Self-propelled construction site watering and dust-settling device

A construction site and dust suppression device technology, applied in construction, cleaning methods, road surface cleaning, etc., can solve the problems of poor dust removal effect and the inability to flexibly adjust the sprinkler angle according to actual needs, etc., to achieve the effect of reducing dust flying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

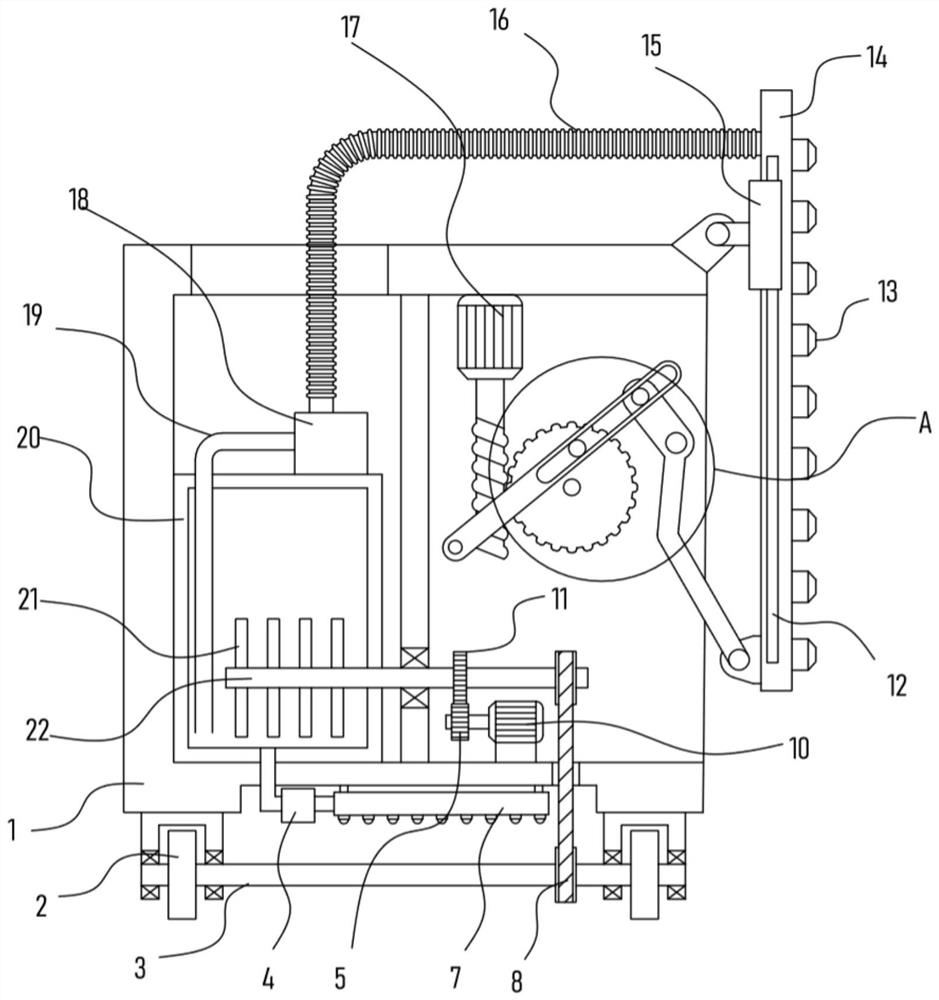

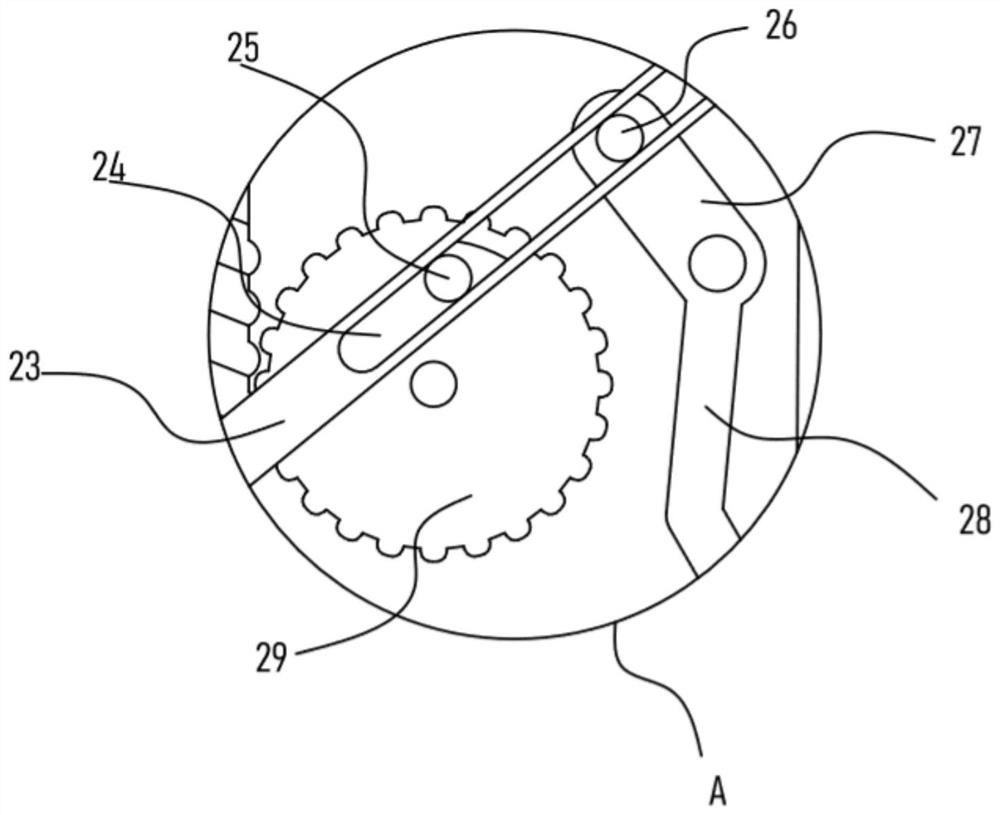

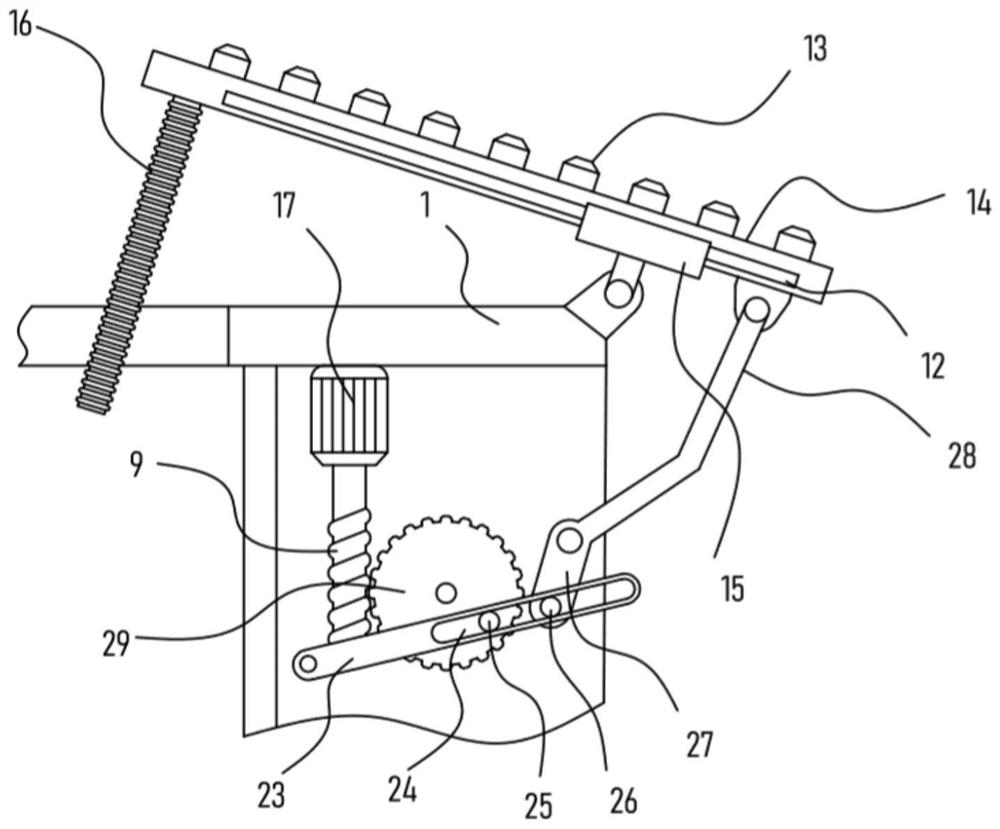

[0023] see Figure 1-4 , a self-propelled construction site sprinkling and dust suppression device, including a mobile frame 1, a water tank 20 is fixed in the mobile frame 1, a driving motor 17 is fixed on the mobile frame 1, and a turning adjustment mechanism is connected to the driving motor 17. The turning A hollow spray plate 14 connected to the water tank 20 is driven and connected to the adjustment mechanism, and several spray heads 13 are evenly distributed on the spray plate 14, and a limit mechanism that is slidably connected with the spray plate 14 is hinged on the moving frame 1 , the moving frame 1 is fixed with a servo motor 10, the servo motor 10 is driven and connected with a dispersing mechanism located inside the water tank 20, and the bottom of the moving frame 1 is rotatably equipped with a traveling wheel 2.

[0024] The inside of the water tank 20 in this device is used to store clean water or disinfectant water that will be sprayed to reduce dust. The wa...

Embodiment 2

[0030] On the basis of Embodiment 1, in addition, the dispersing mechanism of the device includes a main gear 5 coaxially fixed with the output shaft of the servo motor 10, the main gear 5 is meshed with a secondary gear 11, and the secondary gear 11 is coaxially fixed with a seal Extending to the drive shaft 22 in the water tank 20, several pairs of stirring blades 21 are fixed at equal intervals on the side wall of the drive shaft 22.

[0031] The servo motor 10 can drive the main gear 5 to rotate, and the main gear 5 drives the secondary gear 11 meshed with it to rotate. At this time, the drive shaft 22 realizes the rotation, and the drive shaft 22 drives the stirring blade 21 on it to rotate, so as to realize the disinfection of the disinfectant inside the water tank 20. The rotating and agitating effect of the water tank 20 can realize the sufficient mixing of the disinfectant agent and the solution when the disinfectant is filled inside the water tank 20, and realize the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com