Forming equipment for hard carbon fiber thermal insulation material

A technology for thermal insulation materials and molding equipment, which is applied in the direction of cleaning methods using tools, separation of dispersed particles, chemical instruments and methods, etc. It can solve problems such as equipment wear, uneven carbon fibers, and easy accumulation of fiber filaments at the lower end of the molding roller. Achieve the effect of reducing equipment wear and preventing dust from spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

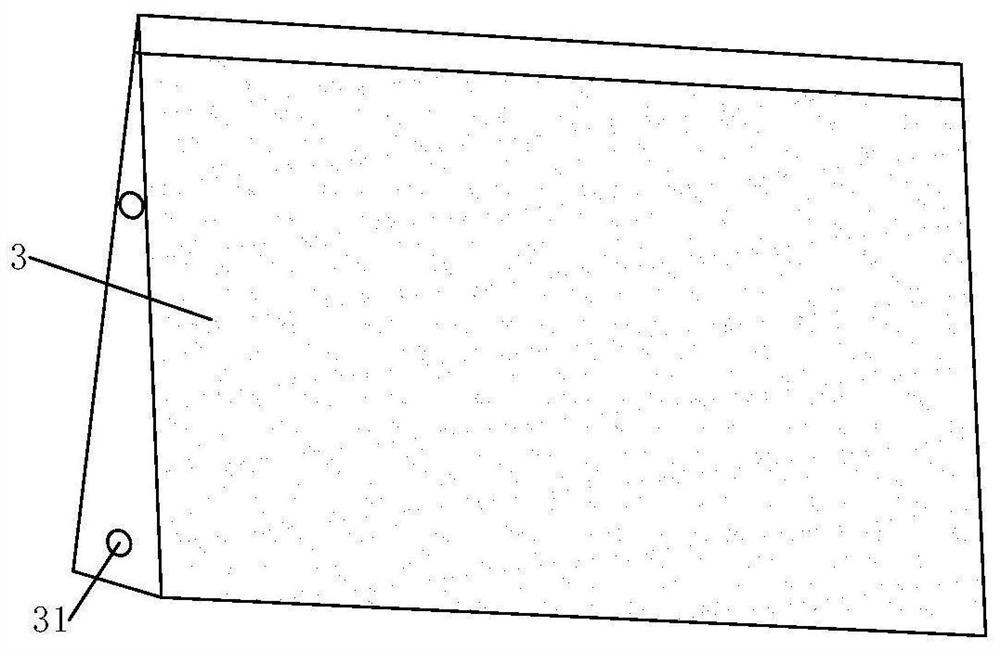

[0032] As a specific embodiment of the present invention, a sealing ring is provided at the joint between the water pipe 31 and the plectrum 3 .

[0033] When the water pipe 31 passes through the water, the moisture flows from the hole provided on the surface of the water pipe 31 to the inside of the paddle 3, and the joint between the water pipe 31 and the paddle 3 is provided with a sealing ring to ensure that the moisture inside the paddle 3 will not flow from the water pipe 31 to the paddle 3. The junction of piece 3 flows out.

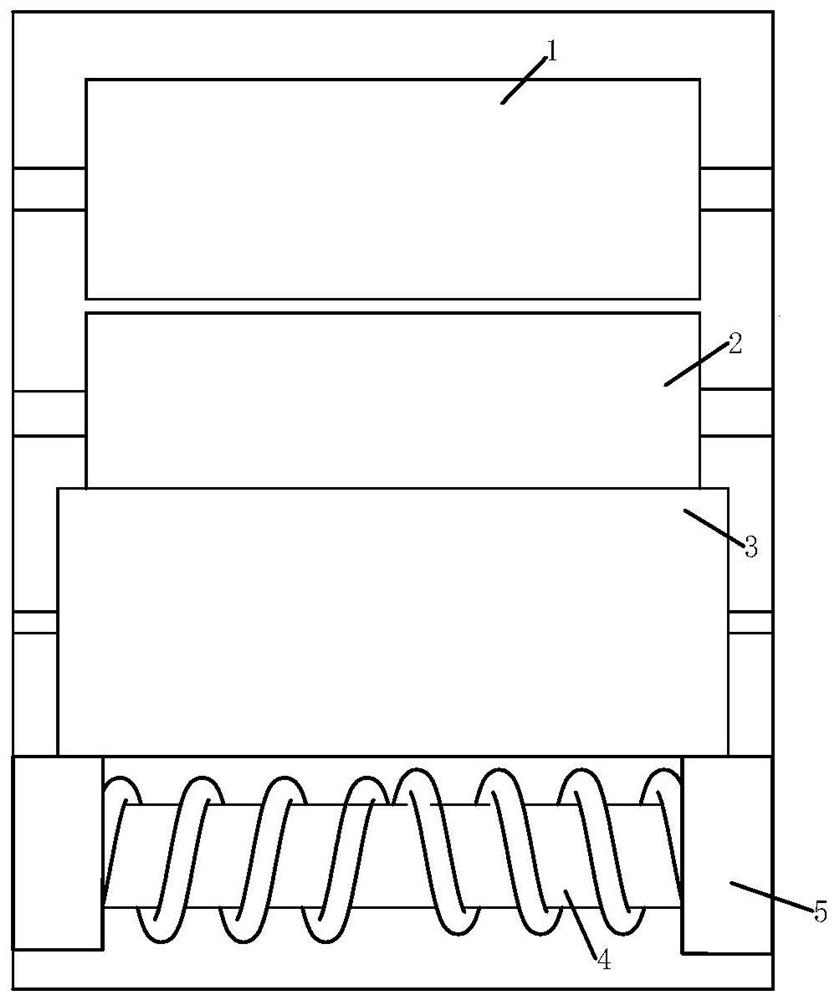

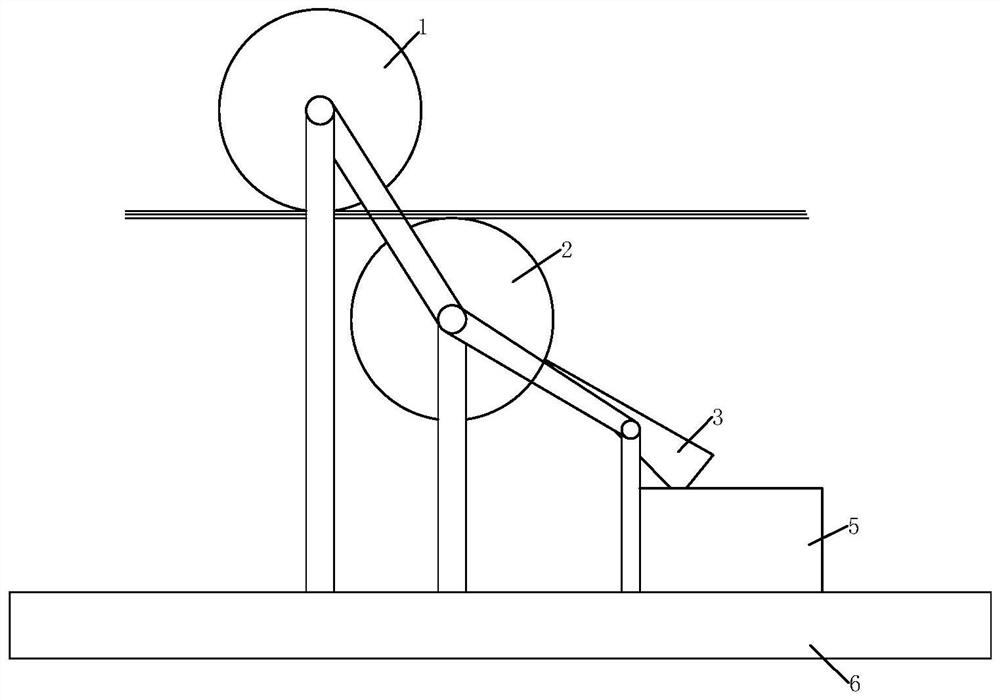

[0034] Working principle: When the machine starts to work, the main roller 1, forming roller 2 and discharge roller 4 start to roll, the paddle 3 is fixedly connected to the frame and remains still, one end of the paddle 3 is in contact with the surface of the forming roller 2, and the paddle 3 A discharge roller 4 is arranged below the other end, and the plectrum 3 scrapes off impurities such as fiber filaments falling from the surface of the for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com