A drilling rig transformed from an excavator

A technology for excavators and drilling rigs, which is applied in the field of drilling rigs transformed by excavators, can solve problems such as affecting the efficiency of drilling operations, increasing the labor intensity of operators, and being unfavorable to environmental protection, so as to achieve efficient and reliable replacement of the brazing process, safe drilling operations and safety. Efficient and avoid the effect of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing.

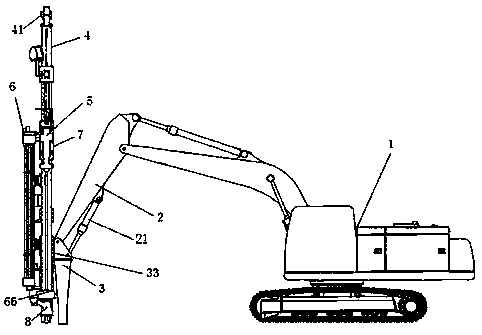

[0033] Such as Figure 1-9 As shown, a drilling rig transformed from an excavator includes an excavator body 1, an excavator arm 2 and a drilling rig working part. Rotate around the axis of the shaft.

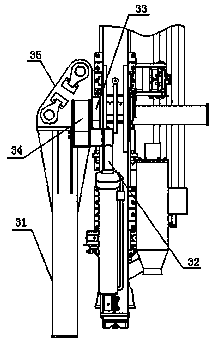

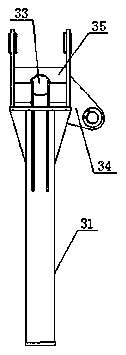

[0034] The working part of the drilling rig includes a long maintenance work device 3 and a drill pipe column assembly, the upper end of the maintenance work device 3 is installed on the lower end of the excavator arm 2 through a rotating shaft, and the excavator arm 2 A hydraulic cylinder 21 is installed on the top, and the cylinder body of the hydraulic cylinder 21 is fixed on the excavator forearm 2, and the piston rod of the hydraulic cylinder 21 is connected with the top of the maintenance work device 3;

[0035] The drill pipe column assembly is installed on the maintenance work device 3 through the installation shaft 33, and the swing cylinder 32 is connected betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com