Battery box locking maintaining structure

A technology of battery lock and holding mechanism, which is applied in the direction of electric power devices, circuits or fluid pipelines, power devices, etc., and can solve problems such as large mass, danger, and inability to replenish energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

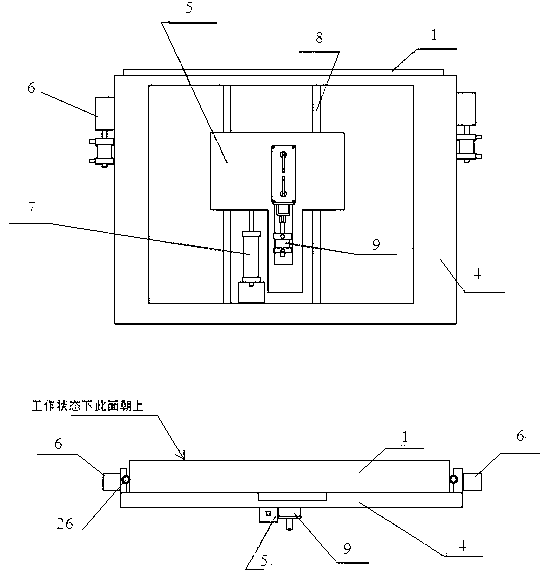

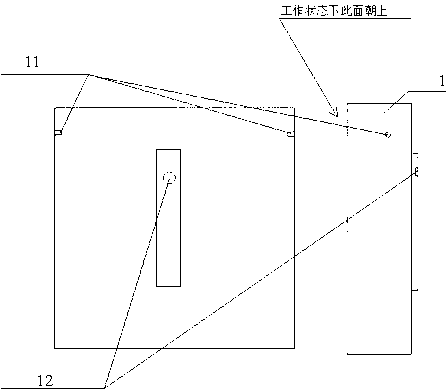

[0056] The pure electric vehicle power battery automatic quick-change battery box system connects the battery outer box 4, the battery inner box 1, the battery box locking and maintaining mechanism 6, the battery loading and unloading mechanism 5, and the battery quick-changing manipulator 21 through the cylinder control system 3. Together, an automated pure electric commercial vehicle power battery quick-change battery box system is formed. Through this system, the vehicle's battery box can be unlocked, the power battery inner box 1 can be automatically replaced, and the battery box is locked to complete the vehicle power battery. Automatic quick replacement; wherein the communication is wired communication or wireless communication; the cylinder control system 3 can complete the human-computer interaction, the battery box and the manipulator 21 information exchange, the battery box controls the locking and maintaining mechanism 6, and the battery loading and unloading mechanis...

specific Embodiment 2

[0064] On the basis of the above-mentioned specific embodiment 1, the positioning pin 17 is replaced by a photosensitive structure, and the sensing effect of the optical sensor is used to sense whether the battery inner box 1 is connected to the battery outer box 4 in place, so as to perform linkage The loading and unloading process of the battery inner box 1.

[0065] Through the setting of the wear-resisting reinforcing belt, the service life of the locking pin is greatly improved, and the safety of the battery box system is enhanced, which is of great significance for the sound development of electric vehicles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com