Dustproof device for wood processing

A dust-proof device and wood technology, applied in wood processing equipment, manufacturing tools, bark area/debris/dust/waste removal, etc., can solve the problem of reducing wood processing efficiency, increasing the labor intensity of workers, and the impact of protective covers, etc. problems, to achieve the effect of reducing flying, preventing dust from flying, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in combination with the accompanying drawings, and specific implementation methods will be given.

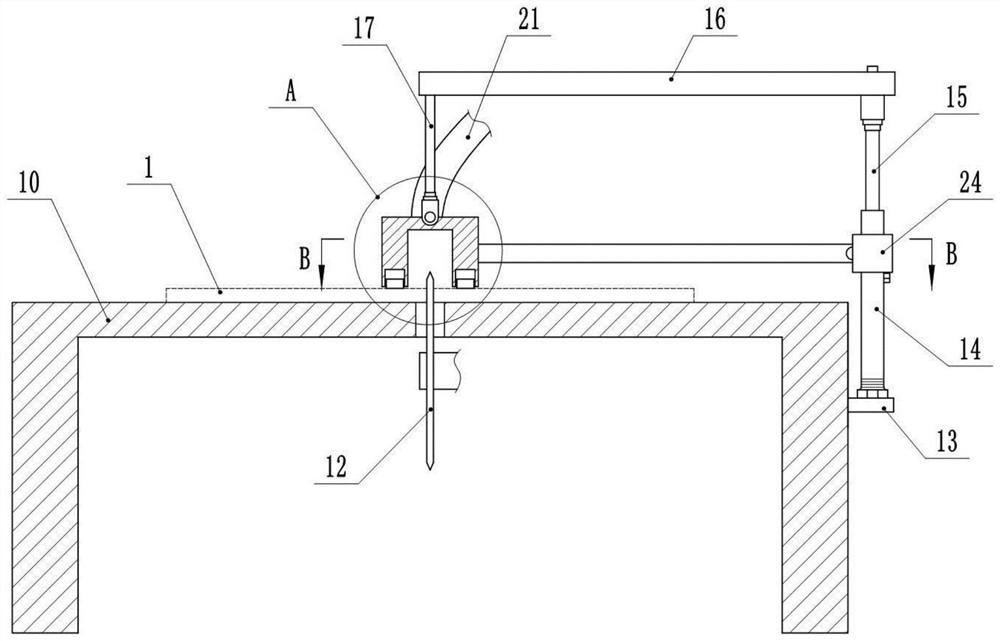

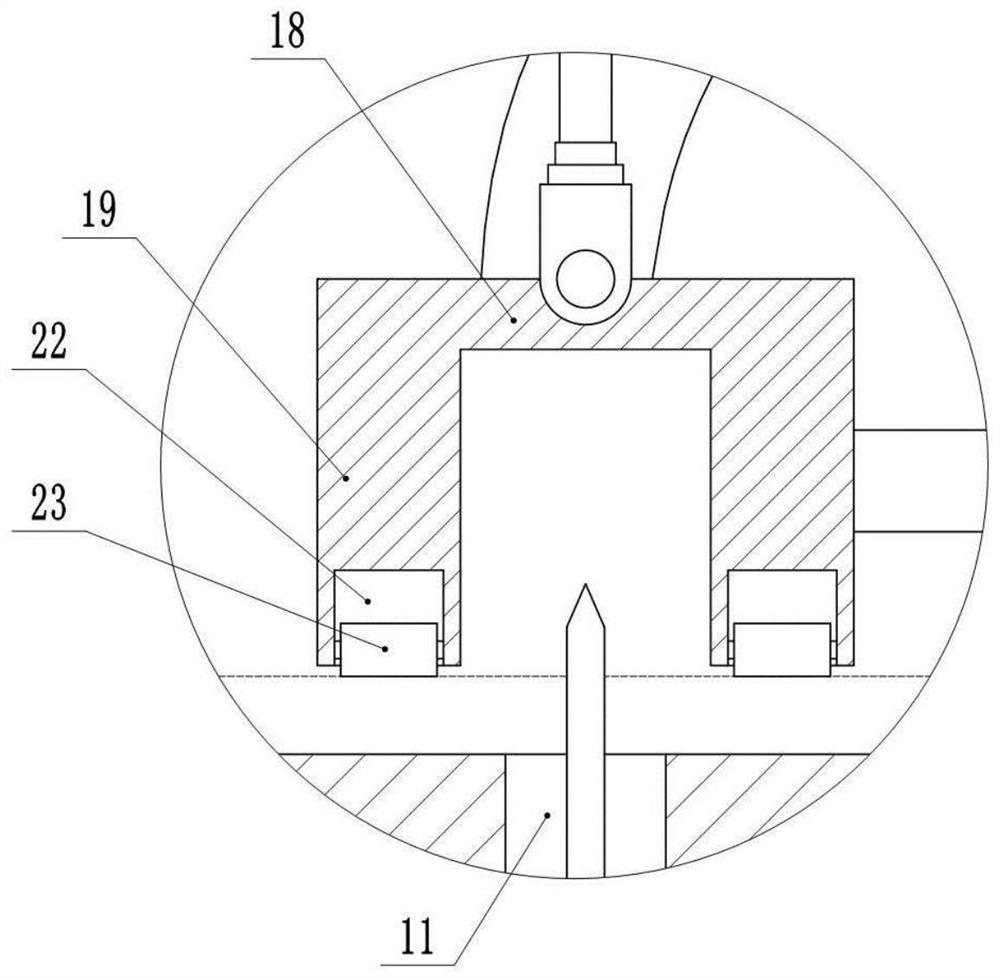

[0024] The embodiment is basically as figure 1 , figure 2 with image 3 As shown, a wood processing dust-proof device includes a workbench 10 for placing planks 1, a strip groove 11 is opened on the workbench 10, a drive motor is fixed below the workbench 10, and the drive motor is connected with a cutting machine. Wheel 12, the top of cutting wheel 12 exposes workbench 10 through strip groove 11.

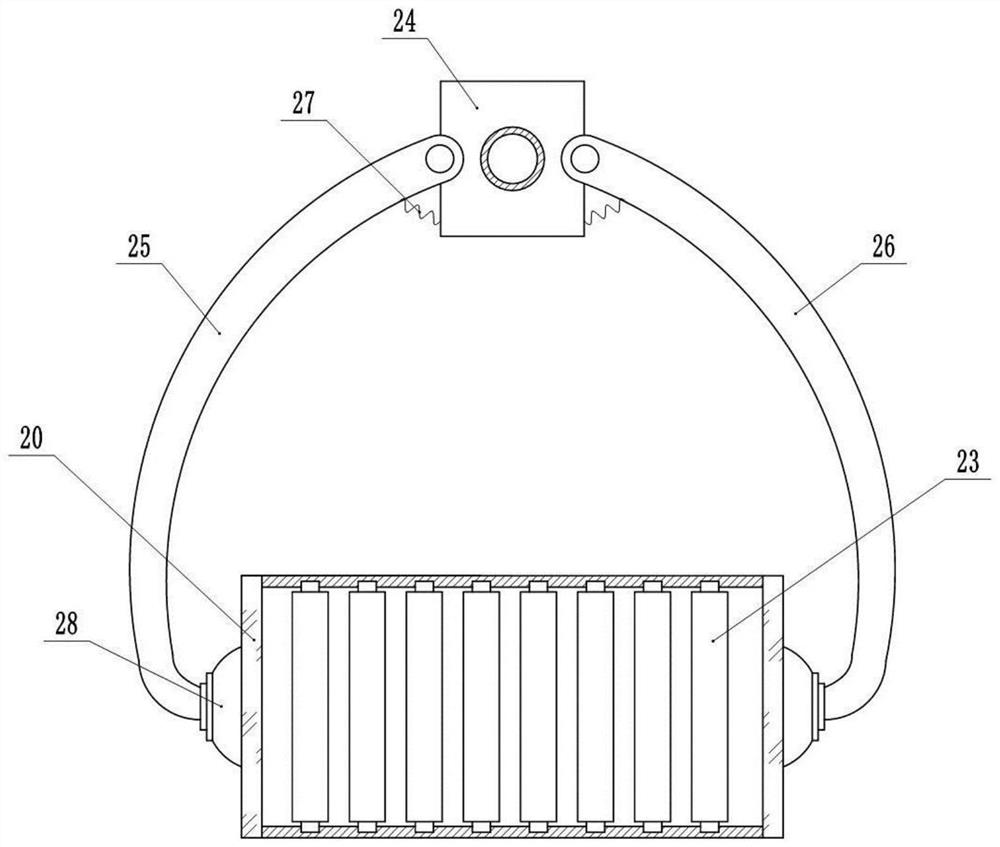

[0025] A support base 13 is fixed on one side of the workbench 10, and a support frame assembly is also provided on the support base 13. In this embodiment, the support frame assembly includes a column fixed on the support base 13, wherein the column is a telescopic column, and an electric motor can be used. Telescopic or manual telescopic structure, since the principle of the column of the telescopic structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com