Patents

Literature

41results about How to "Avoid exaggeration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

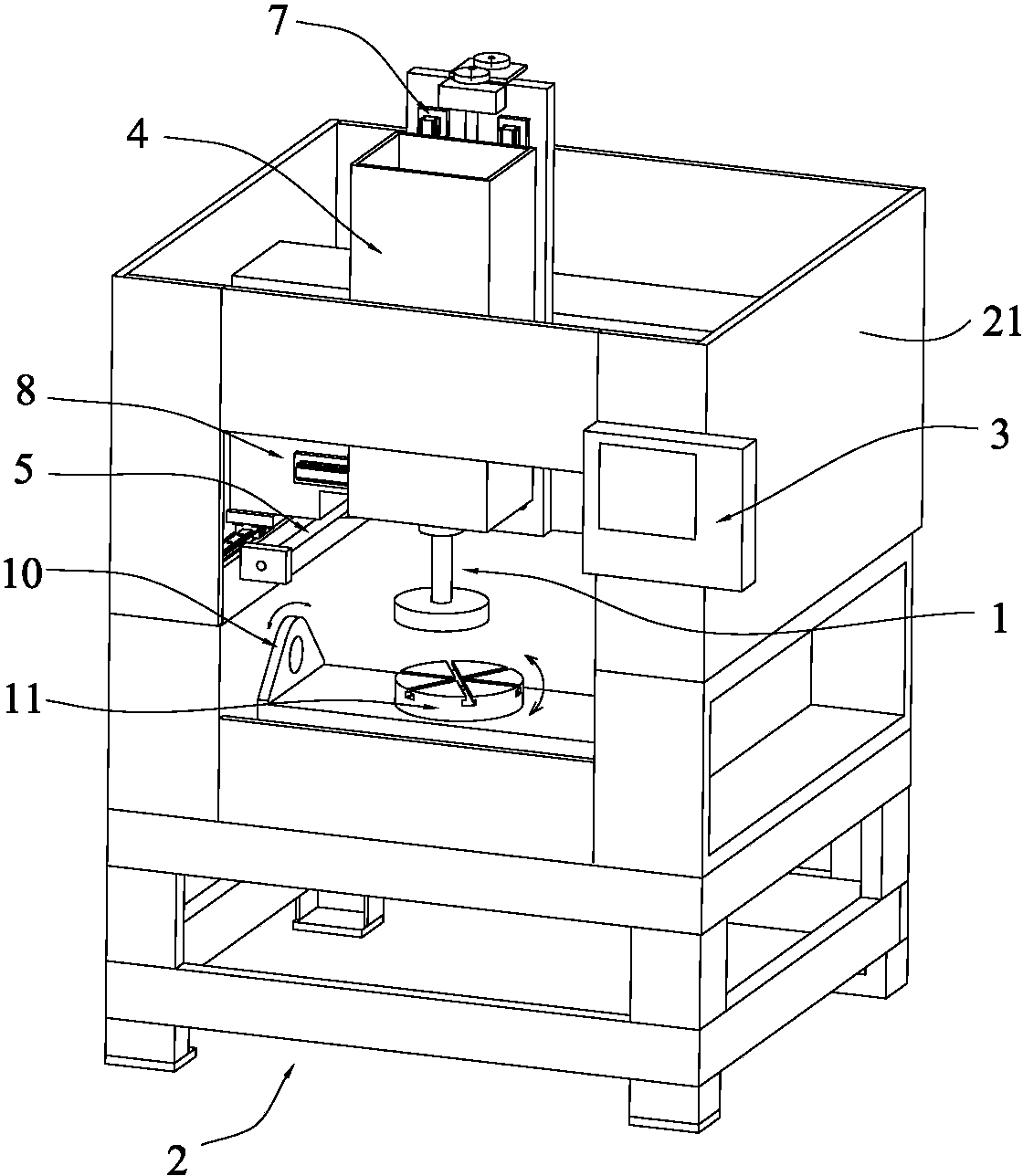

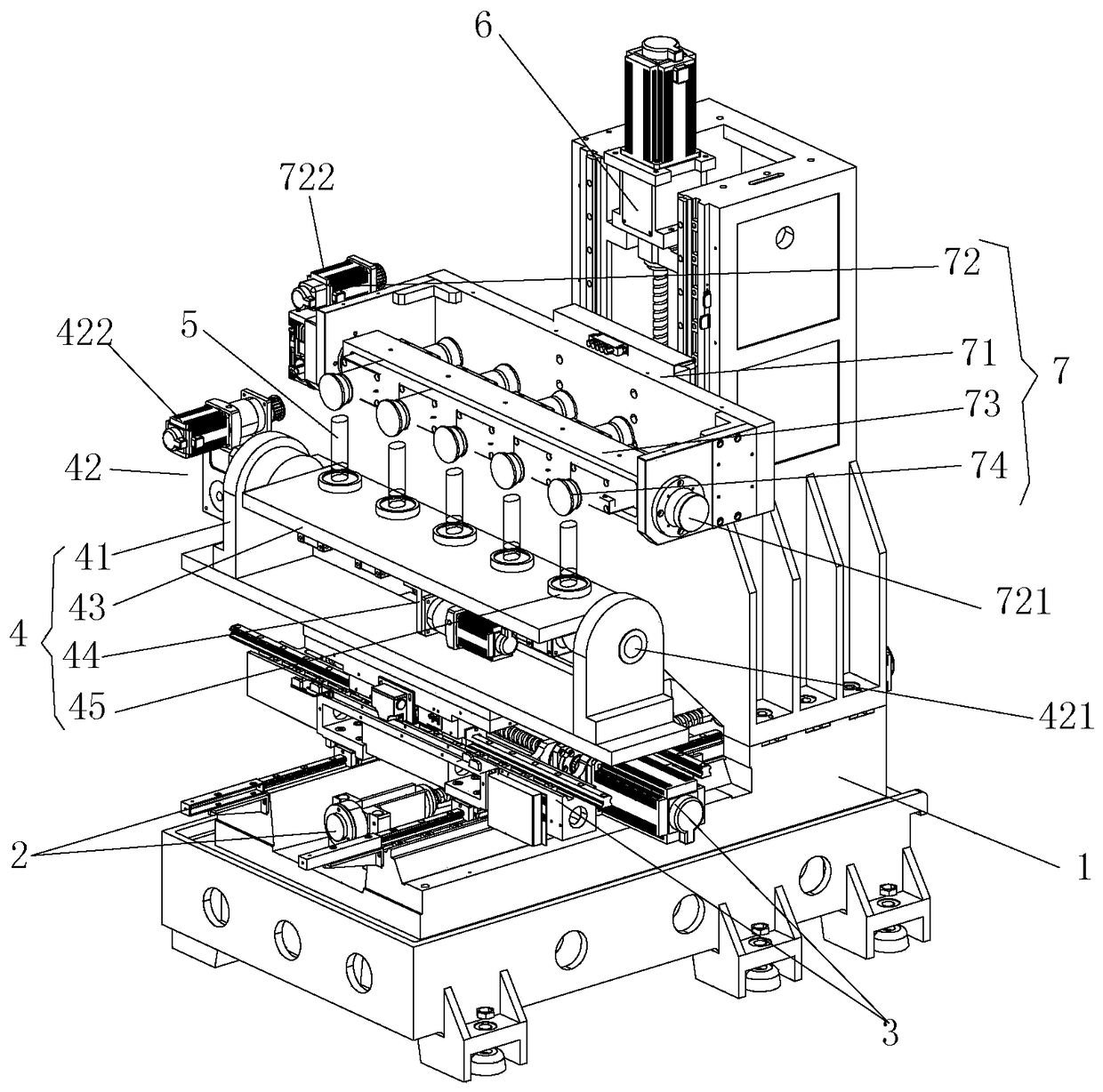

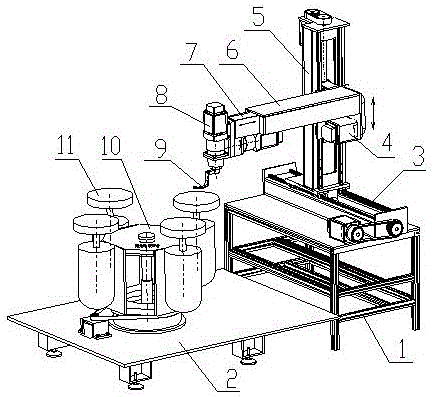

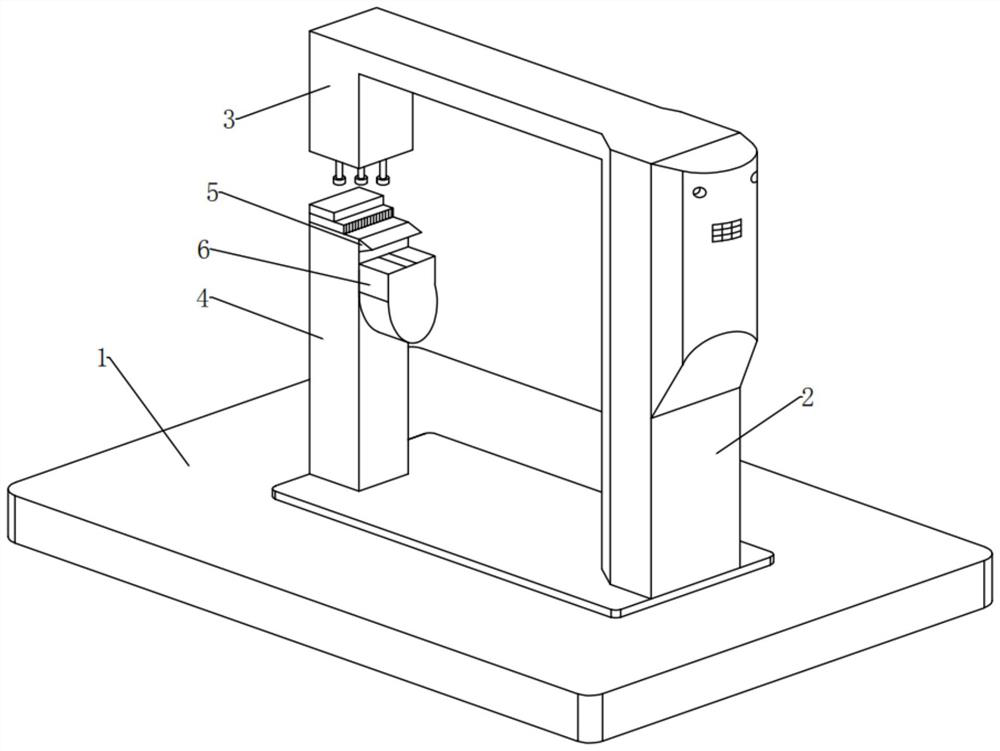

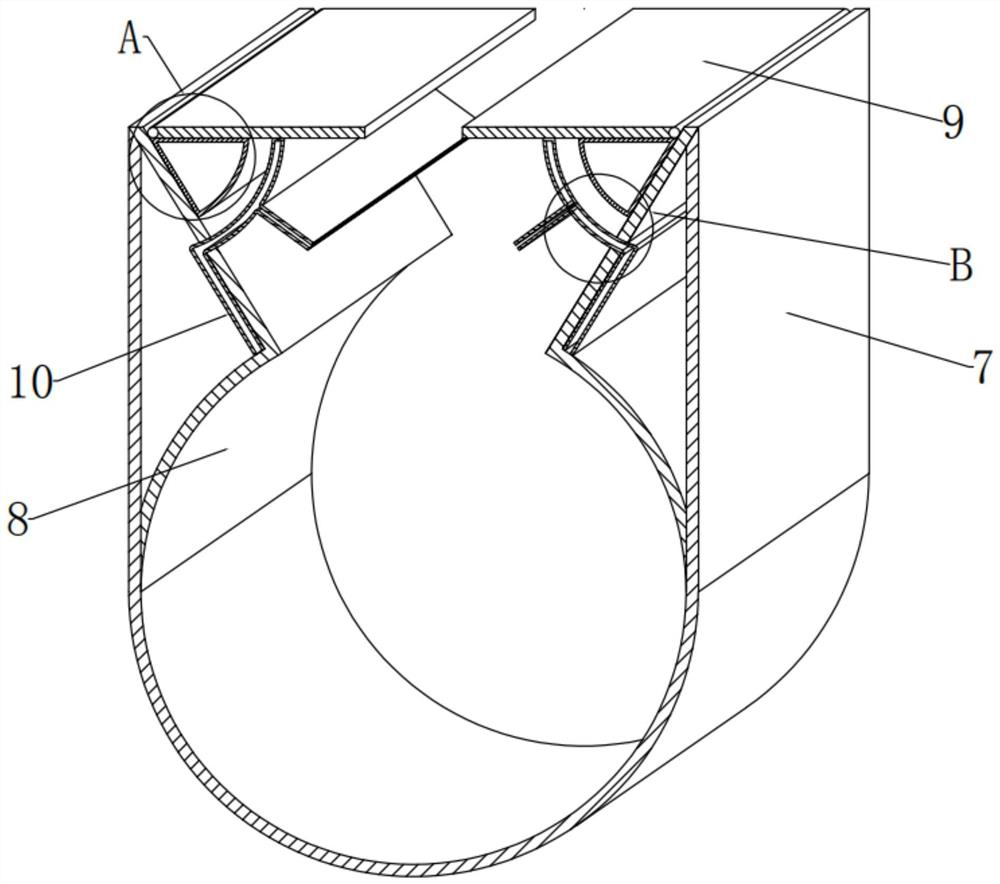

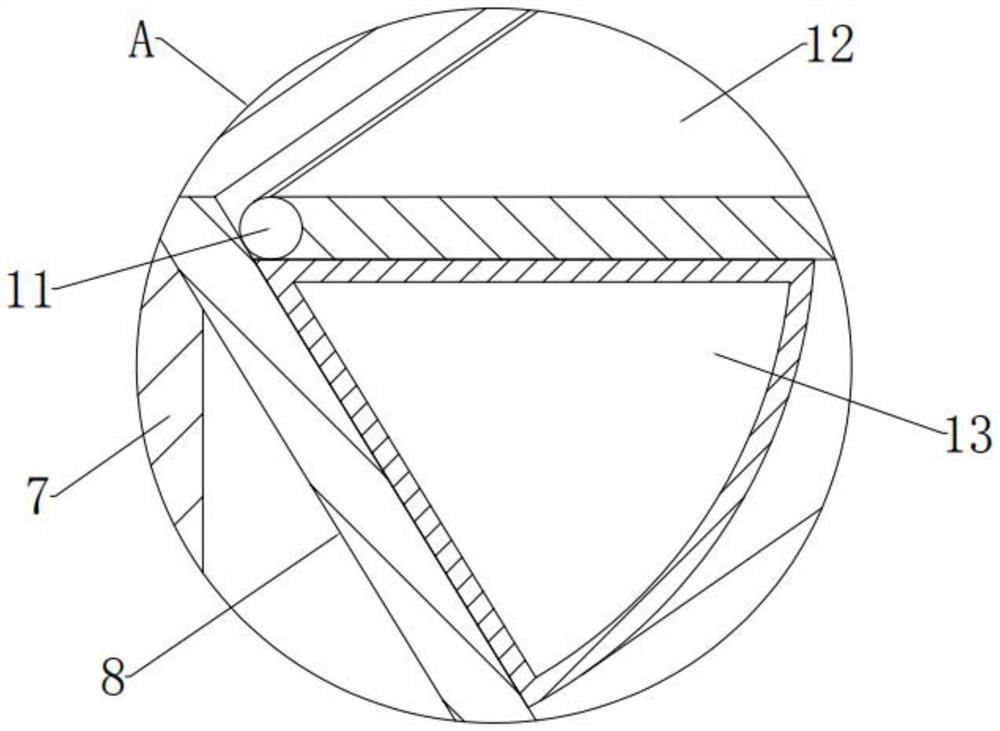

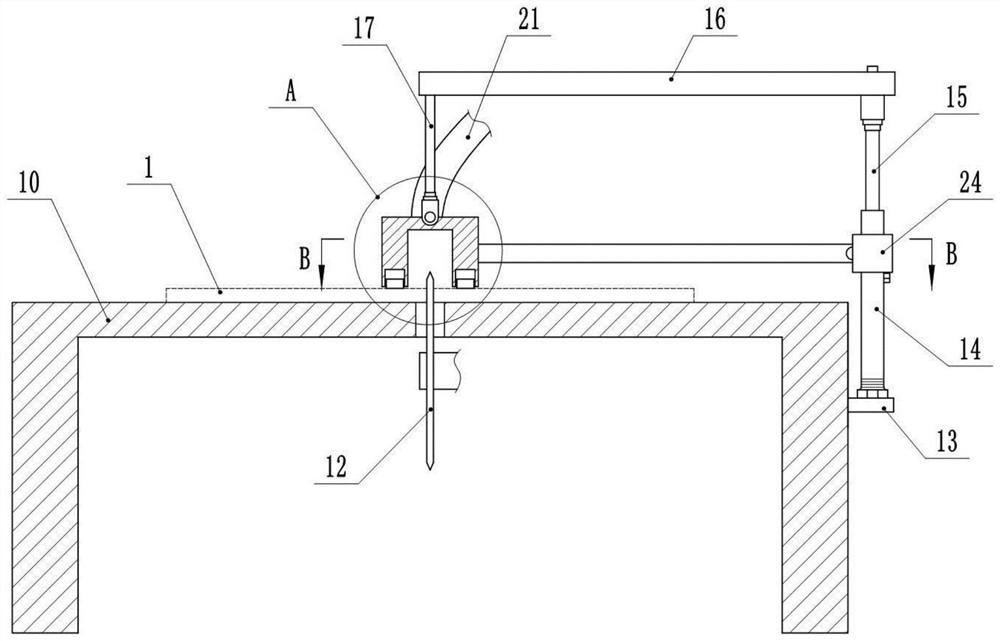

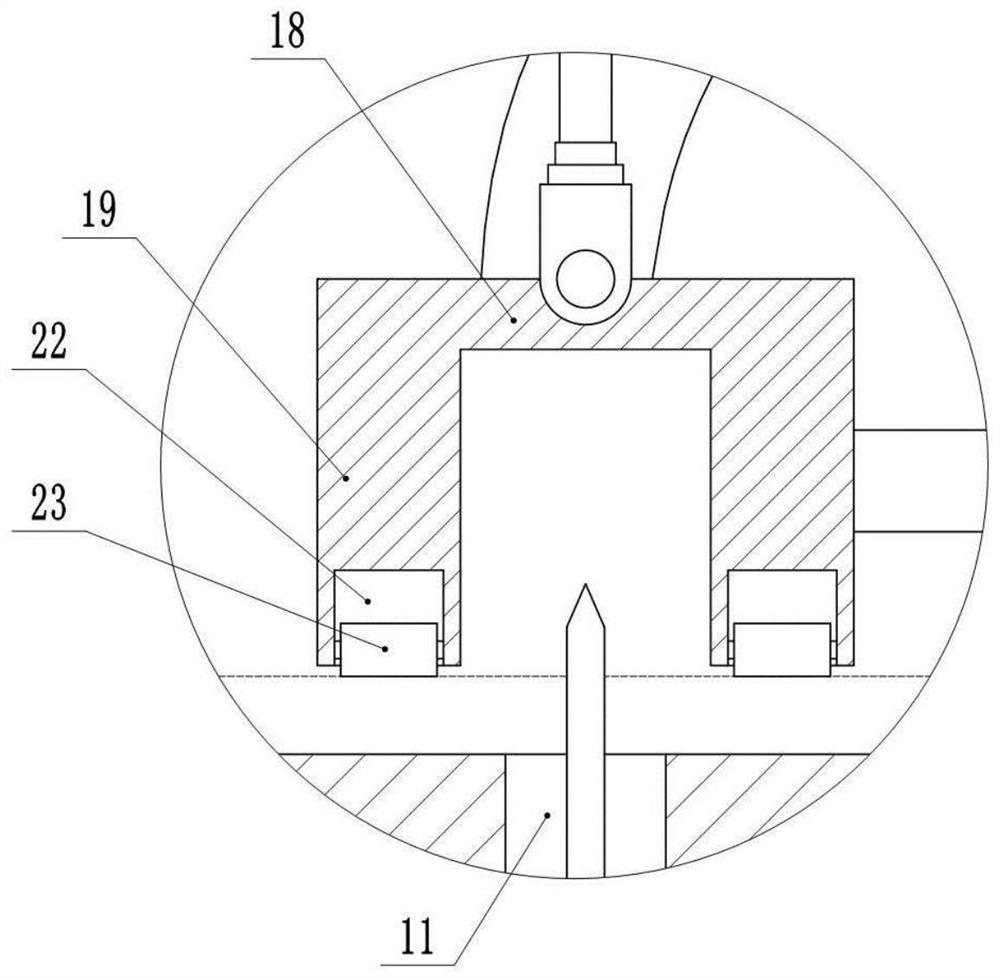

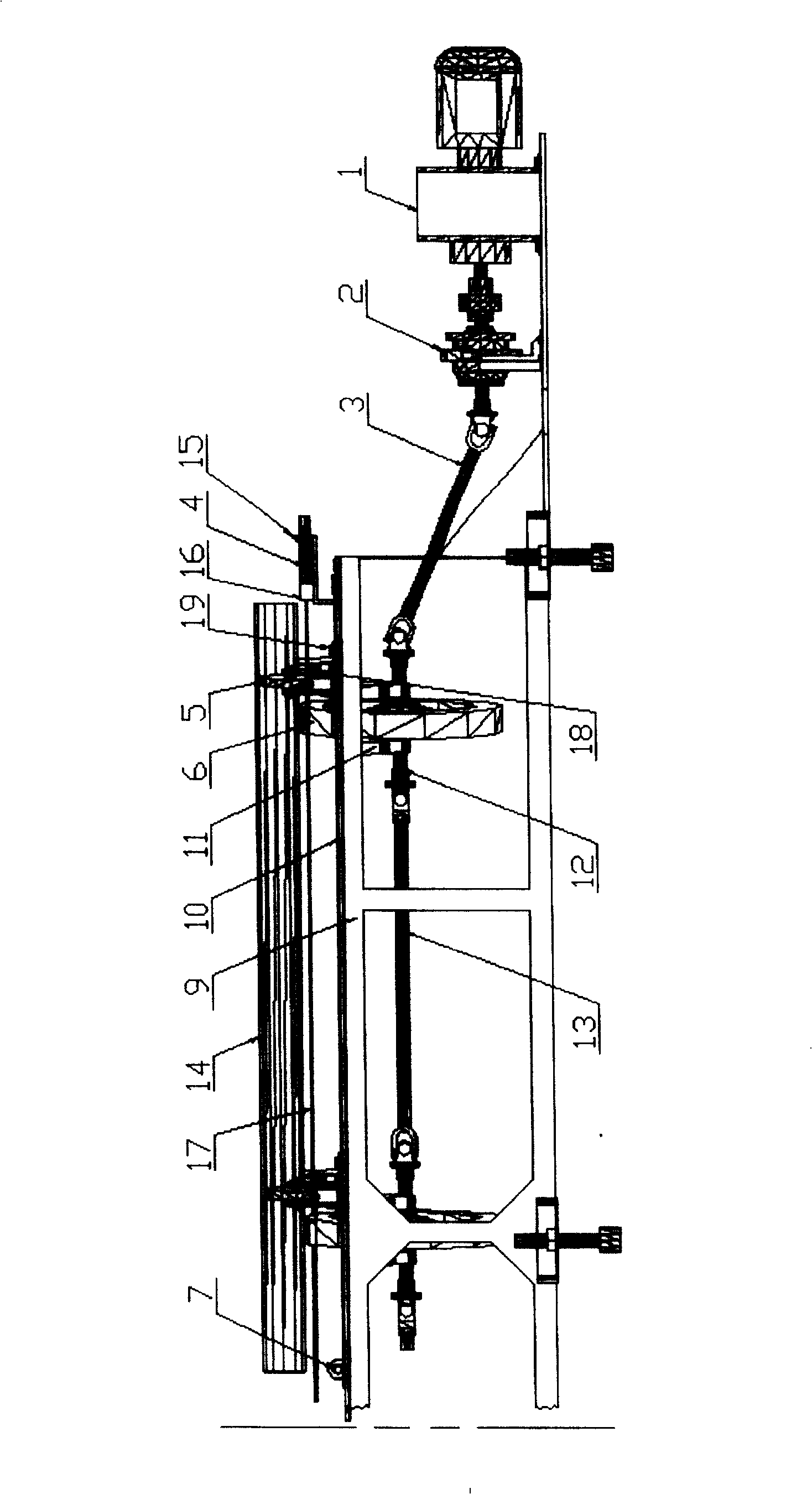

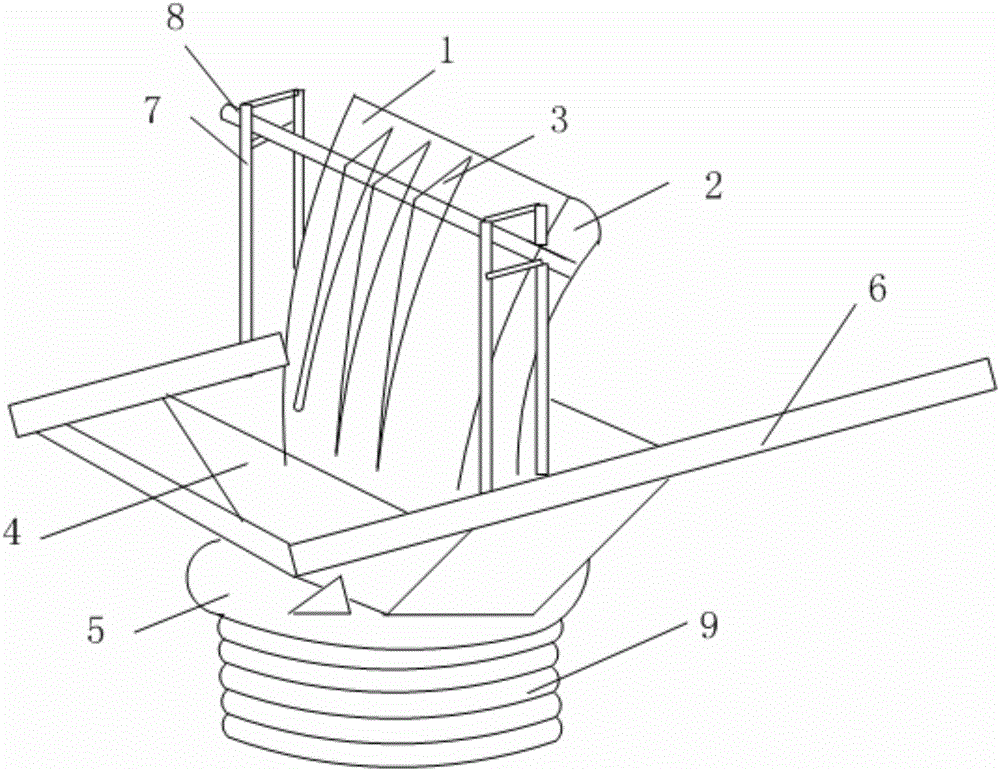

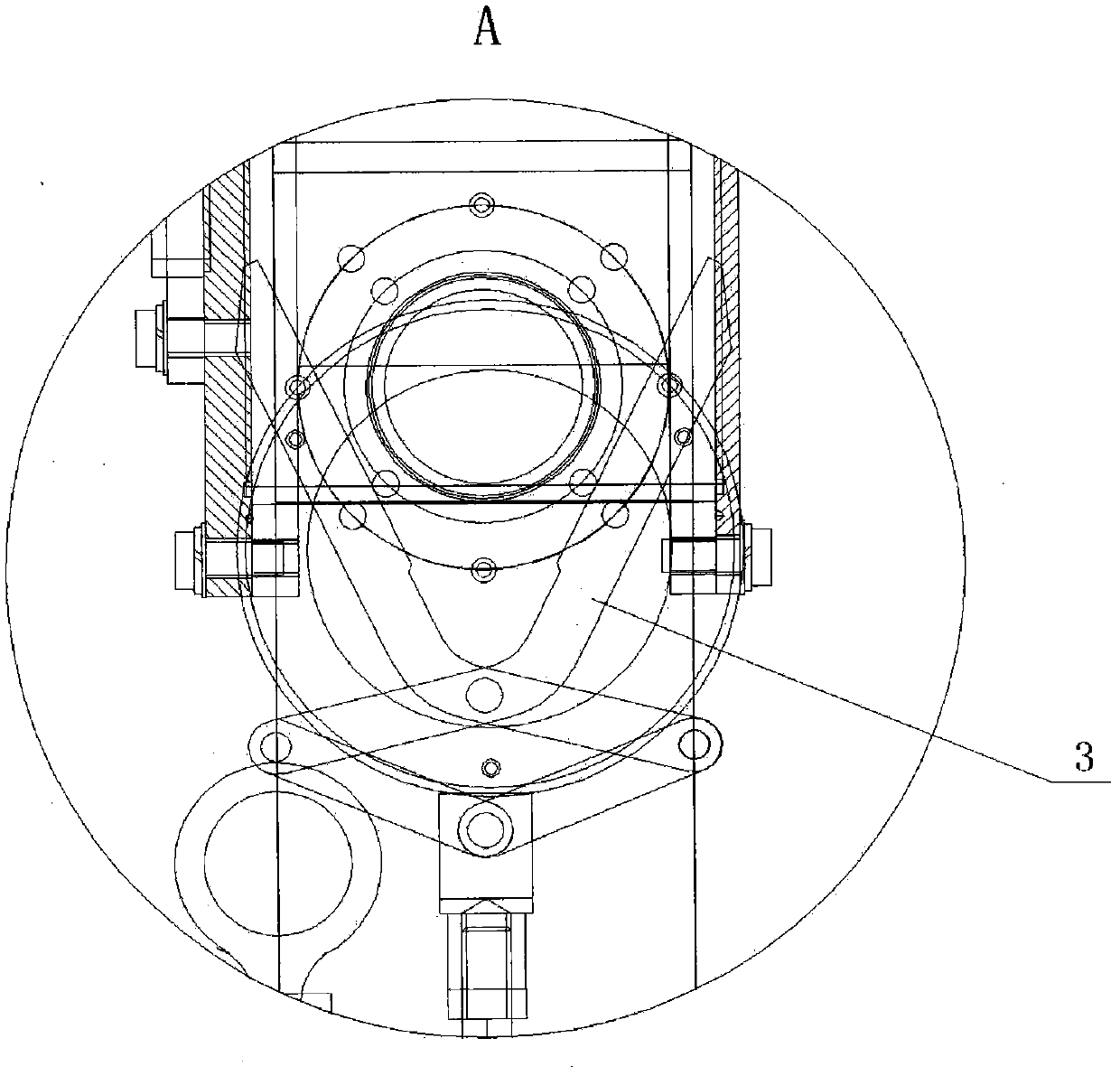

Five-axis numerical control polishing machine capable of changing grinding heads automatically

InactiveCN103465145AAutomatic replacementReduce labor intensityPolishing machinesNumerical controlCurve shape

The invention discloses a five-axis numerical control polishing machine capable of changing grinding heads automatically. The five-axis numerical control polishing machine comprises a plurality of semi-axis grinding heads, a machine body frame, a controller, a polishing head, a grinding head supply mechanism, a spindle clamping device, a Z-axis drive mechanism, an X-axis drive mechanism, a Y-axis drive mechanism, an A-axis rotary workbench and a C-axis rotating mechanism. The polishing head, the grinding head supply mechanism, the spindle clamping device, the Z-axis drive mechanism, the X-axis drive mechanism, the Y-axis drive mechanism, the A-axis rotary workbench and the C-axis rotating mechanism are respectively connected with the controlled and controlled by the same. The five-axis numerical control polishing machine capable of changing grinding heads automatically has the advantages that the polishing machine is ingenious and reasonable in structural design, high in automation level, convenient and fast to operate, high in flexibility by the five-axis linkage structure, and widely applicable; multiple polishing procedures such as rough polishing, fine polishing and mirror polishing can be completed at one-step clamping, clamping time is saved, machining efficiency and precision are increased greatly, polishing effect is guaranteed, work efficiency is increased, labor intensity of workers is lowered, enterprise competitiveness is increased effectively, and polishing of surfaces of complex curve shapes can be achieved.

Owner:东莞市钜铧机械有限公司

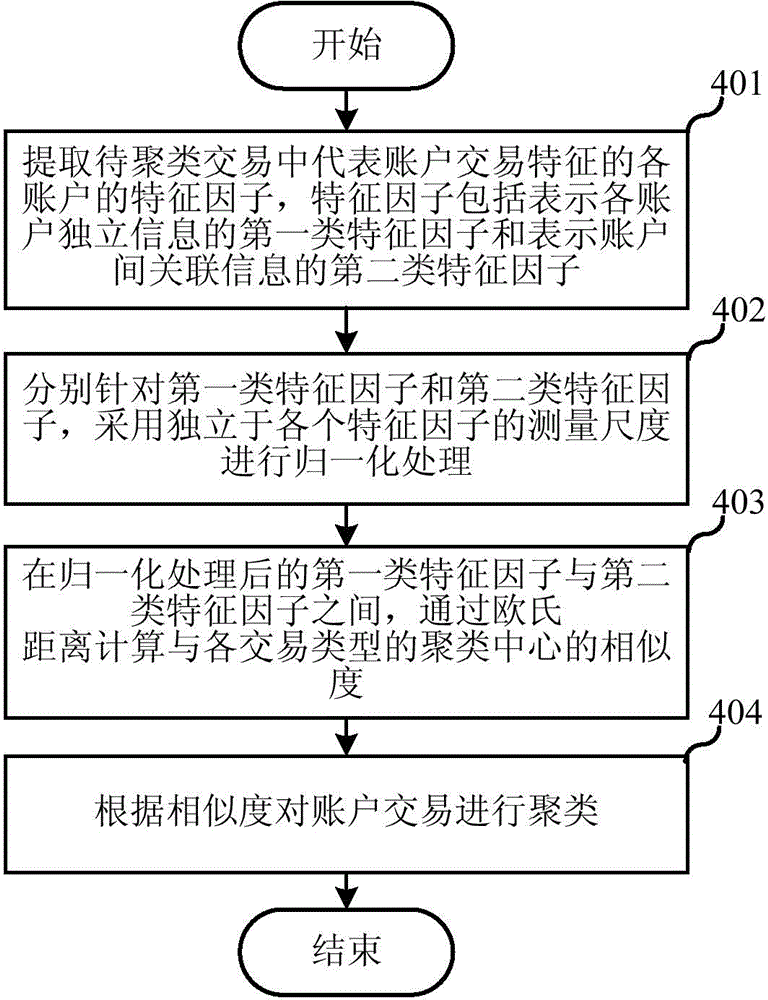

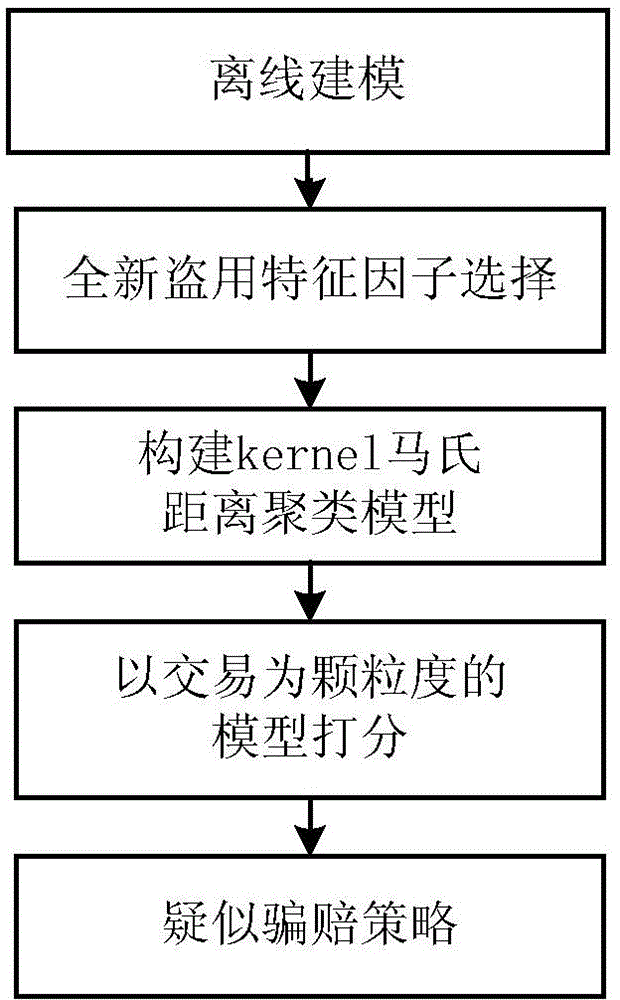

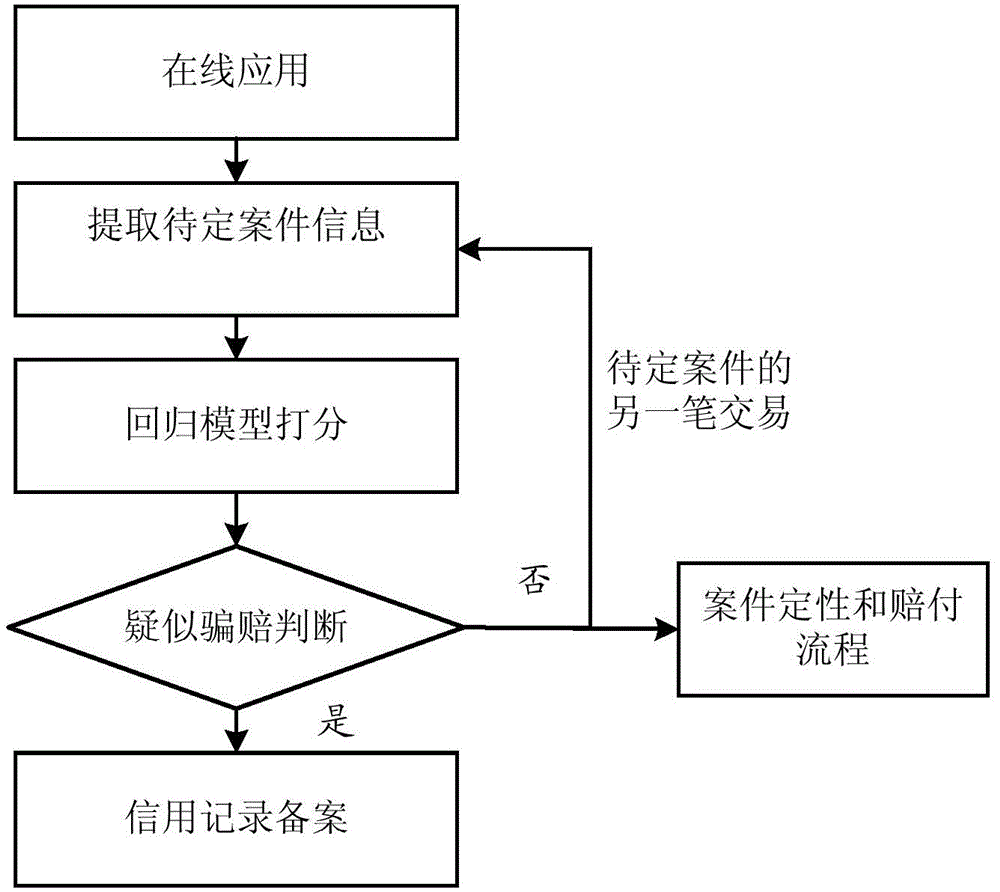

Account transaction clustering method and system thereof

ActiveCN105809448AImprove accuracy and effectivenessAvoid exaggerationPayment architectureMachine learningEuclidean distance

The invention relates to an account security technology, and discloses an account transaction clustering method and system thereof. The method comprises the steps that a characteristic factor, which represents an account transaction characteristic, of each account in to-be-clustered transaction is extracted, wherein the characteristic factor comprises a first class of characteristic factor which represents the independent information of each account and a second class of characteristic factor which represents association information of accounts; for the first class of characteristic factor and the second class of characteristic factor, a measurement scale independent of each characteristic factor is used to carry out normalization; after normalization, Euclidean distance is used to calculate the similarity of clustering centers of various types of transactions; and according to the similarity, account transaction clustering is carried out. For the first class of characteristic factor and the second class of characteristic factor, the independent measurement scale is used to carry out normalization, and then the similarity is calculated for clustering. The problem of different characteristic factor variable dimensions is overcome. Small characteristic factors are prevented from being exaggerated.

Owner:ADVANCED NEW TECH CO LTD

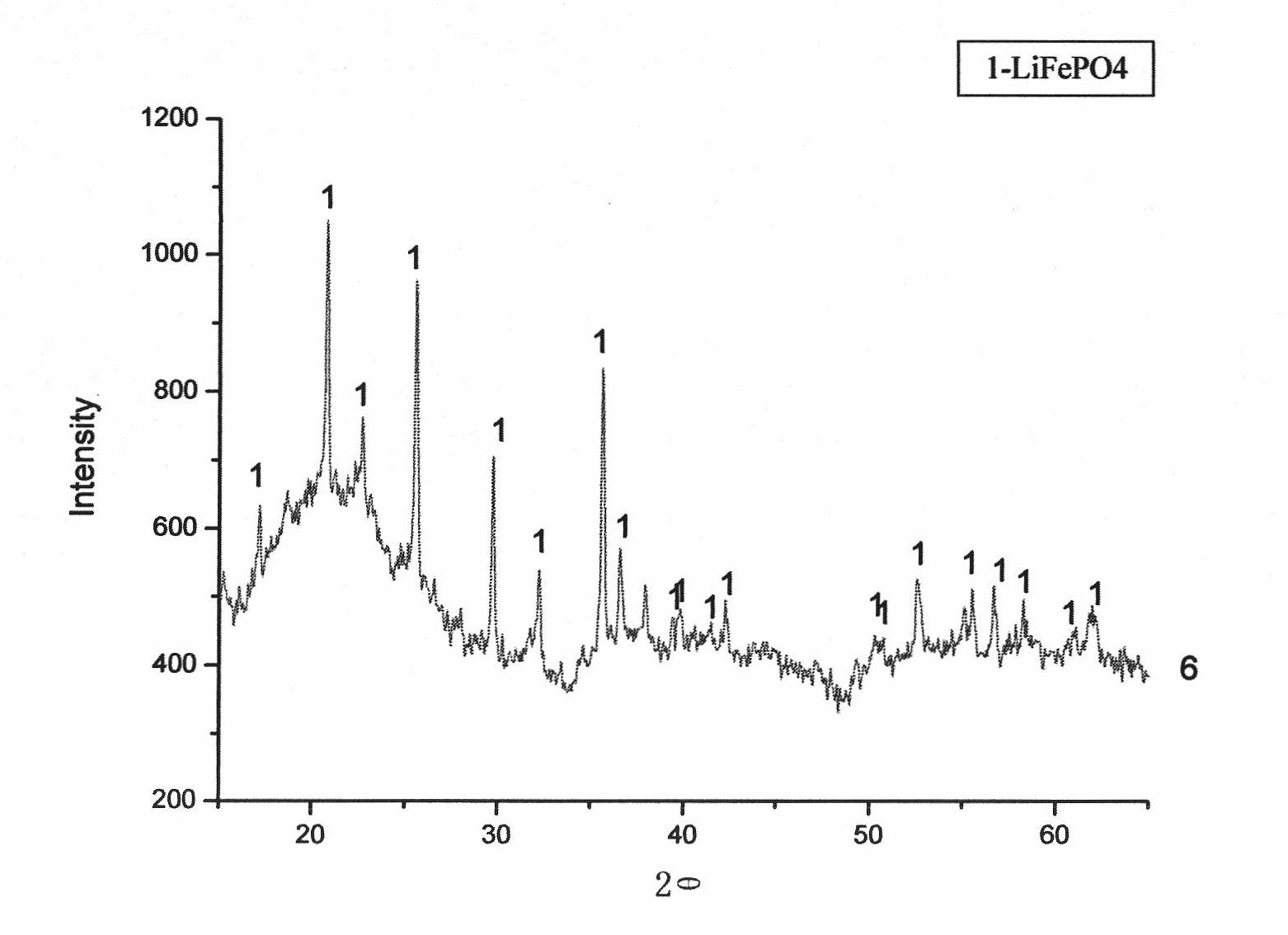

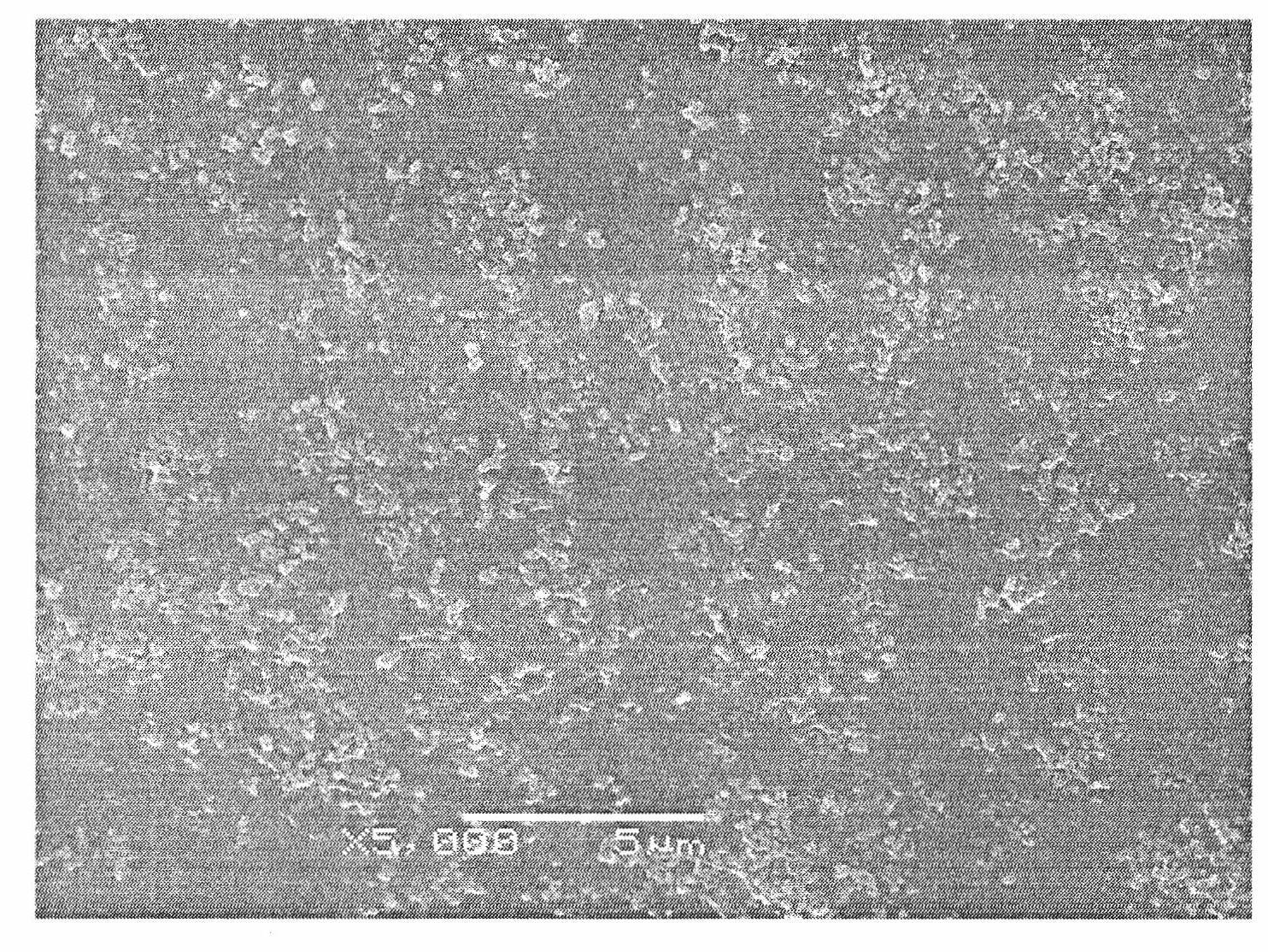

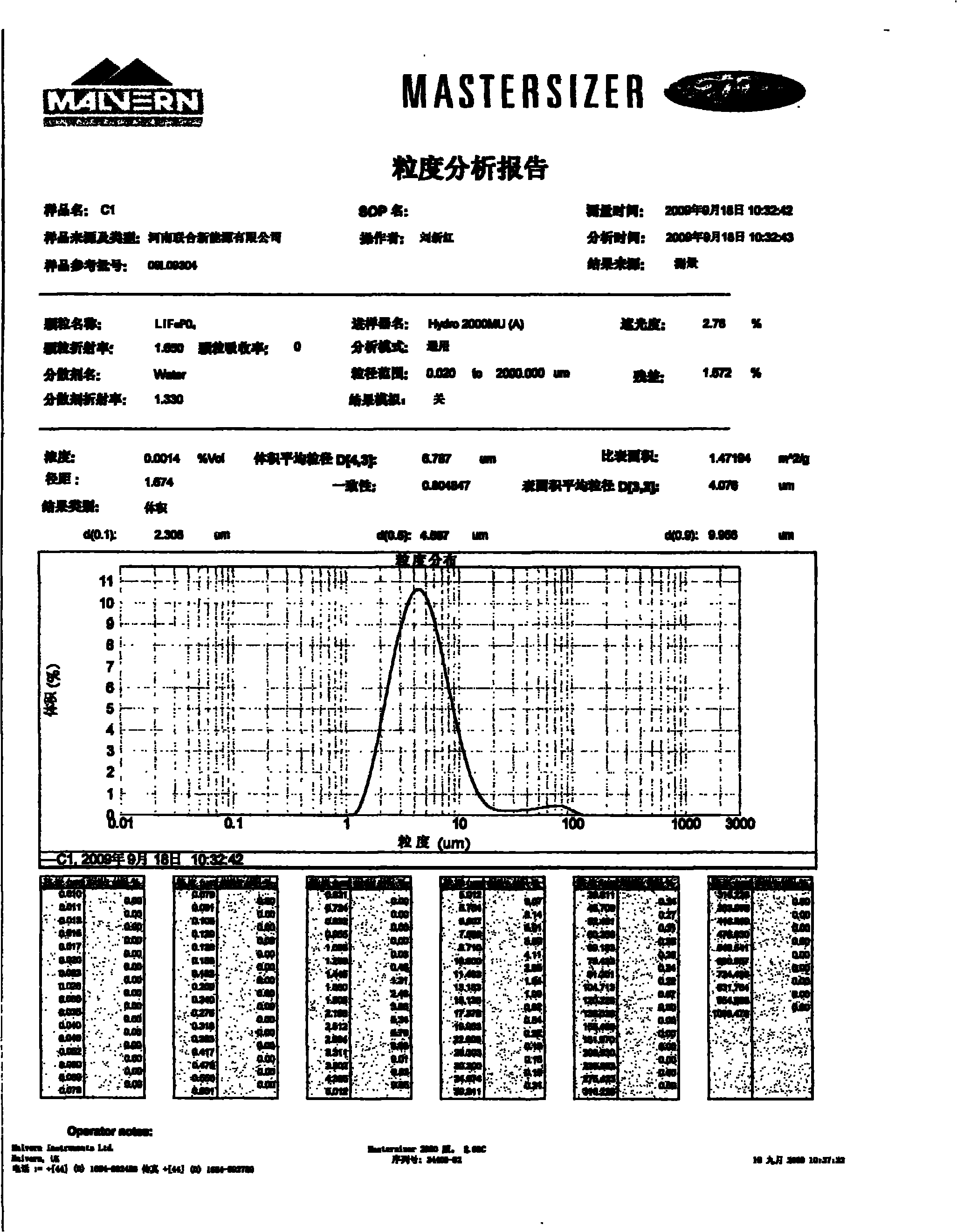

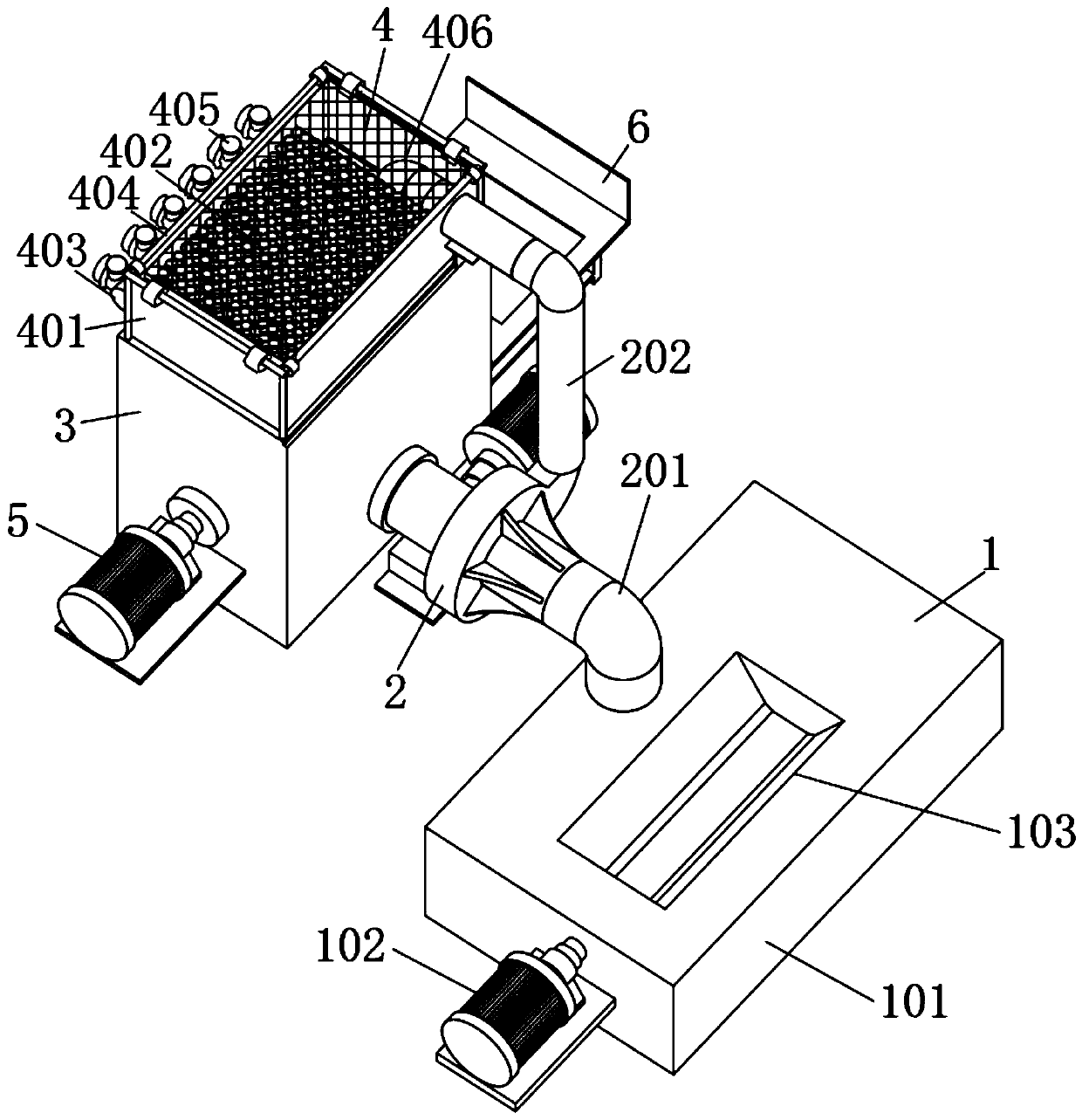

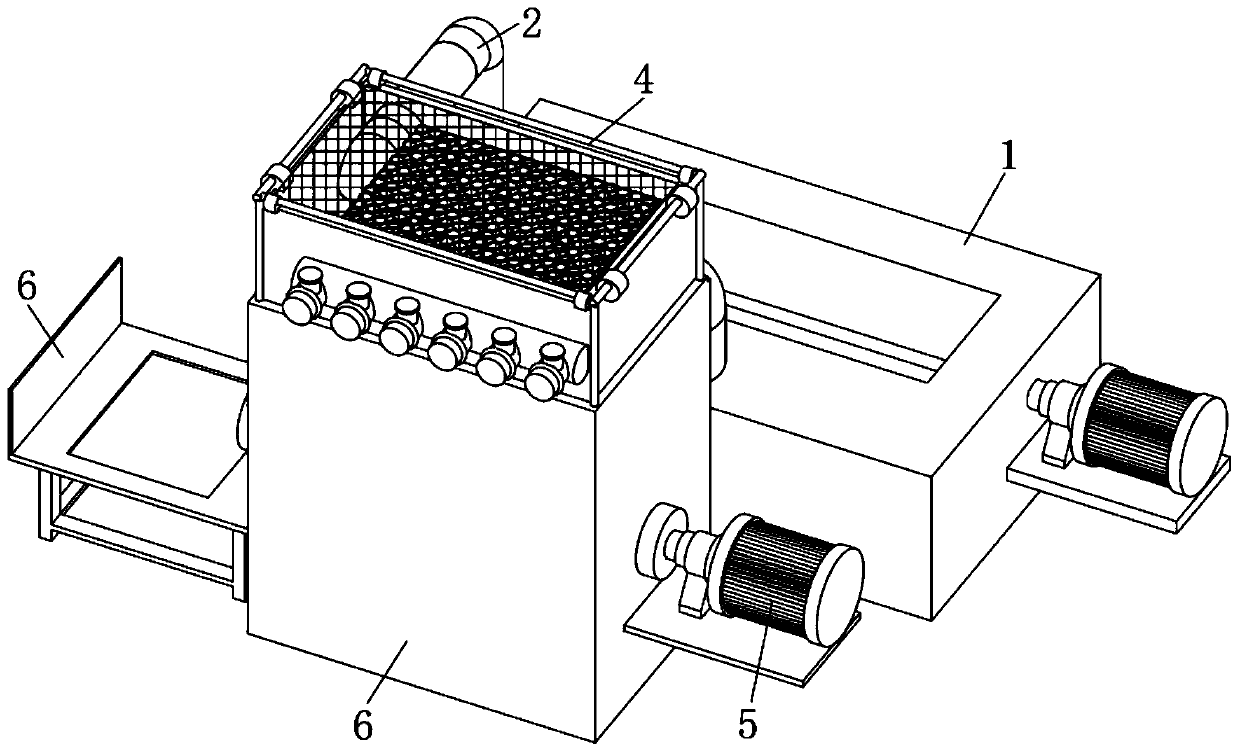

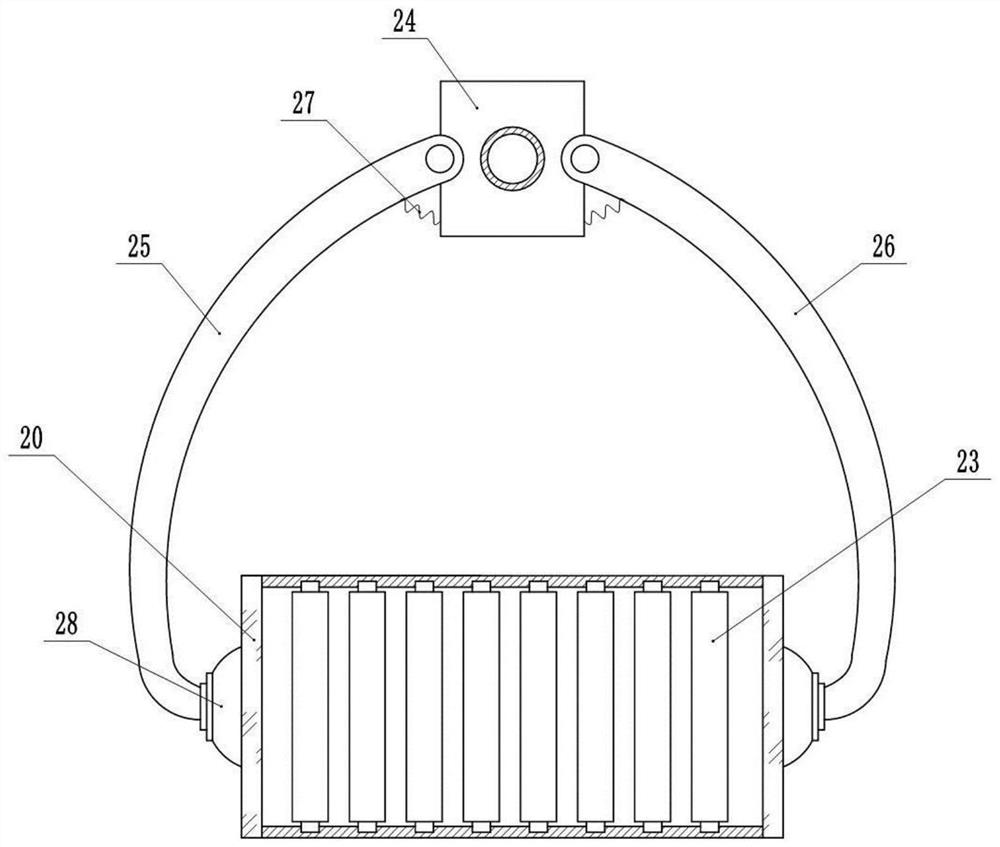

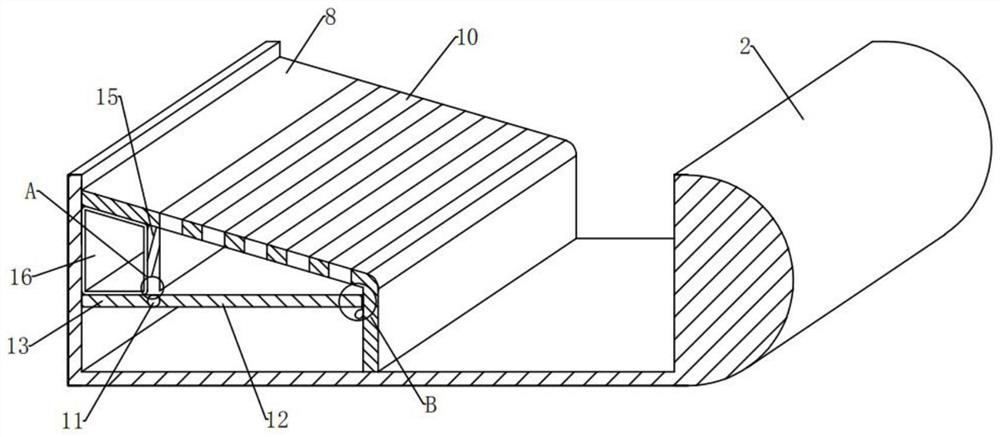

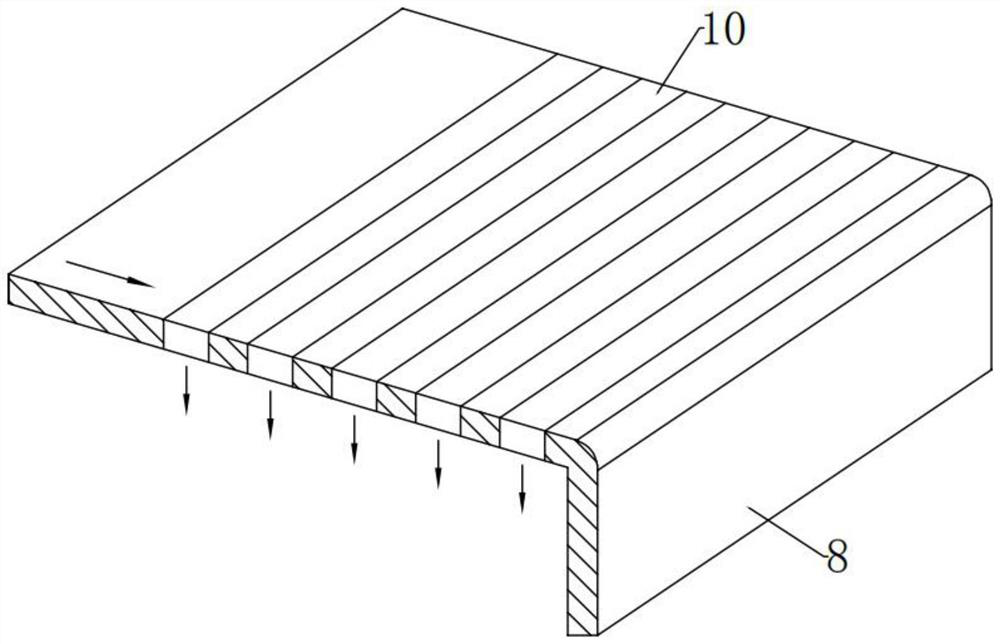

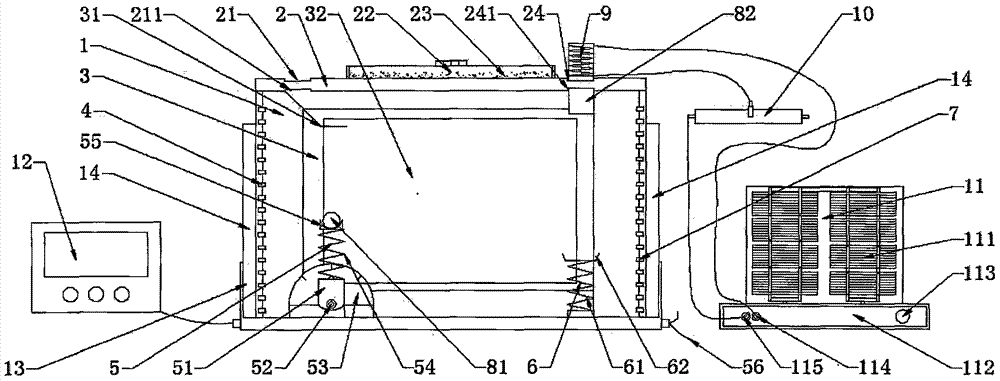

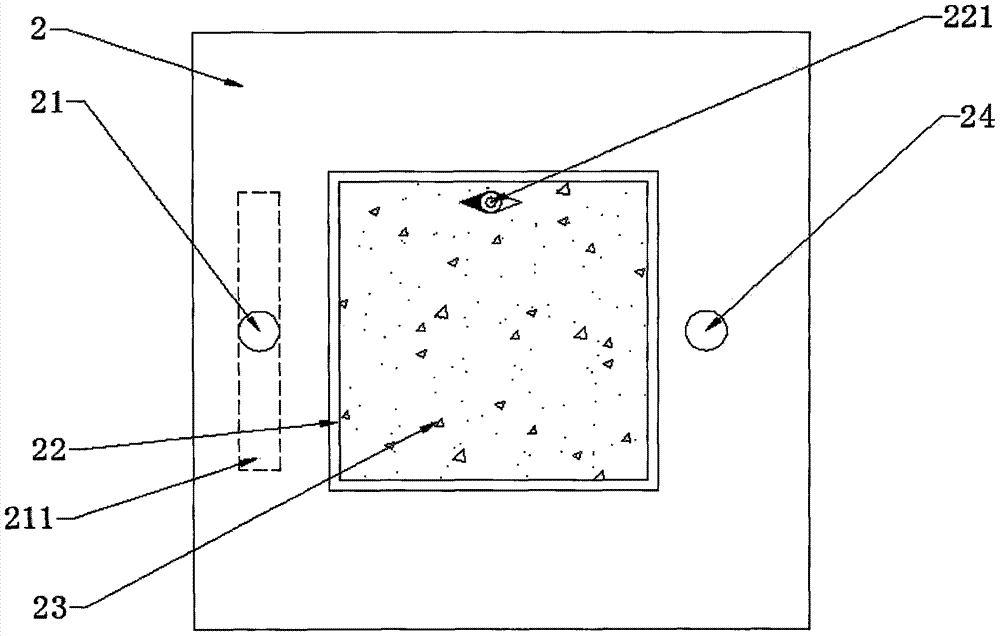

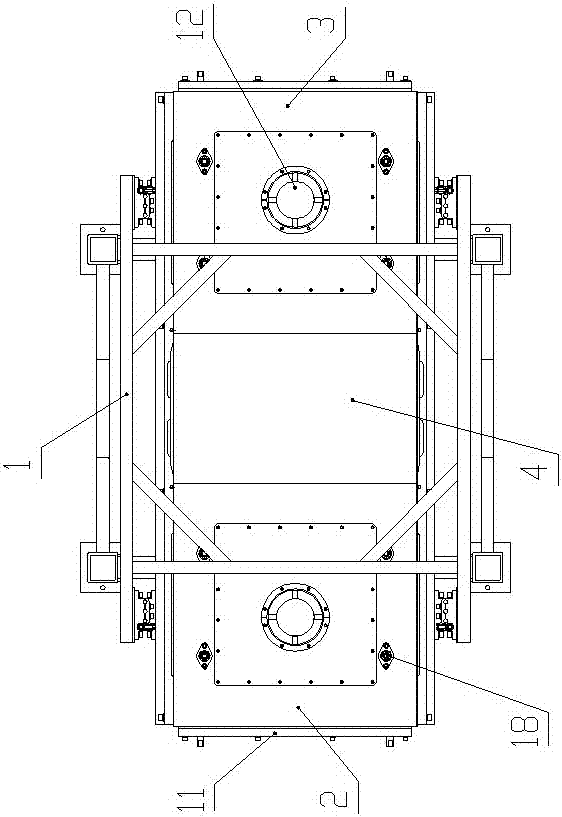

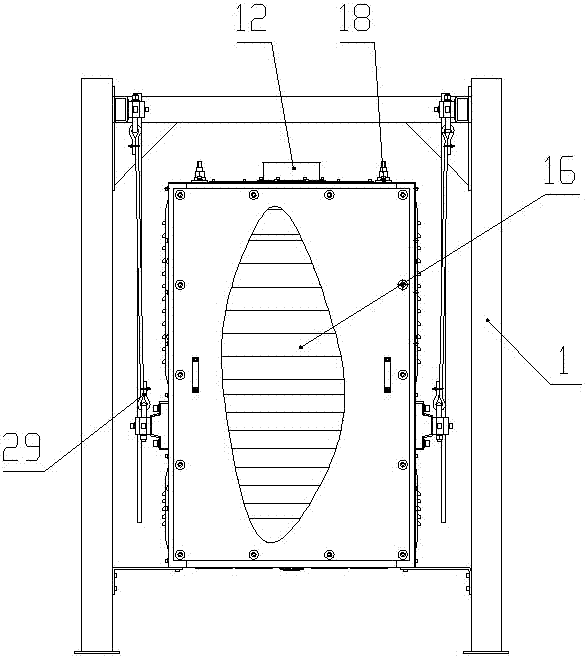

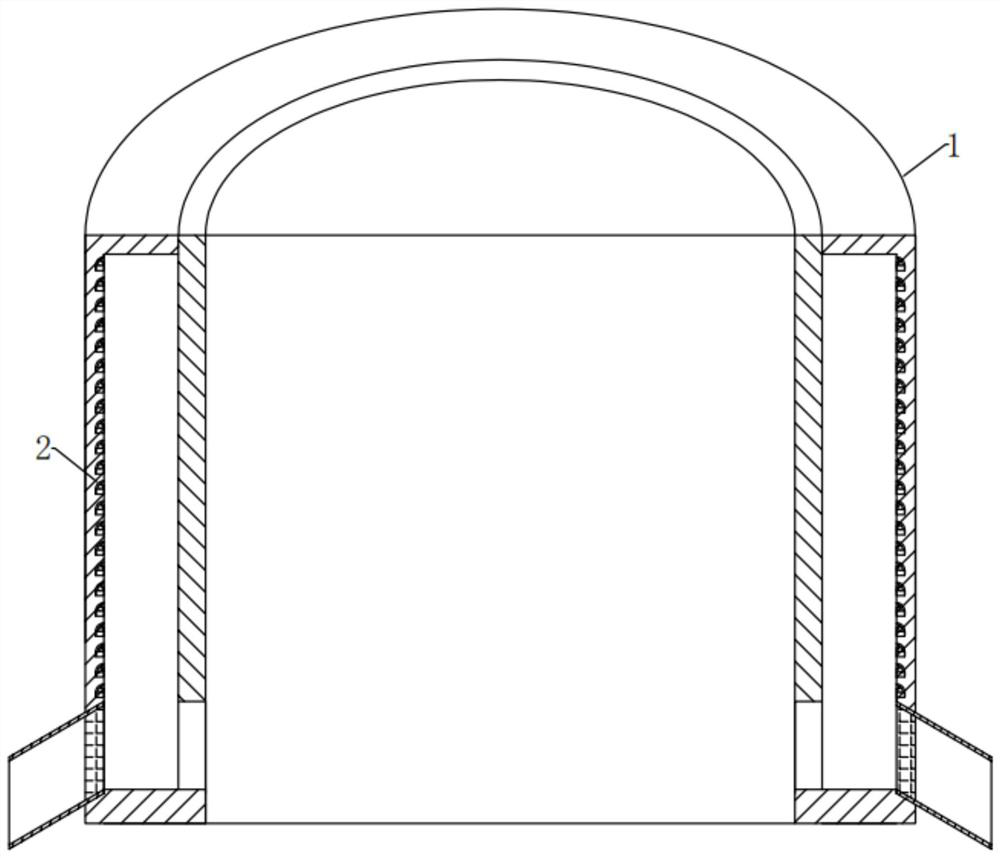

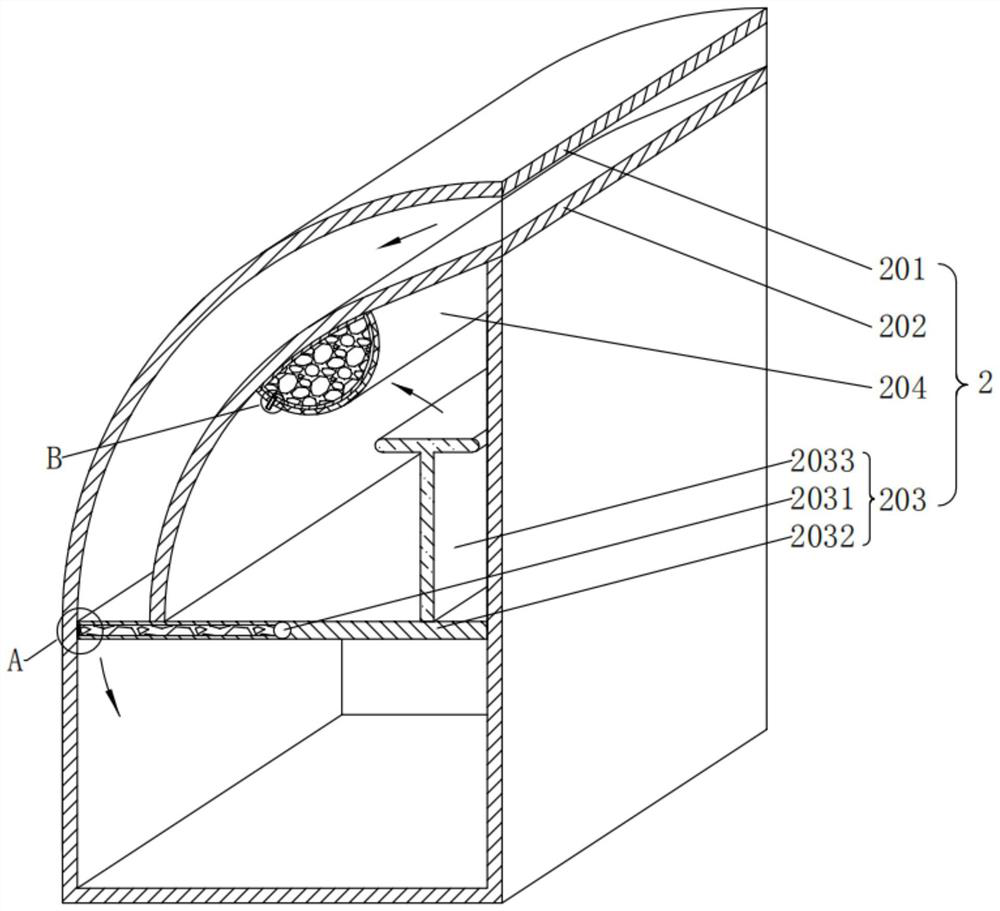

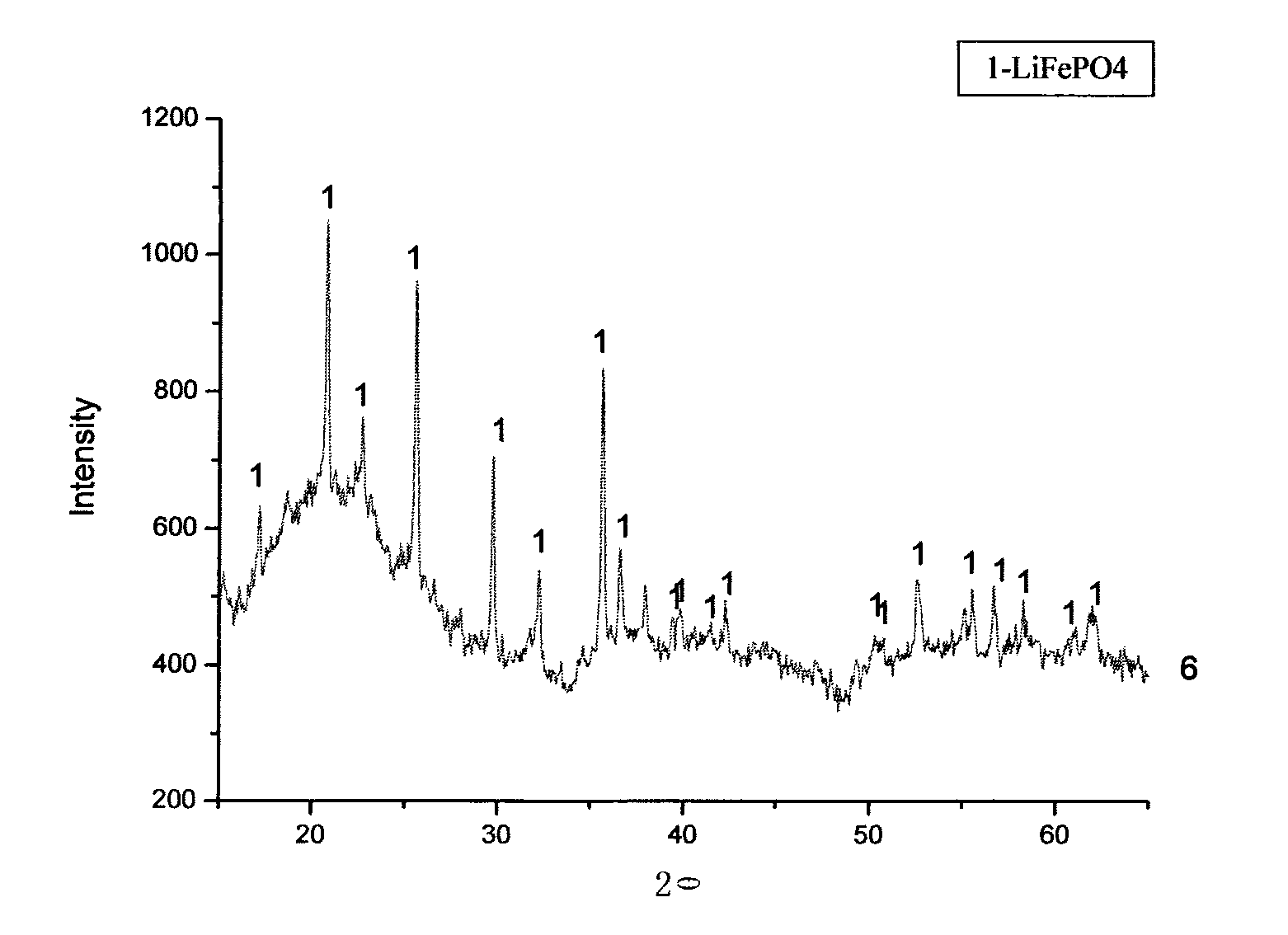

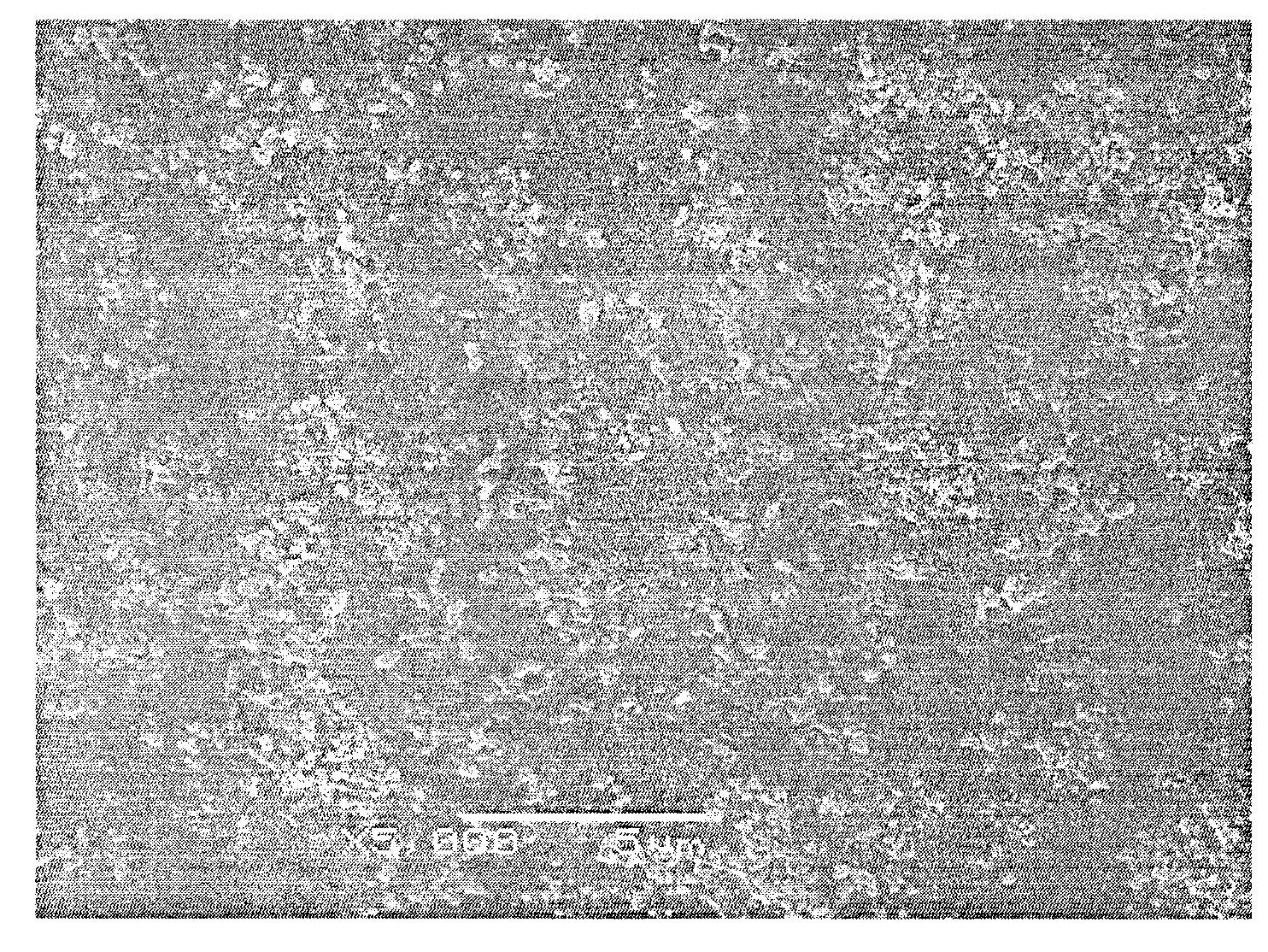

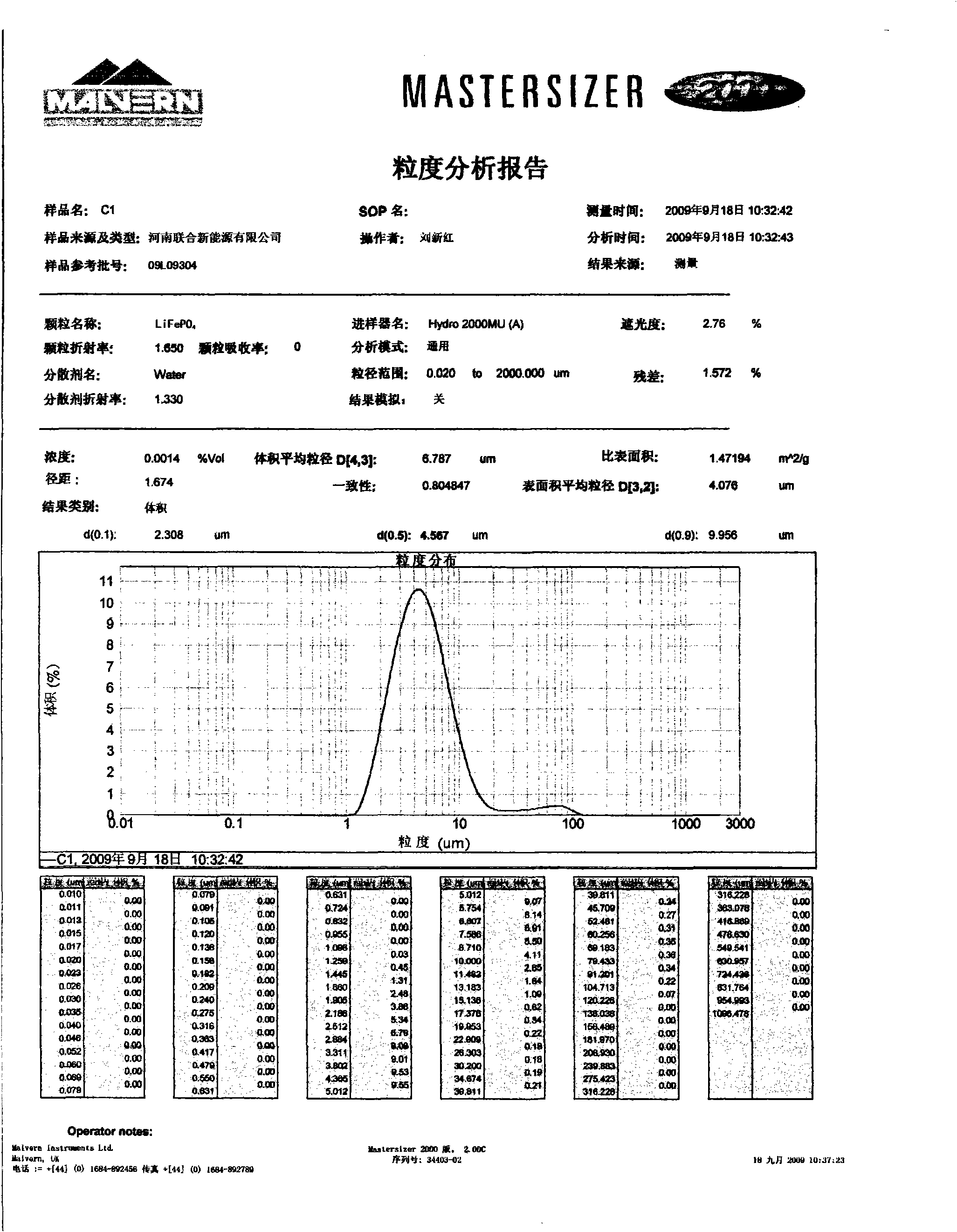

Method for preparing lithium iron phosphate by sintering lithium iron phosphate precursor and microwave sintering equipment

InactiveCN102092699APromote densificationEvenly distributedCell electrodesPhosphorus compoundsLithium iron phosphateControl treatment

The invention discloses a method and equipment for preparing lithium iron phosphate from a lithium iron phosphate precursor. The method comprises the three process steps of pretreatment of the lithium iron phosphate precursor material, pre-sintering and sintering; and in a non-oxidizing environment, the precursor material is heated by a certain number of microwave heaters, and the three process steps are finished by controlling treatment temperature and treatment time to finally prepare the lithium iron phosphate product. The equipment comprises a material inlet, a material feeding ventilation chamber, a pretreatment unit furnace, a pre-sintering unit furnace, a sintering unit furnace, a material discharging ventilation chamber, a cooling material discharging mechanism, a material outlet,a vacuumizing device, a protective gas input device and an equipment control circuit. In the method, the pretreatment and pre-sintering process steps are added to optimize a lithium iron phosphate microwave sintering process and solve keys problems on product quality control. The equipment provided by the invention realizes continuous microwave sintering by a plurality of unit furnaces so as to improve the sintering efficiency and realize large-scale industrial production.

Owner:HENAN UNION NEW ENERGY

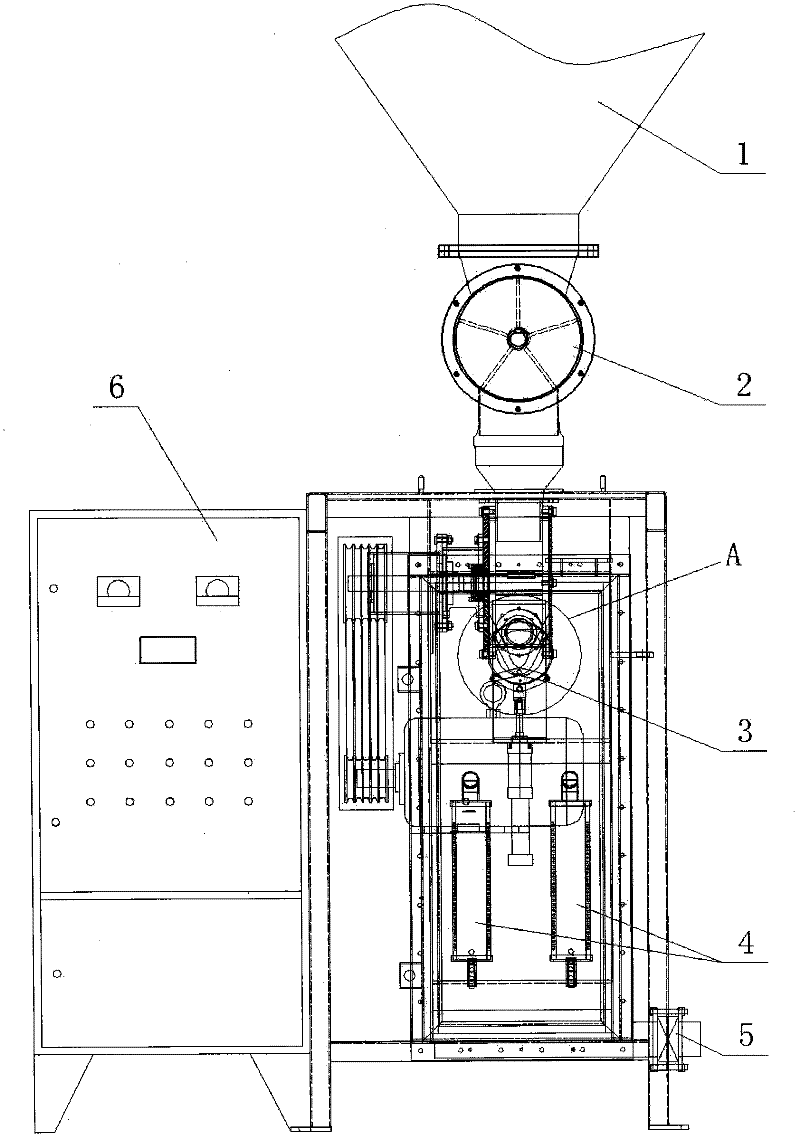

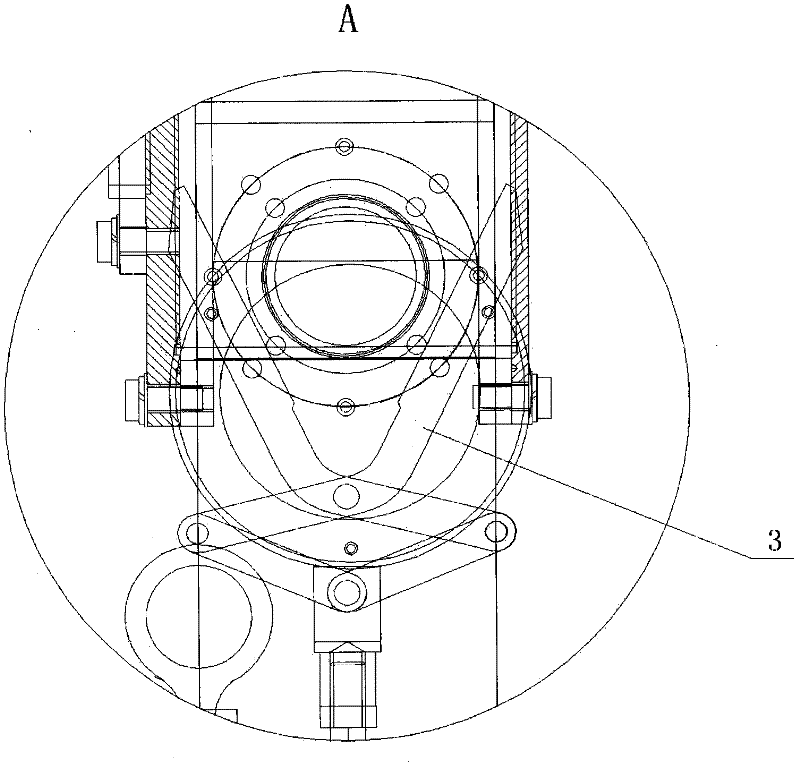

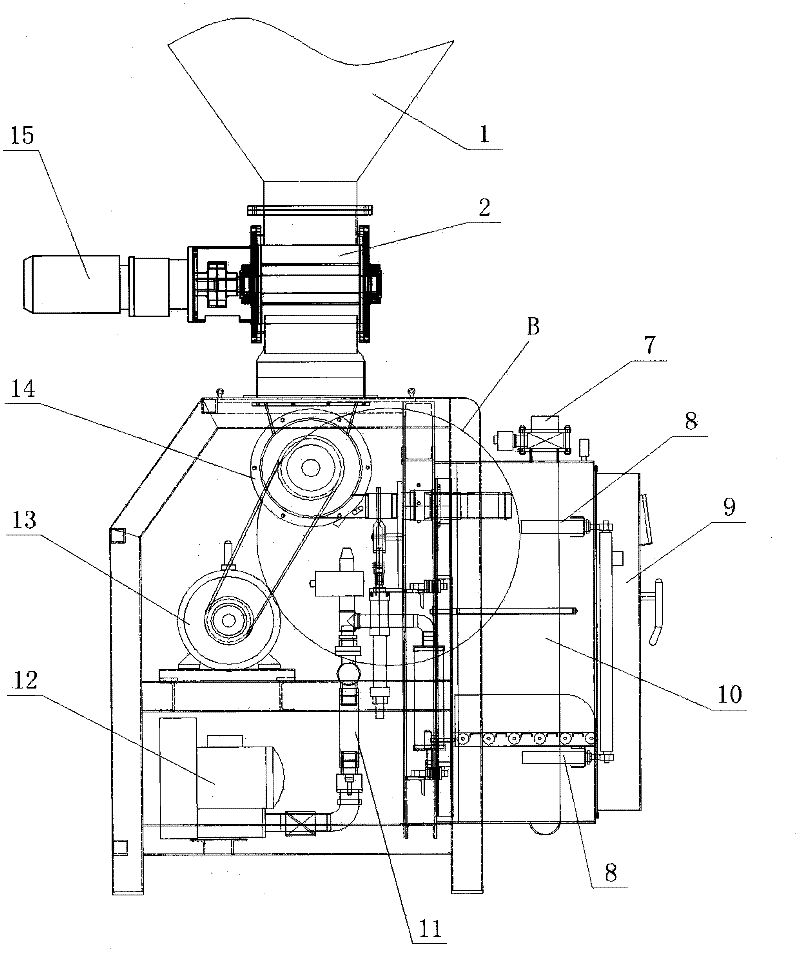

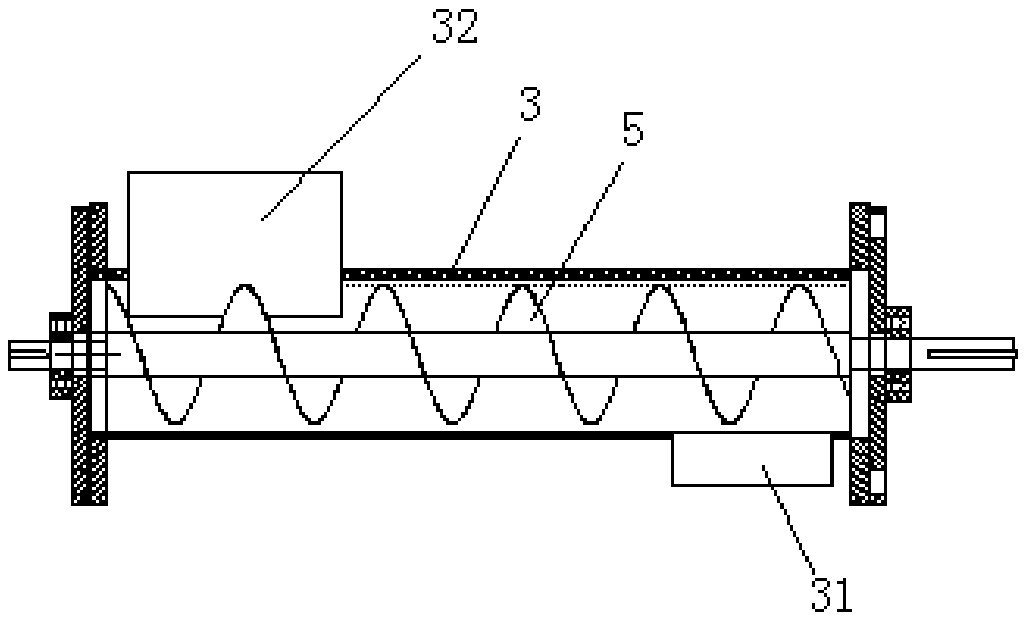

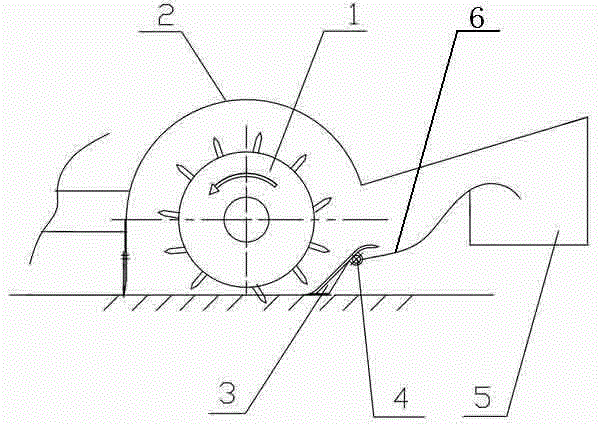

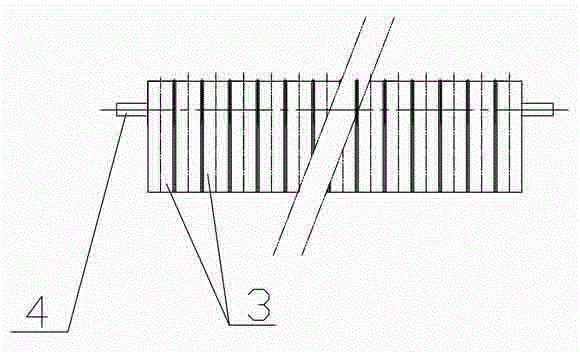

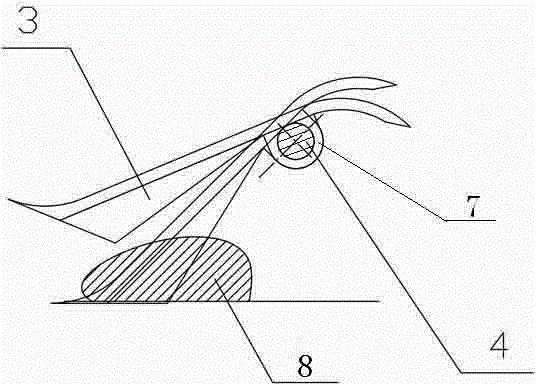

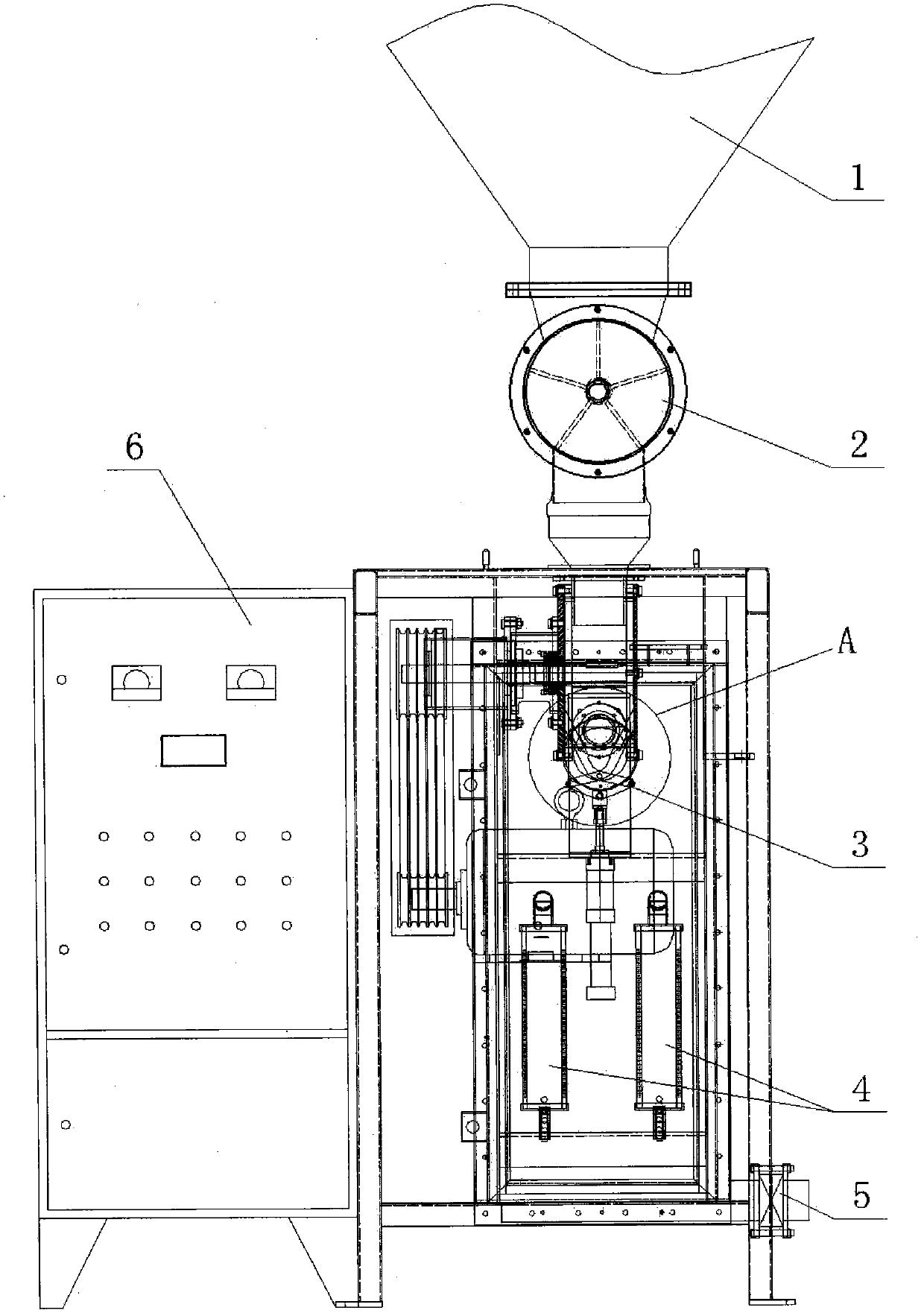

Impeller type vacuum quantitative packaging machine

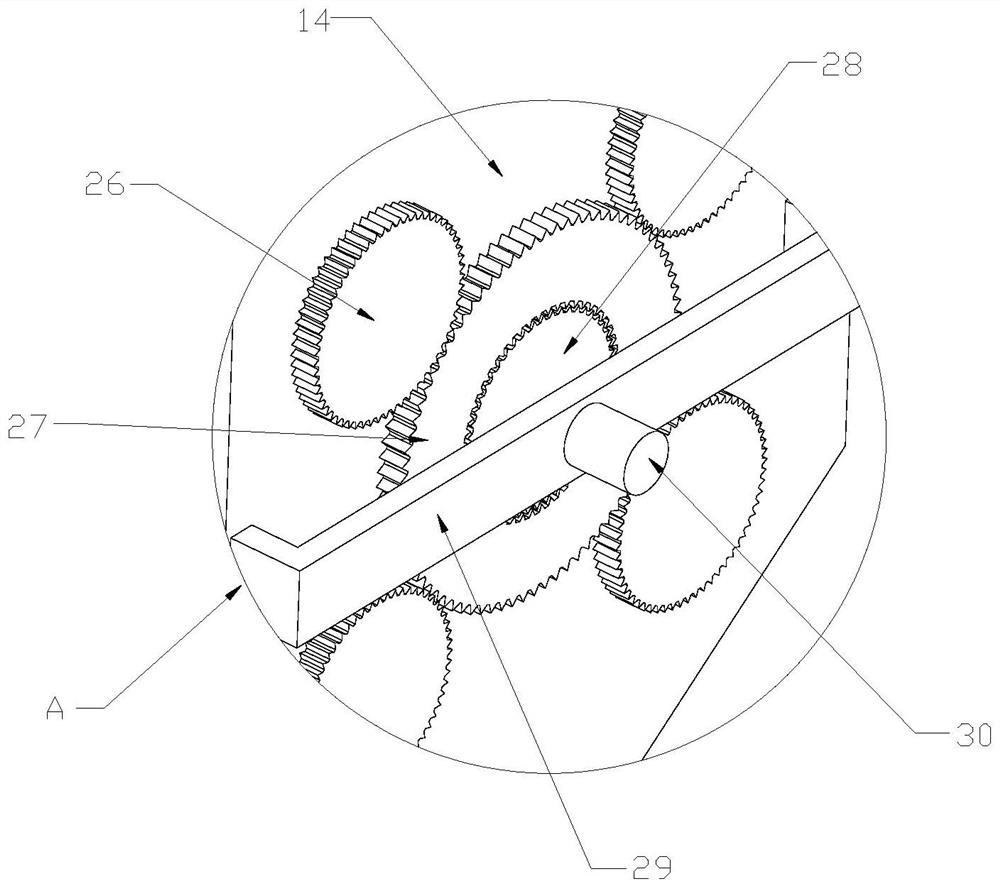

ActiveCN102390551ASealing effect is goodGuaranteed accuracy requirementsPackaging under vacuum/special atmosphereSolid materialImpellerProgrammable logic controller

The invention discloses an impeller type vacuum quantitative packaging machine. The packaging machine is characterized in that a packing driving mechanism of the packaging machine comprises an impeller, and the material driving speed of the impeller is obviously better than the material driving speed of a packing auger, thereby being capable of greatly accelerating the material packing speed of the packaging machine; the material sealing effect of the impeller is good, and a discharge port can be effectively blocked after the end of packaging, thereby preventing the leakage of material; the packaging machine is simultaneously provided with a control valve of scissors at the discharge port, and the control valve of the scissors can flexibly control the discharge flow rate and ensure the requirements on packaging precision; the packaging machine is provided with a bag expansion device at a discharge nozzle, thereby preventing dust from flying to outside during packaging; and an impellerdriving electric motor of the packaging machine can be controlled by a programmable logic controller (PLC) and a frequency converter, thereby having the characteristics of being intelligent and automatic.

Owner:秦皇岛普达电子有限公司

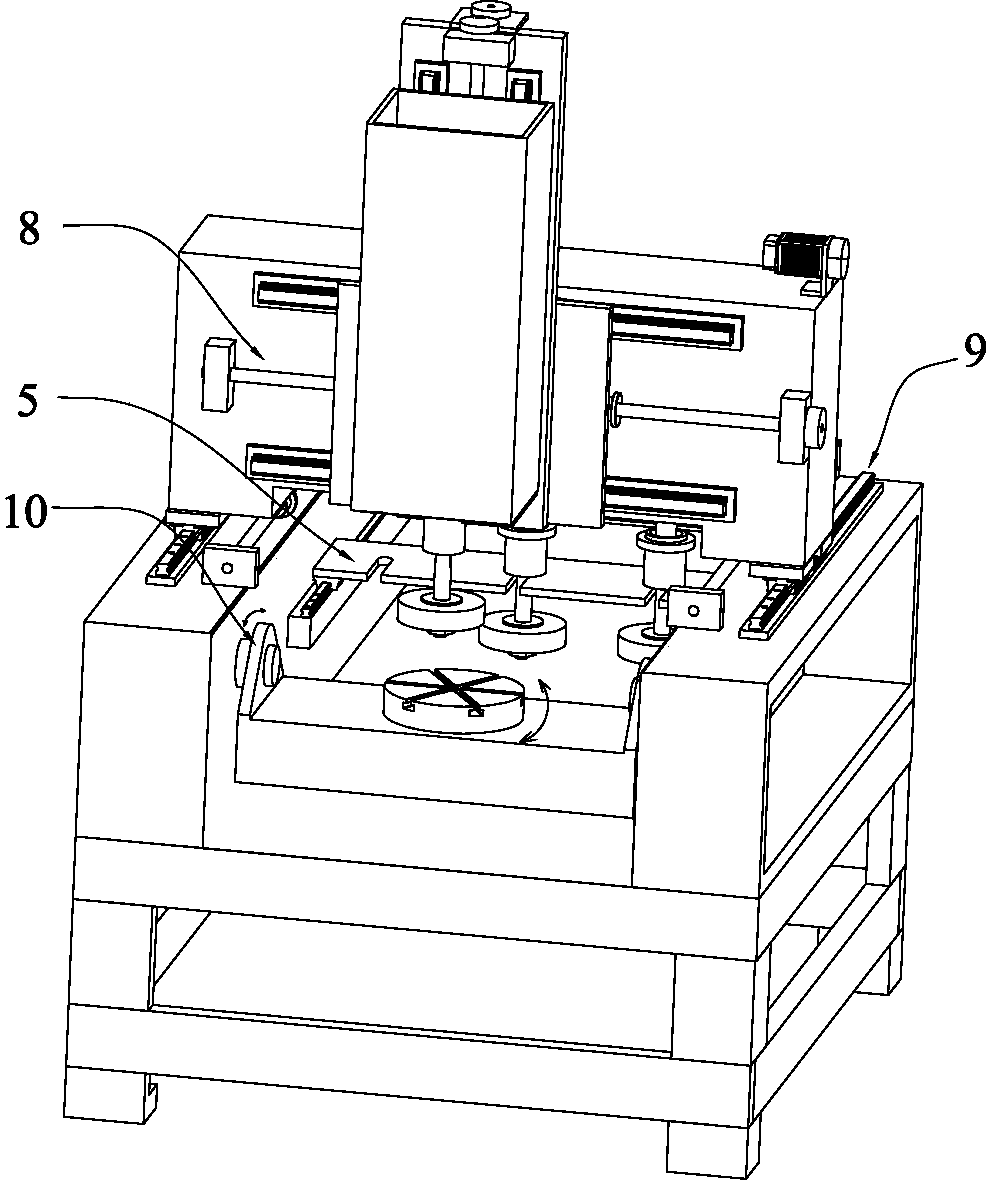

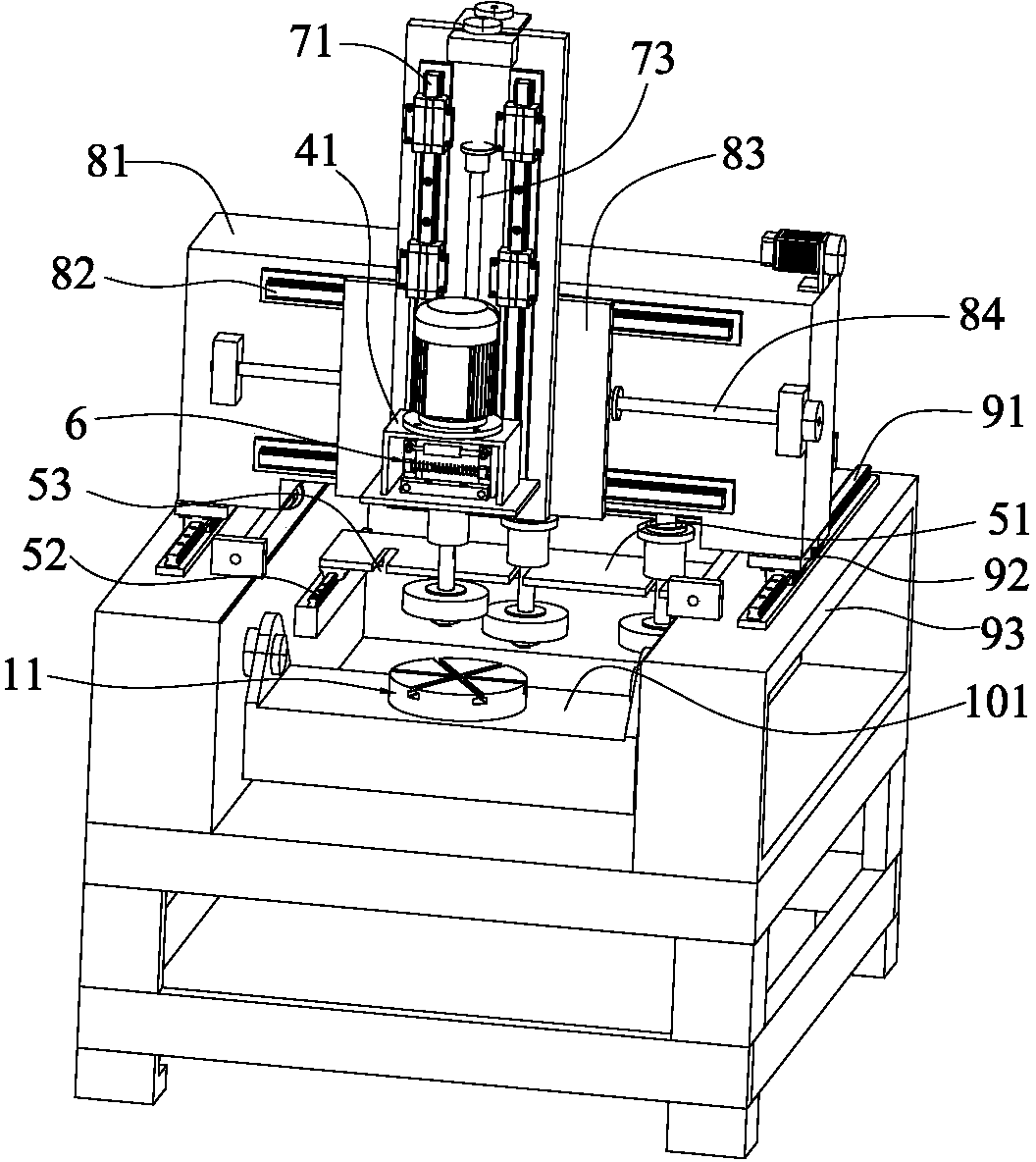

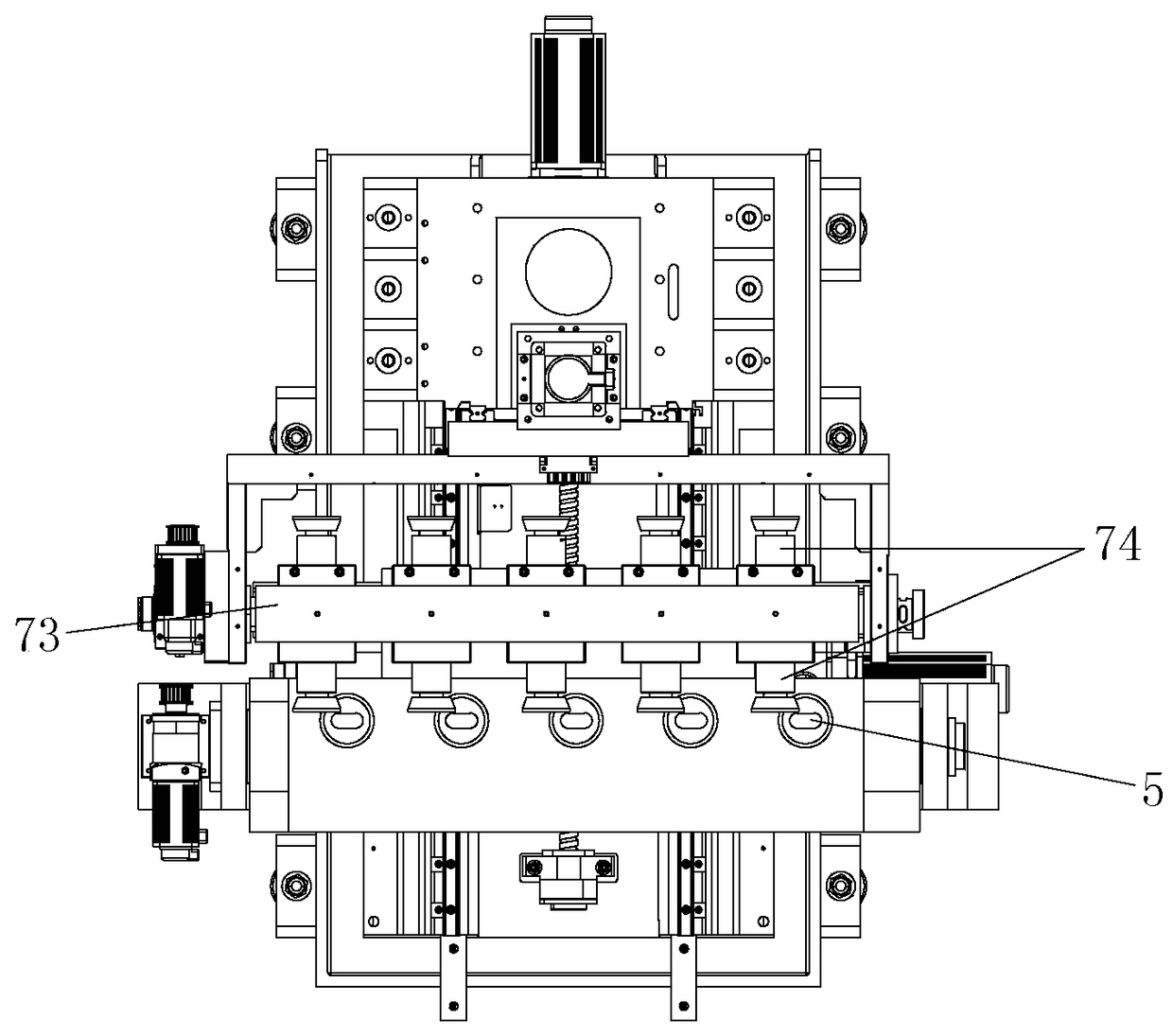

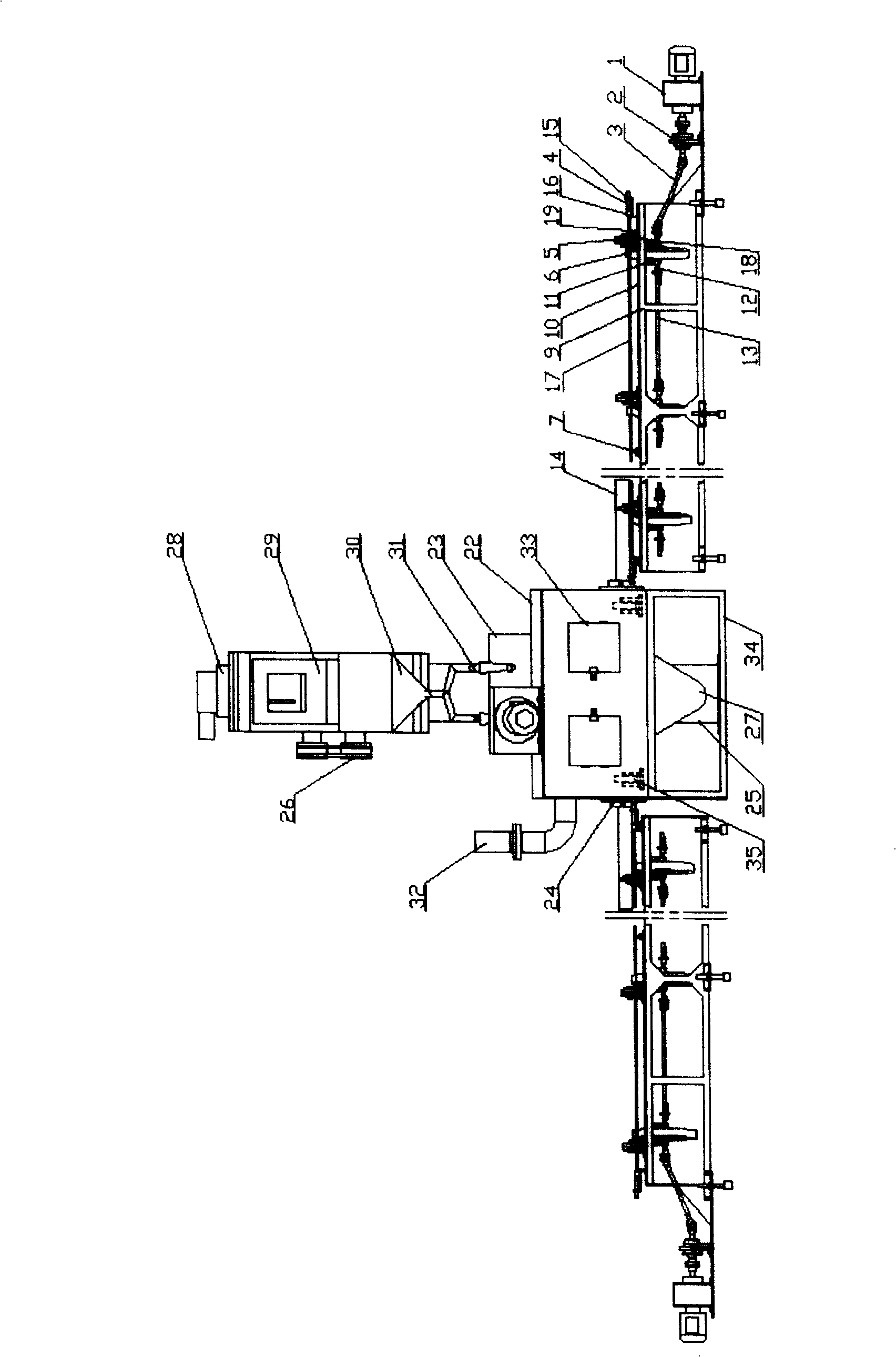

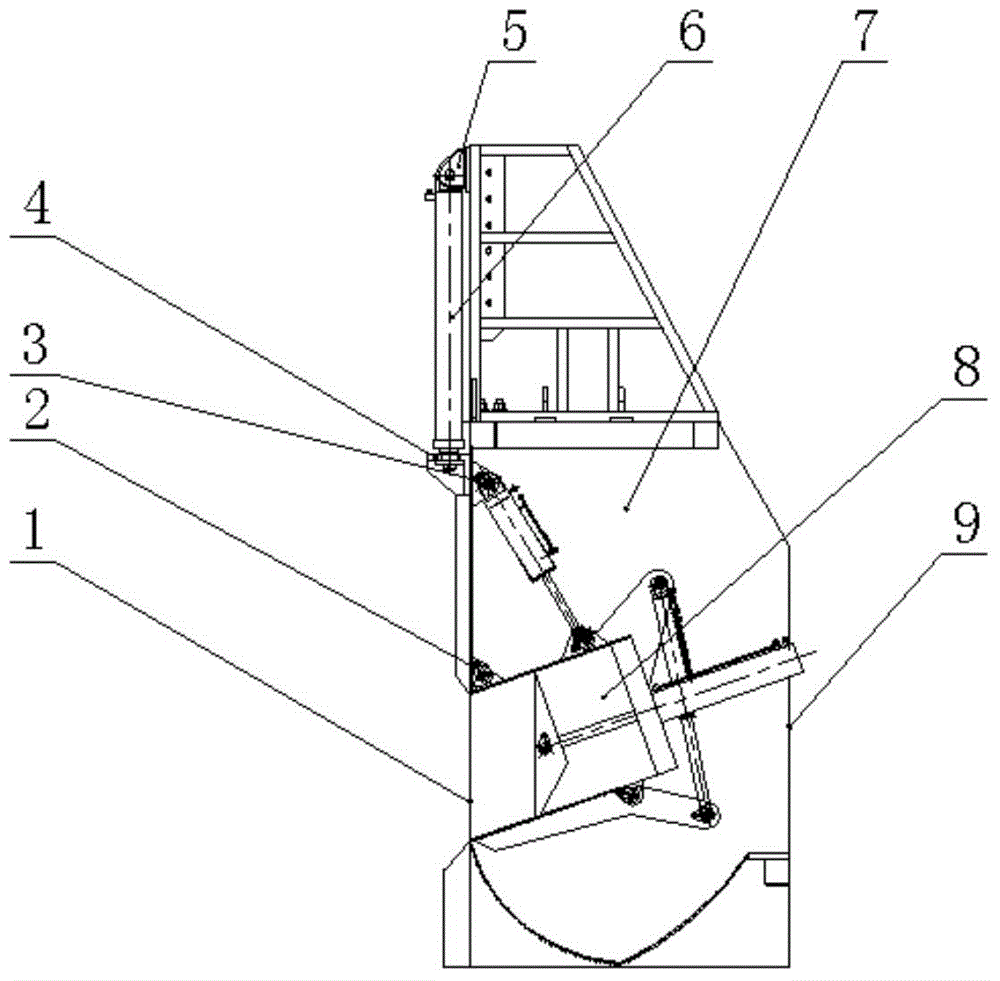

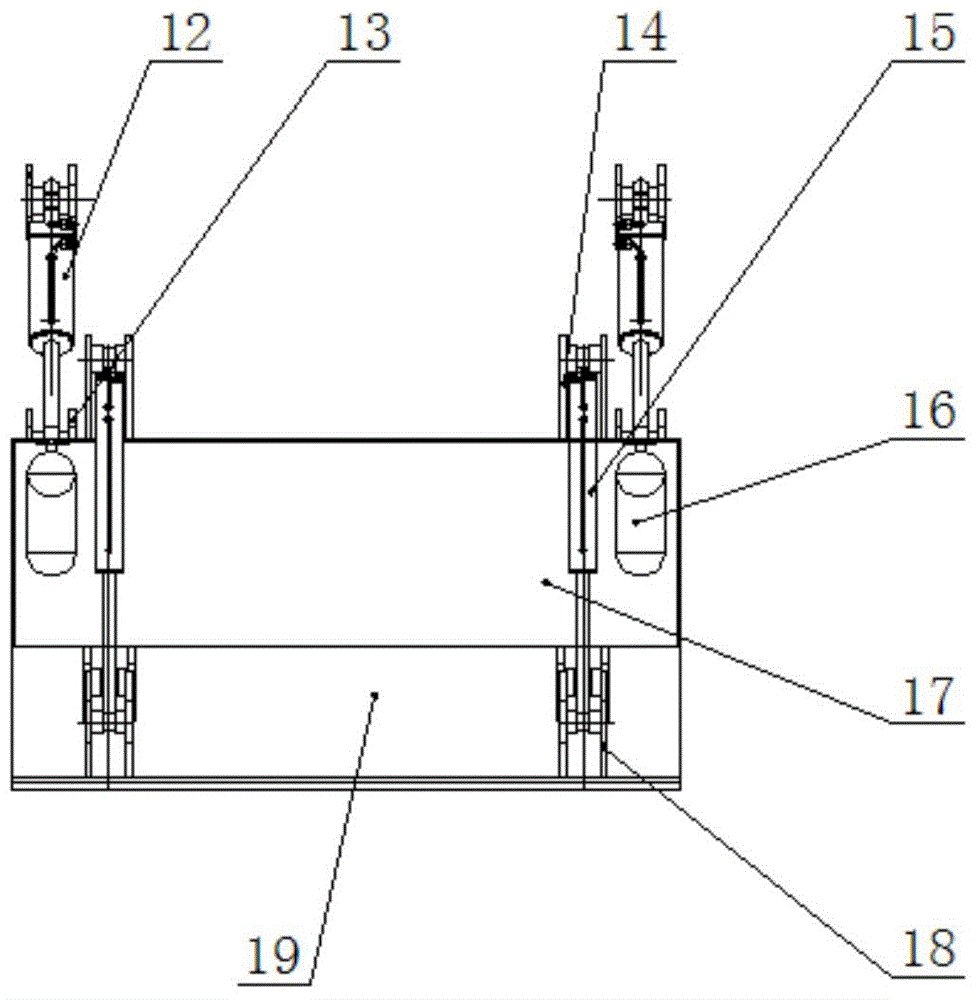

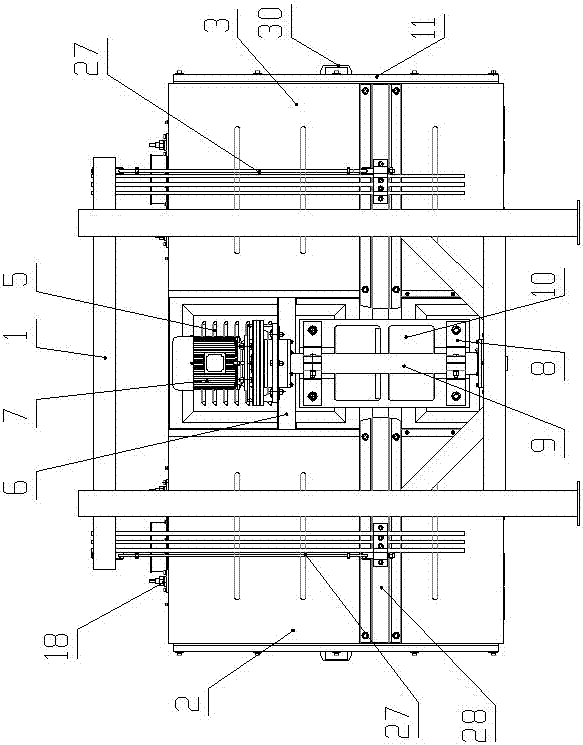

Intelligent double-five-axis-linkage five-station numerical control polishing machine

PendingCN108637864AFast and efficient polishingReduce labor intensityGrinding carriagesPolishing machinesNumerical controlMechanical engineering

The invention discloses an intelligent double-five-axis-linkage five-station numerical control polishing machine, and relates to metal and nonmetal curved surface polishing equipment. The technical defects that an existing polishing machine cannot meet the technological requirement for polishing workpieces with complex curved surface shapes, and the machining efficiency is low are overcome. A lower workbench comprises a lower fixing base, wherein the lower fixing base is connected with an X-axis driving mechanism in an installed mode. The lower fixing base is connected with a lower turnover plate through an A-axis driving mechanism. Two or more C-axis rotating mechanisms which are used for driving workpieces to conduct autorotation are perpendicularly arranged on the lower turnover plate side by side, and workpiece clamps which are used for clamping the workpieces are arranged on the C-axis rotating mechanisms. A polishing and grinding head installation platform comprises an upper fixing base. The upper fixing base is connected with a grinding head fixing base through a B-axis driving mechanism, and the grinding head fixing base and the lower turnover plate are arranged side by side. A front row of polishing and grinding heads and a rear row of polishing and grinding heads are arranged on the grinding head fixing base, and two or more polishing and grinding heads are arranged on each row and correspond to the workpiece clamps in a one-to-one mode. Rapid and efficient polishing operation of the workpieces with the complex curved surface shapes can be achieved, the flexibility is high, the application range is broad, and the structural design is ingenious and reasonable.

Owner:于正华

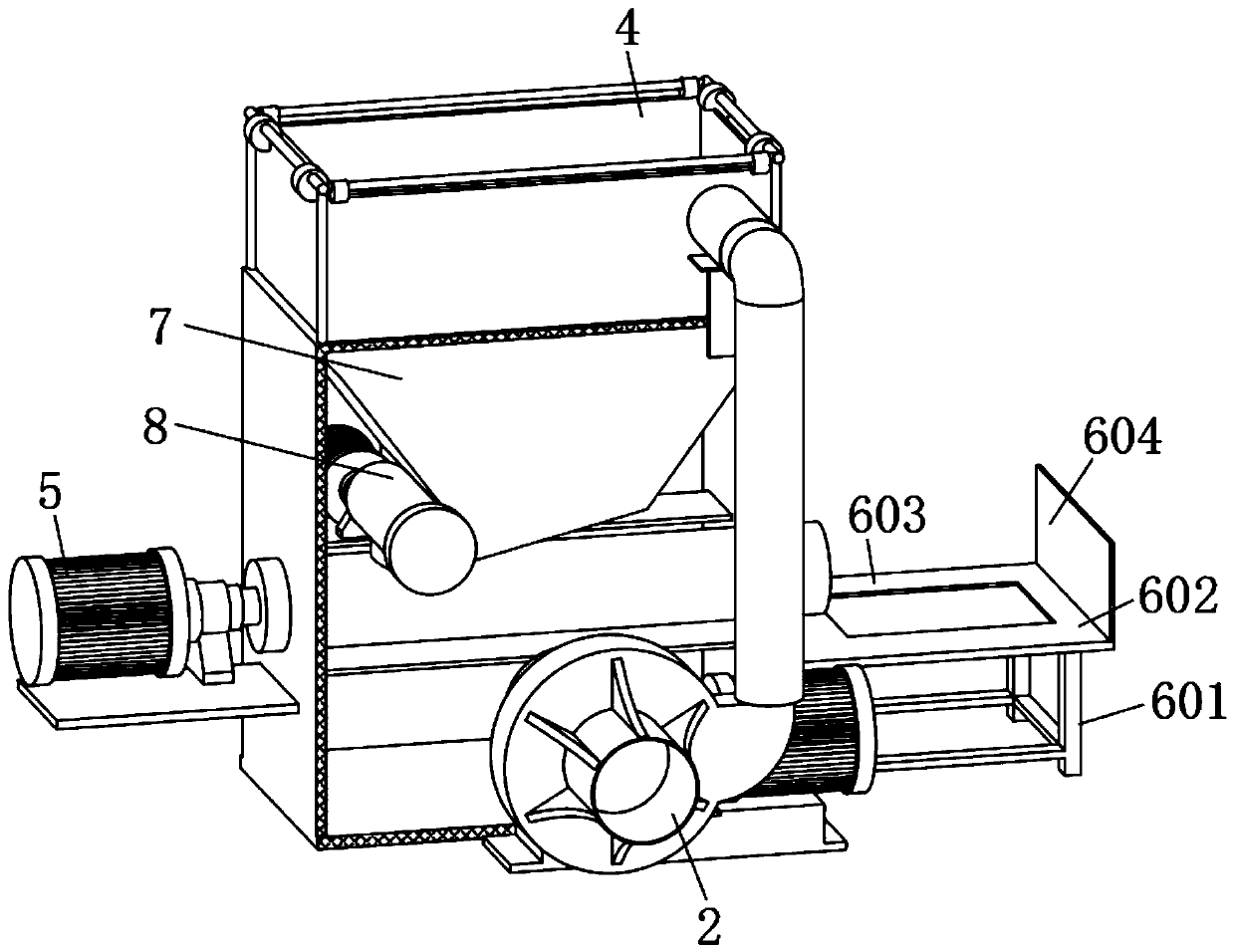

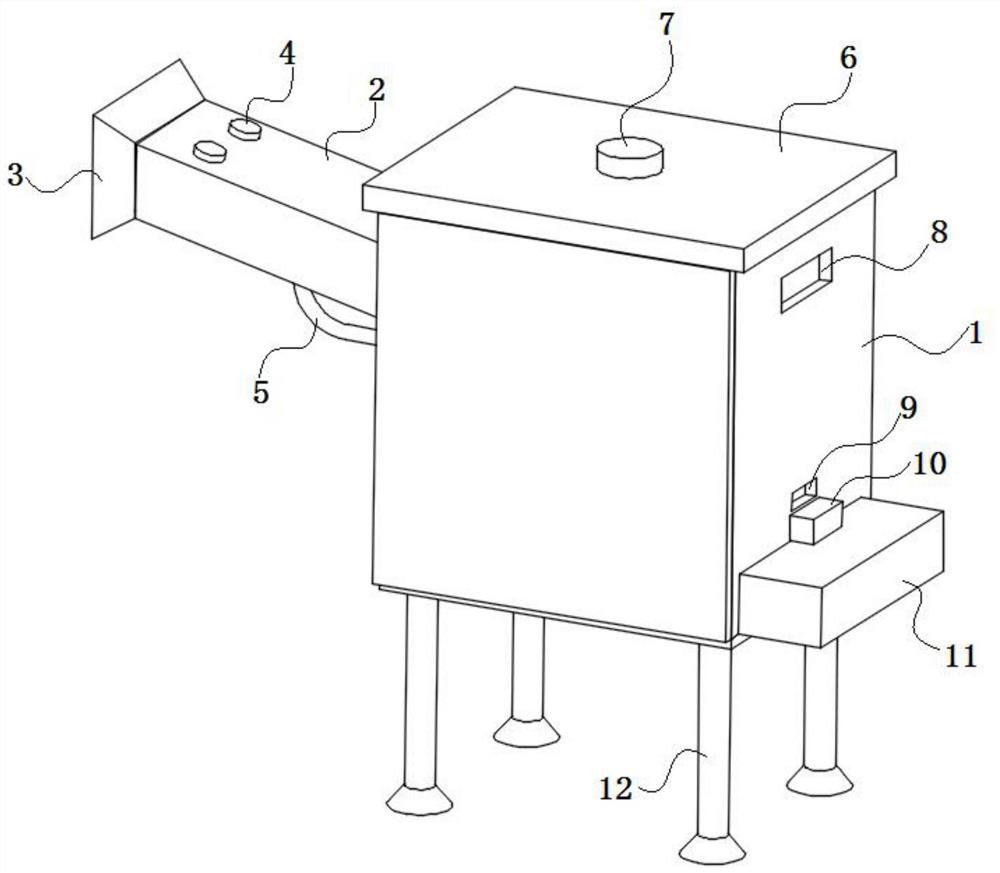

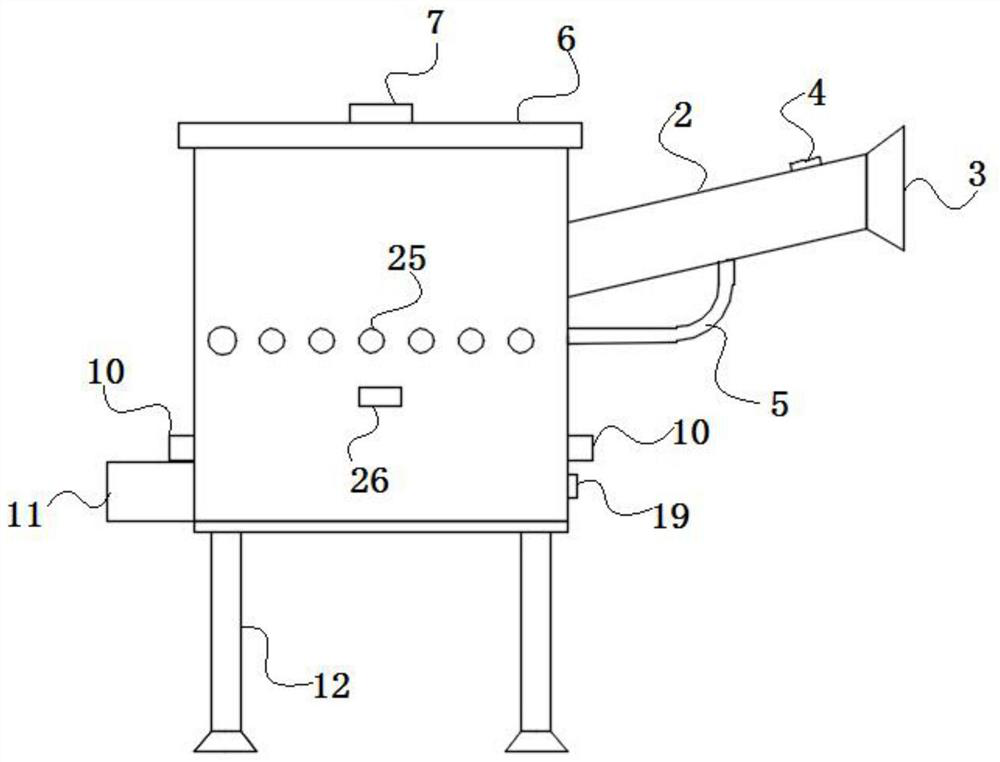

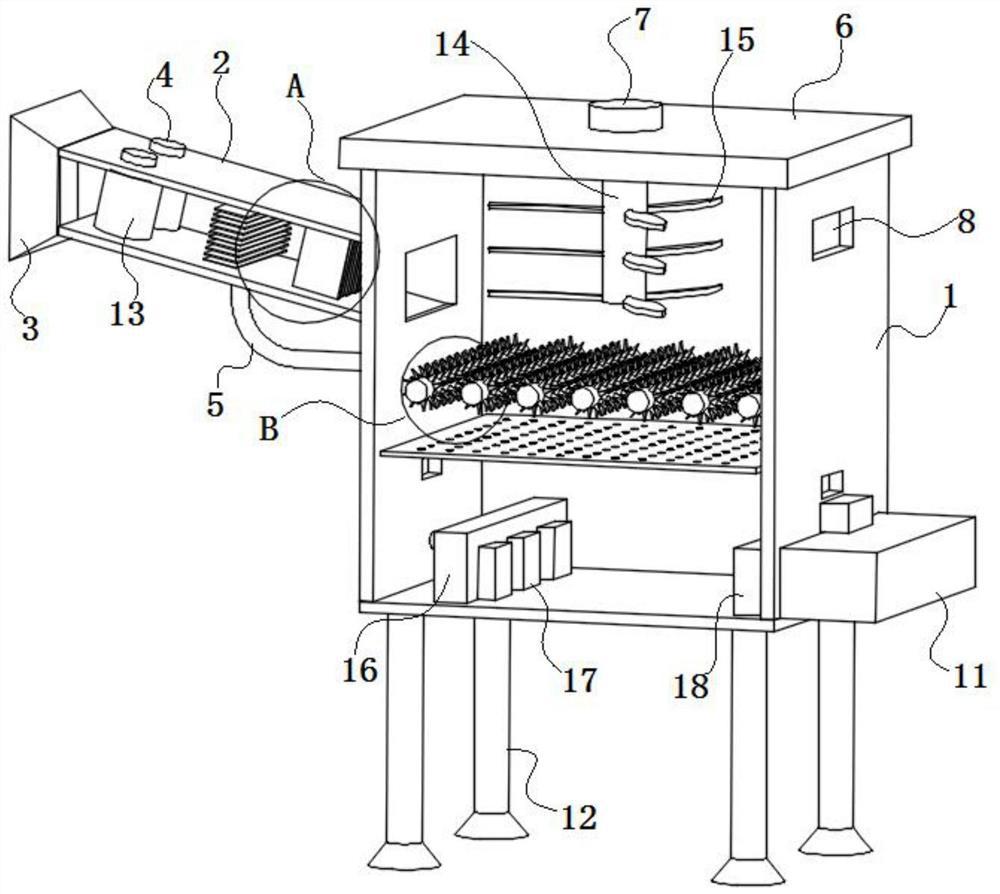

Shredded paper processing and collecting device capable of reducing dust greatly

PendingCN110404655AImprove processing efficiencyReduce pollutionCombination devicesDispersed particle filtrationPulp and paper industryScrew conveyor

The invention discloses a shredded paper processing and collecting device capable of reducing dust greatly, and belongs to the field of waste paper processing. The shredded paper processing and collecting device capable of reducing the dust greatly comprises a crushing mechanism, a blower, a shell, a side jet pulse dust removal device and a screw conveyor. The crushing mechanism is connected withthe side jet pulse dust removal device through the blower, and the top of the shell is fixedly connected with the side jet pulse dust removal device. According to the shredded paper processing and collecting device, after waste paper is crushed and ground, the waste paper is conveyed to an inner cavity of a collection funnel through the blower, dust removal is performed through the side jet pulsedust removal device, then the waste paper and dust are discharged through the screw conveyor for collection, so that the pollution caused by the dust in the process of treating waste paper is greatlyreduced, the environment can be protected, meanwhile, the adverse effect of dust on the bodies of workers is reduced; and the degree of automation is high, the device is simple and convenient to use so that the working efficiency of the workers can be improved, and meanwhile, the efficiency of waste paper treatment is improved.

Owner:浏阳市奥斯特烟花制造有限公司

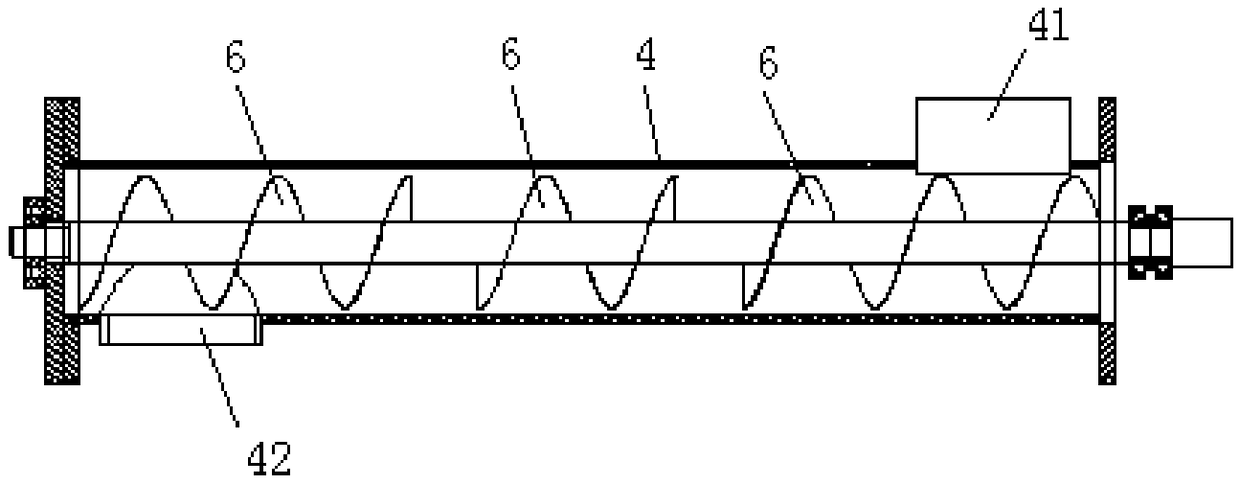

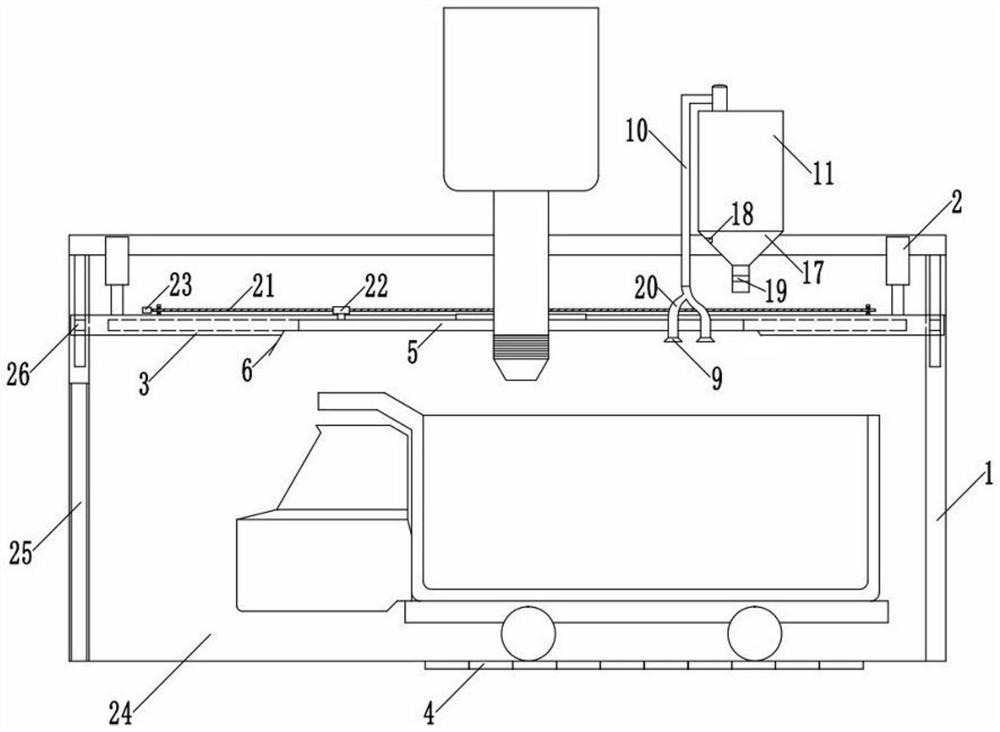

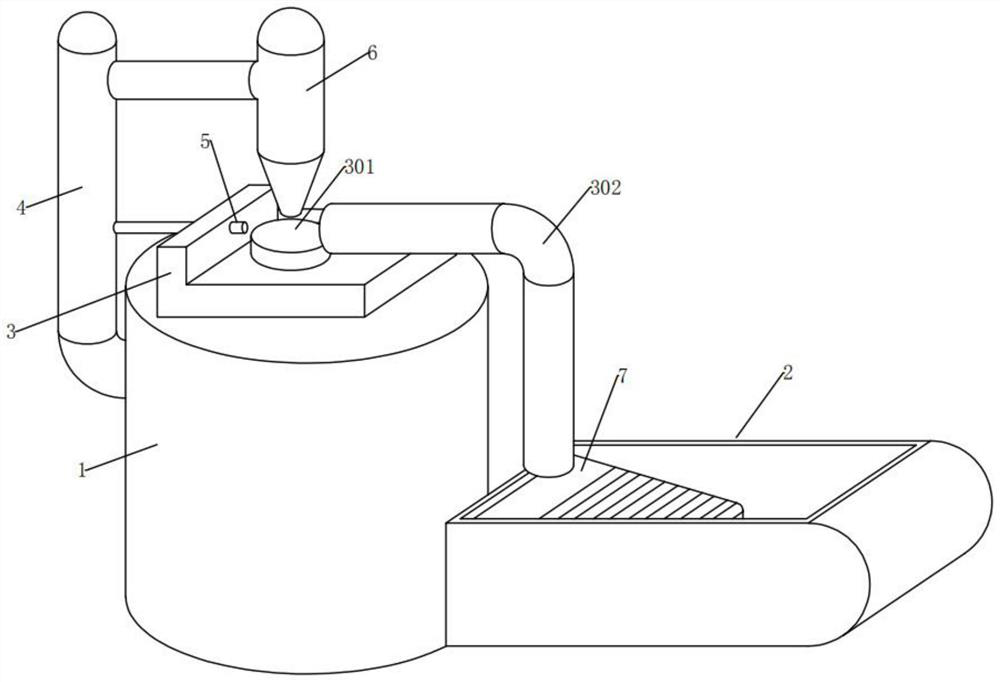

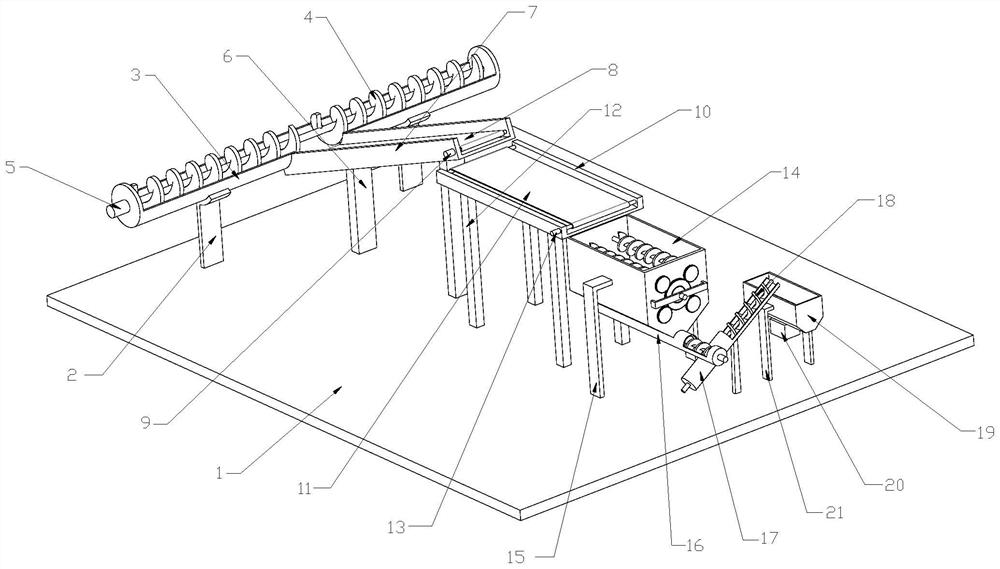

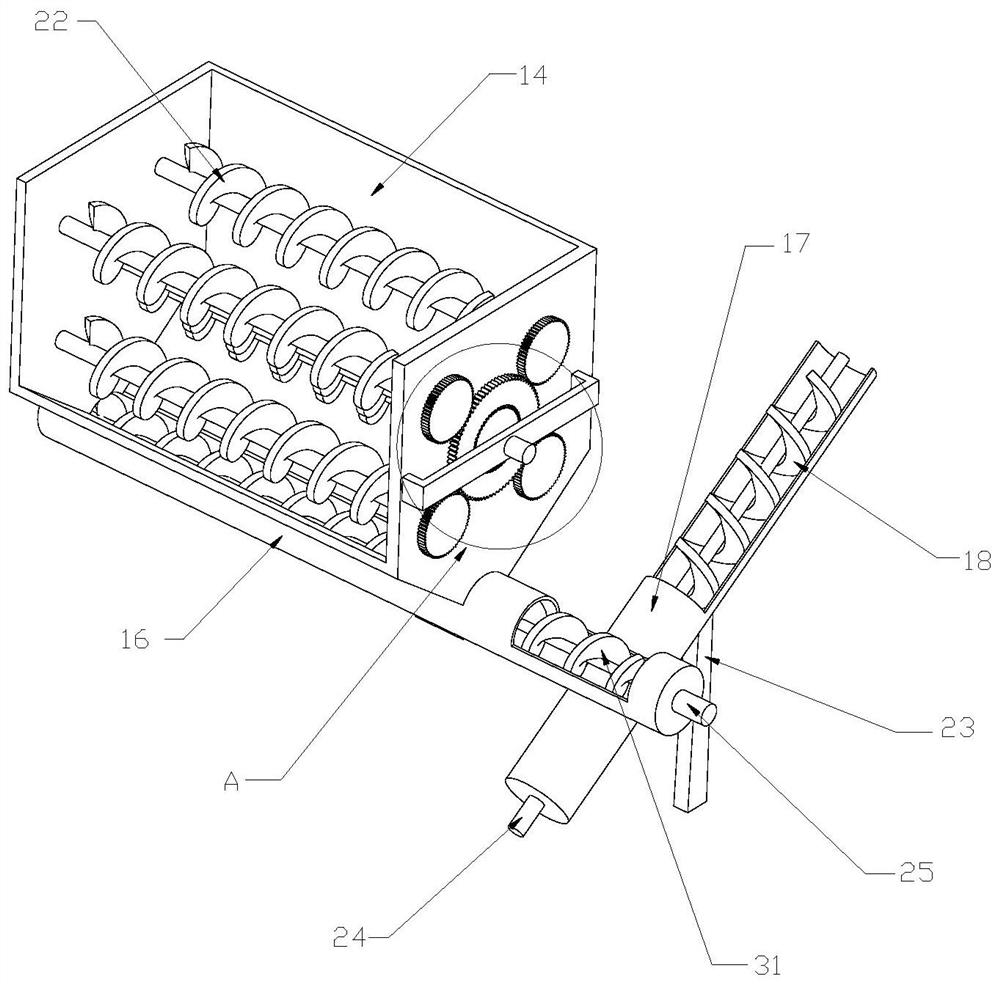

Novel slurry spraying unit

PendingCN108792459AAvoid exaggerationEliminate hazardsPackagingLoading/unloadingSlurryOperation safety

The invention discloses a novel slurry spraying unit which comprises a moving base and a slurry spraying unit body. The slurry spraying unit body comprises automatic feeding mechanisms, dosing packingauger sets, stirring and pushing packing augers and an air material mixing mechanism. Closed structures are adopted in the feeding mechanisms, the dosing packing auger sets and the stirring and pushing packing augers. The automatic feeding mechanisms and dosing packing augers are arranged in pairs. The dosing packing auger sets are arranged transversely. According to the novel slurry spraying unit, materials are conveyed and stirred automatically in a closed manner, the situation that dust flies to the outside is eradicated, the hazard of operators making contact with the dust is eliminated,operation safety of equipment is improved, meanwhile, the structure of the complete equipment is simplified, noise is lowered effectively, and the occurrence rate of occupational disease caused by dust pollution is effectively reduced.

Owner:张殿飞

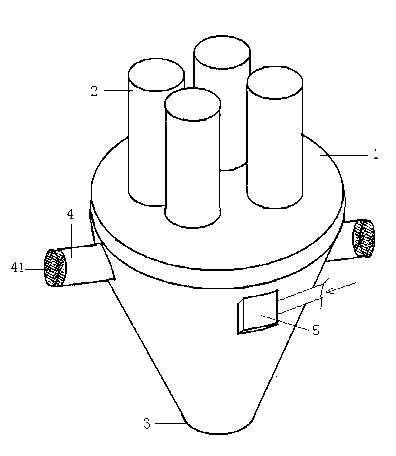

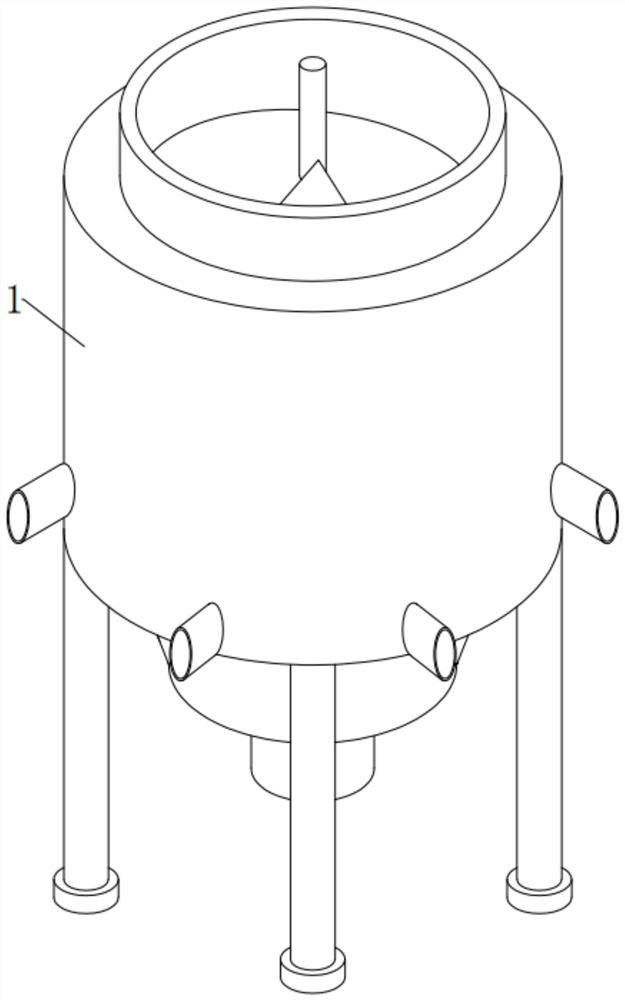

Material collecting bin of polyester fiber color master batch production automatic material feeding device

The invention provides a material collecting bin of a polyester fiber color master batch production automatic material feeding device. The material collecting bin of the polyester fiber color master batch production automatic material feeding device comprises a material collecting bin body in an inverted conical shape, a material feeding pipe and a material discharge port, wherein the material feeding pipe is arranged on the upper top of the material collecting bin body; the material discharge port is arranged on the lower end of the material collecting bin body; air exhaust pipes are arranged at the upper part of the conical surface of the material collecting bin body, and internally provided with filter core devices; and the outer wall of the bin is provided with a vibration device. The material collecting bin of the polyester fiber color master batch production automatic material feeding device changes the traditional concept that the material collecting bin in the industry is an enclosed bin, and solves the bottleneck problems that inherent quality such as dispersibility and viscosity as well as single yield of polyester fiber color master batch are seriously influenced which are solved in the industry for a long time with a simple method, enables the material collecting bin to exhaust a great amount of water vapor, avoids external spreading of dust, can smoothly guarantee the stable supply of extruder materials under the premises of environment protection and material loss reduction, radially eliminates influence factors bringing disadvantages to polyester fiber color master batches and the single yield, and guarantees the quality of polyester fiber color master batch finished products.

Owner:SIYANG BAOYUAN PLASTIC MATERIAL

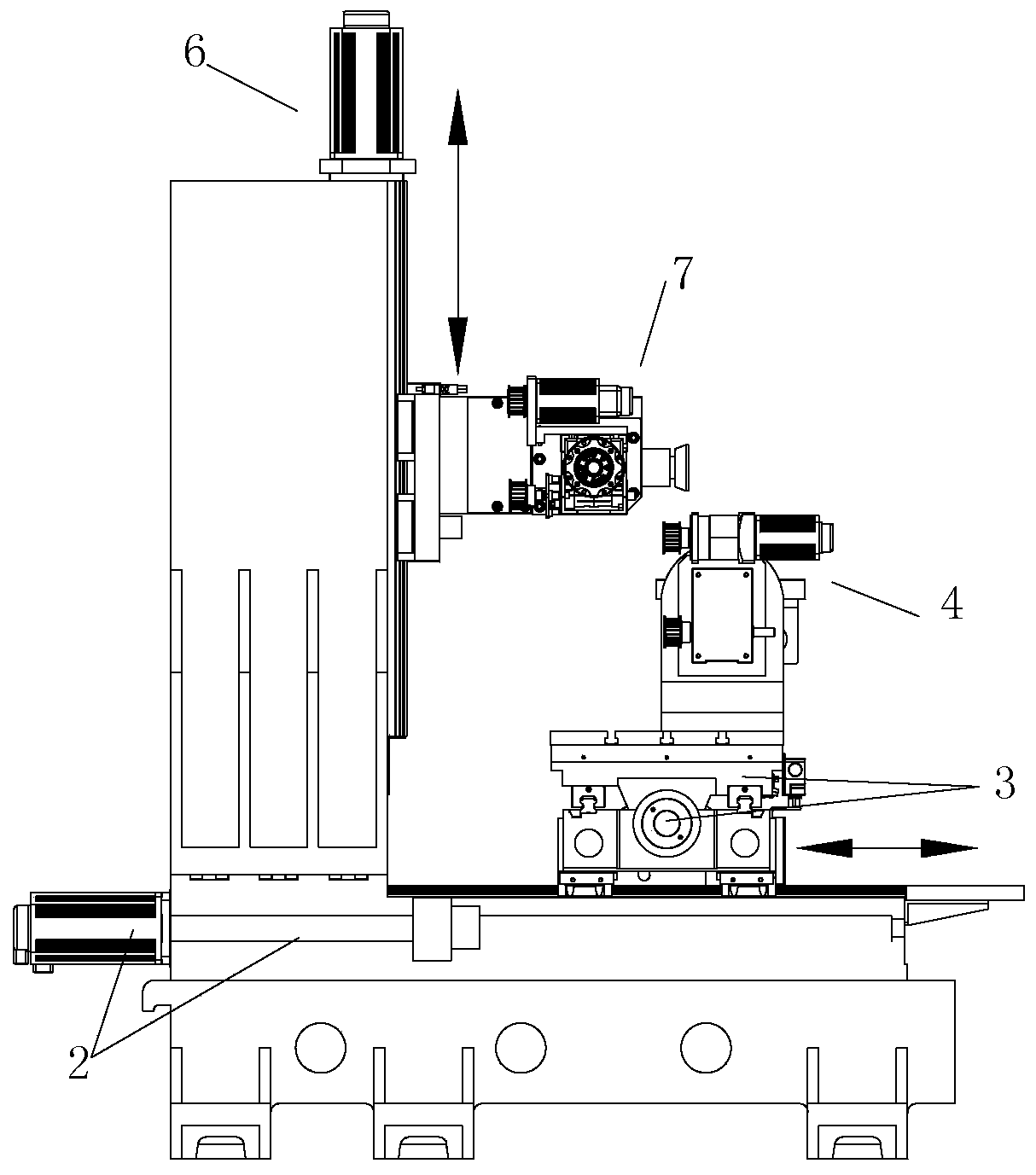

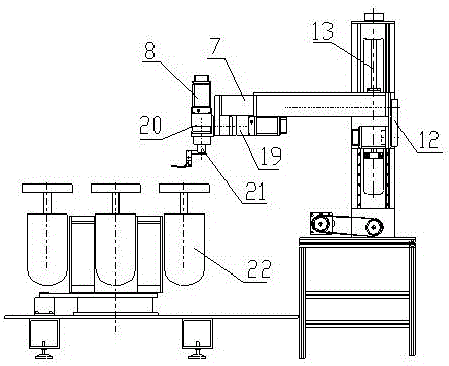

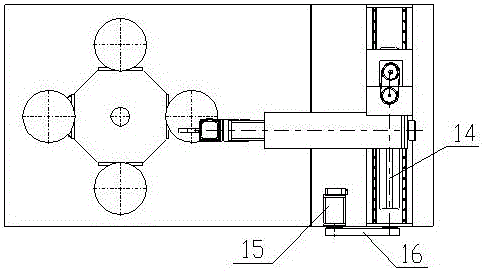

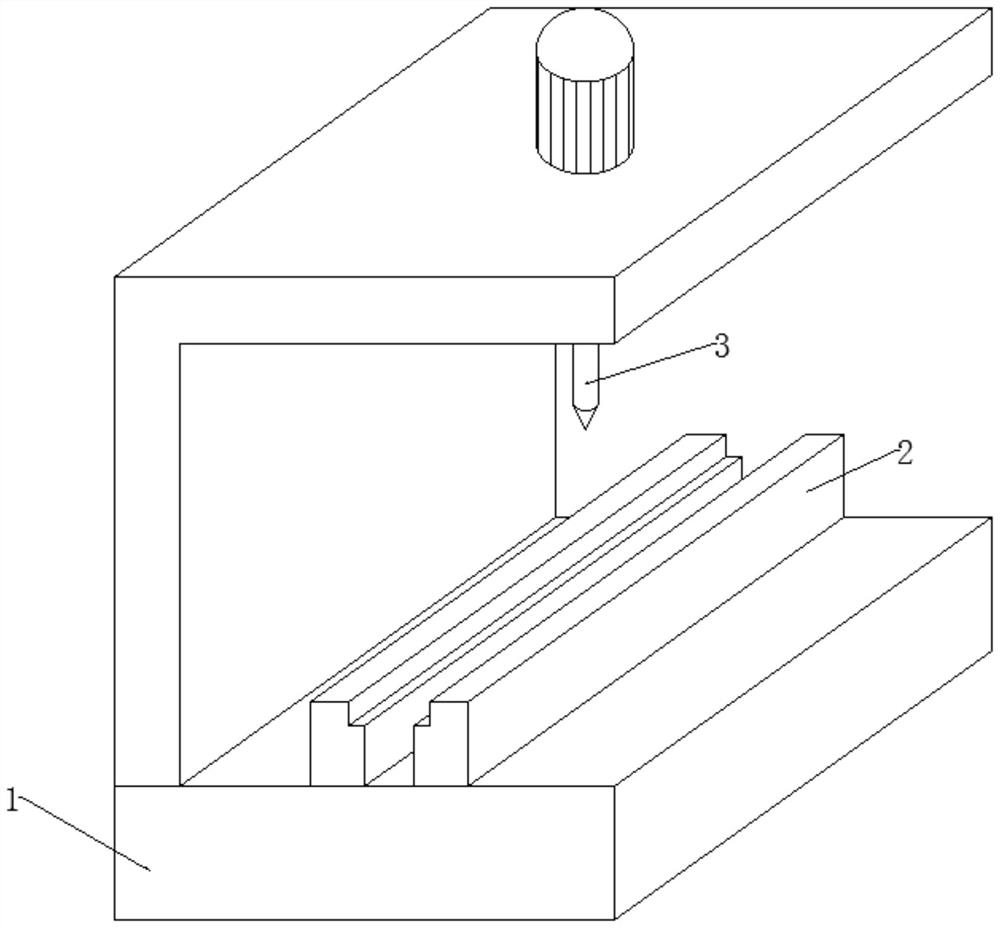

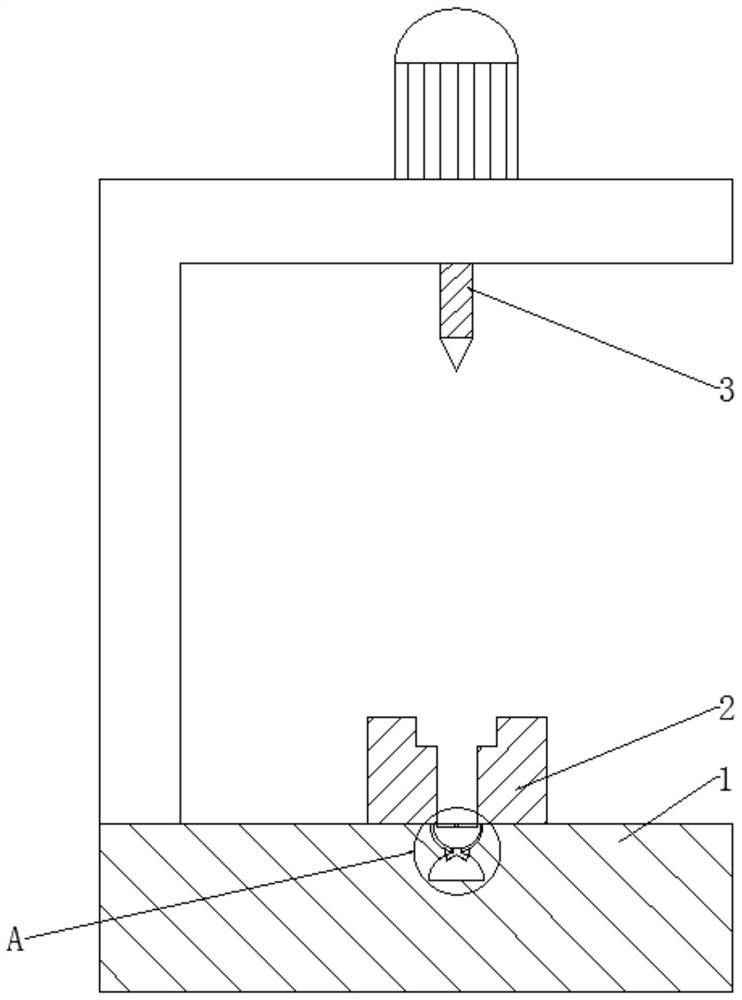

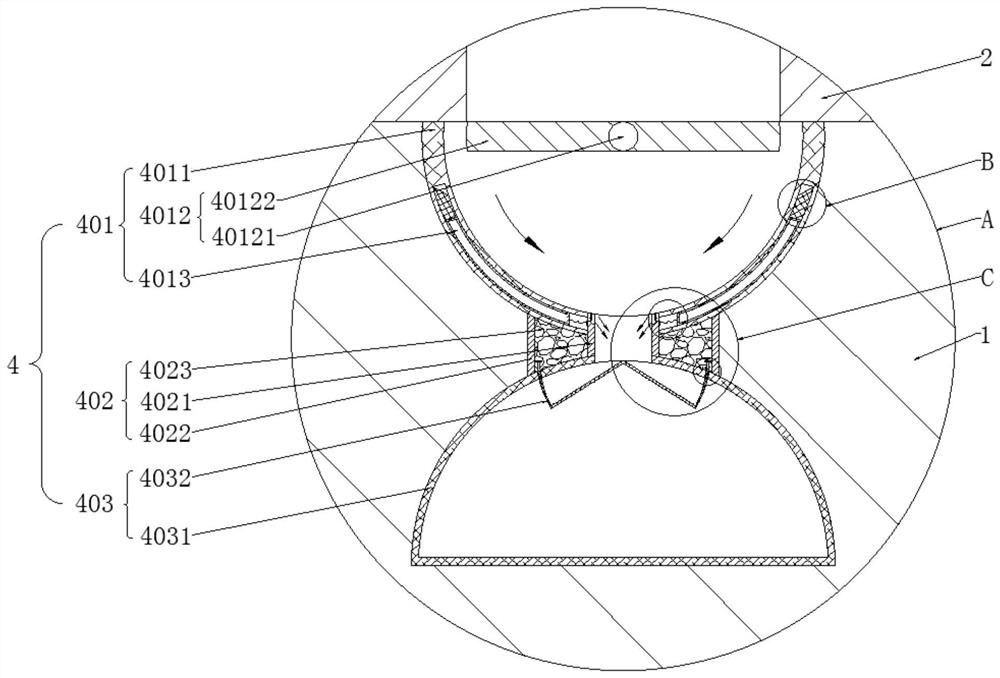

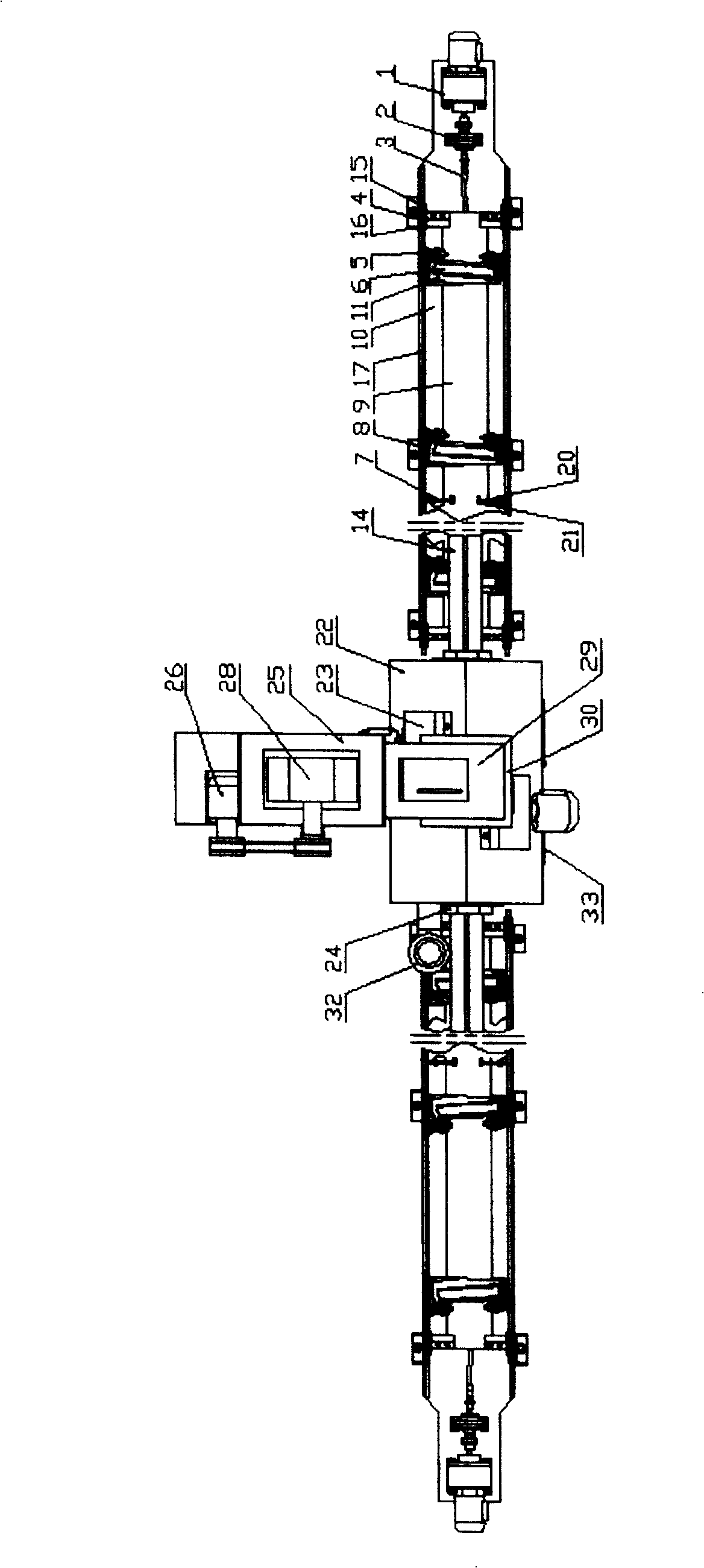

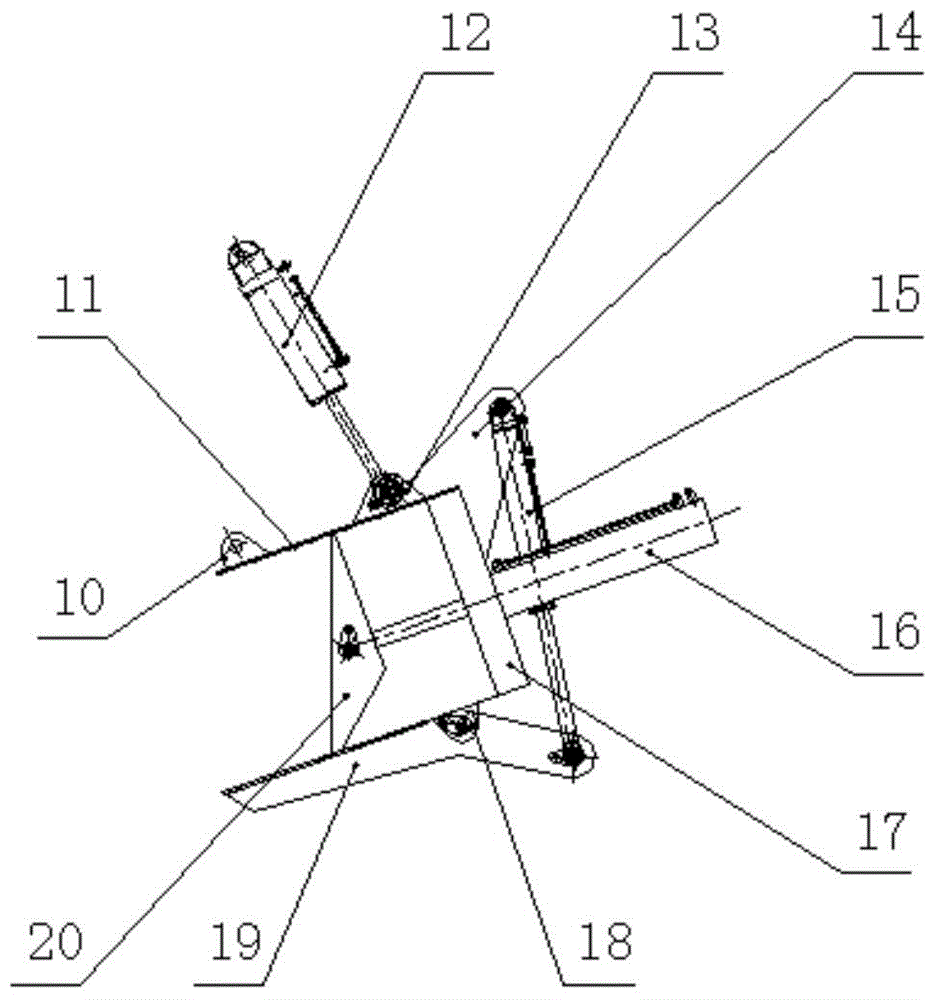

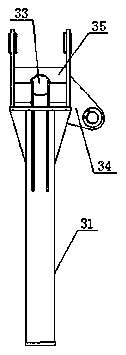

A five-axis linkage CNC manipulator polishing machine

InactiveCN104802064BReduce labor intensityAvoid exaggerationGrinding drivesGrinding machinesNumerical controlEngineering

The invention relates to a five-axis linking numerical control manipulator type polishing machine, and aims at solving the problem of automatic polishing of short-handle products such as a door handle. The machine comprises a Y axis which is horizontally arranged, and a Z axis of which the bottom end is positioned on the Y axis; the Z axis is vertically arranged. The machine is characterized in that a horizontal transverse frame is arranged on the Z axis; an X sliding frame which can axially telescope along the horizontal X axis is arranged in the horizontal transverse frame; an A axis parallel to the X axis is arranged at one end of the X sliding frame; a polishing head is arranged at the end part of the A axis; a manipulator is arranged at the end part of the polishing head; the polishing head is positioned on a C axis vertical to the A axis; a moving device is also arranged on the C axis; a polishing wheel rotating platform is arranged within the working range of the polishing head. With the adoption of the machine, a workpiece can be comprehensively polished in a plurality of directions and angles; the polishing work with a plurality of process requirements such as large thickness, small thickness, fine processing and mirror surface can be performed after one-time assembling, so that the labor intensity of operators can be reduced, the working efficiency can be increased, and the processing precision is high.

Owner:东莞市小可智能设备科技有限公司 +1

Drilling equipment for network transformer

InactiveCN113182924AGuaranteed cleanlinessRealize the collectionMaintainance and safety accessoriesBoring/drilling machinesProcess engineeringDrill bit

The invention provides drilling equipment for a network transformer. The drilling equipment comprises a workbench, two limiting bases and a drill bit, wherein a plurality of cleaning assemblies capable of cleaning a workbench top are installed at the position, close to a groove between the two limiting bases, of the inner surface of the top side of the workbench in the front-back horizontal direction in an equally adjacent and sliding mode, and each cleaning assembly comprises a dust control assembly capable of controlling entering and exiting of dust, a water storage assembly capable of storing clear water and a dust collection assembly capable of collecting and absorbing the dust. According to the drilling equipment for the network transformer, the workbench can have a self-cleaning function, in a drilling process of the network transformer, the dust is prevented from being left and accumulated in the groove between the two limiting bases for a long time, the dust can be cleared in time, stable clamping of the network transformer is guaranteed, the drilling error is reduced, and the accuracy is improved.

Owner:江西顺群电子科技有限公司

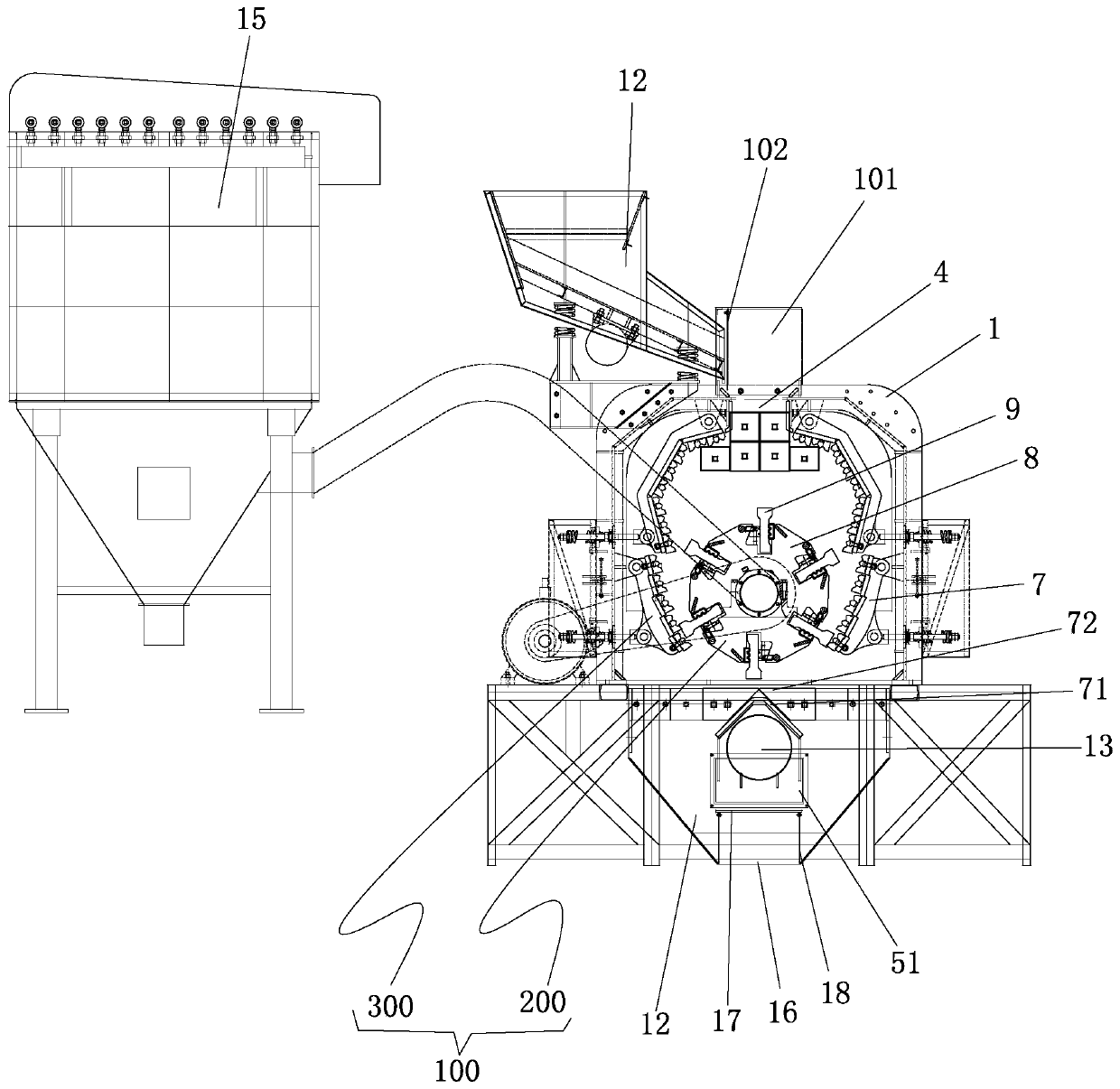

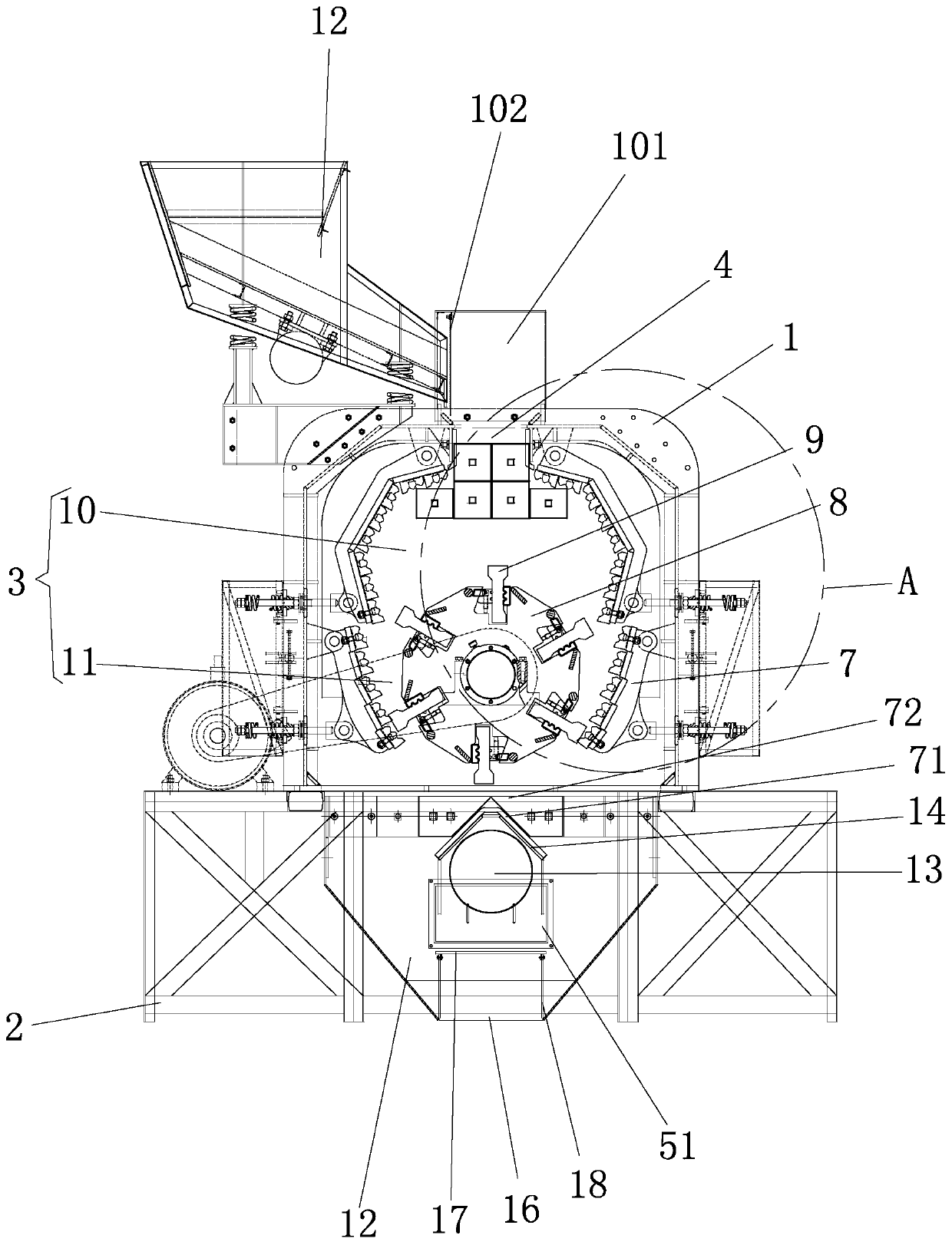

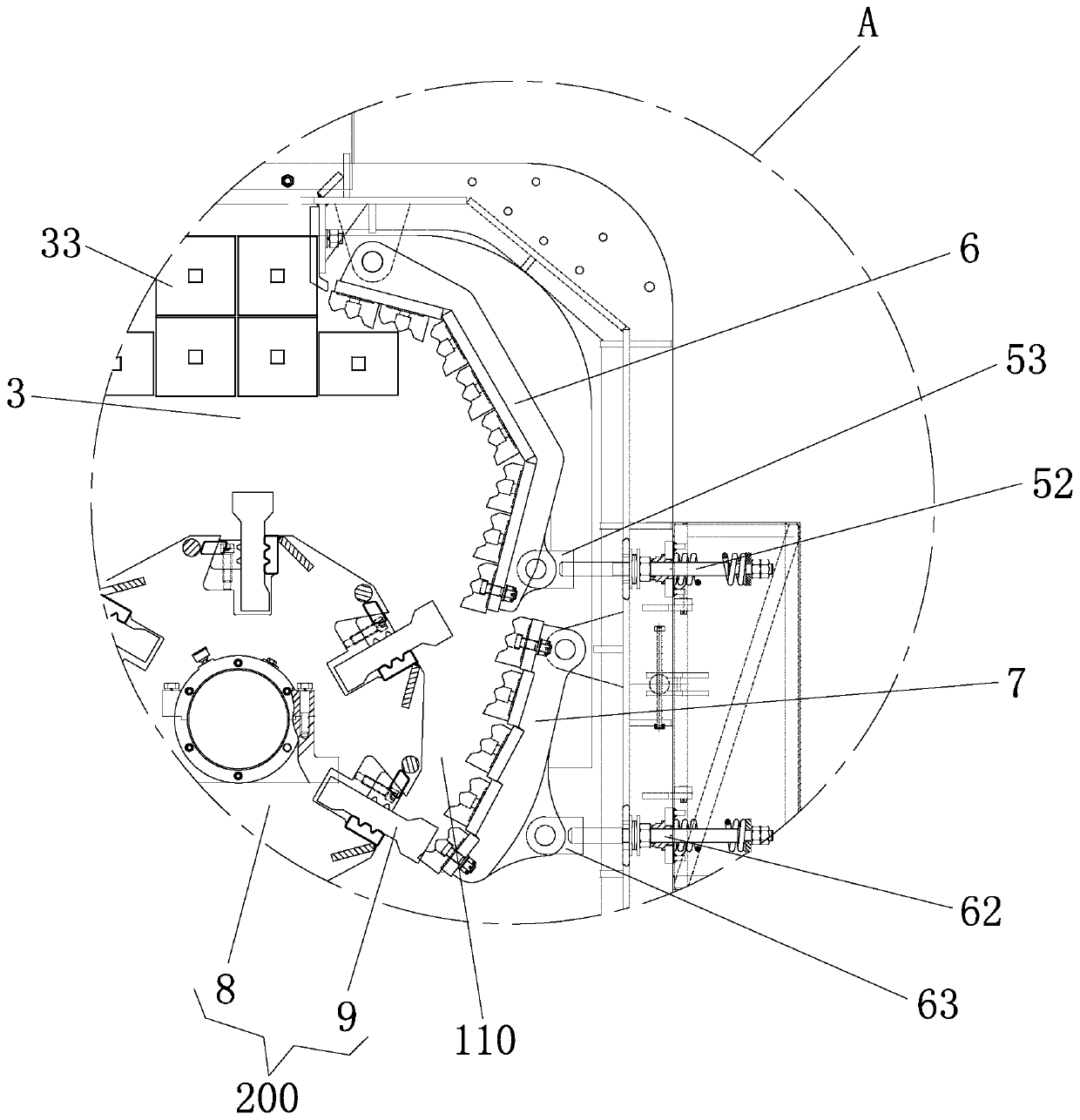

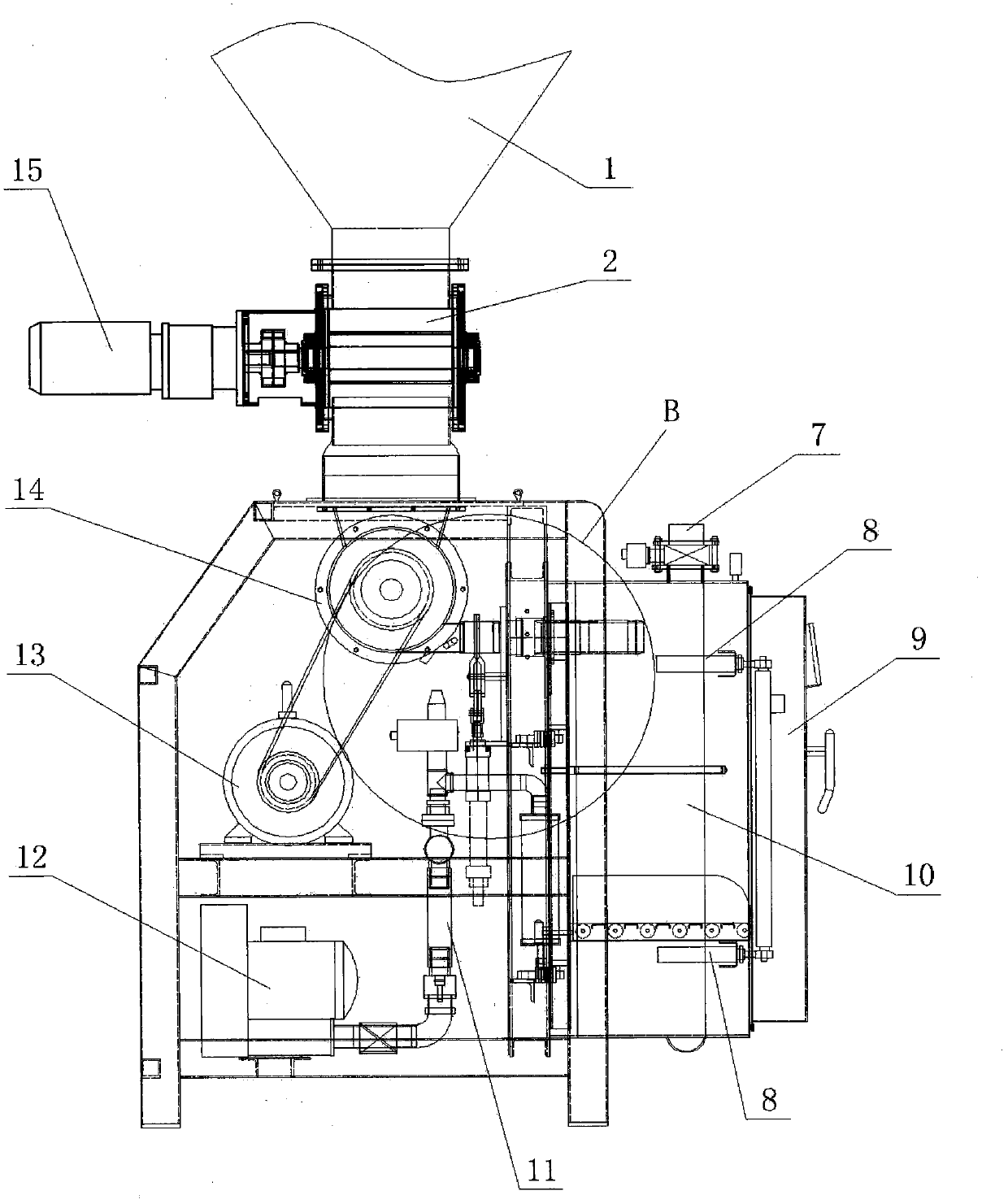

Environment-friendly efficient sand making machine adopting centrifugal crushing and sand discharging

The invention discloses an environment-friendly efficient sand making machine adopting centrifugal crushing and sand discharging. The environment-friendly efficient sand making machine adopting centrifugal crushing and sand discharging comprises a stone crushing and sand making main machine and a machine seat connected to the bottom of the stone crushing and sand making main machine. A crushing cavity is arranged in the stone crushing and sand making main machine. The upper end and the lower end of the stone crushing and sand making main machine are provided with a feed port and a discharge port which communicate with the crushing cavity. A crushing device used for crushing building stone is arranged in the crushing cavity and comprises a crushing rotor assembly and crushing wall plates, wherein the crushing rotor assembly is rotationally connected and installed on the front wall face and the back wall face of the crushing cavity, the crushing wall plates are installed on the left andright inner walls of the crushing cavity, and the horizontal interval between the outer wall of the crushing rotor assembly and the crushing wall plates forms a passage. A material receiving hopper used for containing and receiving sand is connected to the lower end of the discharge port in a sealed manner. The crushing rotor assembly rotates so as to form an airflow which starts from the inside of the crushing cavity, turns along the crushing rotor assembly, passes through the passage and then enters the material receiving hopper, the crushed sand finished products are rapidly discharged outof the crushing cavity, secondary impact on small sand particles meeting the particle size is reduced, and therefore the powder content is reduced.

Owner:SHAOGUAN HELI HEAVY IND MACHINERY

Short thread end cutting device of column type sewing machine

InactiveCN114182445ARealize the collectionAvoid exaggerationNeedle severing devicesEngineeringSewing machine

The invention provides a column type sewing machine short thread end cutting device which comprises a collecting assembly, and the collecting assembly capable of collecting thread ends and cloth scraps is fixedly installed at the position, located under a cutter, of the upper end of the outer surface of the front side of a feeding stand column. The collecting assembly comprises a collecting shell, a folding plate, a material control assembly capable of controlling thread residue rag to enter and exit and a material guiding assembly capable of guiding out materials wetted by the thread residue rag. A collecting shell is fixedly installed at the position, under the cutter, of the upper end of the outer surface of the front side of the feeding stand column. Folded plates are fixedly mounted between the left end and the right end of the interior of the collecting shell and the top; and material control assemblies are movably mounted on the left and right parts of the top end in the collecting shell and located at the upper ends of the outer surfaces of the folded plates. According to the short thread end cutting device of the column type sewing machine, the collecting function can be achieved on the feeding stand column, in the process that a cutter cuts a short thread end, cut thread ends and cloth waste can be collected in time, and the normal thread cutting effect is guaranteed.

Owner:徐州力达缝纫设备制造有限公司

Dustproof device for wood processing

PendingCN114311169AReduce flyingEasy to installProfiling/shaping machinesBark-zones/chip/dust/waste removalAgricultural engineeringWood machining

The invention belongs to the technical field of wood processing equipment, and particularly discloses a wood processing dustproof device which comprises a workbench, a supporting frame assembly, a dustproof assembly and an adsorption assembly, the workbench is provided with a strip-shaped groove, the dustproof assembly is fixed to the supporting frame assembly, and the dustproof assembly comprises a protective cover body and a transparent plate. The protective cover body comprises a top plate and side plates, the two transparent plates are fixed to openings in the two ends of the protective cover body correspondingly, a cutting cavity is formed between the protective cover body and the transparent plates, the adsorption assembly is used for adsorbing wood chips in the cutting cavity, mounting grooves are formed in the bottoms of the side plates, and a plurality of rubber rollers are rotationally connected into the mounting grooves. And the rubber roller is perpendicular to the cutting wheel. By the adoption of the scheme, the problems that a protective cover can affect a worker to observe the wood cutting process, meanwhile, a large amount of wood chips are prone to being accumulated at the protective cover, the worker needs to clean the wood chips regularly, the labor intensity of the worker is increased, and meanwhile the wood processing efficiency is reduced are solved.

Owner:重庆佳利乐包装有限公司

Movable dust supporting plate of sanitizer

Disclosed is a movable dust supporting plate of a sanitizer. The movable dust supporting plate is characterized in that dust supporting plate bodies are mounted at an inlet of a dust passage, connected with a dustbin, of an outer dust cover of a sweeping roller, a positioning ring is arranged at the upper portion of each dust supporting plate body, the dust supporting plate bodies are mounted on a pin shaft at the inlet of the dust passage through the positioning rings thereon, and the multiple dust supporting plates identical in structure are mounted on the same pin shaft. During use of the movable dust supporting plate of the sanitizer, in the process of operation and forwarding of the sanitizer, when obstacles such as stone are on the ground, the one or more dust supporting plate bodies in contact with the obstacles are jacked up by the obstacles, the dust supporting plate bodies return to the original position after passing through the obstacles, the dust cover and the dust passage can be kept isolated from the external environment by the quick returning, outward raising of the dust is prevented, the dust on the ground and the dust at the uneven low-lying positions can be absorbed cleanly, and the whole ground is clean.

Owner:熊林华

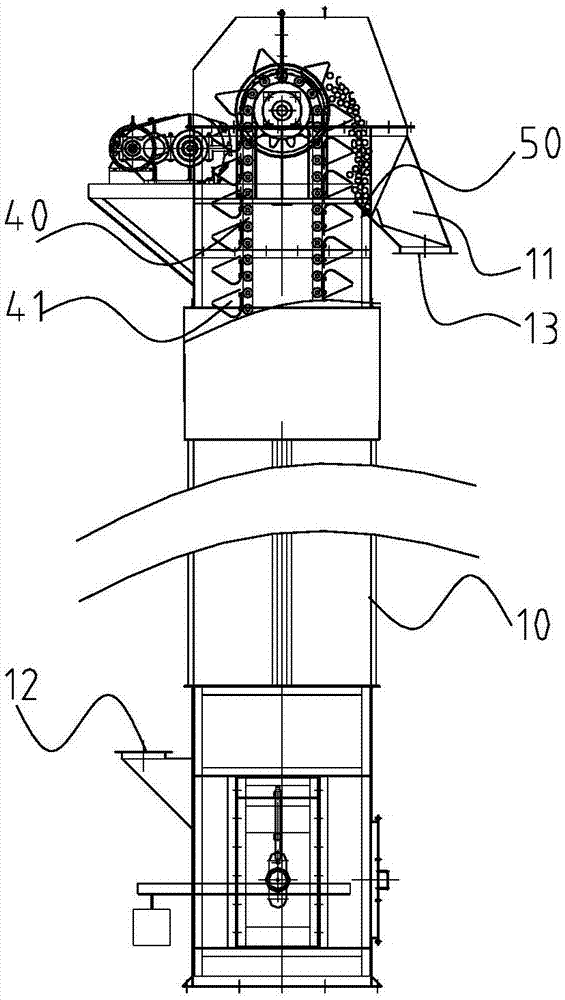

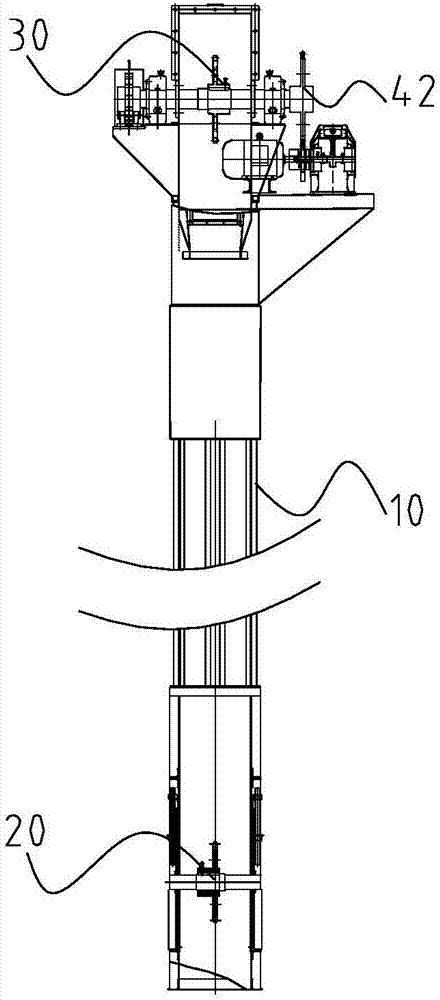

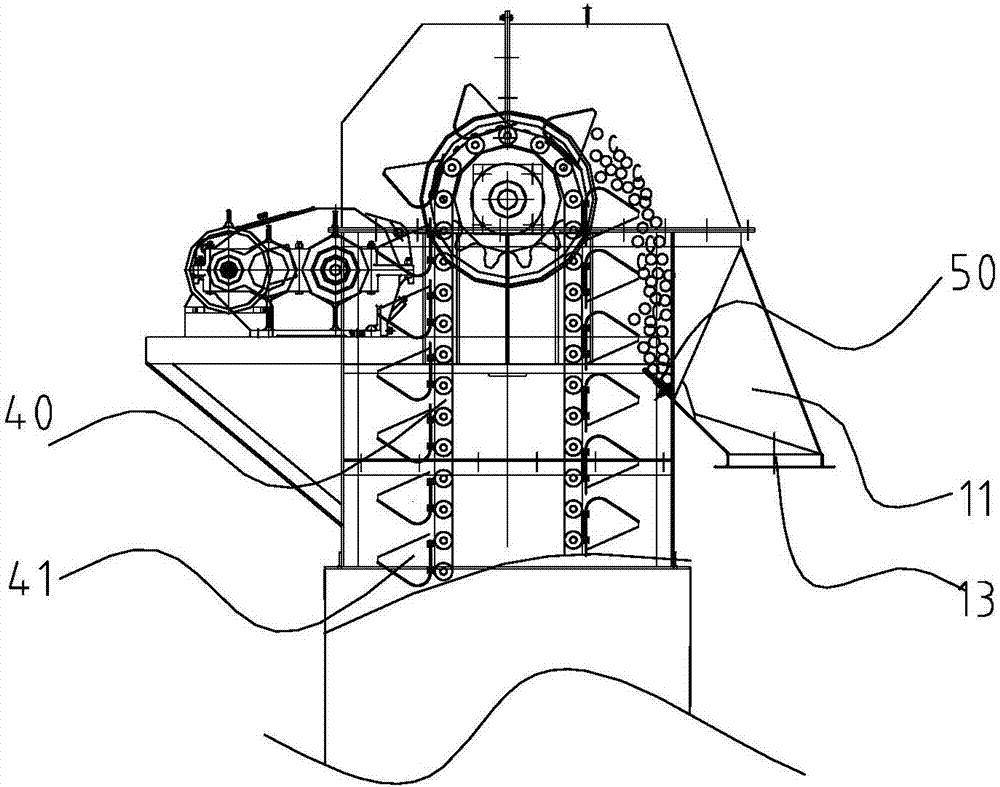

Bucket elevator

The invention relates to a bucket elevator. The bucket elevator comprises a tail wheel positioned at the bottom end of a main case and a head wheel positioned at the top end of the main case, whereina chain is wound between the tail wheel and the head wheel; a plurality of hoppers are uniformly fixed on the chain; a material receiving chute is arranged at the top end of the main case and positioned below the center of the head wheel, and penetrates the inner wall of the main case to extend toward the outer wall; a striker plate is arranged at the material receiving chute in an extending manner in the direction toward the head wheel and comprises a material stopping rubber sheet and baffles positioned on two sides of the material stopping rubber sheet; a pressing plate is arranged at the end, adjacent to the baffles, of the material stopping rubber sheet and fixed on the material receiving chute; and the baffles are fixed on the main case. According to the bucket elevator, raising of dust at the tail wheel is favorably reduced, the operation resistance of a motor is reduced, and energy saving and environmental pollution are facilitated.

Owner:SHANGHAI BAOYE CONSTR INDAL FURNACE ENG TECH

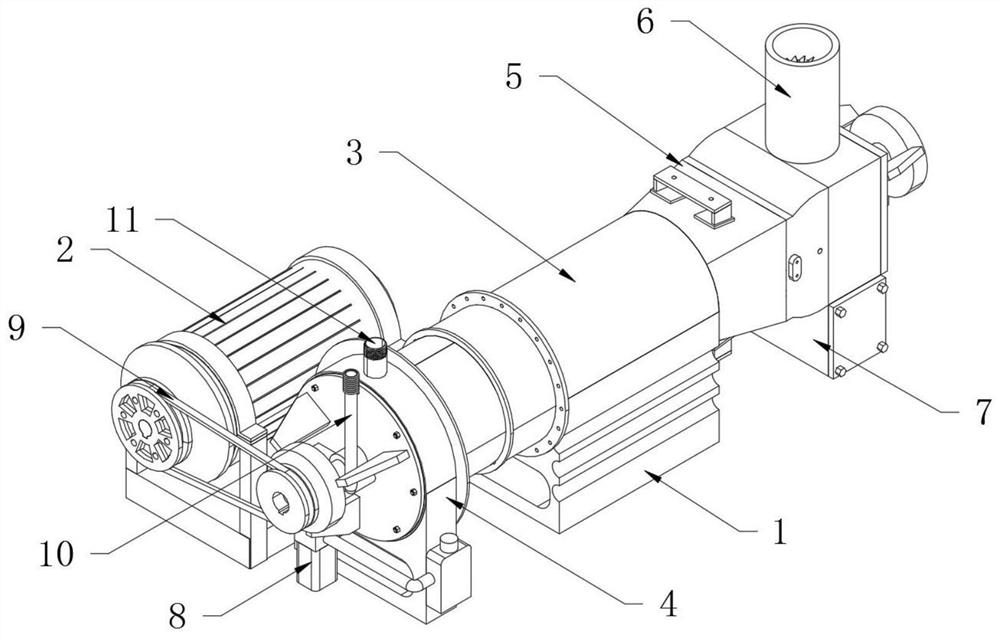

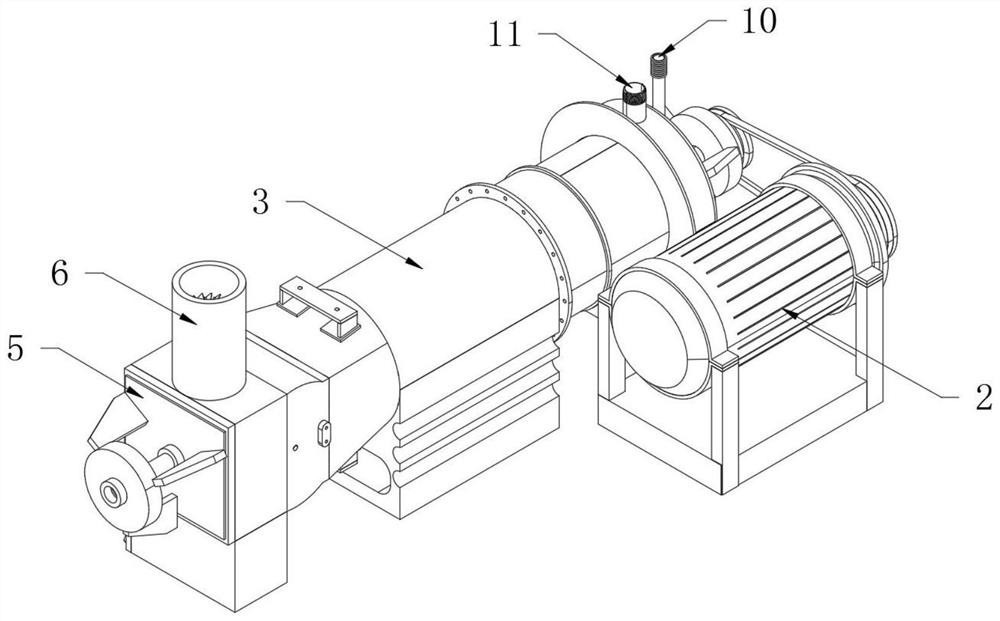

Burner facility for biomass boiler combustion system

ActiveCN110645564BIncrease productionPrevent outreachPulverulent fuel combustion burnersSolid removalFlame arresterCombustion system

The invention provides a burner facility of a biomass boiler combustion system, which includes a base, a dust-blocking plate and an ash leakage tray; a longitudinal cylindrical burner body is fixedly installed on the top of the base; the burner body The left end is fixedly provided with a feeding cabin, while the right end of the burner body is fixedly provided with a heat collecting cabin; the upper end of the feeding cabin is vertically provided with an air inlet pipe. The present invention provides a burner facility for a biomass boiler combustion system. Its feed cabin and gas distribution pipe are arranged, and an interlayer is provided through the part of the feed cabin close to the shell, and the gas distribution pipe is connected in a fire-stopping ring in two layers inside and outside. The other end of the air distribution pipe is inserted into the interlayer of the feed cabin, so that the air entering the intake pipe can be evenly distributed in the interlayer of the feed cabin in advance, and then diffused evenly to the fire arresting plate by the air distribution pipe to avoid Air flow is disturbed, resulting in increased fly ash production.

Owner:陕西分布式能源股份有限公司

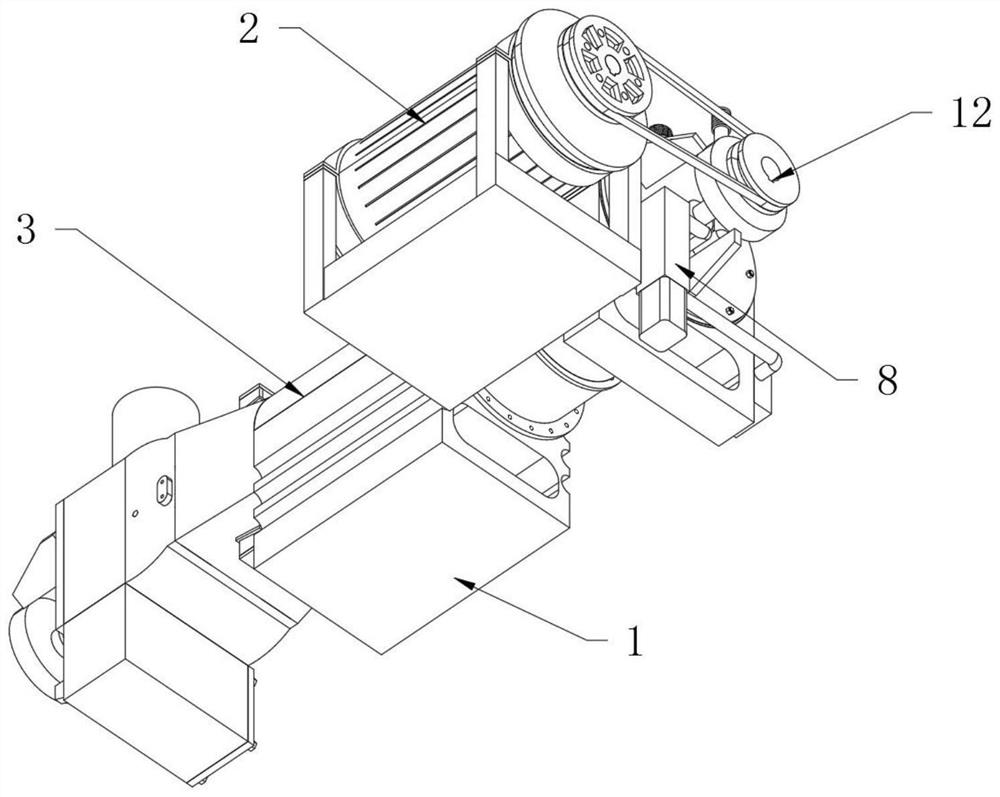

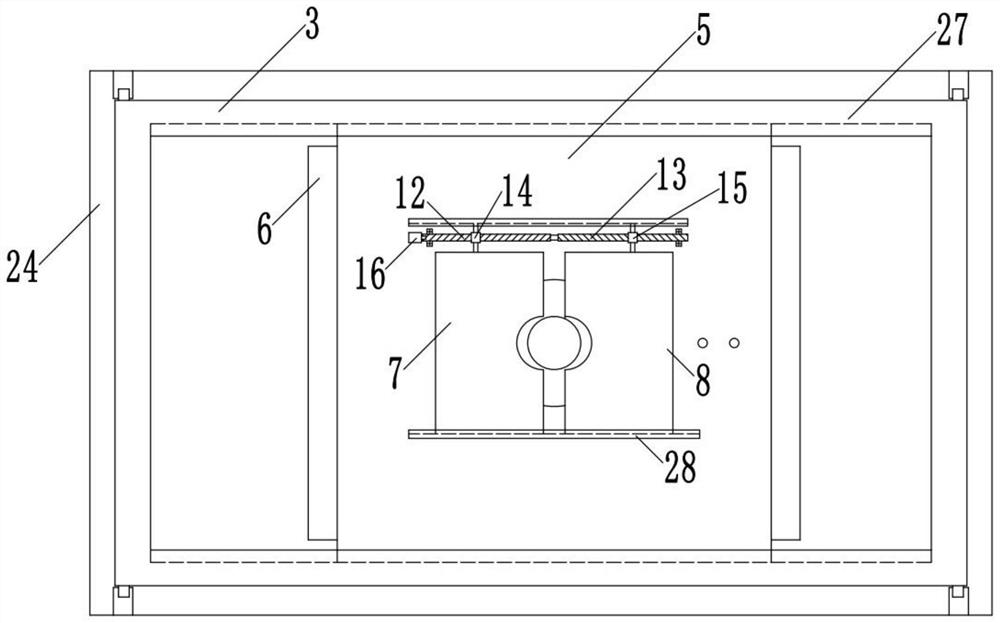

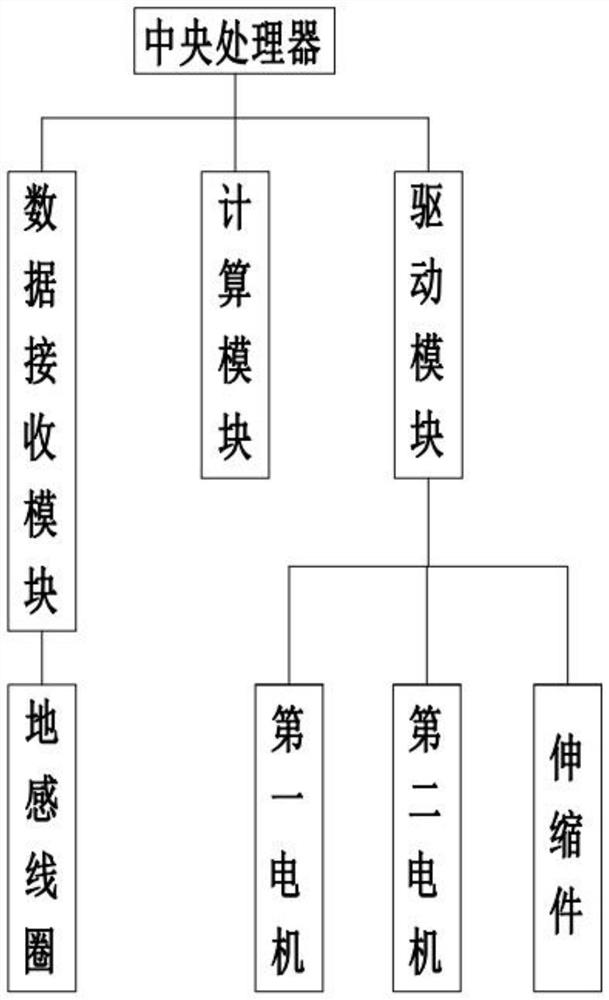

Dust collection equipment for slag bin

PendingCN114476733AAvoid affecting accessAvoid exaggerationConveyorsControl devices for conveyorsControl systemMoving parts

The invention provides slag bin dust collection equipment which comprises a supporting frame, a telescopic part is fixed to the supporting frame, the telescopic end of the telescopic part is vertically downward and connected with a supporting frame, a moving mechanism is fixed to the supporting frame, and a moving part of the moving mechanism is connected with a dustproof device. The slag bin dust collection equipment further comprises a control system. The control system comprises a plurality of ground induction coils, a data receiving module, a calculation module, a driving module and a central processing unit. The plurality of ground sensing coils are laid on the ground and used for sensing the positions of front wheels and rear wheels of a vehicle, and the data receiving module is connected with each ground sensing coil and used for receiving oscillation signals generated by the ground sensing coils; the calculation module is used for calculating the moving distance of the dustproof device after the vehicle is completely covered; the driving module is connected with the telescopic piece and a driving piece of the moving mechanism; the height and the horizontal position of the dustproof device can be adjusted according to the collected vehicle position information, so that the dustproof device covers the vehicle hopper to the maximum extent, and raised dust is reduced.

Owner:陕西精益化工有限公司

Biomass straw crushing and briquetting integrated device

The invention discloses a biomass straw crushing and briquetting integrated device, and relates to the technical field of agricultural equipment. The device comprises a feeding pipe, a box body, a crushing chamber and a briquetting chamber, wherein one outer side surface of the box body is fixedly connected with the feeding pipe; the crushing chamber and the briquetting chamber are arranged in thebox body; the crushing chamber is positioned above the briquetting chamber; and supporting legs are arranged at the bottom of the box body. By means of arrangement of conveying rotating wheels, firstcutting blades, second cutting blades, first crushing blades and second crushing blades, multiple crushing steps are conducted in sequence, so that the device can adapt to biomass straw with different hardness, the biomass straw is crushed more sufficiently, meanwhile, the crushing process is conducted in the box body, and dust is prevented from flying outwards and polluting the environment; andthe briquetting chamber is arranged below the crushing chamber, and a discharging chamber is tightly connected to the outer side of the briquetting chamber, therefore, briquetting and discharging arecompleted in one step, and the working efficiency is improved.

Owner:安徽昊天生物科技有限公司

Multiple steel tube and reinforcing steel bar delivery and derusting device

InactiveCN100420547CImprove the efficiency of derusting operationsGood rust removal qualityAbrasive machine appurtenancesAbrasive blasting machinesRebarMovement control

The invention relates to a device for transmitting and scaling several steel tubes, wherein the tube transmitting system comprises that the active wheel power controls the rotation speed of active wheel; the active wheel rotation controls the horizontal rotation and angle of active wheel; the inactive wheel rotation controls the horizontal rotation and angle of inactive wheel; the inactive wheel movement controls its horizontal movement and its distance from the active wheel. The invention can transmit several different tubular and cylinder steel objects and scale them at one time. The scale system can wash and scale the objects in transmission. The invention has simple structure, low cost and high efficiency.

Owner:张景远

Automatic defective product removing device for chip detection

PendingCN113964058AAvoid exaggerationAvoid flaringSemiconductor/solid-state device manufacturingCleaning using gasesEngineeringMechanical engineering

The invention provides an automatic defective product removing device for chip detection, which comprises a chip detection table, a bracket is fixedly arranged at the center position of the top end of the chip detection table, the appearance of the bracket is L-shaped on a longitudinal section, and a chip placing table is fixedly arranged at the center position of the outer surface of the top side of the bracket; a collecting box is included and is fixedly mounted at the bottom of the right end of the chip detection table, and the collecting box is hollow inside, open at the upper part, closed at the lower part, straight at the left part and convex at the right part; and a dust collection assembly is also included. According to the automatic defective product removing device for chip detection, the collecting box can have a dust collecting function, when defective products are removed by blowing of a blowing device on the chip placing table, even if external dust impurities and chips are blown into the collecting box together through the collecting pipe, and dust in the collecting box can be collected and treated. And the phenomenon that too much dust and impurities adhere to the surfaces of the collected chips, and consequently the chips are damaged is avoided.

Owner:蓝芯存储技术(赣州)有限公司

Dust-proof type belt conveyor discharge port

InactiveCN106429355AEffectively adjust the placement heightMeet collectionConveyorsLoading/unloadingEngineeringBelt conveyor

The invention discloses a dust-proof type belt conveyor discharge port comprising a material collection device. A reducing device is installed at the lower end of the material collection device. A lifting device is installed on the reducing device. The tail section of the reducing device is connected with a dust prevention device. In this way, the placement height of the material collection device can be effectively adjusted, different materials can be collected, and dust can be prevented from rising outwards. The reducing device is arranged, and the collected materials stably fall at a constant speed. A dust prevention cloth bag is adopted, can appropriately deform and is not likely to be damaged, dust diffusion can be prevented, and therefore the dust effect can be improved. The dust-proof type belt conveyor discharge port is simple in overall structure and easy to use and maintain.

Owner:MARTIN ENG KUNSHAN

Impeller type vacuum quantitative packaging machine

ActiveCN102390551BSealing effect is goodGuaranteed accuracy requirementsPackaging under vacuum/special atmosphereSolid materialImpellerProgrammable logic controller

The invention discloses an impeller type vacuum quantitative packaging machine. The packaging machine is characterized in that a packing driving mechanism of the packaging machine comprises an impeller, and the material driving speed of the impeller is obviously better than the material driving speed of a packing auger, thereby being capable of greatly accelerating the material packing speed of the packaging machine; the material sealing effect of the impeller is good, and a discharge port can be effectively blocked after the end of packaging, thereby preventing the leakage of material; the packaging machine is simultaneously provided with a control valve of scissors at the discharge port, and the control valve of the scissors can flexibly control the discharge flow rate and ensure the requirements on packaging precision; the packaging machine is provided with a bag expansion device at a discharge nozzle, thereby preventing dust from flying to outside during packaging; and an impellerdriving electric motor of the packaging machine can be controlled by a programmable logic controller (PLC) and a frequency converter, thereby having the characteristics of being intelligent and automatic.

Owner:QINHUANGDAO PUDA ELECTRONICS CO LTD

Garbage compressor

Owner:广西玉柴专用汽车有限公司

A physical multifunctional experimental device

The invention relates to a physical multifunctional experimental device, which includes a moving object, a box body, an electromagnet, a solar power generation device, and a permanent magnet. The moving object includes a parabola and a potential energy object. The box body is provided with a box cover, and the upper surface of the box cover is provided with a display stand, a positioning groove for a parabolic electromagnet, and a positioning groove for a potential energy object electromagnet, and the lower surface of the box cover is connected to the positioning groove for the parabolic electromagnet, the positioning groove for a potential energy object electromagnet. The position corresponding to the positioning groove is provided with a parabolic positioning groove and a potential energy object positioning groove. The bottom surface of the box is provided with a spring device 1, a spring device 2, and a back plate. The beneficial effects are: energy saving and environmental protection, and can directly display the gravitational potential energy and kinetic energy , The conversion between kinetic energy and elastic potential energy, showing the factors that affect the direction and strength of the magnetic field of the electromagnet, showing the distribution of the magnetic field of the electromagnet and the difference in the trajectory of the conductor under the action of the magnetic field, and providing data reference, which is conducive to students' understanding study.

Owner:湖州通元石料有限公司

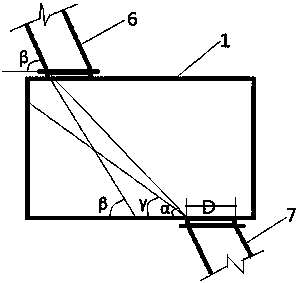

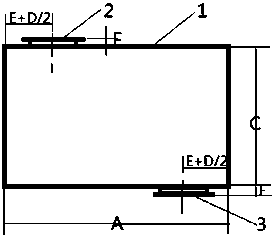

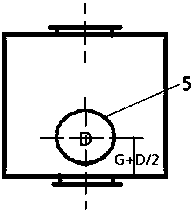

Grain forward-direction feeding buffering box

The invention discloses a grain forward-direction feeding buffering box. The buffering box is in a square shape and comprises a box body (1), and a feeding port (2) is formed in the upper portion of the box body (1), and a discharging port (3) is formed in the lower portion of the box body (1); an operation hole (5) is formed in the position close to the feeding side of the box body (1), and the feeding port (2) is connected with an inlet sliding pipe (6) through a flange (4), and the discharging port (3) is connected with an outlet sliding pipe (7) or equipment through a flange; and the buffering box is characterized in that the positions and directions of the feeding port (2) and the discharging port (3) are consistent with the grain conveying direction in a forward-direction mode, and an included angle alpha is formed between the direction from the feeding port (2) to the discharging port (3) and the horizontal direction. The grain forward-direction feeding buffering box is simple in structure, convenient to mount and easy to operate, the speed of grain can be effectively reduced through the buffering box, abrasion and impact of the grain on the sliding pipes and main equipmentare reduced, the service lives of the sliding pipes and the main equipment are prolonged, material crushing and external flying of dust are reduced, and the process effect is improved.

Owner:JIANGSU VOCATION & TECHNICAL COLLEGE OF FINANCE & ECONOMICS

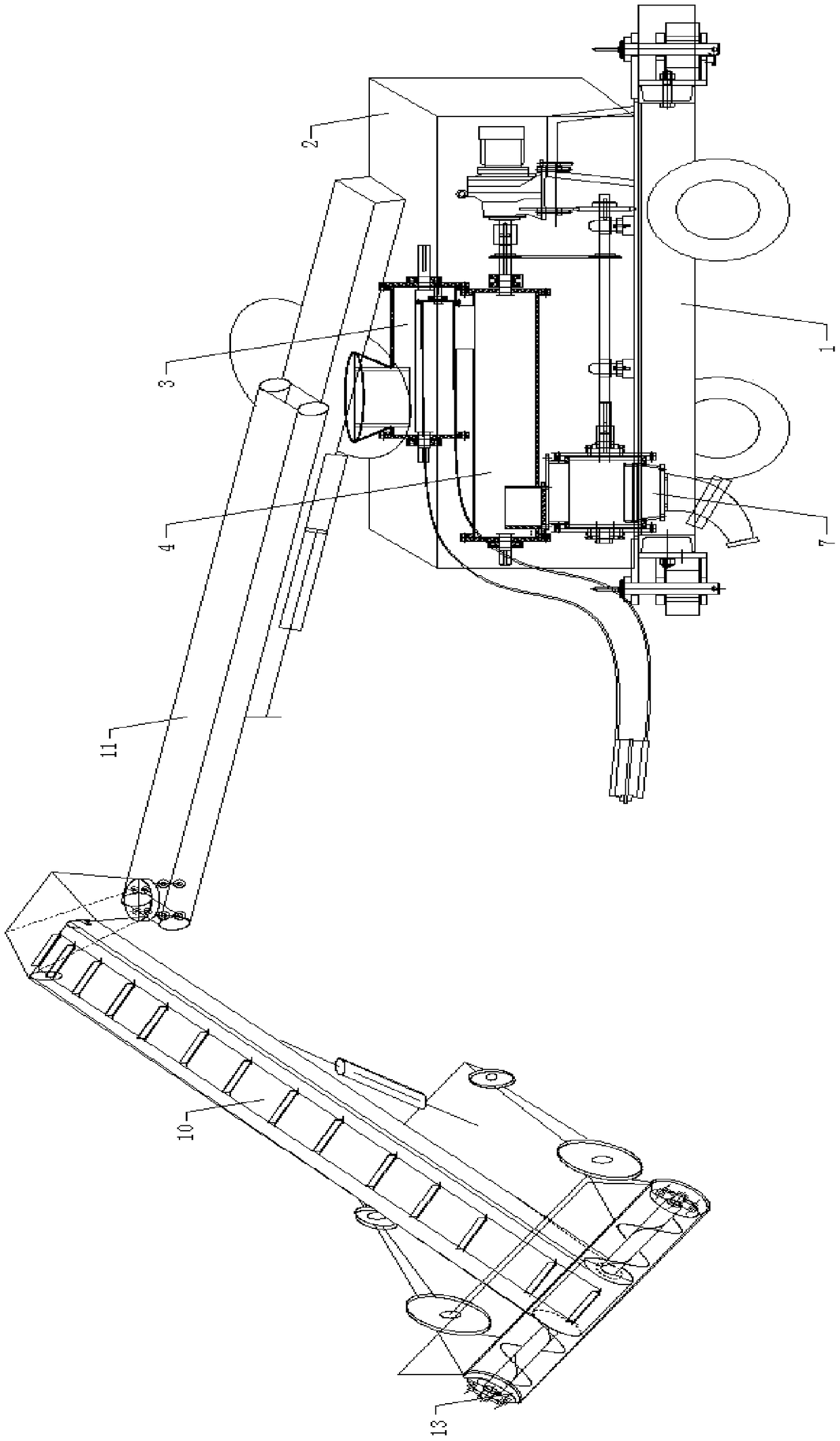

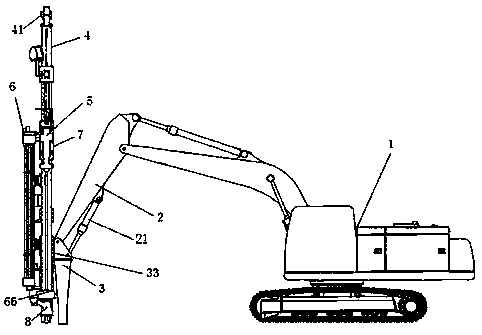

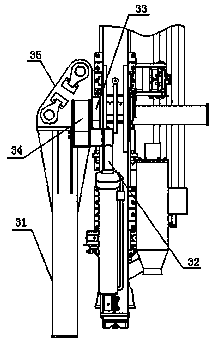

A drilling rig transformed from an excavator

ActiveCN106437510BStrong enoughEnsure safetyCore removalDrilling machines and methodsHydraulic cylinderExcavator

The invention discloses a drilling machine formed through transformation of an excavator. The drilling machine comprises an excavator body, an excavator forearm and a drilling machine working portion, wherein the drilling machine working portion replaces a bucket, is installed at the lower end of the excavator forearm through a rotary shaft, and can rotate with the axial direction of the rotary shaft as a circle center; the drilling machine working portion comprises a long maintenance working device and a drilling rod stand column assembly; the upper end of the maintenance working device is installed at the lower end of the excavator forearm through the rotary shaft; a hydraulic cylinder is installed on the excavator forearm, a cylinder body of the hydraulic cylinder is fixed to the excavator forearm, and a piston rod of the hydraulic cylinder is connected with the upper portion of the maintenance working device; and the drilling rod stand column assembly is installed on the maintenance working device through an installation shaft, a swinging oil cylinder is connected between the drilling rod stand column assembly and the maintenance working device, and through telescoping of the swinging oil cylinder, the drilling rod stand column assembly rotates with the axial direction of the installation shaft as a circle center.

Owner:广西徐沃工程机械设备有限公司 +2

Closed efficient double-bin sifter

The invention provides a closed efficient double-bin sifter which comprises a rack and a sifter box. The sifter box is fixedly connected into the rack through a hanging device. A left sifter bin, a right sifter bin and a drive chamber are arranged in the sifter box. Heat dissipating windows are arranged on the front side and the rear side of the drive chamber. A fixing plate is arranged horizontally in the middle of the drive chamber. The upper portion of the fixing plate is fixedly connected with a drive motor. A transmission shaft is rotationally connected between the fixing plate and the bottom of the drive chamber. An eccentric block is mounted in the middle of the transmission shaft. The left side of the left sifter bin and the right side of the right sifter bin are fixedly connected with sifter doors through bolts correspondingly. Feeding inlets are formed in the tops of the left sifter bin and the right sifter bin correspondingly. Discharging outlets are formed in the bottoms of the left sifter bin and the right sifter bin correspondingly. Vertical pressing mechanisms are arranged at the tops of the left sifter bin and the right sifter bin correspondingly. Horizontal pressing mechanisms are arranged on the left side of the left sifter bin and the right side of the right sifter bin correspondingly. The closed efficient double-bin sifter provided by the invention is compact in structure, stable in work, convenient and fast to operate, high in screening efficiency and good in screening effect.

Owner:河南粮院机械制造有限公司

Raw material screening device for concrete production and processing

PendingCN113857025ARealize the collectionAvoid exaggerationSievingScreeningEnvironmental geologyMechanical engineering

The invention provides a raw material screening device for concrete production and processing. The raw material screening device comprises a fixed cylinder, and multiple dust collecting assemblies capable of collecting dust are embedded in the inner wall of the longitudinal side of the fixed cylinder in the up-down vertical direction in an equally adjacent manner in a surrounding manner; each dust collecting assembly comprises a dust collecting groove, a dust guide plate, a dust closing assembly capable of closing collected dust to prevent the collected dust from flying outwards and a dust insulation assembly capable of humidifying the collected dust to isolate the collected dust; the dust collecting grooves are embedded in the inner wall of the longitudinal side of the fixed cylinder in the up-down vertical direction in an equally adjacent manner in a surrounding manner; the dust guide plates are fixedly mounted at the positions between the front and rear inner walls of the upper ends in the dust collecting grooves; and the dust closing assemblies are movably mounted at the positions of the lower ends in the dust collecting grooves. According to the raw material screening device for concrete production and processing, the functions that a dust collecting function is achieved in the fixed cylinder, when raw materials are screened through a screening cylinder and spiral blades, dust is not prone to being blown out of a discharging pipe, dust diffusion is prevented, and the operation environment is improved can be achieved.

Owner:邱晓燕

Method for preparing lithium iron phosphate by sintering lithium iron phosphate precursor and microwave sintering equipment

InactiveCN102092699BPromote densificationEvenly distributedCell electrodesPhosphorus compoundsLithium iron phosphateControl treatment

Owner:HENAN UNION NEW ENERGY

Coupling type efficient environment-friendly pulp shooting machine

PendingCN113863960AAvoid exaggerationReduce dust exposureMining devicesUnderground chambersProcess engineeringPollution

The invention discloses a coupling type efficient environment-friendly pulp shooting machine. The coupling type efficient environment-friendly pulp shooting machine comprises a bottom plate, a first feeding pipe, a stirring cavity, a second feeding pipe, a third feeding pipe, a storage bin and an air lock valve. According to the coupling type efficient environment-friendly pulp shooting machine, the coupling closed type design is adopted, dust flying is eradicated, the probability that constructors make contact with dust is reduced, and environment pollution is effectively reduced; the air lock valve is additionally arranged, during the period that high-pressure air blows aggregate for pulp shooting, the high-pressure air is prevented from flowing backwards into the storage bin, the dust flying phenomenon is effectively avoided, production safety and body health of the constructors are guaranteed, and high practicability is achieved; and automatic feeding and stirring can be achieved, manual participation is not needed in the whole process, the labor intensity of the constructors is reduced, and the overall automation degree is high. The problems that in the prior art, a pulp shooting machine conducts manual feeding and stirring, the labor intensity of the constructors is increased, dust is prone to being generated, underground dust pollution is caused, underground safety production is influenced, and the production safety and body health of the constructors are seriously influenced are solved.

Owner:ANHUI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com