Distribution network hot-line work robot with automatic quick-change work tool system

A working tool and live working technology, applied in the field of live working robots in distribution network

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

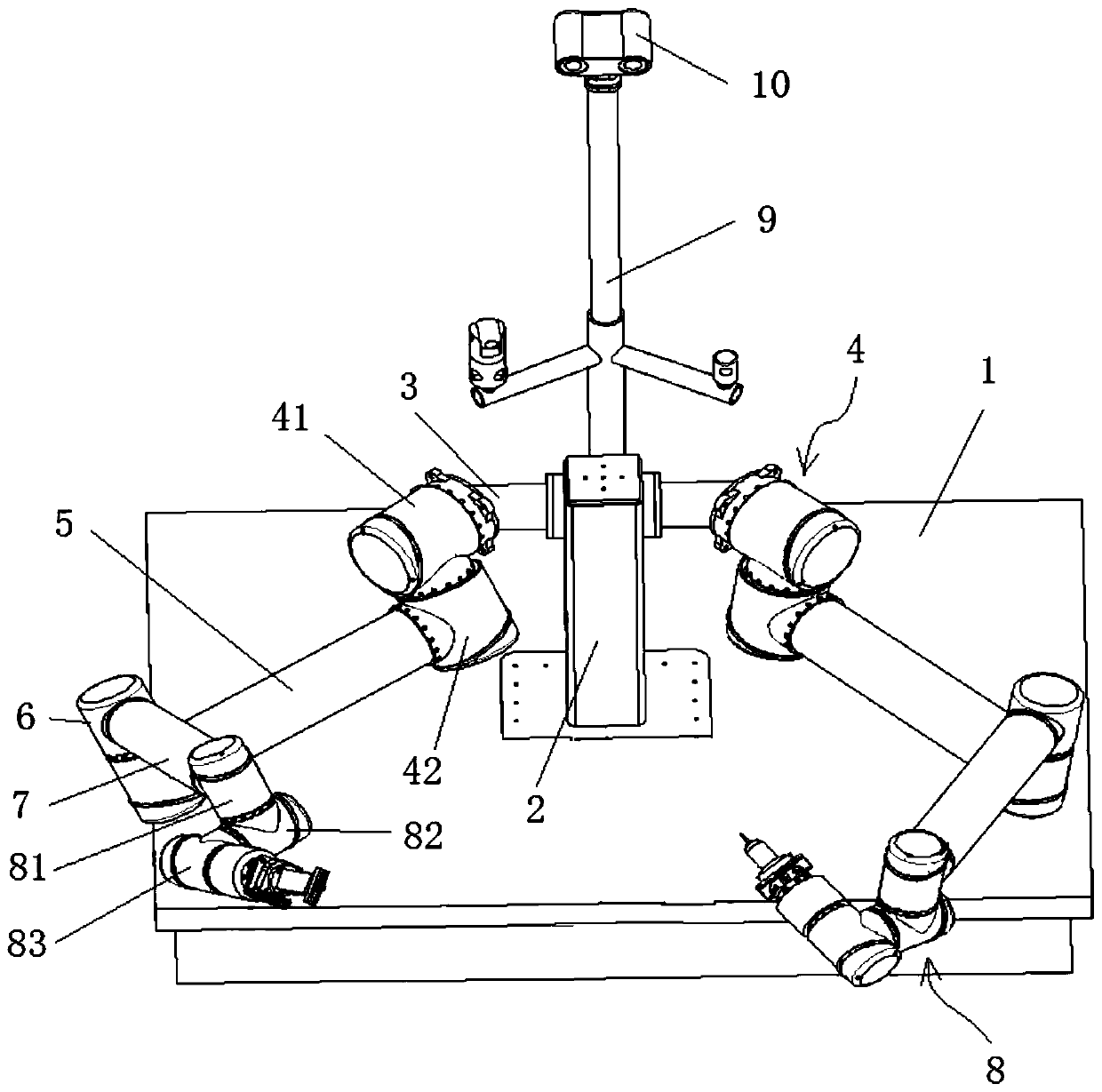

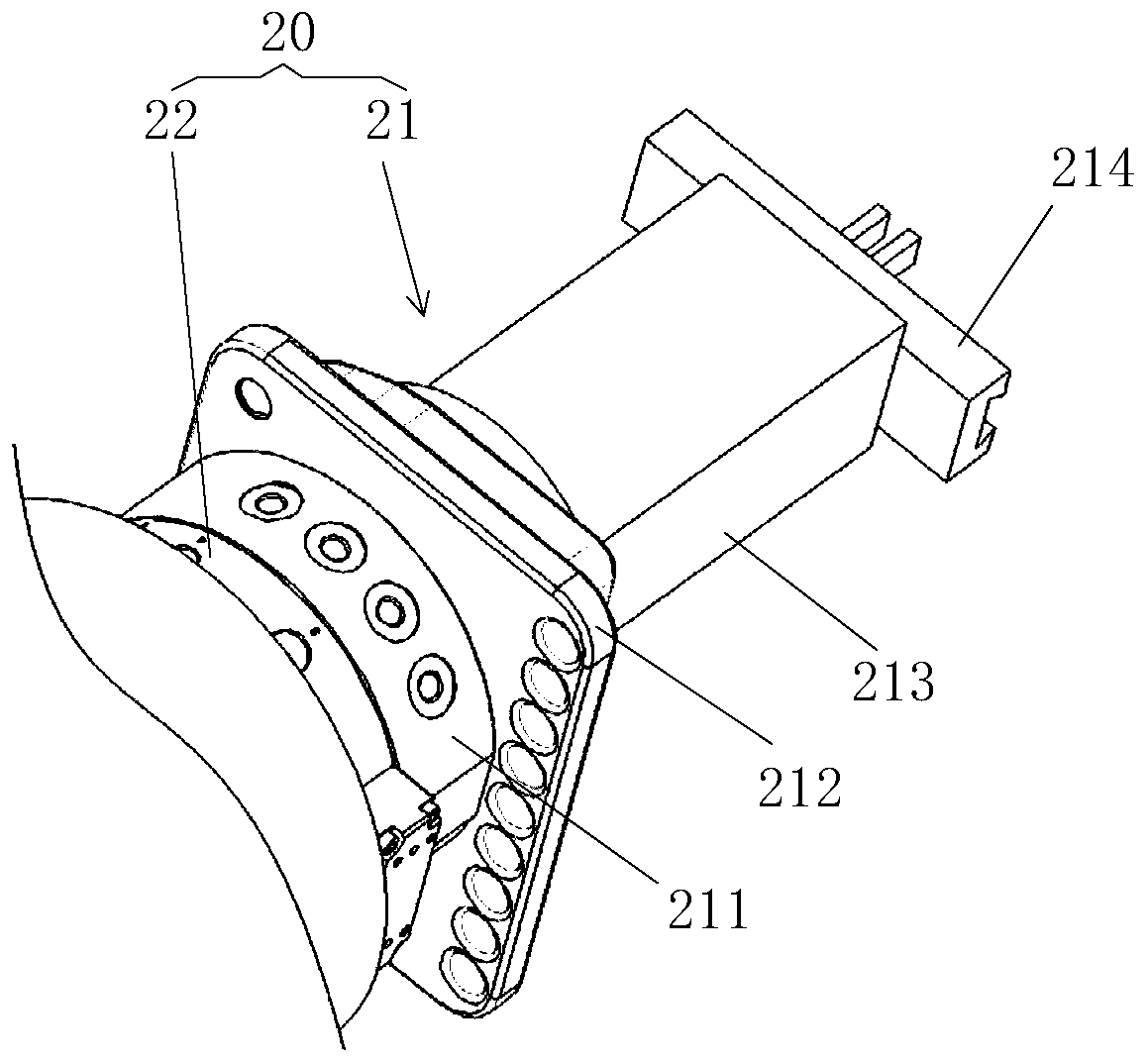

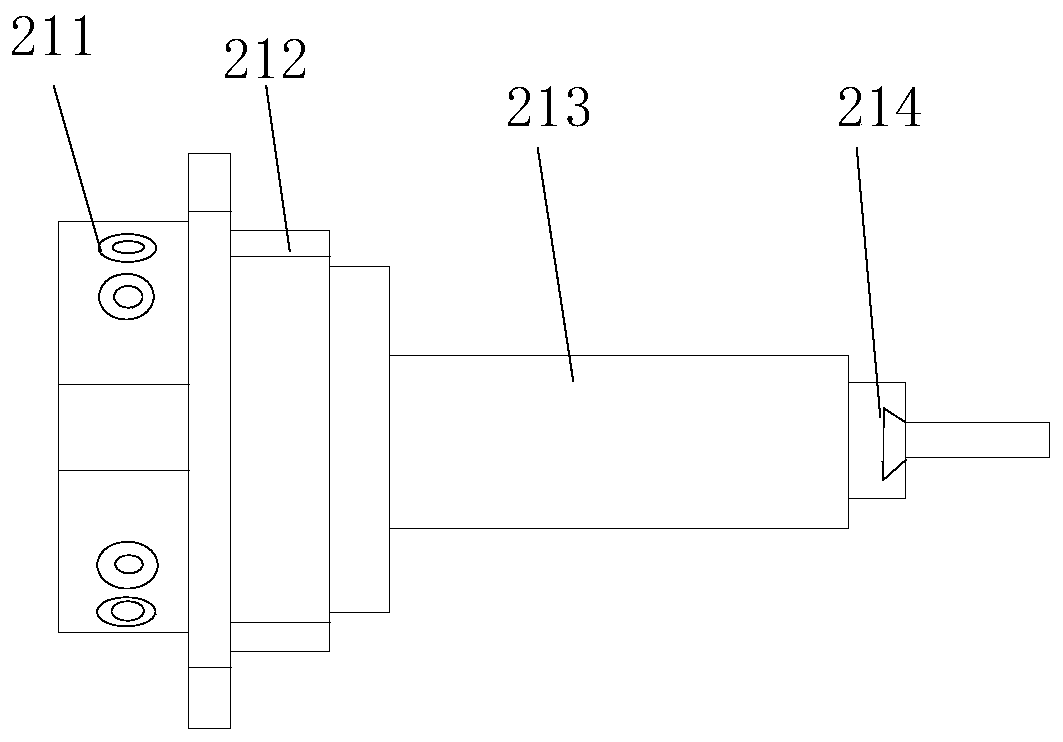

[0026] Figure 1 to Figure 8 Some embodiments according to the invention are shown.

[0027] Live work includes live disconnection, live wiring, live replacement of lightning arresters, live replacement of isolating switches, assembly and disassembly of line fault indicators or grounding clips for electrical inspection, live replacement of drop-out fuses, live replacement of warning signs or insulation protection tubes, cleaning and cleaning. Obstacles, etc. When a robot performs a live work task, it often needs a variety of work tools, which requires the replacement of tools during the work. In addition, the robot may also perform multiple tasks at the same time, so as to realize the automa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com