Mounting and dismounting mechanism for electrombile battery and mounting and dismounting method thereof

A technology for electric vehicle batteries and loading and unloading mechanisms, which is applied in the direction of electric power devices, power devices, vehicle components, etc., and can solve problems such as danger, long battery replacement time, and low replacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

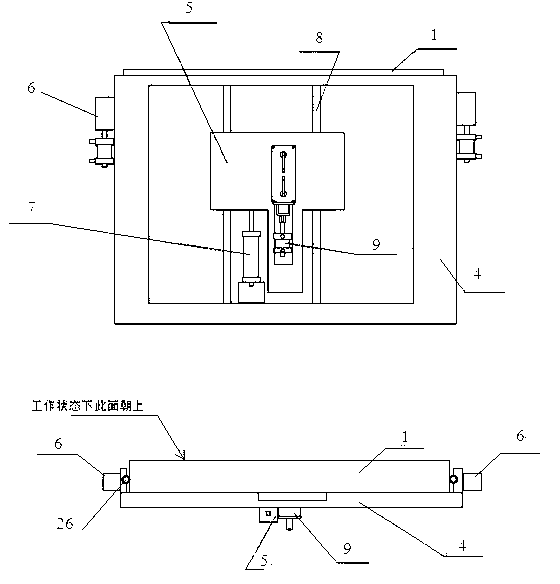

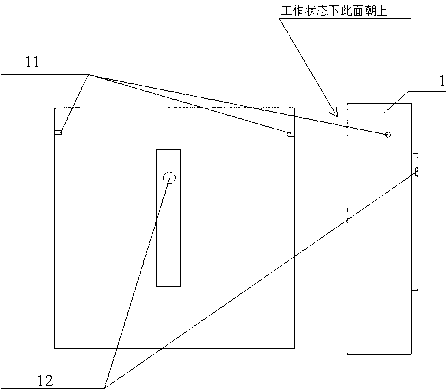

[0060]The pure electric vehicle power battery automatic quick-change battery box system connects the battery outer box 4, the battery inner box 1, the battery box locking and maintaining mechanism 6, the battery loading and unloading mechanism 5, and the battery quick-changing manipulator 21 through the cylinder control system 3. Together, an automated pure electric commercial vehicle power battery quick-change battery box system is formed. Through this system, the vehicle's battery box can be unlocked, the power battery inner box 1 can be automatically replaced, and the battery box is locked to complete the vehicle power battery. Automatic quick replacement; wherein the communication is wired communication or wireless communication; the cylinder control system 3 can complete the human-computer interaction, the battery box and the manipulator 21 information exchange, the battery box controls the locking and maintaining mechanism 6, and the battery loading and unloading mechanism...

specific Embodiment 2

[0067] On the basis of the above-mentioned specific embodiment 1, the positioning pin 17 is replaced by a photosensitive structure, and the sensing effect of the optical sensor is used to sense whether the battery inner box 1 is connected to the battery outer box 4 in place, so as to perform linkage The loading and unloading process of the battery inner box 1.

specific Embodiment 3

[0068] According to the battery loading and unloading mechanism of the pure electric vehicle power battery automatic quick-change battery box system of the specific embodiment, the specific loading and unloading method is as follows: when loading, when the tensioning cylinder 7 pulls the battery inner box 1 into the outer box In the assembly position, the positioning pin 17 can automatically enter the positioning pin hole at the bottom of the battery inner box 1 under the action of elastic force. At this time, the action of the locking cylinder 18 is triggered accordingly, and the locking pin 19 connects the battery inner box 1 with the battery outer box. The box 4 is locked; when the battery inner box 1 is unloaded, the cylinder control system 3 sends an unlocking signal to the signal receiving device of the locking cylinder 18, and correspondingly stimulates the locking cylinder 18 to take action, and at the same time the lock The tightening pin 19 and the positioning pin 17 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com