Material collecting bin of polyester fiber color master batch production automatic material feeding device

An automatic feeding device, polyester fiber technology, applied in the automatic feeding device of polyester fiber coloring masterbatch production, polyester fiber color masterbatch production automatic feeding device collection bin field, can solve the problem of rising heat, hindering the transportation and supply of powder materials Problems such as material instability in the extruder, to ensure the quality of finished products, reduce material loss, and prevent dust from flying out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

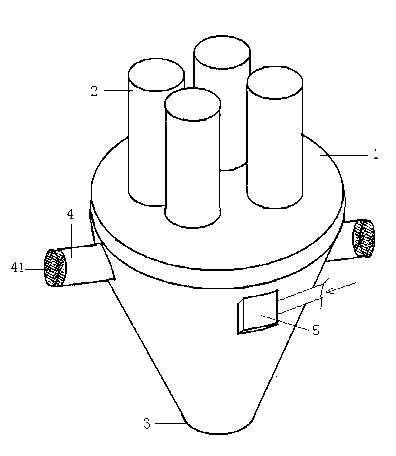

[0012] Such as figure 1 as shown,

[0013] The collection bin of the automatic feeding device in the present invention includes a collection bin body 1, a feed pipe 2 arranged on the top of the collection bin body, and a discharge port 3 arranged at the lower end of the collection bin body. The upper part of the conical surface of the collection bin body is also provided with an exhaust pipe 4 leading to the outside, and a filter element 41 is installed in the exhaust pipe; the vibration head 5 of the gas vibration device is installed on the outer wall of the collection bin body ( The air vibration device is not shown in the figure, and the direction of the arrow shown is the air flow direction).

[0014] When the automatic feeding device is working, the collecting bin obtains the weighed materials of each single type from multiple feeding pipes, mixes them in the bin, and discharges them from the outlet to the extruder. At the same time, the hot air of the extruder rises f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com