Material collecting assembly of large planetary ball mill

A planetary ball mill and aggregate technology, applied in grain processing, etc., can solve problems affecting the health of workers in the production environment, flying dust in the production environment, and easy leakage of powder, so as to reduce the flying of powder, ensure health, The effect of production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

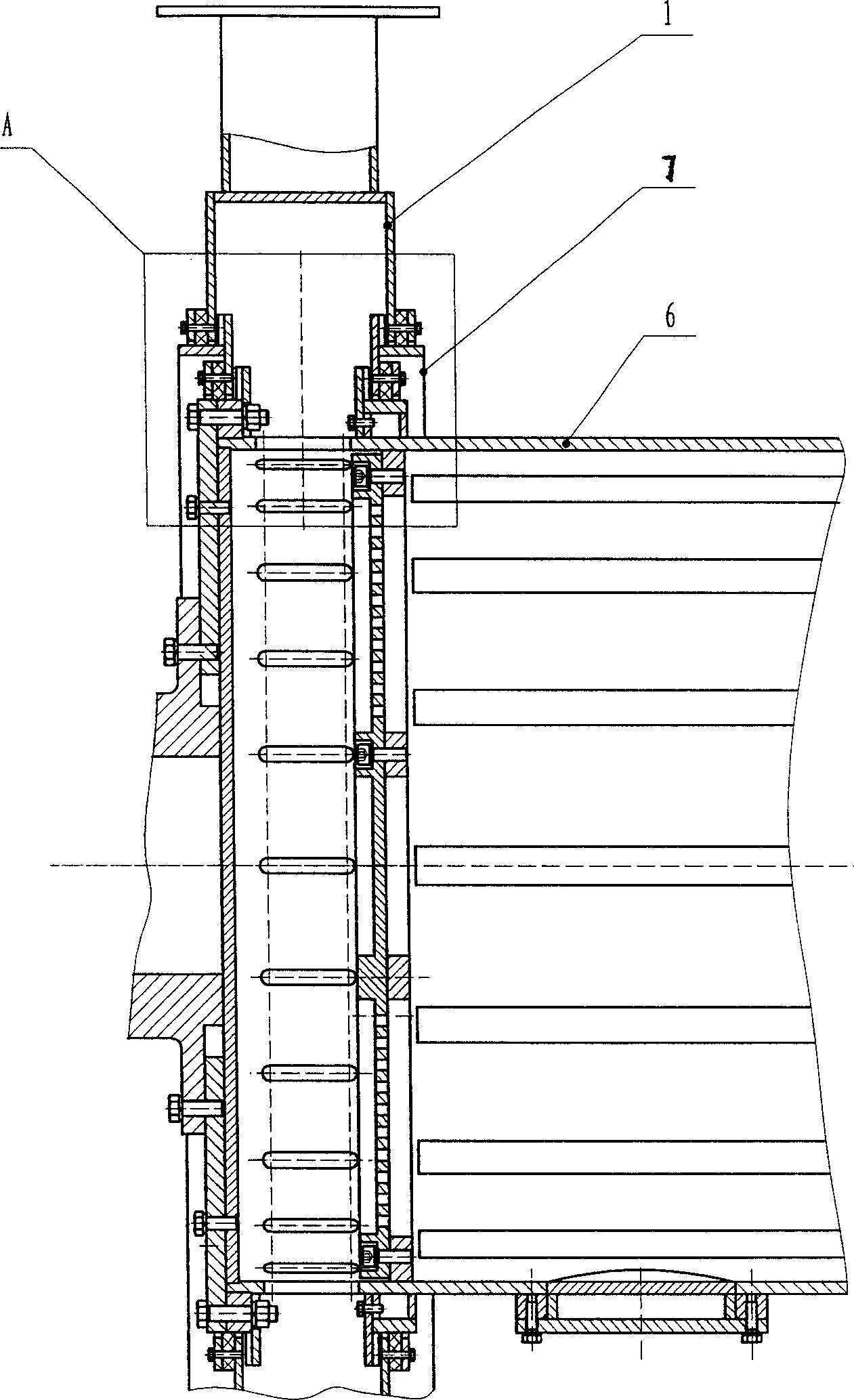

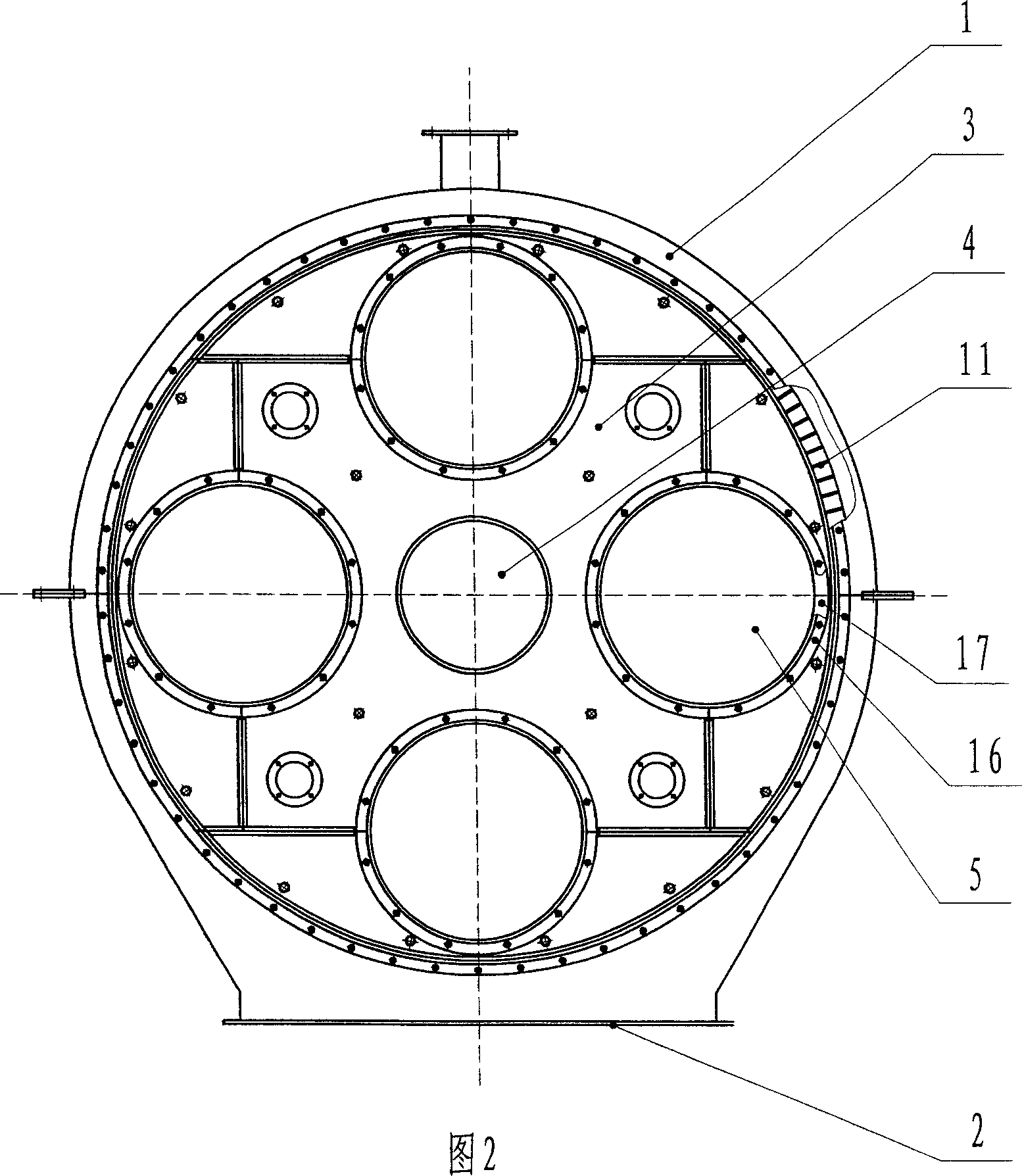

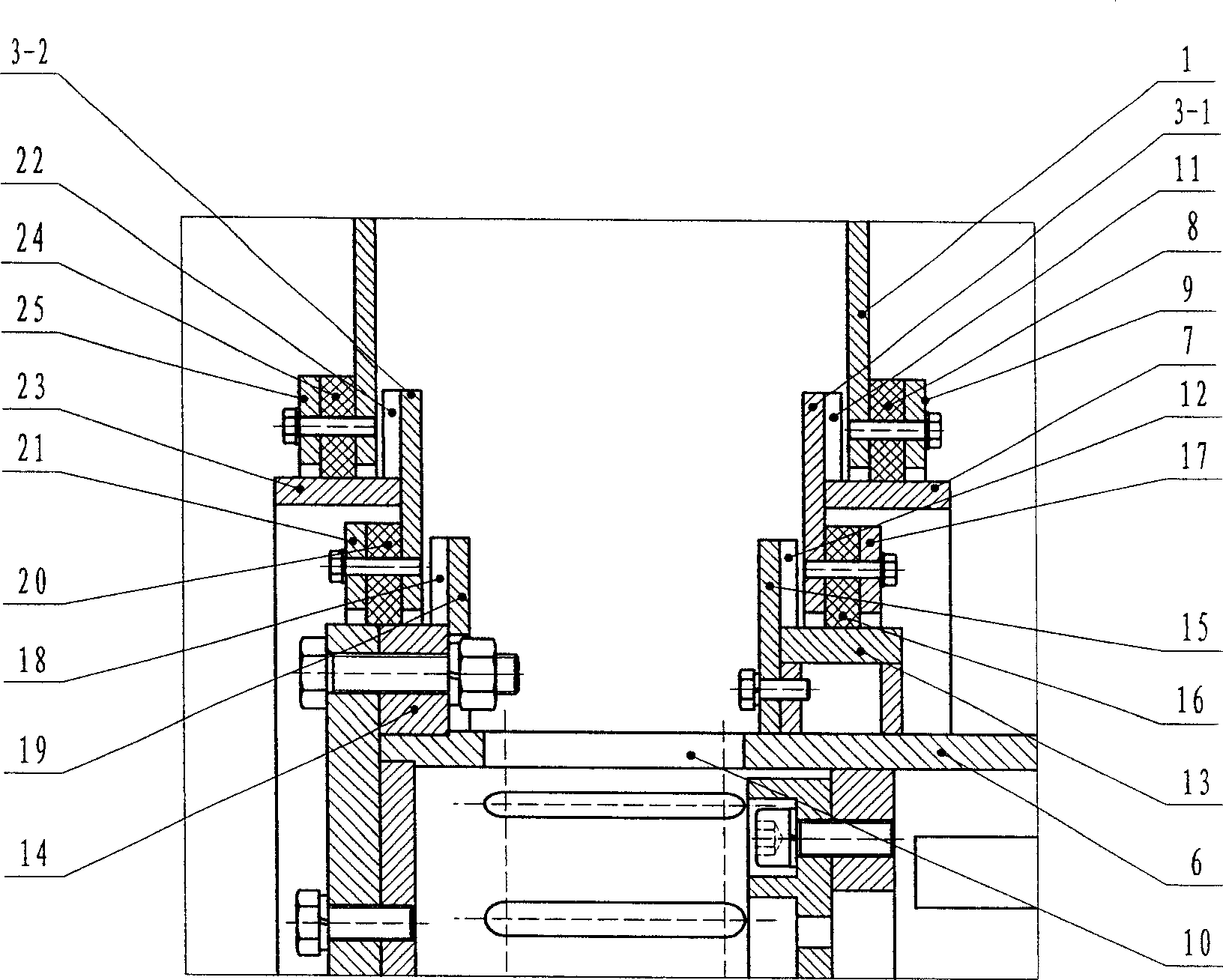

[0015] The lower end of the collection cover 1 is provided with a discharge port 2, and round holes are respectively provided on the two end faces of the collection cover 1, and the two end faces 3-1, 3-2 of the collection turntable 3 are respectively matched on each round hole to collect The material turntable 3 can be assembled and formed.

[0016] A central hole 4 is provided at the center of the two end surfaces 3-1, 3-2 of the collection turntable 3, and the central hole 4 is used for passing through the main shaft of the planetary ball mill. Four grinding cylinder sleeve holes 5 are evenly distributed on the outside of the central hole 4, and the discharge bins at the rear of the four grinding cylinders 6 are respectively extended into the corresponding grinding cylinder sleeve holes 5.

[0017] The discharge chute 10 at the rear of the grinding drum 6 is located in the cavity of the collection cover 1 . Two flanges 13 , 14 matching with the sleeve holes 5 are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com