Water softener control valve and control method thereof

A technology for controlling valves and water softeners, which is applied in water treatment parameter control, chemical instruments and methods, and valve operation/release devices, etc. It can solve the complex flow path inside the valve body, affect the life of the soft water valve, and design difficulties for planar valves, etc. problems, to achieve the effect of simple structure, good regeneration effect and water saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

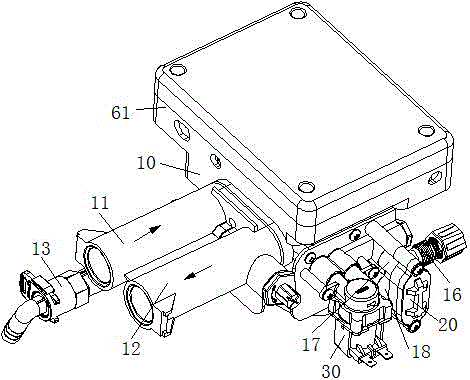

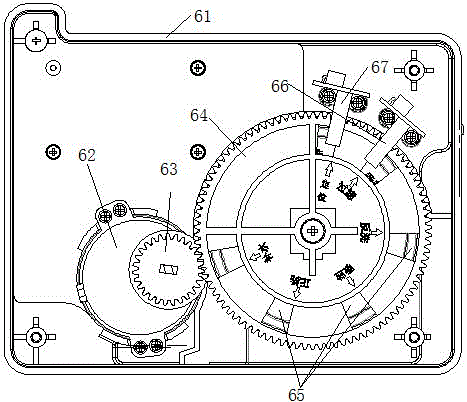

[0040] refer to Figure 1 to Figure 16

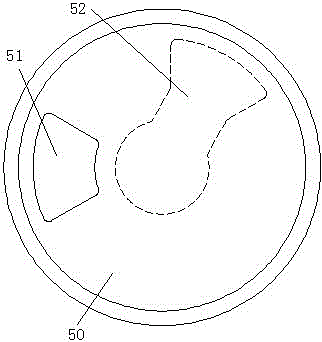

[0041] A water softener control valve, comprising a valve body 10, the valve body is provided with a water inlet 11, a water outlet 12, a sewage outlet 13, a filter element outer interface 14, a filter element inner interface 15 and a salt suction port 16, and the valve body is provided with a useful In the injector inlet 17 and the injector outlet 18 connected with the injector 20, and the electromagnetic valve inlet and the electromagnetic valve outlet used to be connected with the solenoid valve 30, a fixed valve plate 40 is also arranged in the valve body and driven by The movable valve plate 50 driven by the mechanism, the first to sixth through holes 41, 42, 43, 44...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com