Five-axis numerical control polishing machine capable of changing grinding heads automatically

A polishing machine and grinding head technology, applied in the field of polishing machines, can solve problems such as troublesome tool changing process, complex overall structure, and troublesome operation, and achieve the effects of saving clamping time, improving the working environment, and avoiding dust from flying outside

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

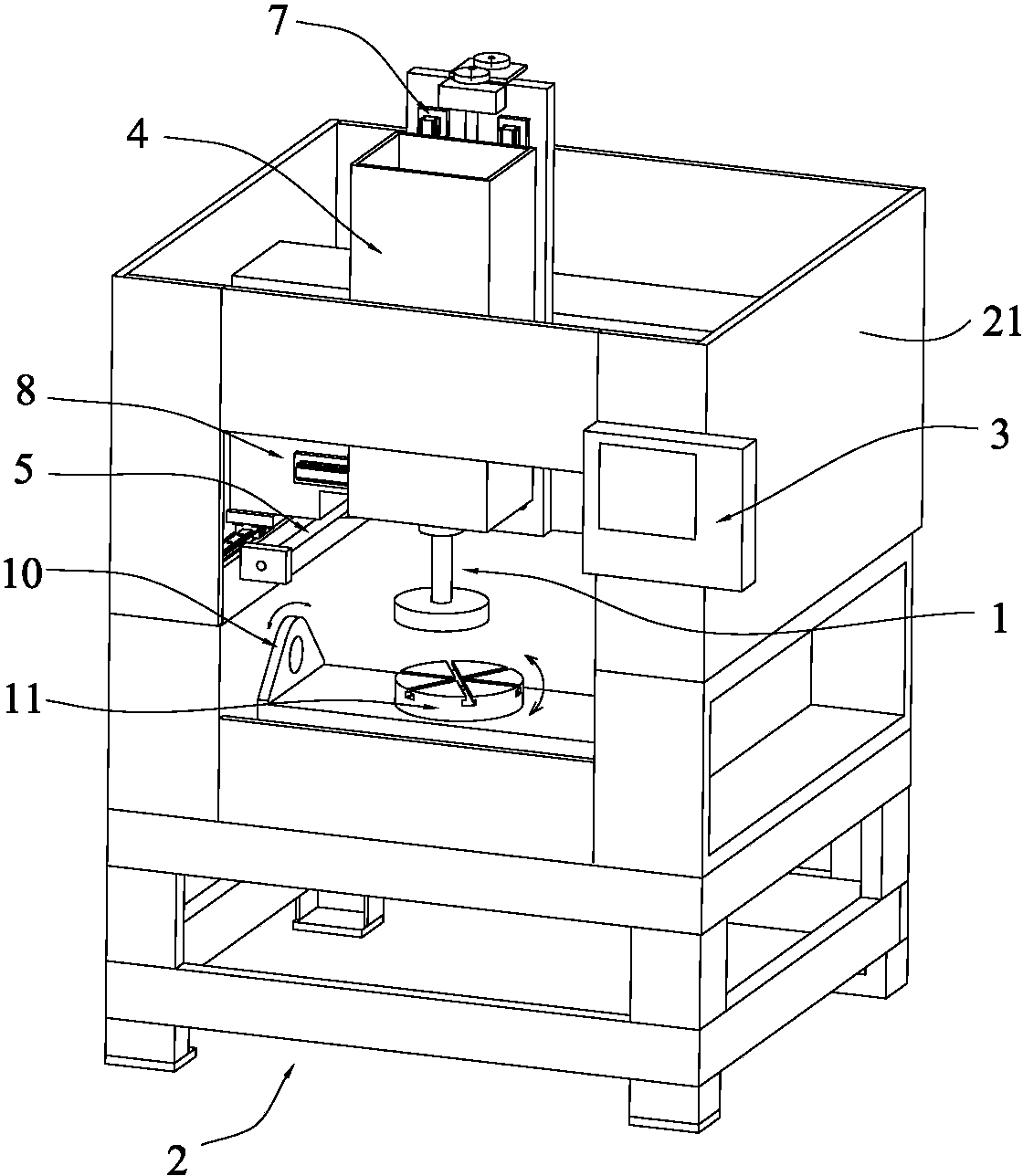

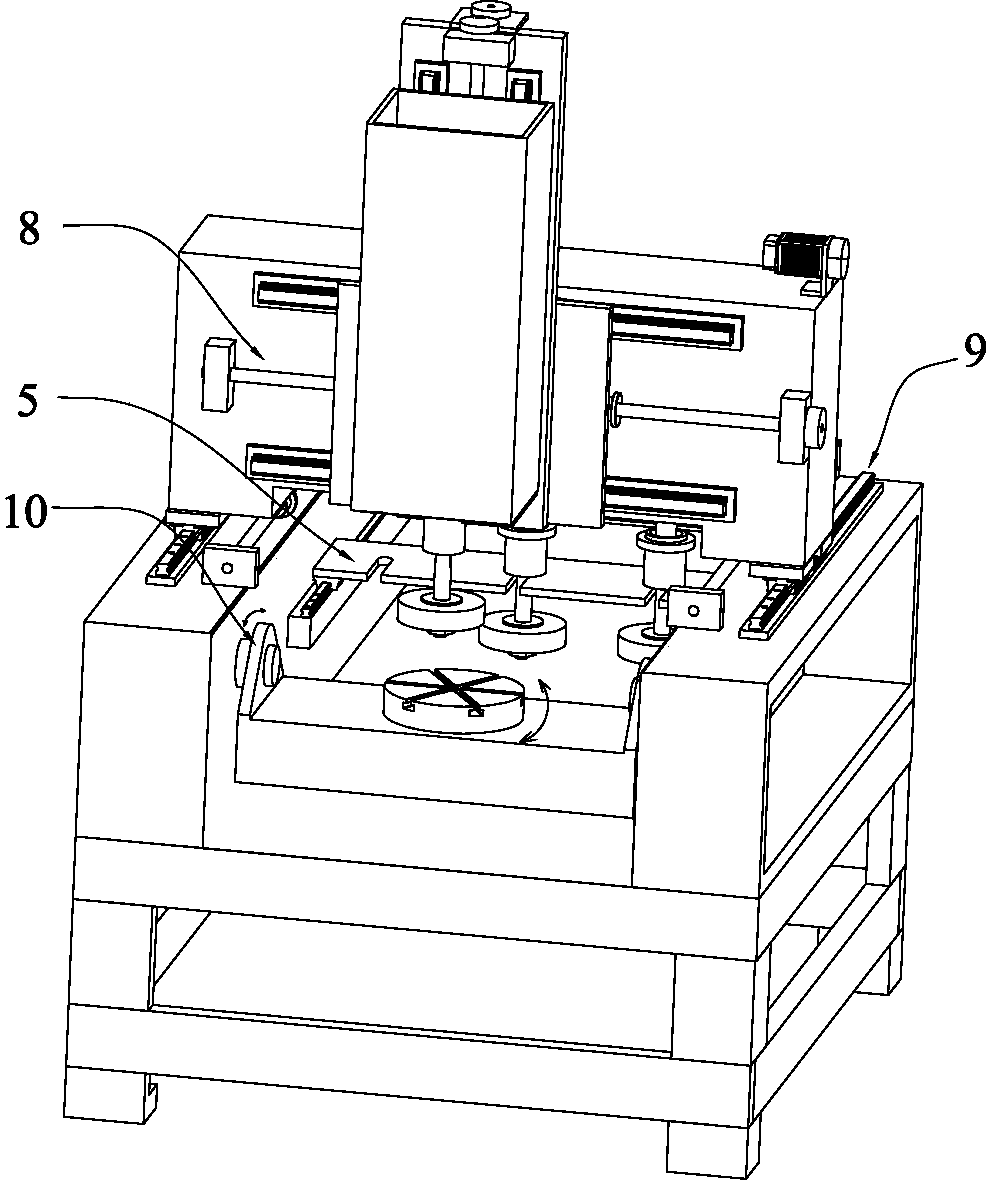

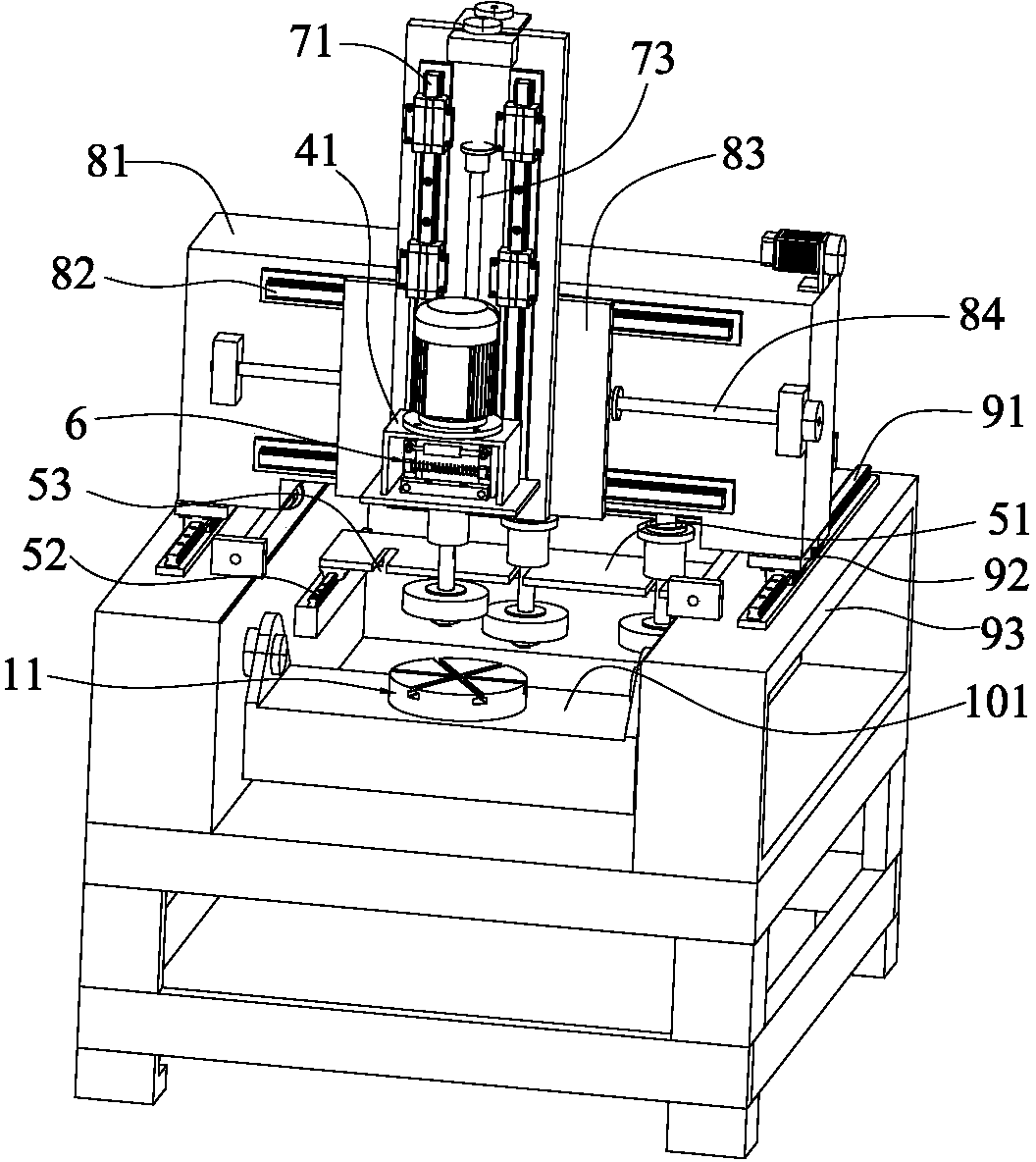

[0030] Examples, see Figure 1 to Figure 11 , a five-axis CNC polishing machine with automatic grinding head replacement provided in this embodiment includes a plurality of half-axis grinding heads 1, a fuselage frame 2, and a controller 3, which are respectively connected to and controlled by the controller 3 Polishing machine head 4, grinding head supply mechanism 5, spindle clamp 6, Z-axis drive mechanism 7, X-axis drive mechanism 8, Y-axis drive mechanism 9, A-axis rotary table 10 and C-axis rotary mechanism, the The X-axis driving mechanism 8 is arranged on the body frame 2 through the Y-axis driving mechanism 9, the polishing machine head 4 is arranged on the X-axis driving mechanism 8 through the Z-axis driving mechanism 7, and the spindle clamp The clamp 6 is arranged at the lower end of the polishing machine head 4, and a plurality of half-axis grinding heads 1 are arranged side by side on the grinding head supply mechanism 5, and the grinding head supply mechanism 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com