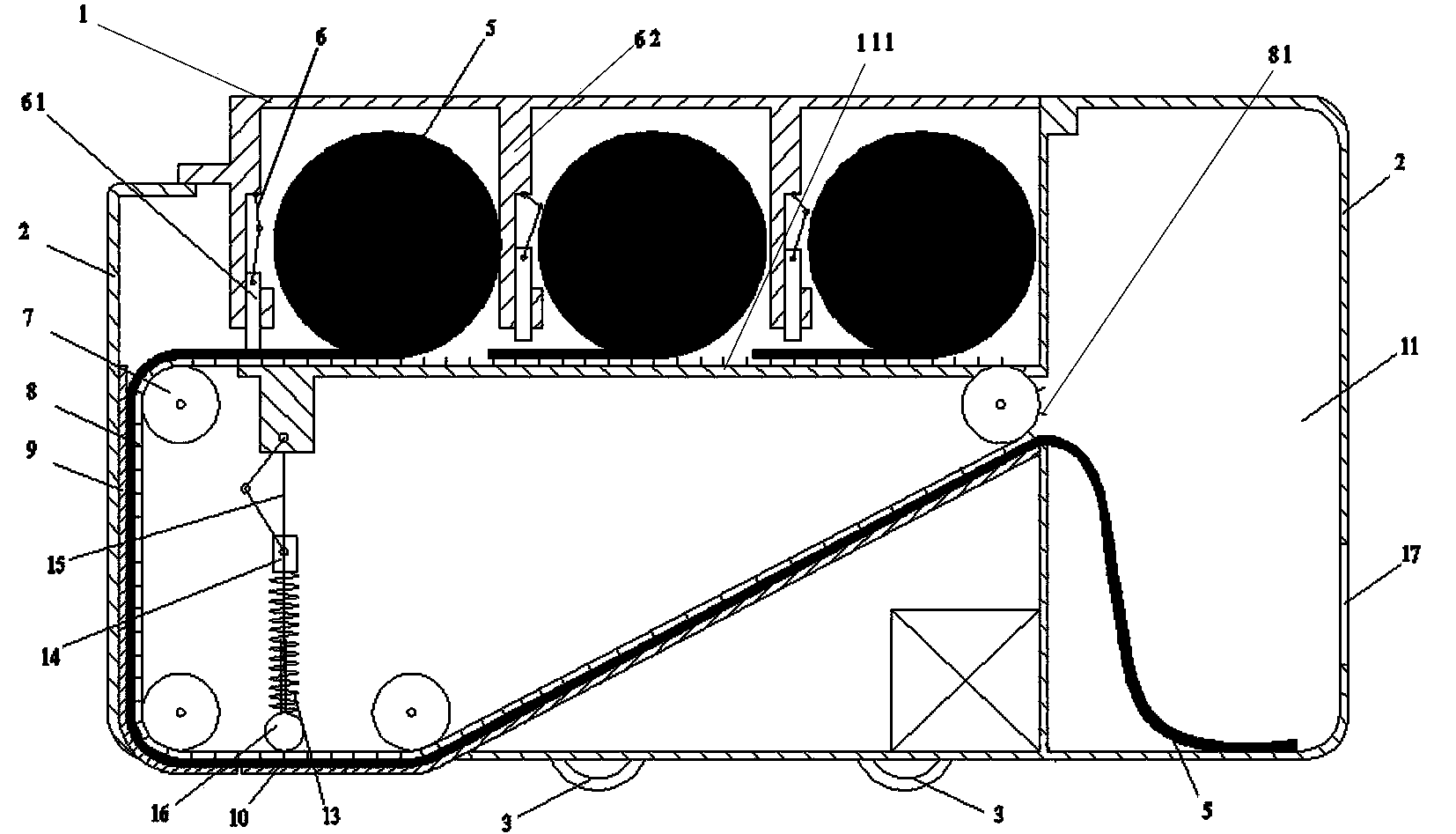

Household floor cleaning machine

ActiveCN103505157AReduce the amount of cleaningReduce volumeMachine detailsFloor-scrubbing machinesEngineeringAutomation

The invention belongs to a cleaning appliance and particularly relates to a household floor cleaning machine which is suitable for household use. The household floor cleaning machine is characterized by comprising a vehicle body, a towel box arranged at the bottom of the vehicle body, a transport component, a conveying and pushing part, a pushing component for pushing a towel transported by the transport component to the bottom of the vehicle body, and a dirty towel storage box for storing dirty towels, wherein the dirty towel storage box is provided with a dirty towel inlet and a dirty towel outlet, and a towel pushing outlet is formed in the position, corresponding to the lower part of the pushing component, at the bottom of the vehicle body. The cleaning machine cleans the ground by automatically transporting and pushing the towel, is in tight contact with the ground, has a good cleaning effect. The transport is convenient and smooth, and jamming is not likely to happen. The equipment cannot be easily damaged and is long in service life. The cleaning machine is simple in structure, low in cost, high in degree of automation and good in cleaning effect.

Owner:如东县东广物流有限公司

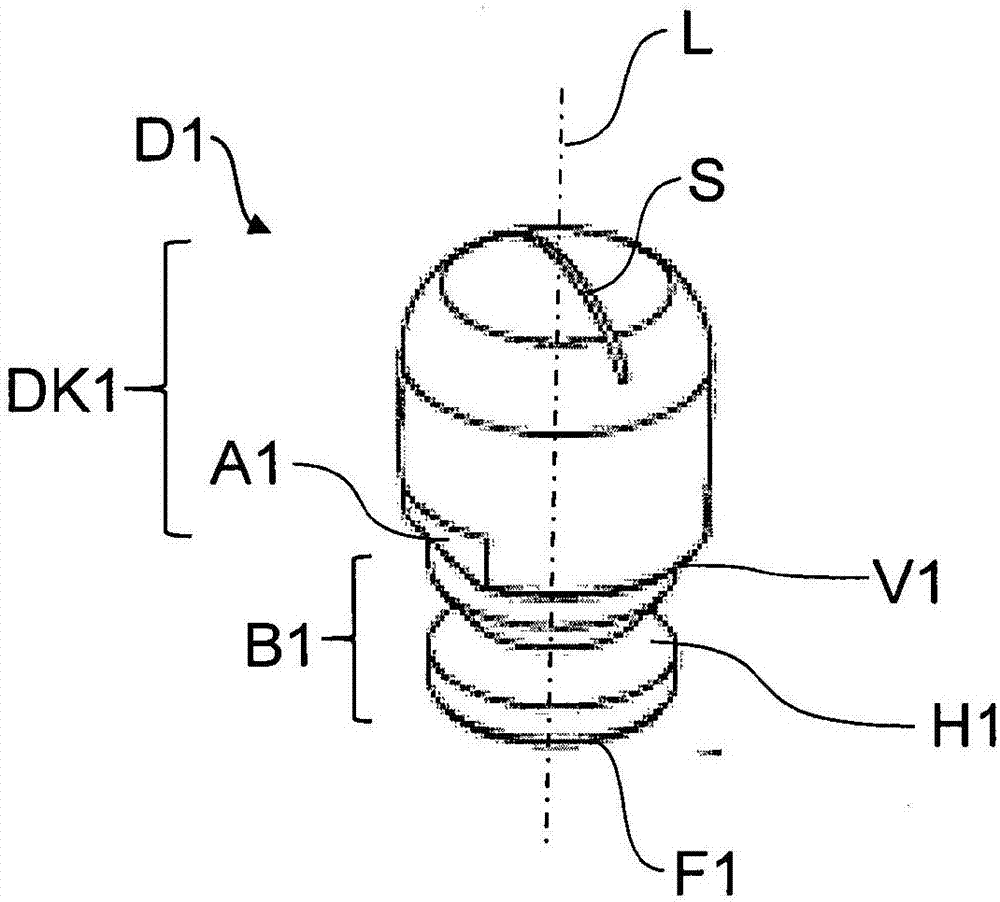

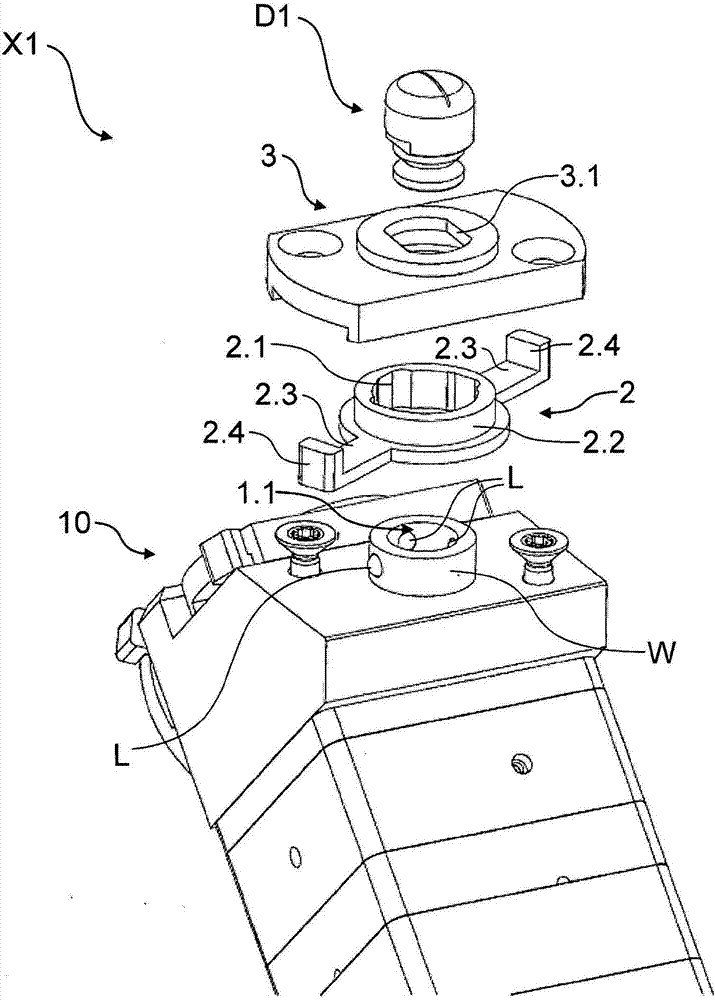

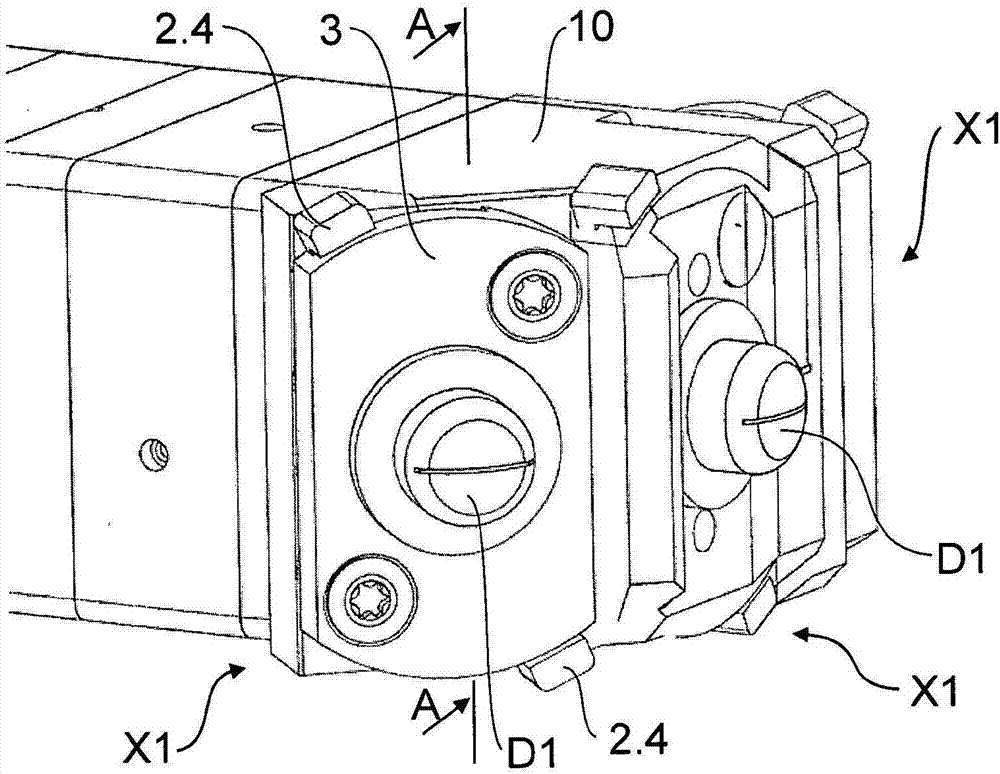

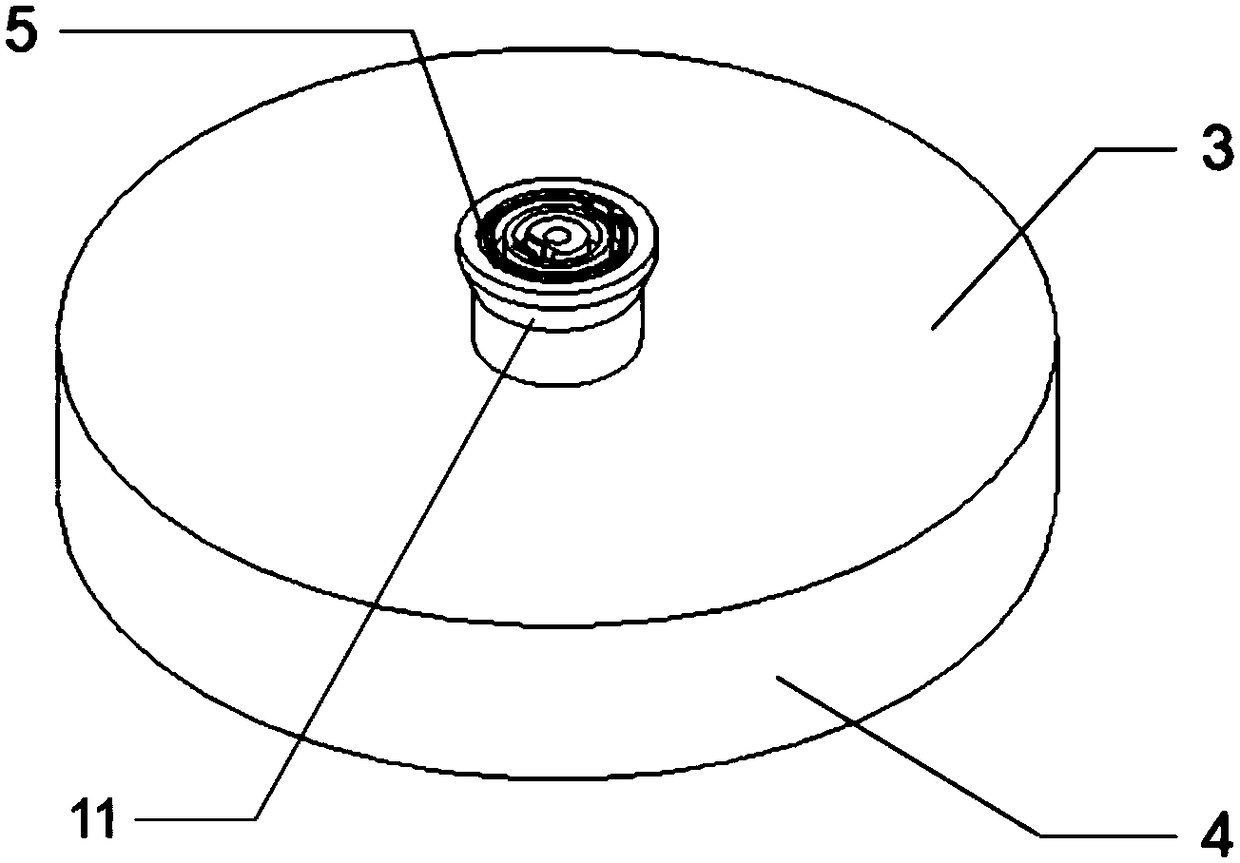

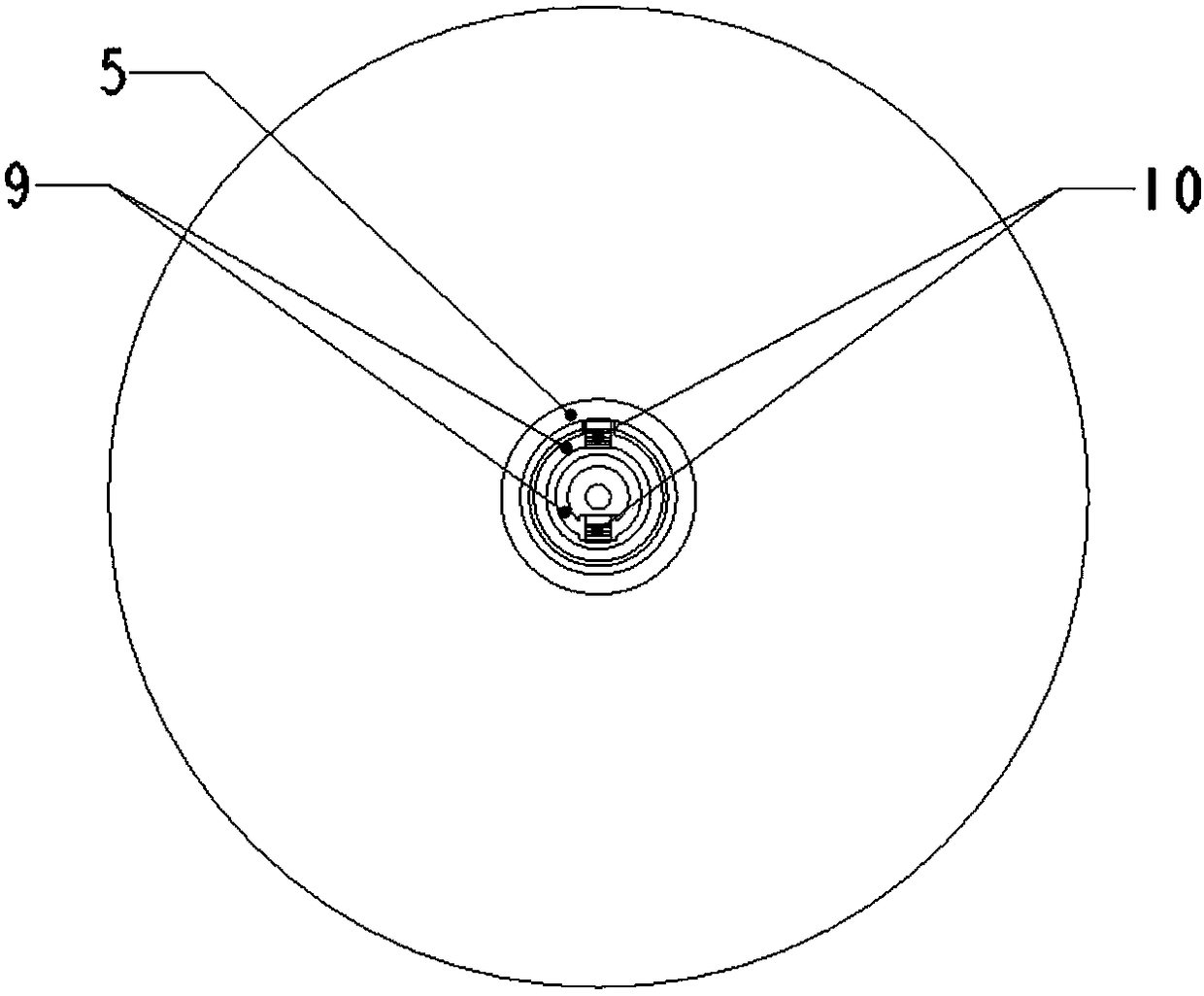

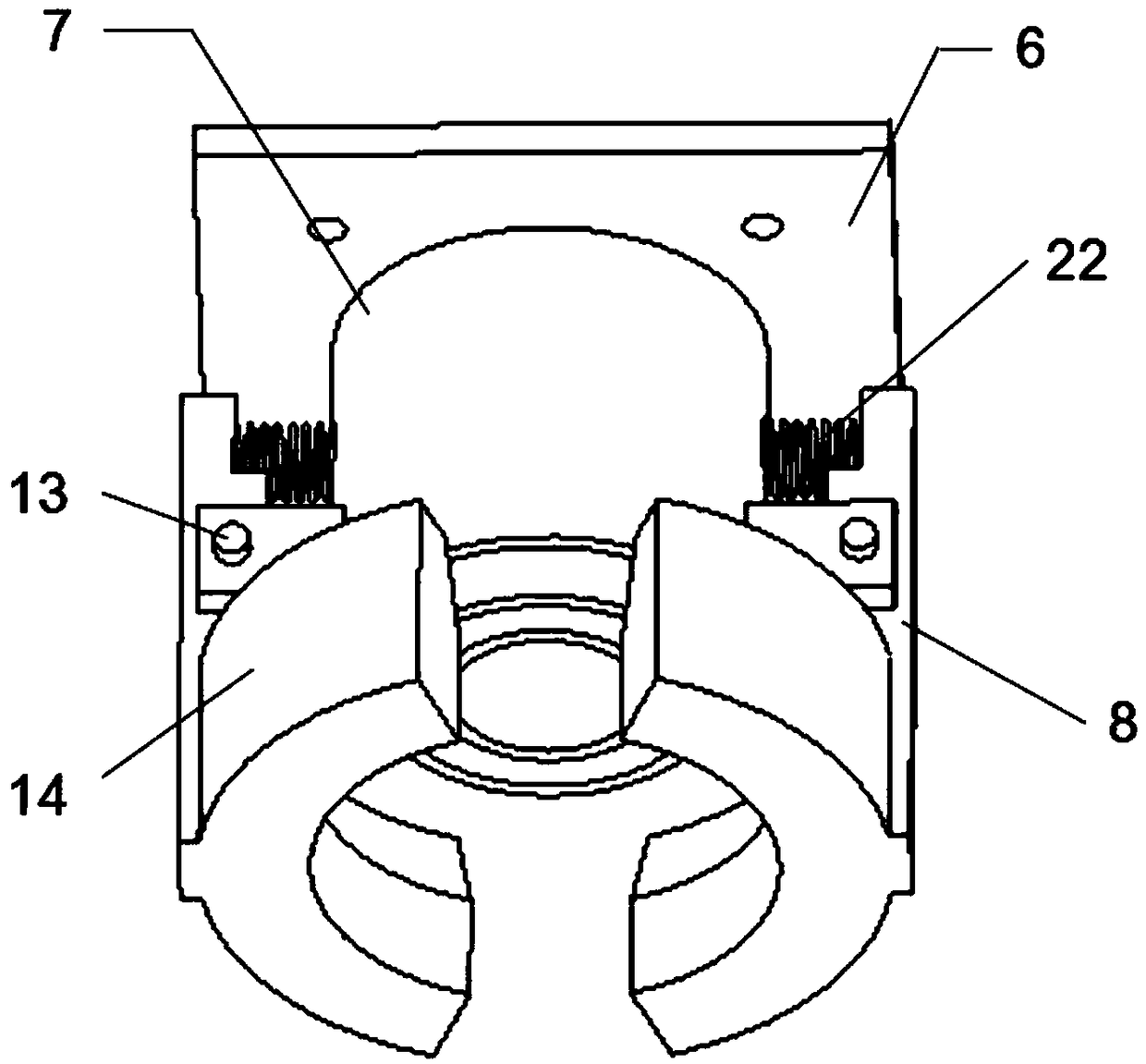

Quick-change nozzle, associated nozzle quick-change system and associated application system

The invention relates to an interchangeable nozzle (D1, D2), in particular a quick-change nozzle, for application of an application means onto a component and for fastening to a nozzle change system (X1, X2). The nozzle (D1, D2) comprises a nozzle base having an alignment device (A1, H2) for the angularly correct, mechanical alignment of the nozzle (D1, D2) relative to the change system (X1, X2). The invention further relates to an associated change system (X1, X2) and to an associated application system (100).

Owner:DUERR SYST GMBH

Detachable battery change-over charging device

ActiveCN108515866AImprove fault toleranceReduced precision requirementsCharging stationsElectric propulsion mountingElectrical batteryElectrical and Electronics engineering

Owner:JIANGNAN UNIV

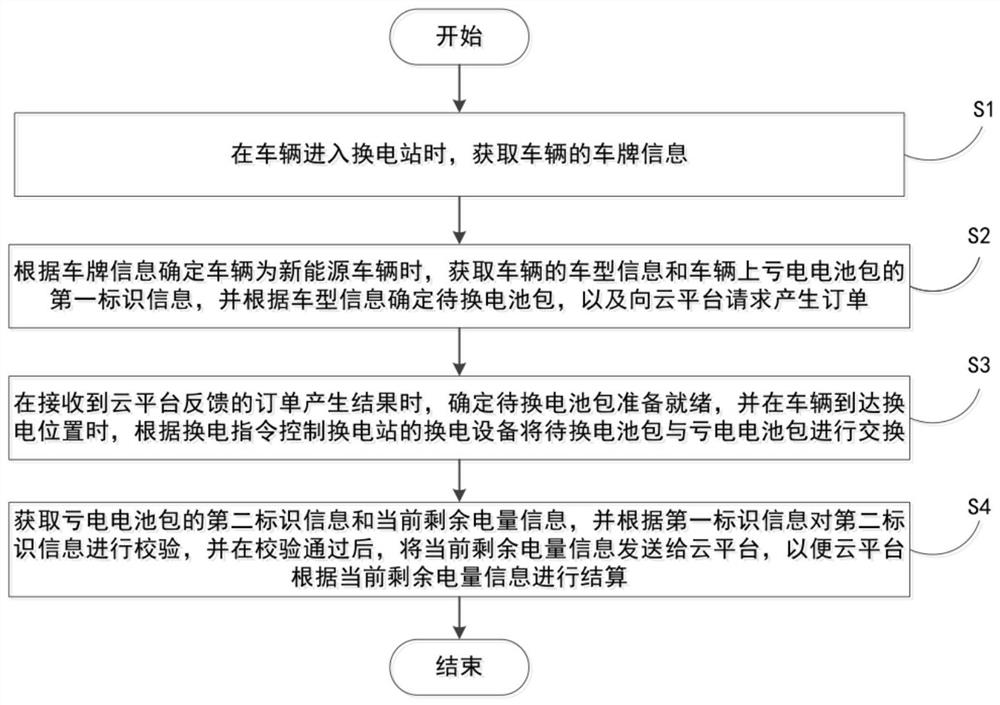

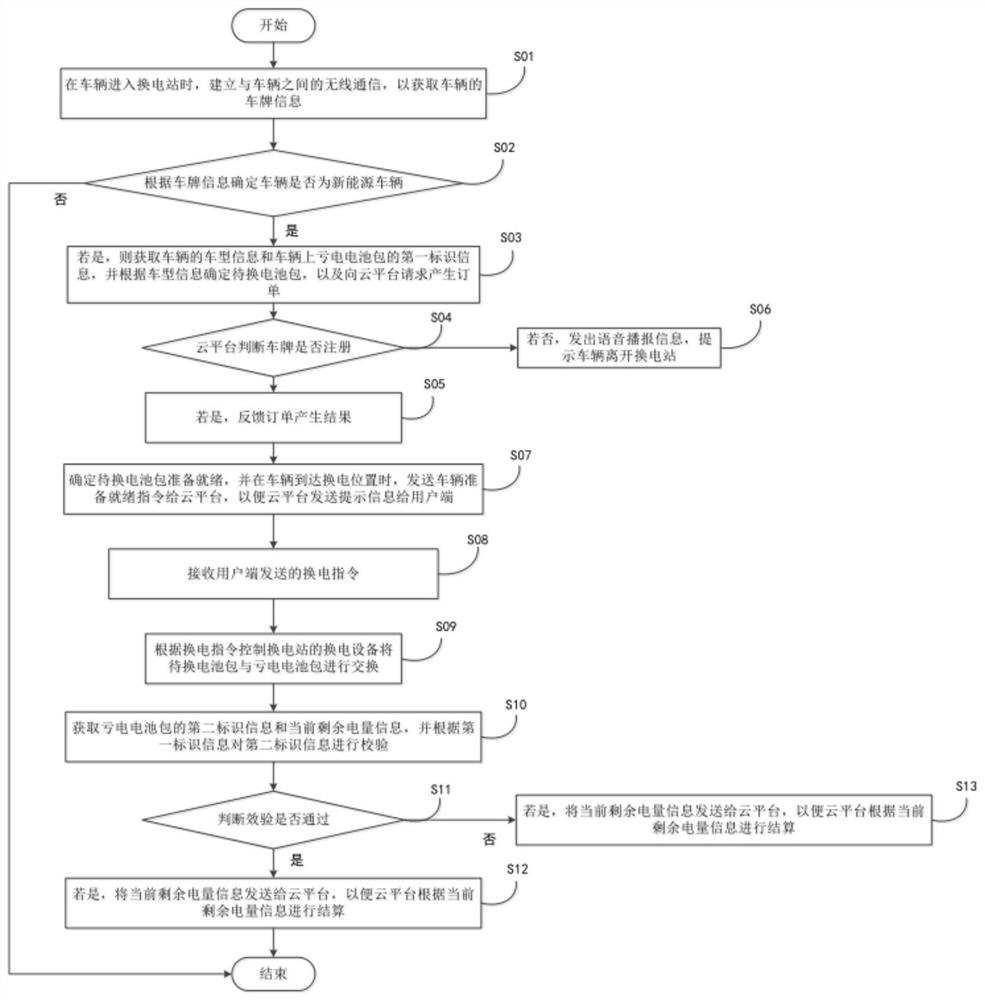

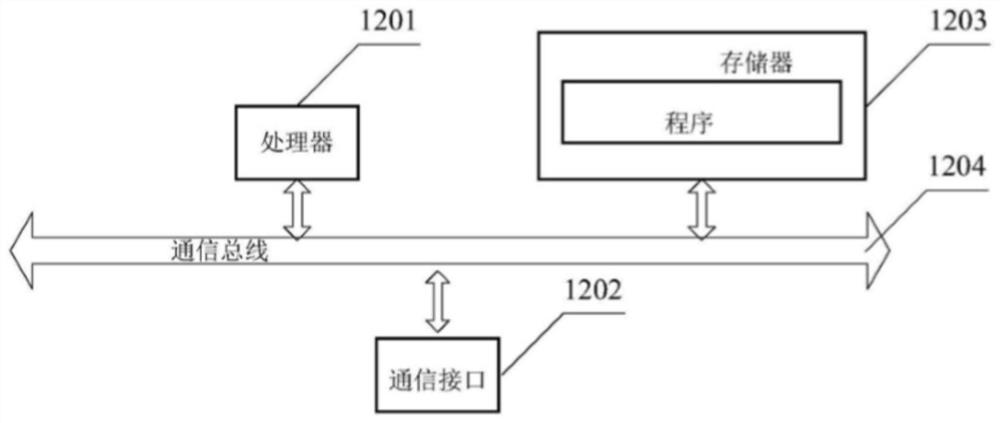

Intelligent battery replacing method of battery replacing station, battery replacing station control system and readable storage medium

PendingCN113415204ASmart replacementAutomatic replacementCharging stationsBuying/selling/leasing transactionsElectrical batteryControl system

The invention provides an intelligent battery replacing method of a battery replacing station, a battery replacing station control system and a readable storage medium. The intelligent battery replacing method for the battery replacing station comprises steps of obtaining the license plate information of a vehicle when the vehicle enters the battery replacing station; obtaining the vehicle type information of a vehicle and first identification information of a power-lack battery pack on the vehicle, determining a to-be-replaced battery pack according to the vehicle type information, and requesting a cloud platform to generate an order; when an order generation result fed back by the cloud platform is received, determining that the to-be-replaced battery pack is ready, and when the vehicle arrives at the battery replacement position, battery replacement equipment of the battery replacement station being controlled to exchange the to-be-replaced battery pack with the power-deficient battery pack according to the battery replacement instruction; and obtaining the second identification information and the current residual electric quantity information of the power-lack battery pack, and sending the current residual electric quantity information to the cloud platform so that the cloud platform performs settlement according to the current residual electric quantity information. The method is advantaged in that through the intelligent battery replacing method of the battery replacing station, the battery pack can be automatically and intelligently replaced for the vehicle, and labor cost can be saved.

Owner:蓝谷智慧(北京)能源科技有限公司

Blood cross matching tester of unknown blood type

The invention discloses a blood cross matching tester of an unknown blood type. Before blood transfusion, blood type detection and a blood cross matching test should be carried out in a professional lab by a professional tester. The tester comprises an upper shell, a lower shell, a reagent sucking and feeding mechanism, a base, a centrifugation test mechanism, a blood matching tube, a microscope camera, an extraction tube claw, a test tube claw, a receptor test tube claw, a test tube storage box, an extraction tube storage box, a waste test tube collection box, and a waste extraction tube collection box. The centrifugation test mechanism comprises an upper disc, a support disc, a centrifugal rotation shaft, a positioning rotation shaft, and an elevating and shaking assembly. The reagent sucking and feeding mechanism comprises a reagent disc, a layered collector, a polybrene medium reagent storing device, a serum conduit, a normal saline storage box, a first serum storage box, and a second serum storage box. The provided tester can automatically finish blood type detection and a blood cross matching test and reduces the workload for the medical workers in blood matching.

Owner:HANGZHOU DIANZI UNIV

Automatic cross-matching tester for bloods with unknown types

ActiveCN108761101ASimplify workloadConvenient treatmentBiological testingMedical staffBlood compatibility test

The invention discloses an automatic cross-matching tester for bloods with unknown types. Blood group detection and blood cross matching experiments need to be completed by professional testers in a professional laboratory before blood is transfused. The tester comprises an upper shell, a lower shell, needle releasers, hemostixes, thimble devices, a reagent sucking and adding mechanism, a pedestal, a centrifuging test mechanism, blood matching test tubes, a microscope camera, extracting tube grippers, a test tube gripper for test, a blood receptor test tube gripper, a test tube storage box, anextracting tube storage box, a waste test tube collecting box and a waste extracting tube collecting box. The centrifuging test mechanism comprises an upper disc, a supporting disc, a centrifuging rotating shaft, a positioning rotating shaft and a lifting shaking assembly. The reagent sucking and adding mechanism includes a reagent tray, layered collectors, condensed amine medium reagent stores,serum guiding tubes, a normal saline storage box, a first serum storage box and a second serum storage box. The tester can automatically complete blood group detection and the blood cross matching test, and reduces the workload of medical staff in the blood matching process.

Owner:HANGZHOU DIANZI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com