Quick-change nozzle, associated nozzle quick-change system and associated application system

A nozzle, fast technology, applied in the direction of spraying device, spraying device, connecting components, etc., can solve the problem of bulky

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

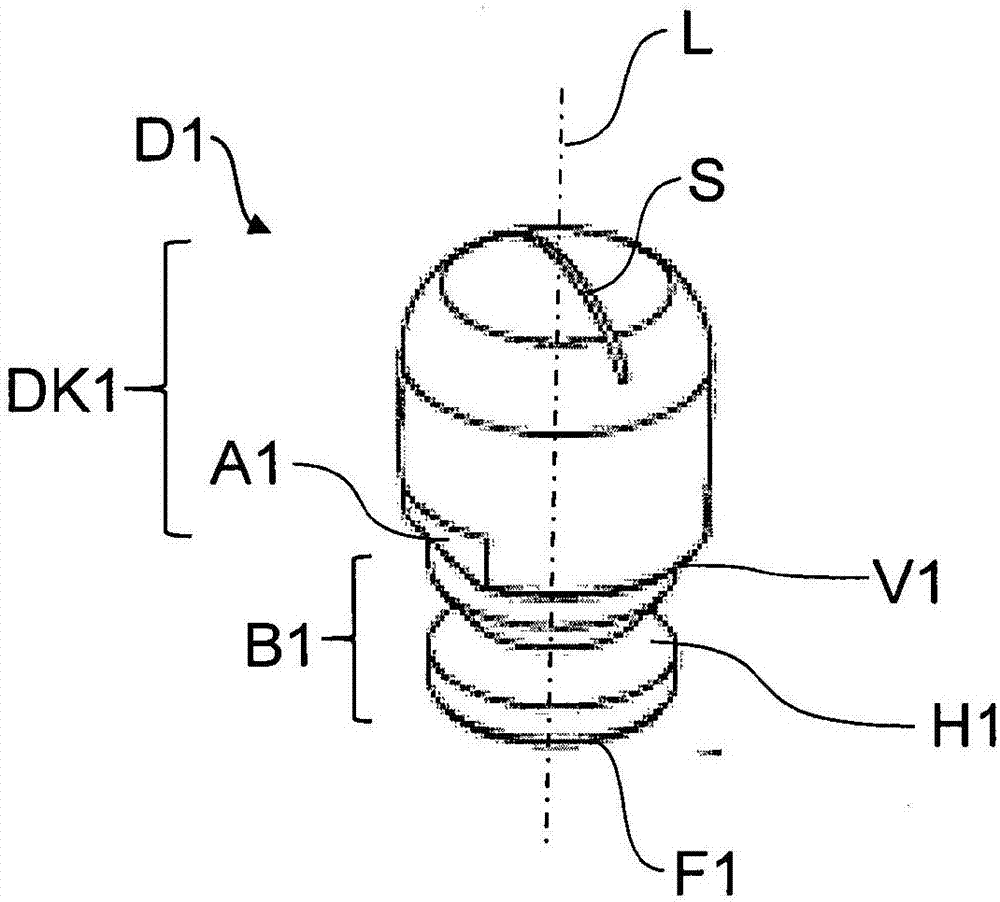

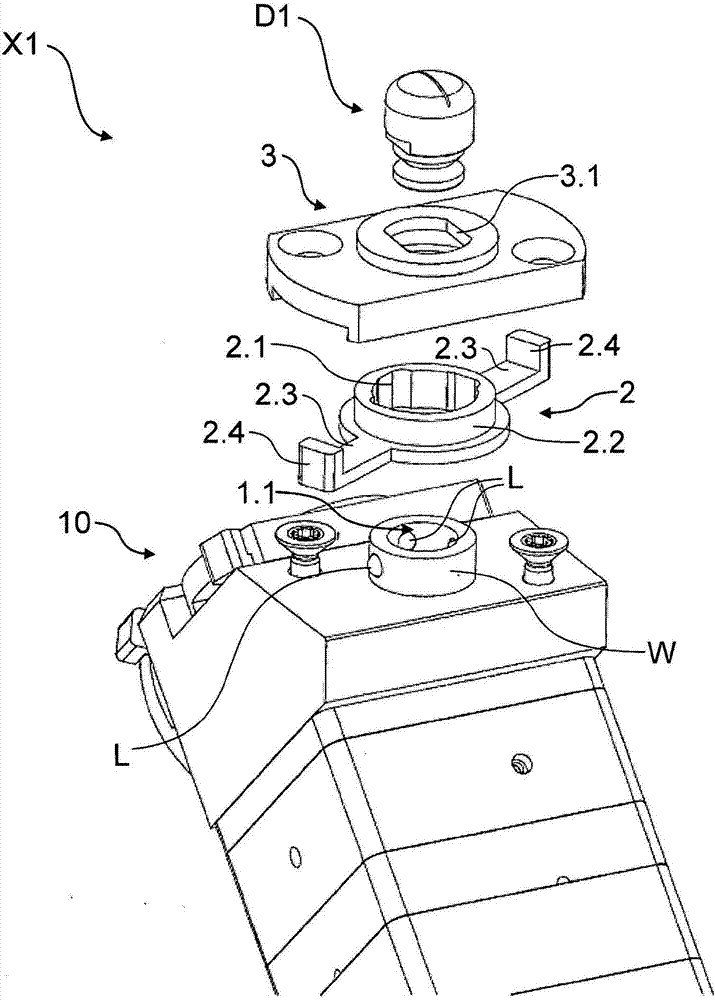

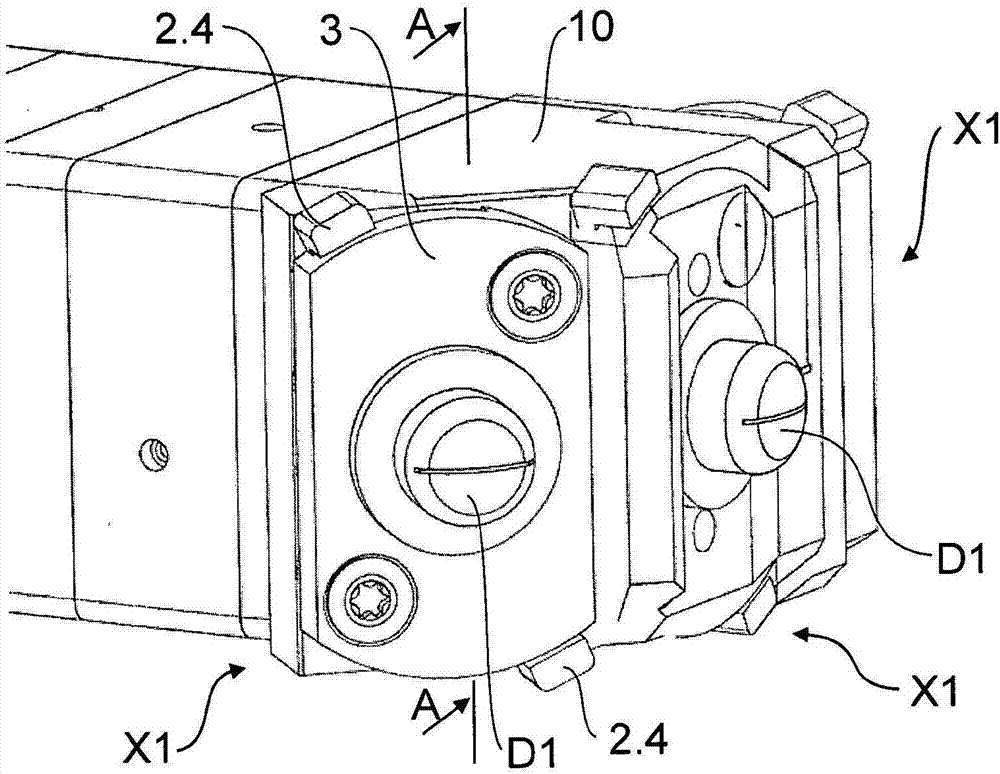

[0085] figure 1 A perspective view of a nozzle D1 according to one embodiment of the invention is shown.

[0086] Nozzle D1 is an exchangeable nozzle for applying coating agent to components, such as motor vehicle bodies, and for fastening to the exchange system X1 ( Figure 2-6and 11-13) above. The nozzle D1 is in particular a slot nozzle with a slot-shaped nozzle outlet S for producing a seam seal on a motor vehicle body. However, nozzle D1 can also have other nozzle outlets and is therefore not limited to slot nozzles.

[0087] The exchangeable nozzle D1 is designed as a quick-change nozzle and can be mounted on and removed from the exchange system X1 without additional tools. Furthermore, the nozzle 1 is removed from the exchange system X1 without the need to remove parts different from the nozzle D1 itself.

[0088] The nozzle body of the nozzle D1 comprises an orientation device A1 for angularly correct mechanical orientation of the nozzle D1 on the exchange system X...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com