Thick stuff sewing machine

A technology of sewing machine and machine head, which is applied in the direction of sewing machine components, sewing machine needle seat, sewing machine ring mechanism, etc., which can solve the problems of low production efficiency, increased auxiliary preparation time, increased labor intensity, etc., and achieve improved production efficiency , Reduce labor intensity, fast lifting speed of the needle bar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

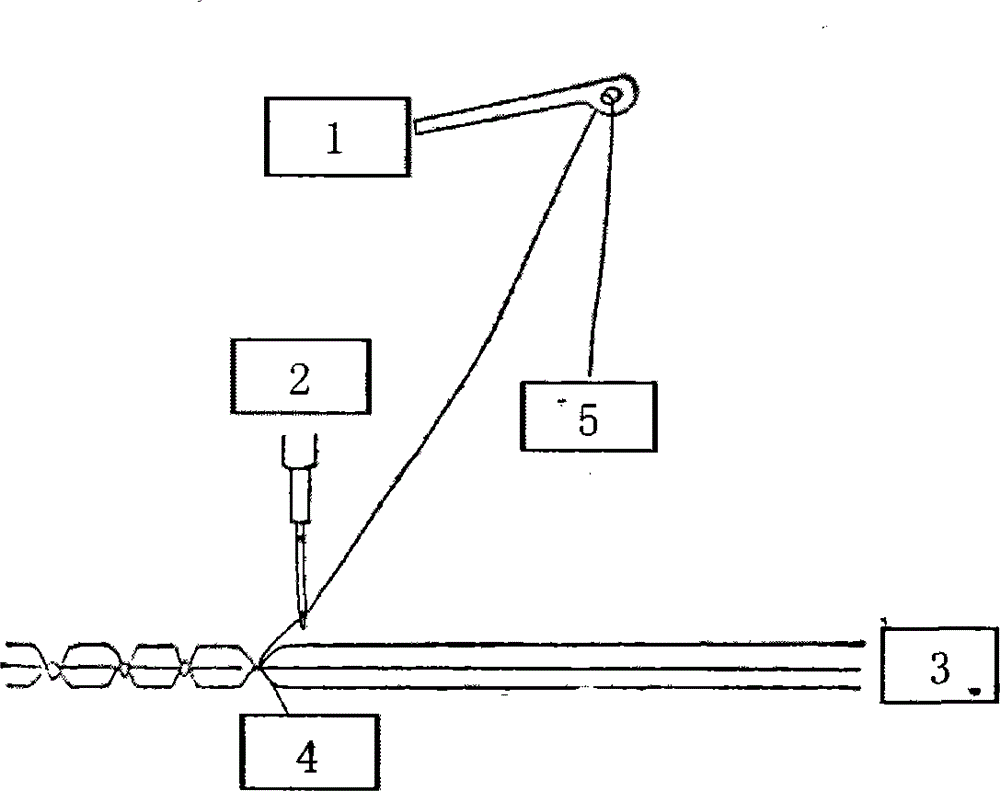

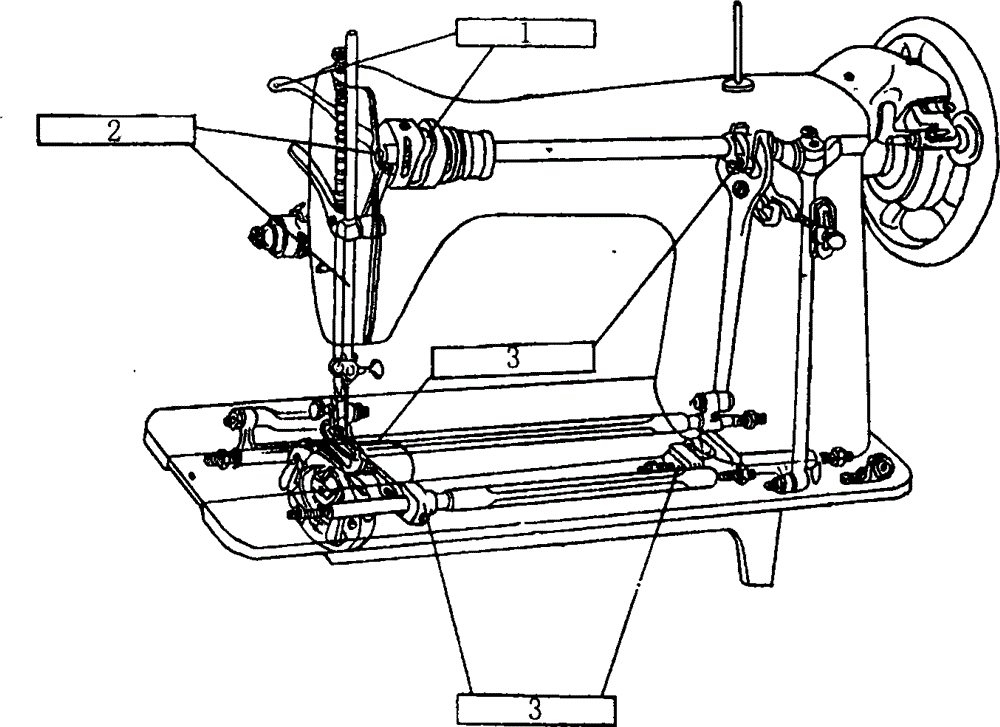

[0025] Such as figure 1 with figure 2As shown, a thick material sewing machine is composed of four parts: head, machine base, transmission and accessories, wherein the head part includes stabbing mechanism 2, thread hook mechanism 4, thread take-up mechanism 1, feeding mechanism 3 main mechanism and winding mechanism Auxiliary mechanism for thread, pressing material, and falling teeth. The transmission part includes a frame and a motor. Installed directly on the head of the sewing machine, the accessories of the sewing machine include machine needles, hooks, knives, and oilers.

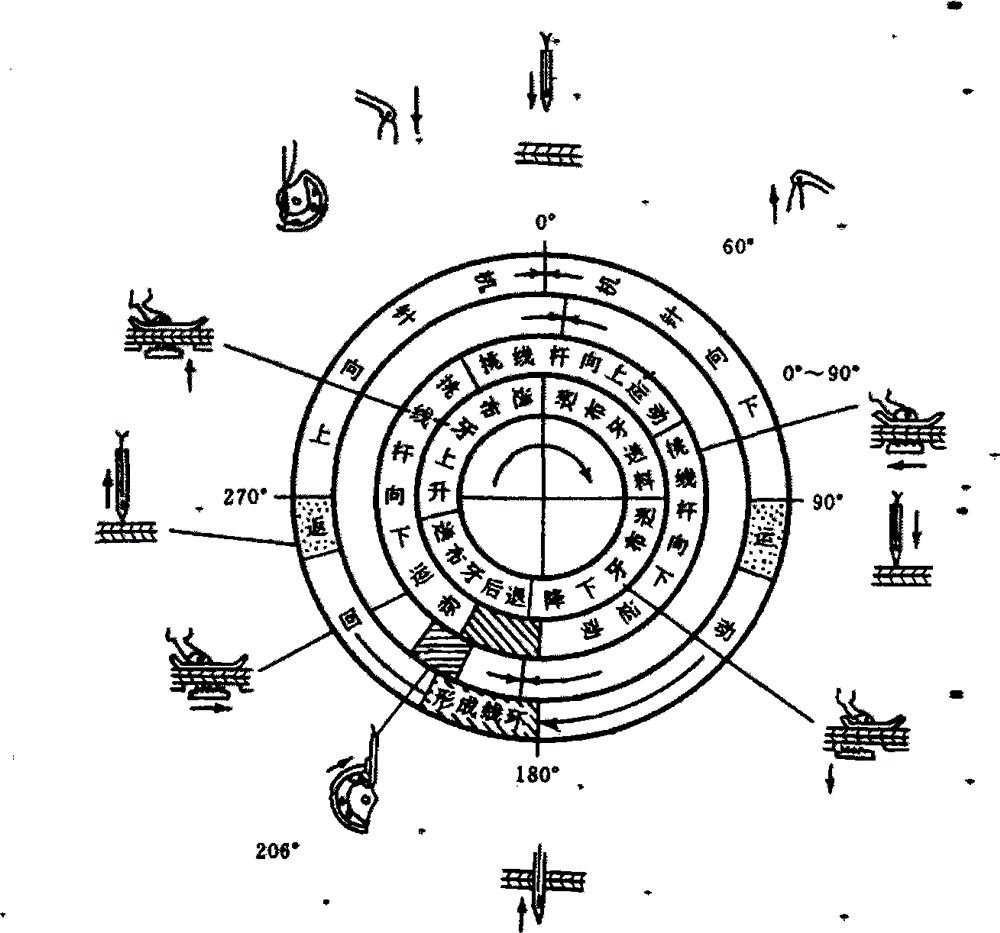

[0026] Such as image 3 As shown, from the formation process of the stitches, it can be seen that the formation of a stitch is mainly realized by the regular movement of four main parts such as the needle, the hook, the thread take-up lever, and the cloth feeding dog. Therefore, the sewing machine head can be divided into four major mechanisms such as stabbing mechanism 2, thread hook mechanism 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com