Garbage compressor

A technology for garbage compressors and garbage, which is applied in presses, manufacturing tools, etc. It can solve problems such as short strokes, secondary pollution, and garbage entrained in guide rails, so as to increase the contact area, prevent secondary dust and odor, Easy to clean and maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

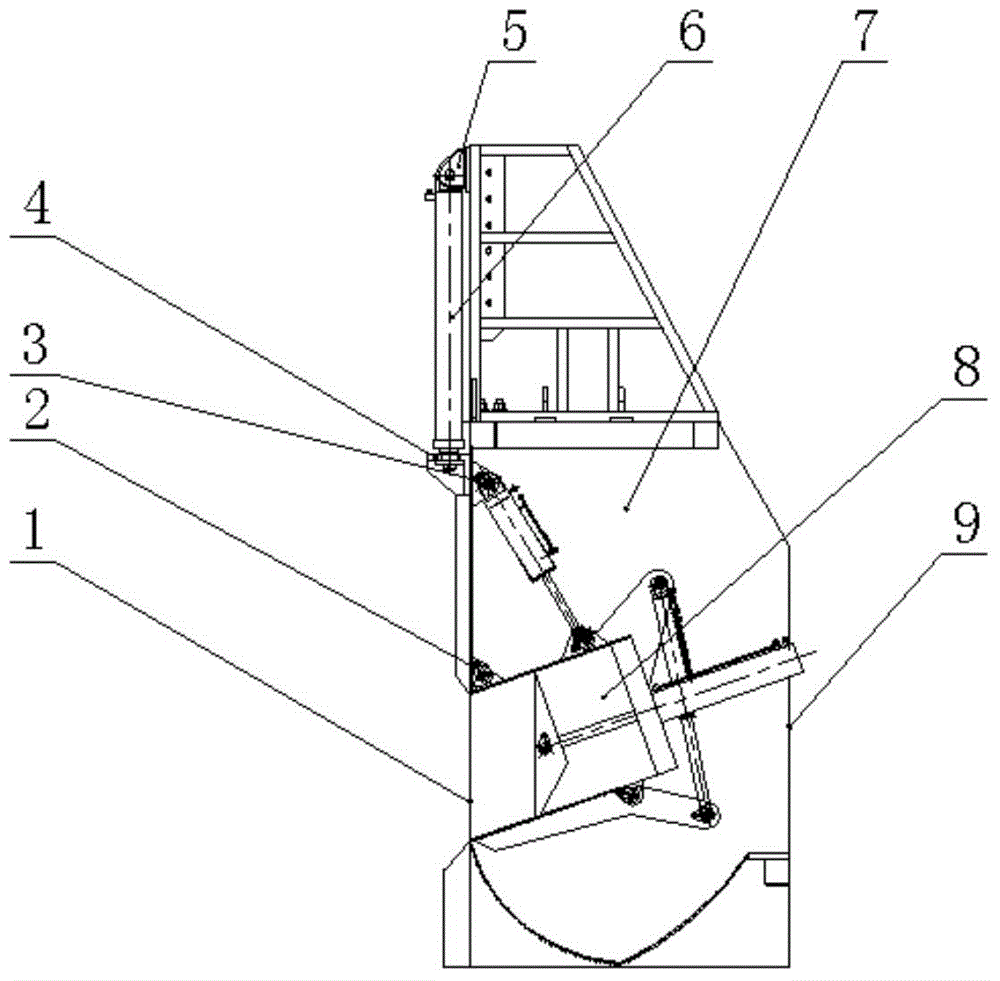

[0045] A trash compactor such as figure 1 As shown, it includes: a body 7, a gate oil cylinder support 5, a gate oil cylinder 6, a docking mechanism 4 and a compression mechanism 8, wherein the gate oil cylinder support 5 is fixedly installed on the upper end of the side of the body 7 where the garbage outlet 1 is located, and the gate oil cylinder 6 cylinders The tail end of the body is fixedly connected to the gate oil cylinder support 5, the head of the piston rod of the gate oil cylinder 6 is fixedly connected to the docking mechanism 4, and the inner side of the upper end of the garbage outlet 1 of the body 7 is provided with two first hinge seats 2 before and after. Two second hinge seats 3 are arranged above the hinge seat 2, and the compression mechanism 8 is integrally installed in the inner cavity of the body 7 through the two first hinge seats 2 and the second second hinge seats 3.

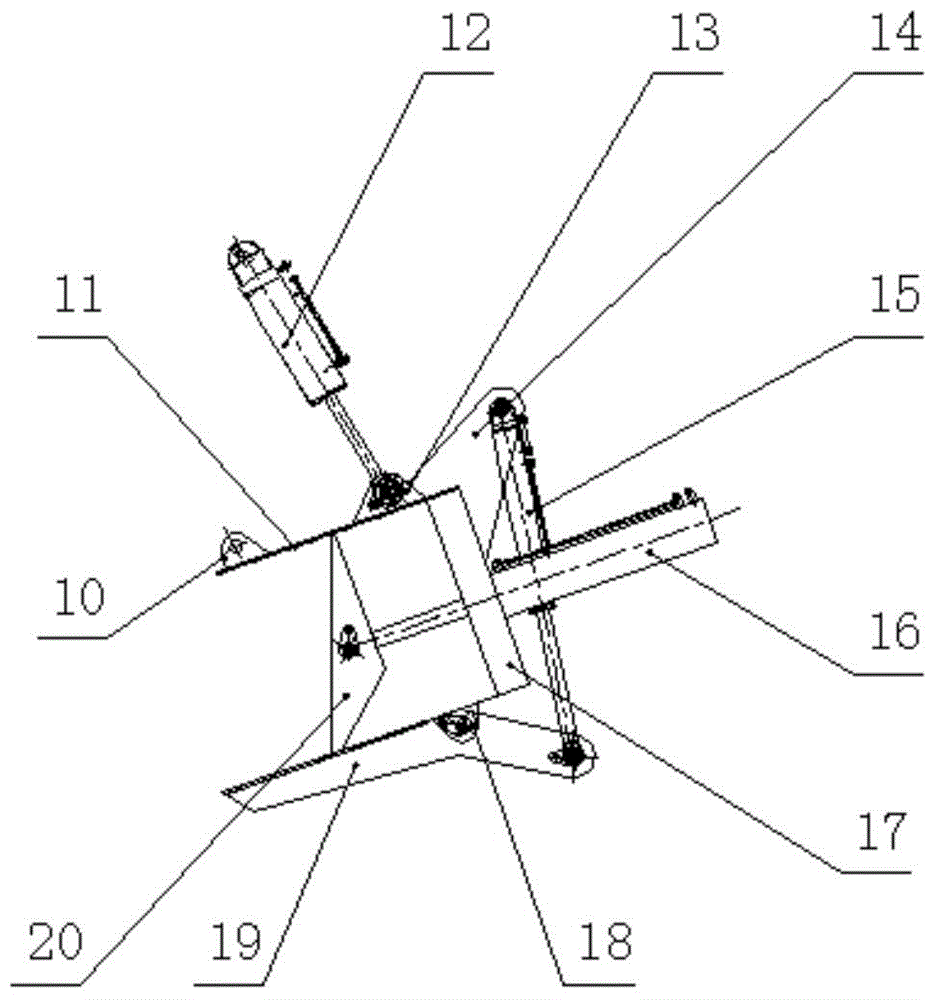

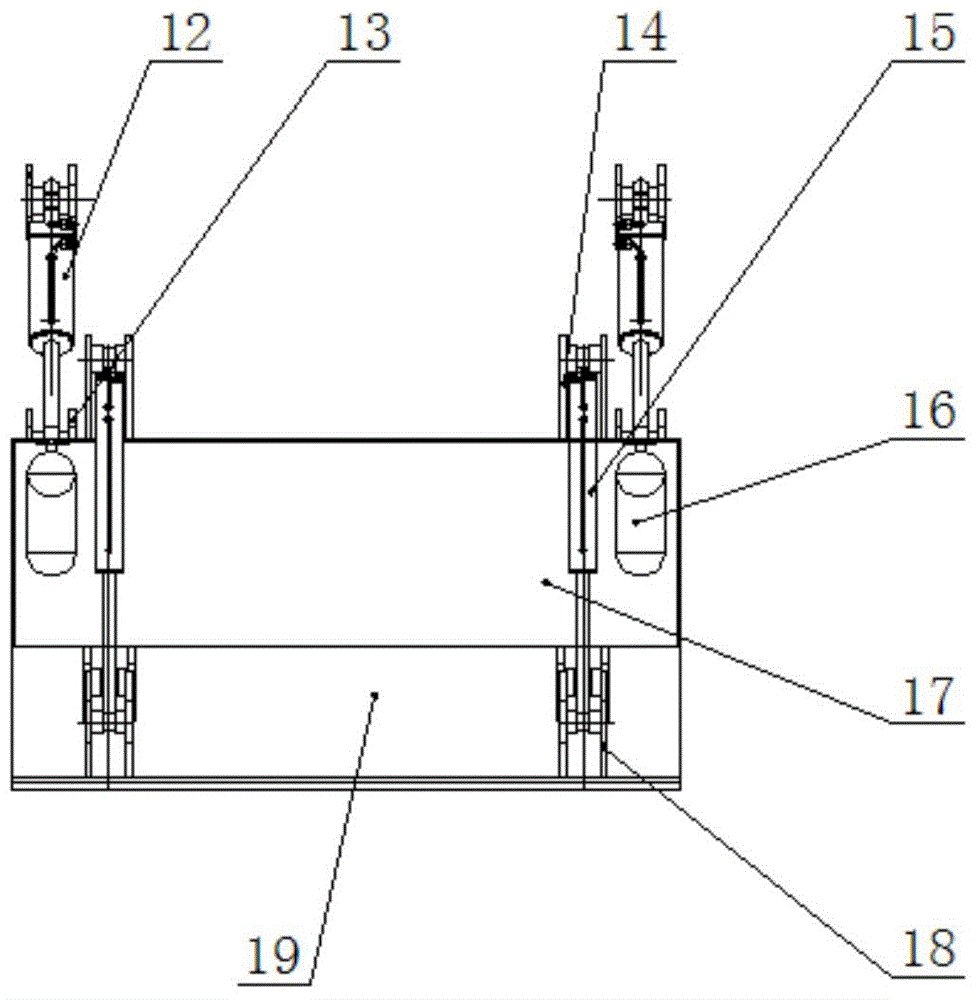

[0046] Such as figure 2 and image 3 As shown, the compression mechanism 8 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com