Patents

Literature

172results about How to "Extend equipment life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

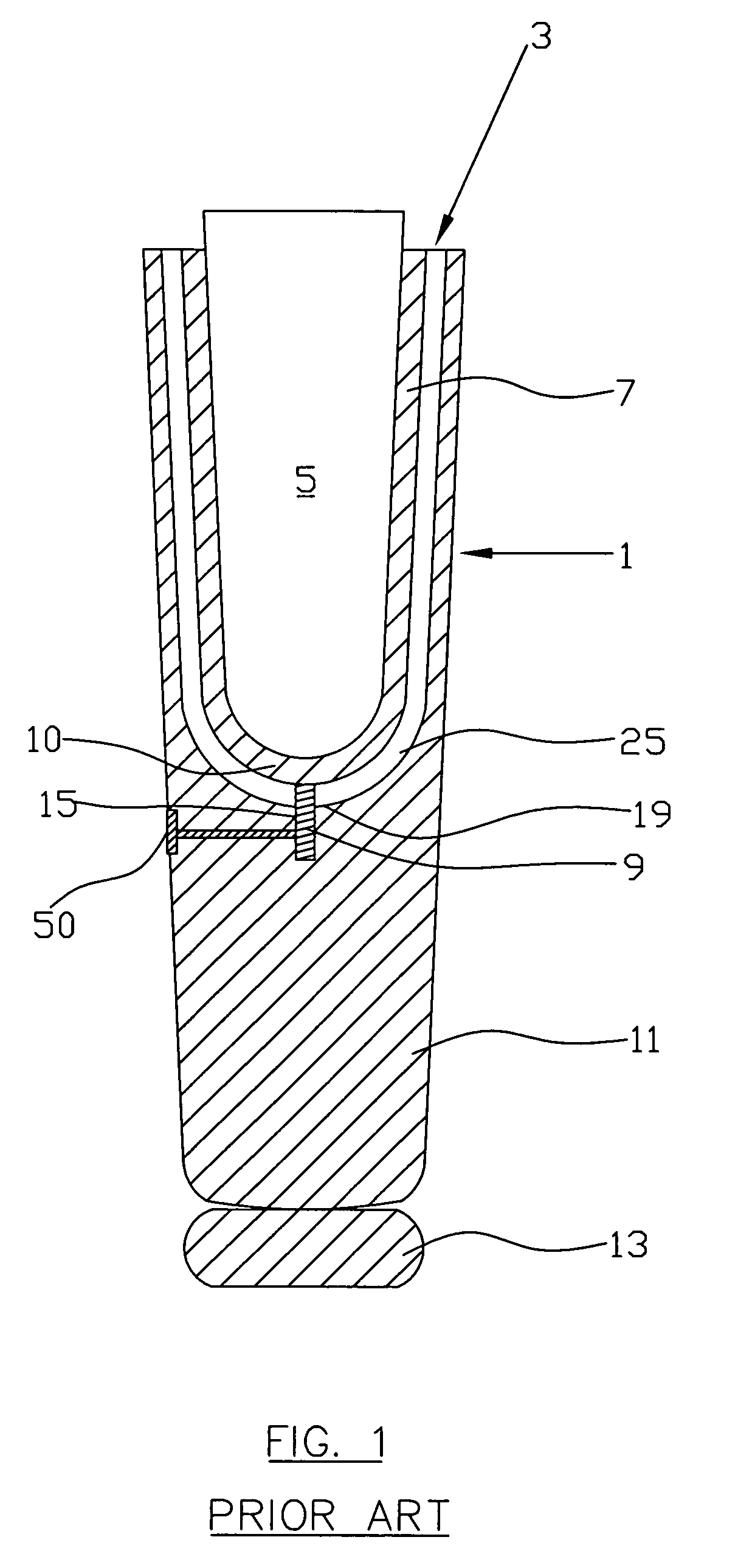

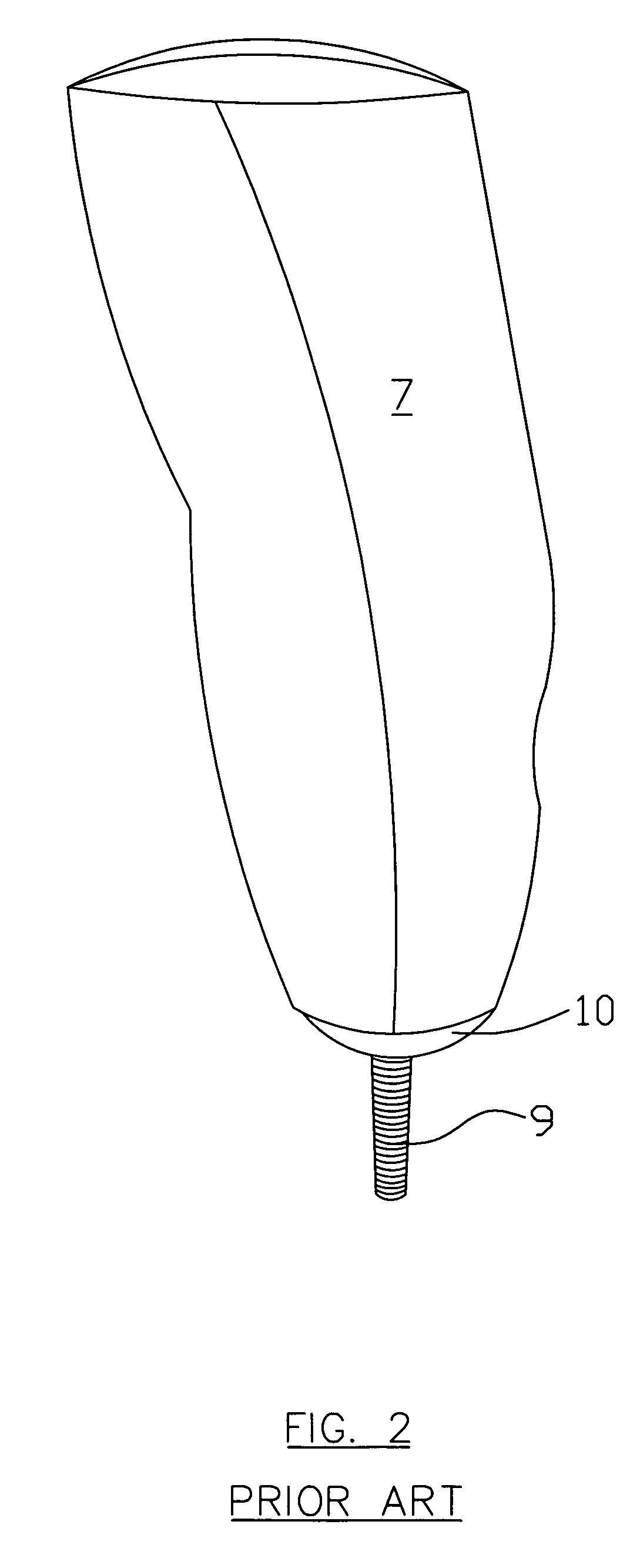

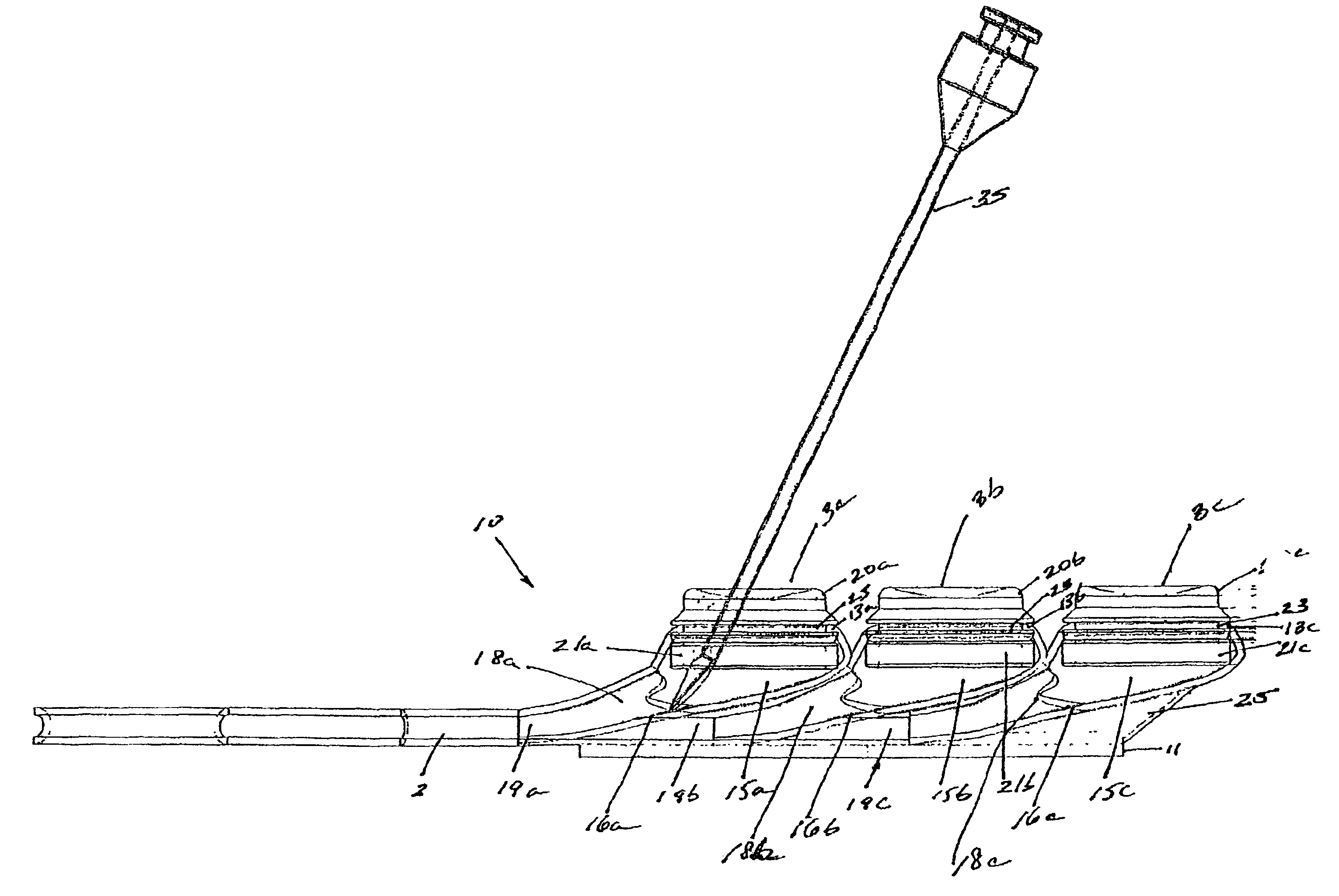

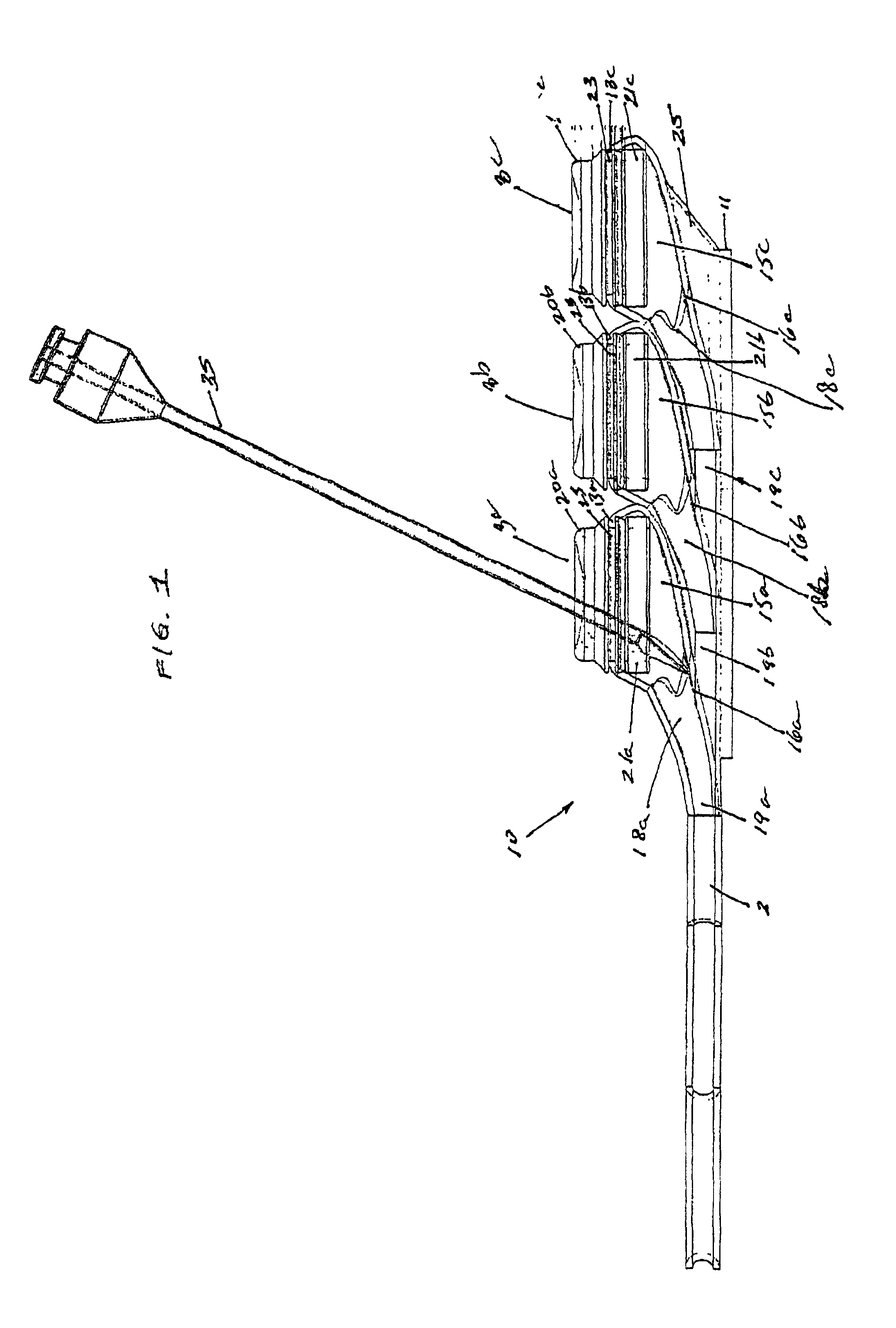

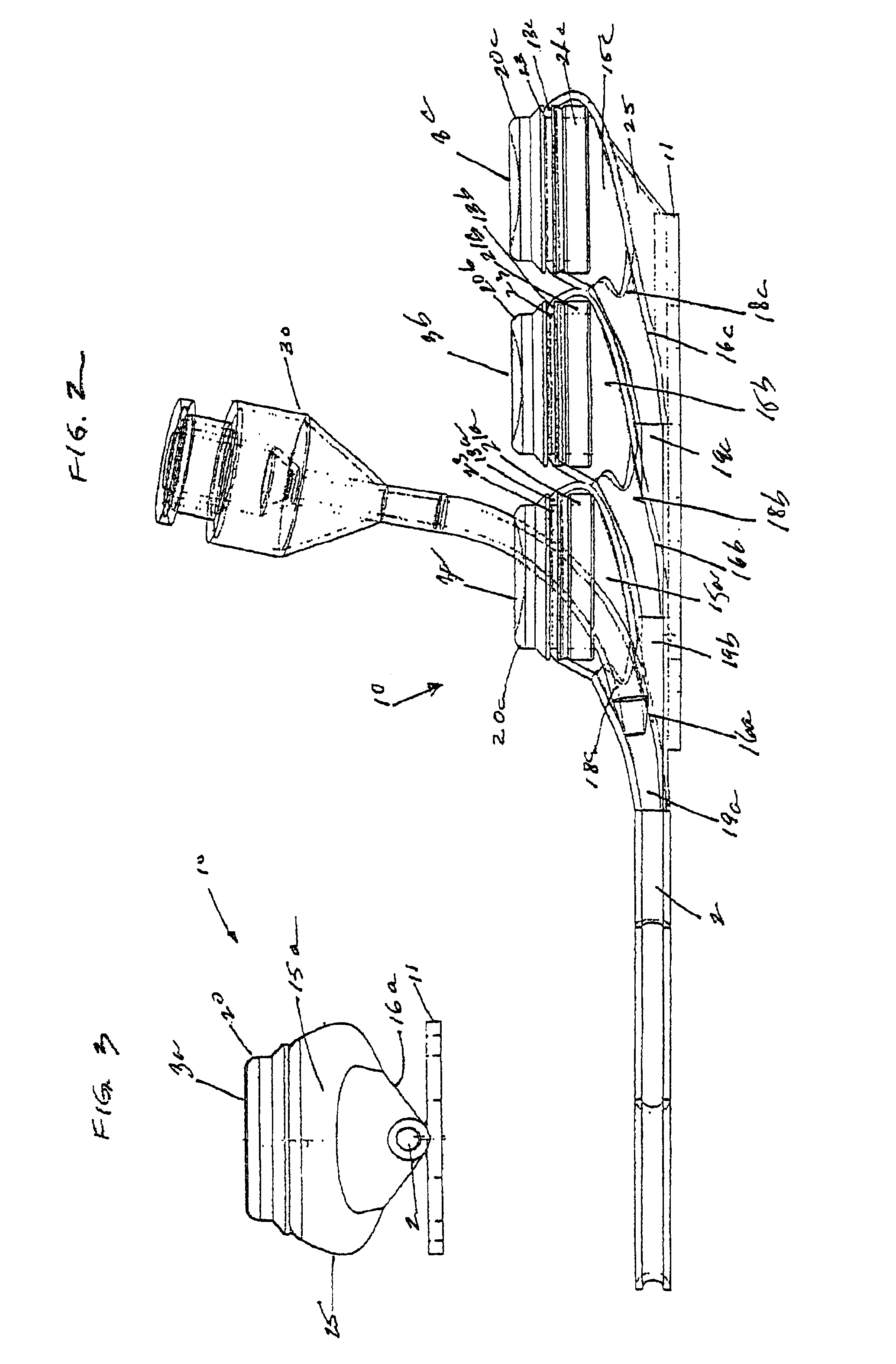

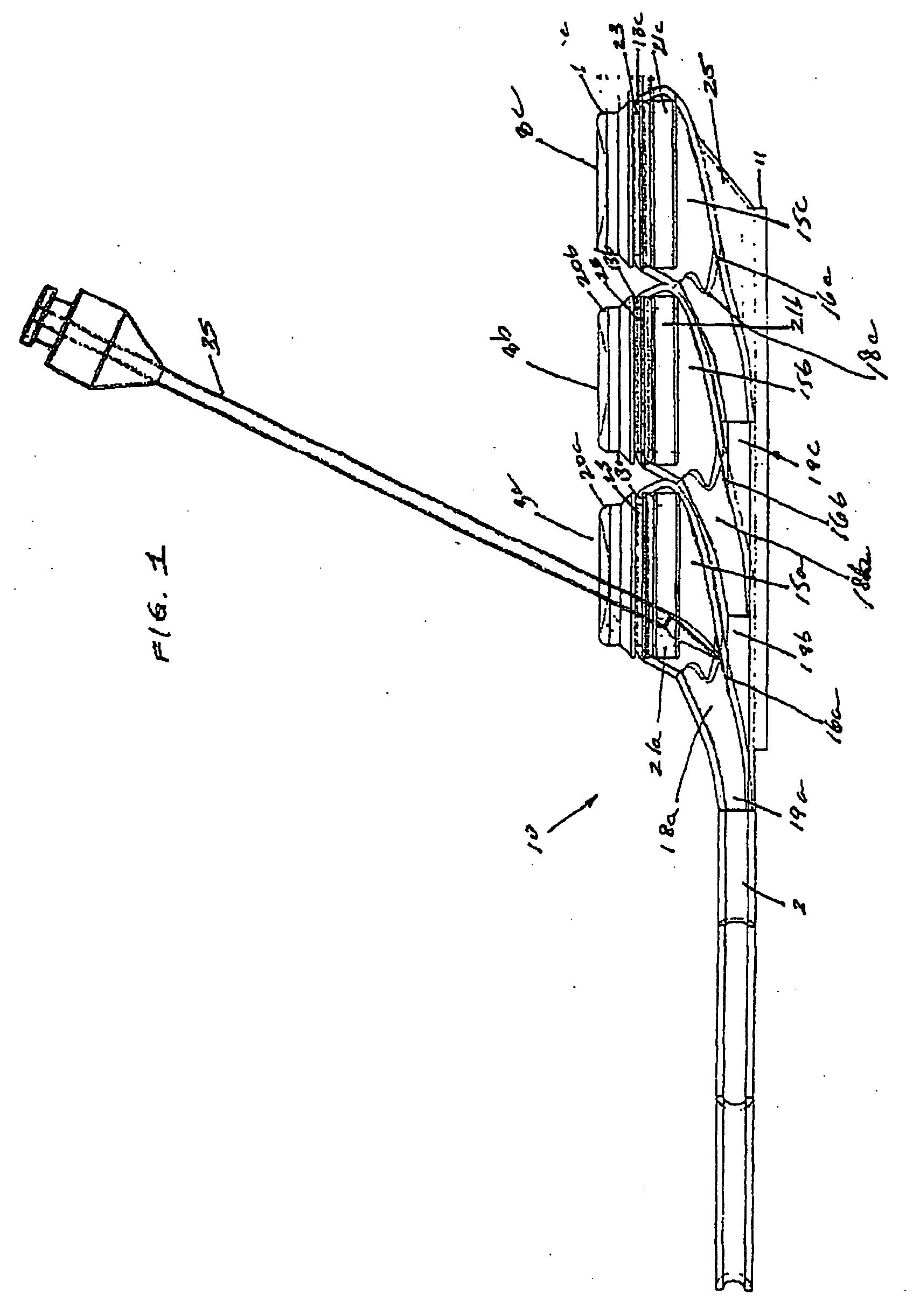

Implantable hemodialysis access device

InactiveUS6962577B2Extend equipment lifeLess traumaPharmaceutical delivery mechanismMedical devicesHaemodialysis machineDilator

A hemodialysis port comprising a flexible housing member defining one or more ports. Each port has a selectively-permeable septum member disposed thereon to permit medical devices, for example, Huber needles, sheath and / or dilators to be inserted therein. At the interface between the housing and the septum, a spring member is provided to provide an axial force on the septum which seals the puncture created by the aforementioned medical devices. In one exemplary embodiment, the hemodialysis access port of the present invention is comprised of a plurality of ports designed for multiple hemodialysis treatments over the life of the port. In other exemplary embodiments, the bottom of each port may comprise a needle stop insert formed of, for example, metal, titanium, stainless steel or ceramic.

Owner:VERSAGO VASCULAR ACCESS

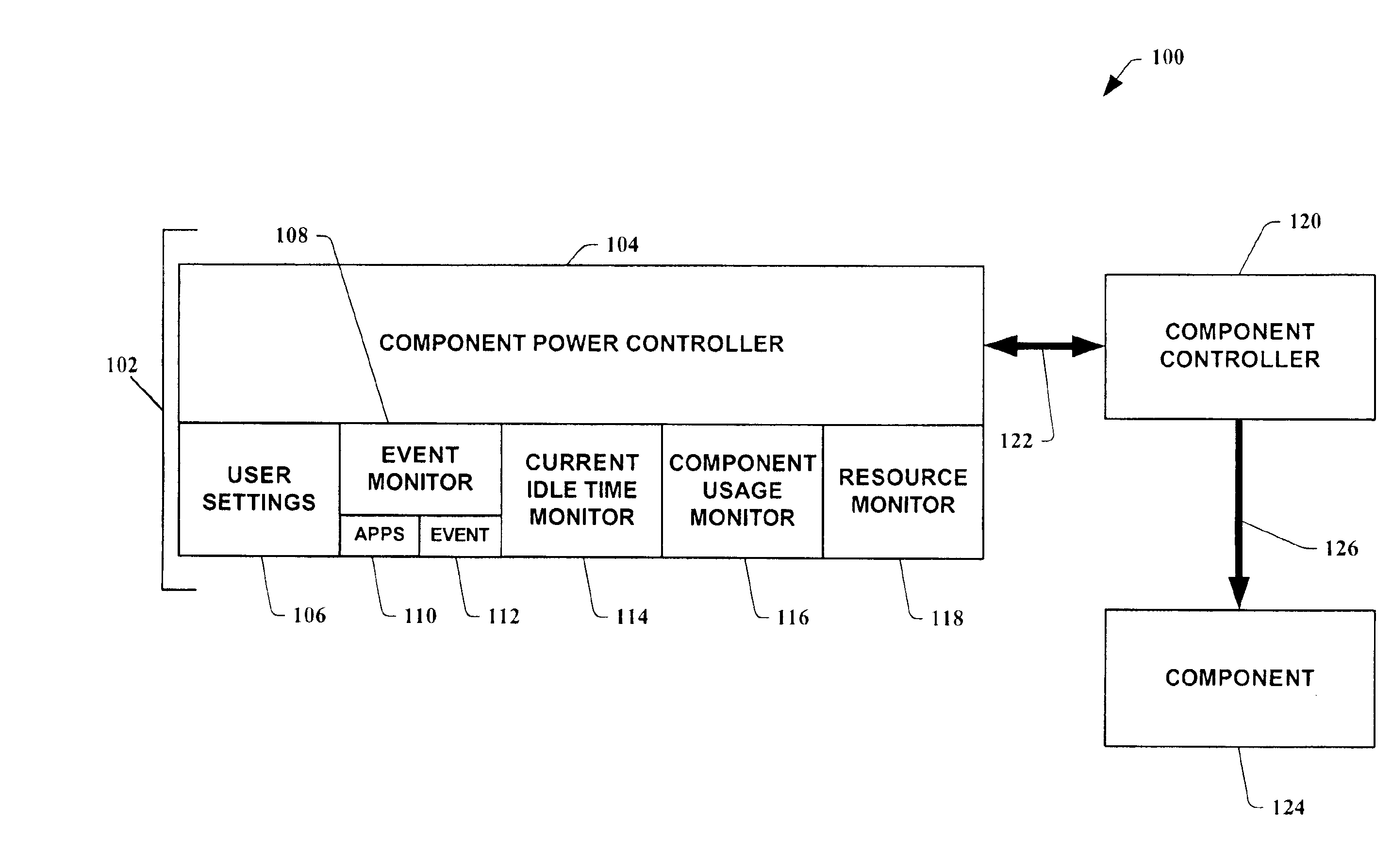

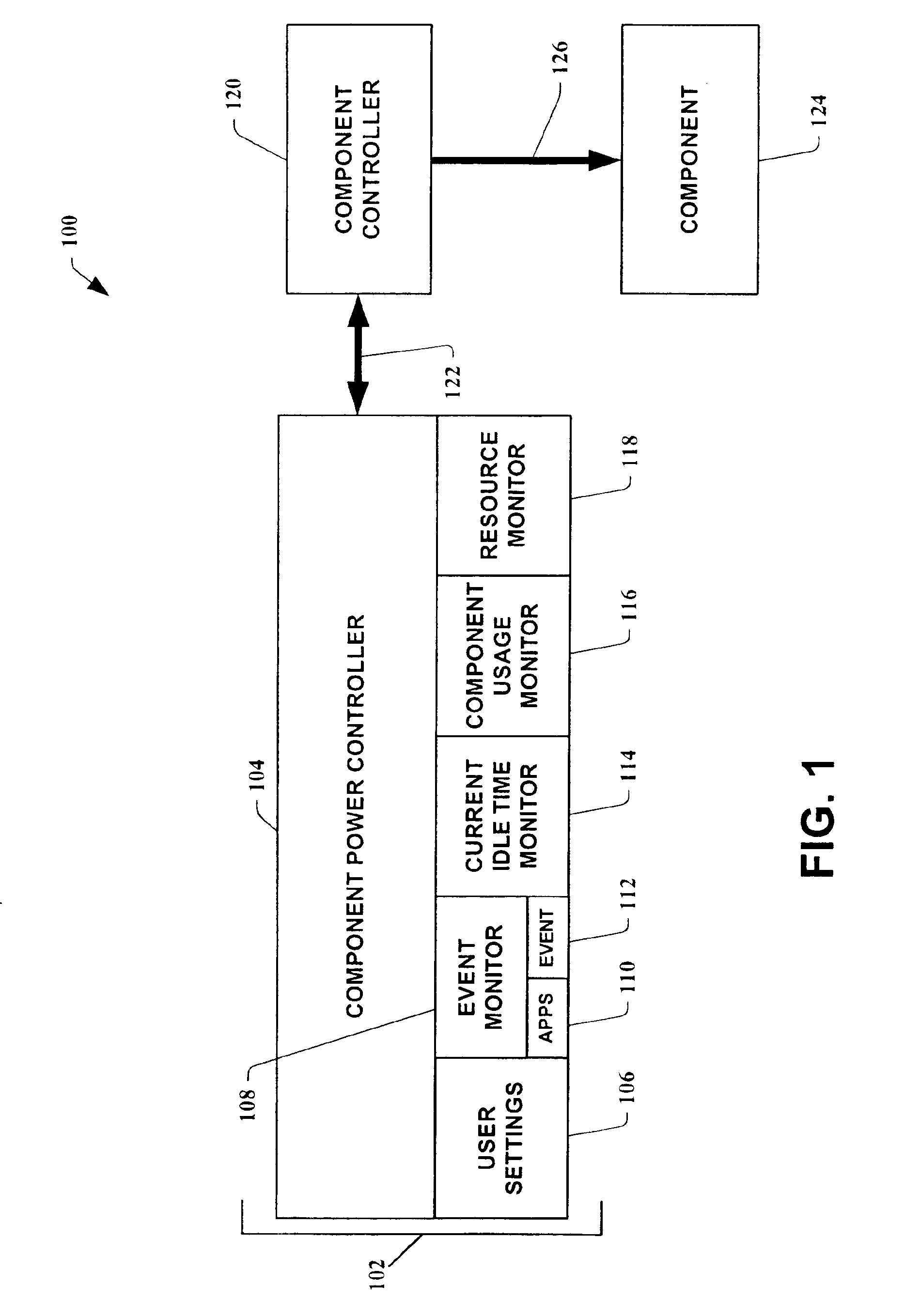

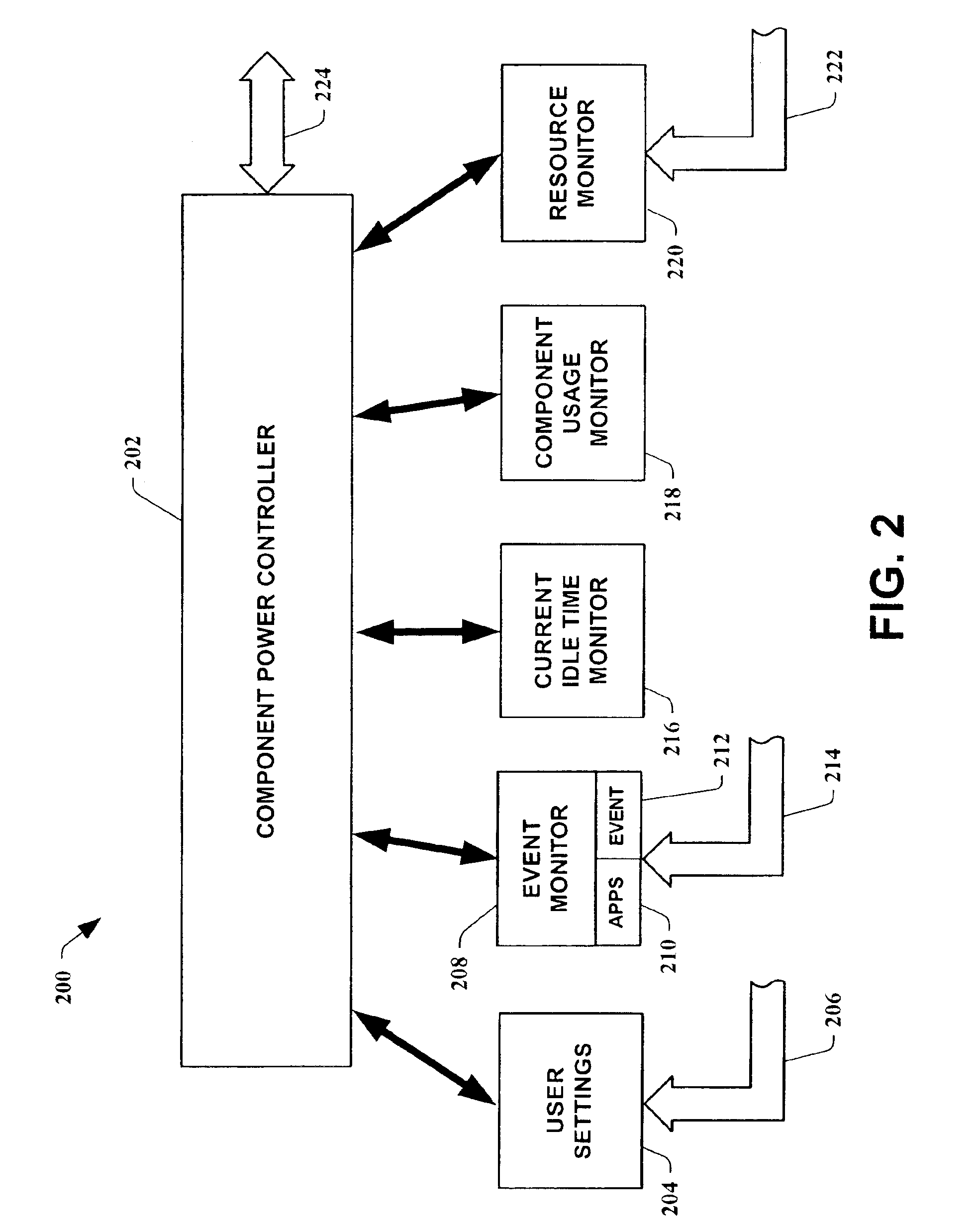

Dynamic power control apparatus, systems and methods

InactiveUS6885974B2Reduce dependenceImprove practicalityEnergy efficient ICTElectric devicesPower controllerIdle time

Dynamic power controller apparatus, systems and methods are provided which utilize system and user data to control power to components. The present invention employs dynamically controlled idle timeout values which are based, in part, on the historical use of the component. It can also employ user settings, event occurrences and available resources of a system to dynamically control the power to one of the system's components or a remote component. In an instance of the present invention related to hard disk power control, it is employed in an operating system's kernel where disk idleness is monitored. When the hard disk's idle time meets a dynamically computed power control idle timeout, the disk driver is commanded to power down the device.

Owner:MICROSOFT TECH LICENSING LLC

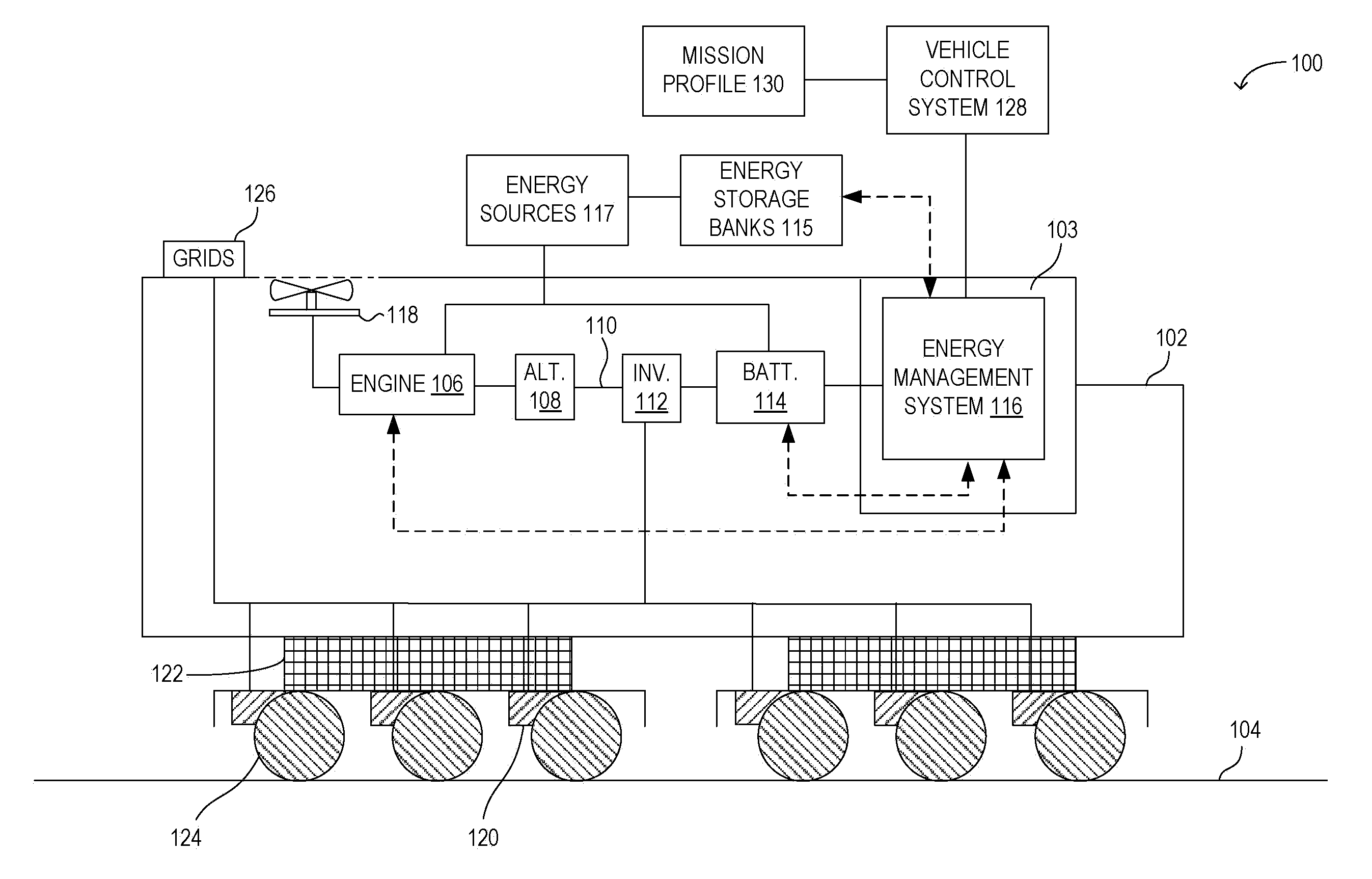

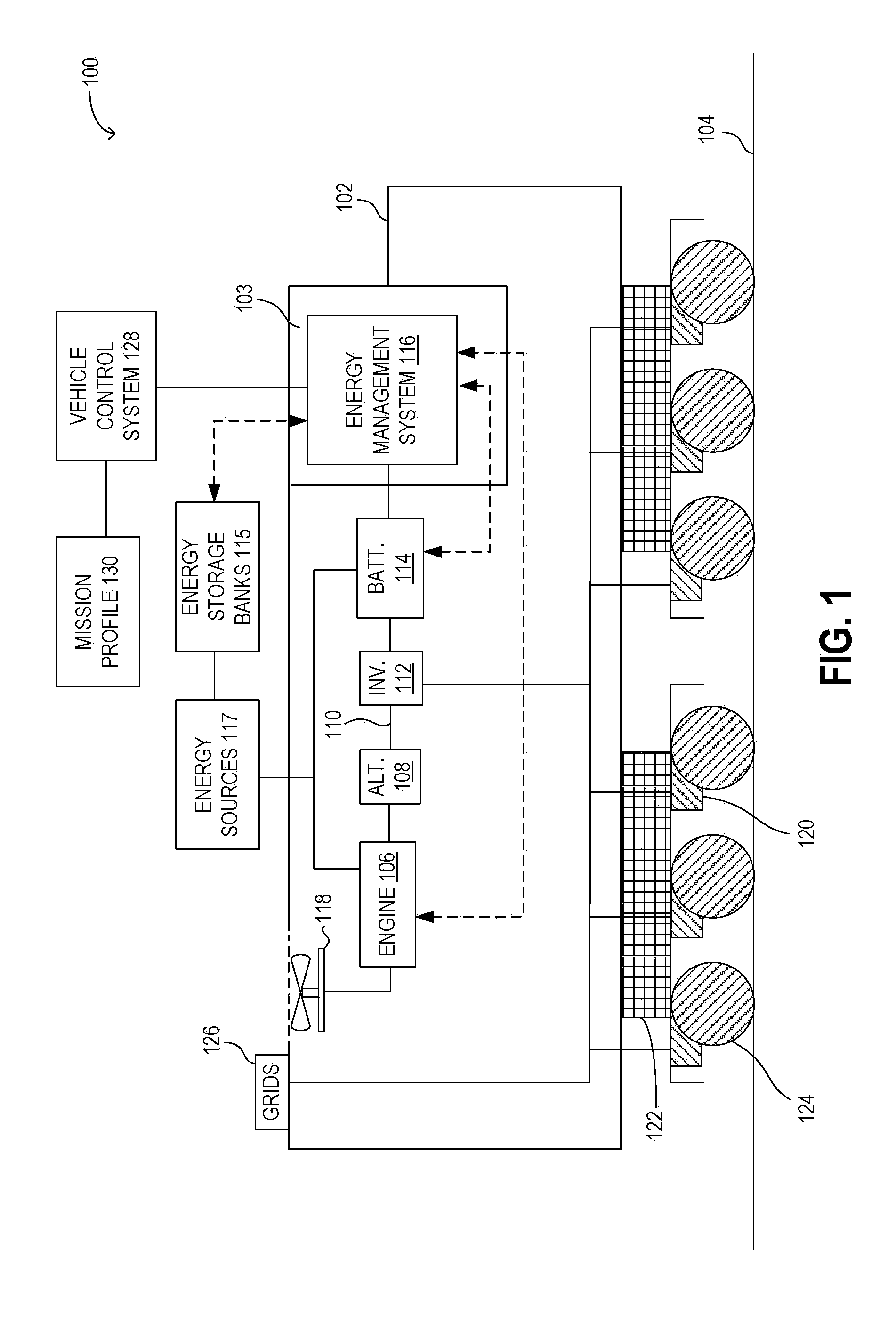

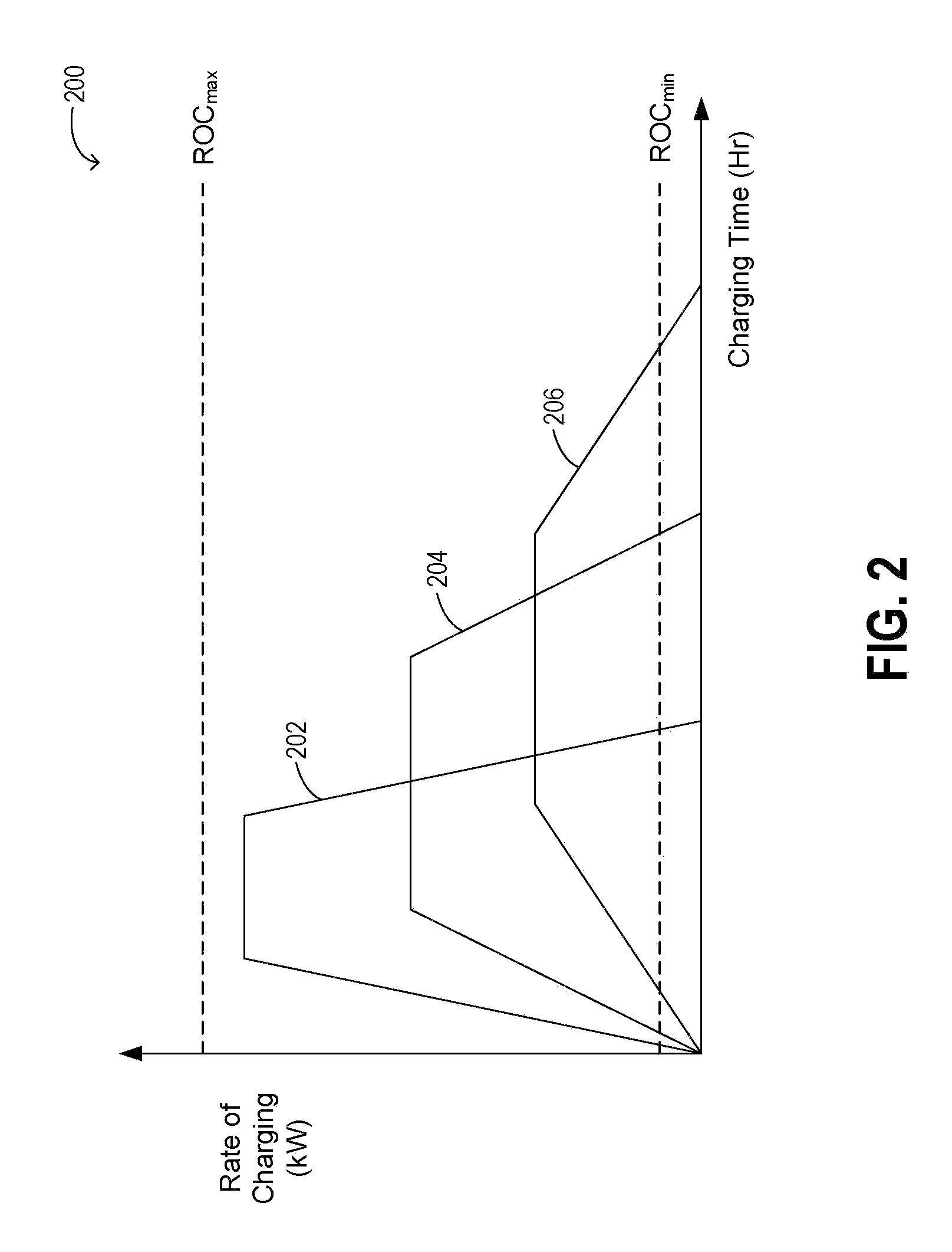

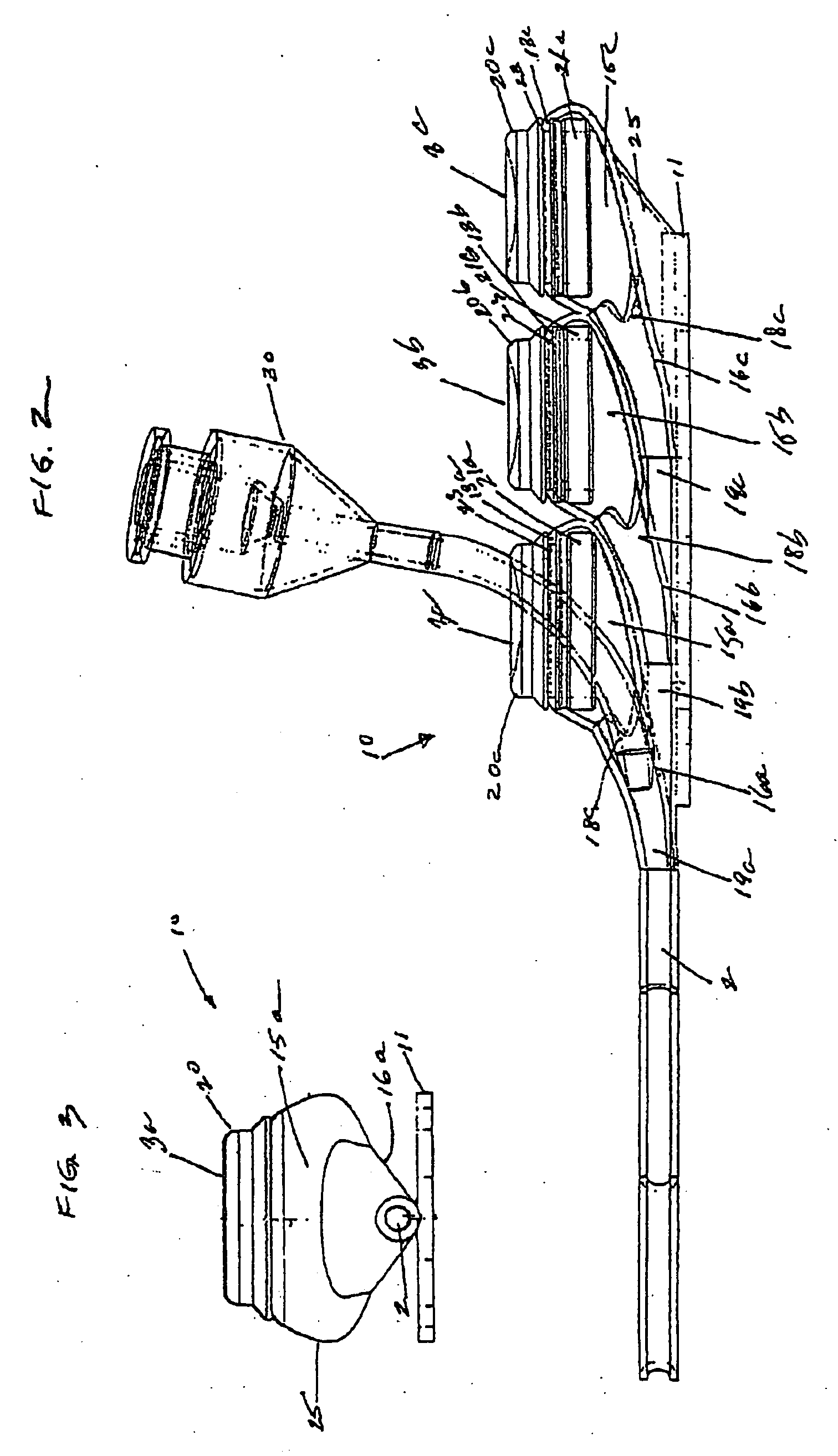

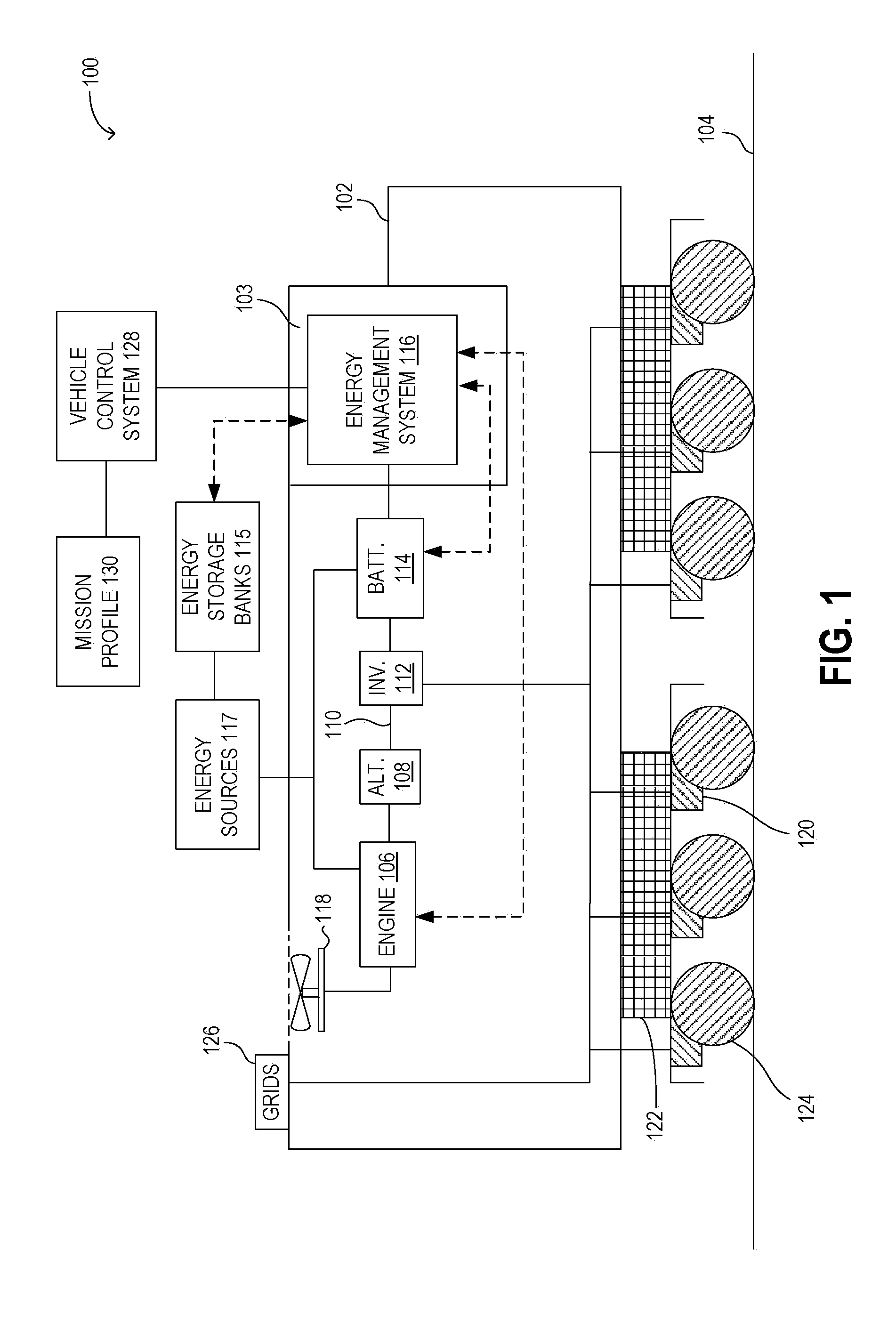

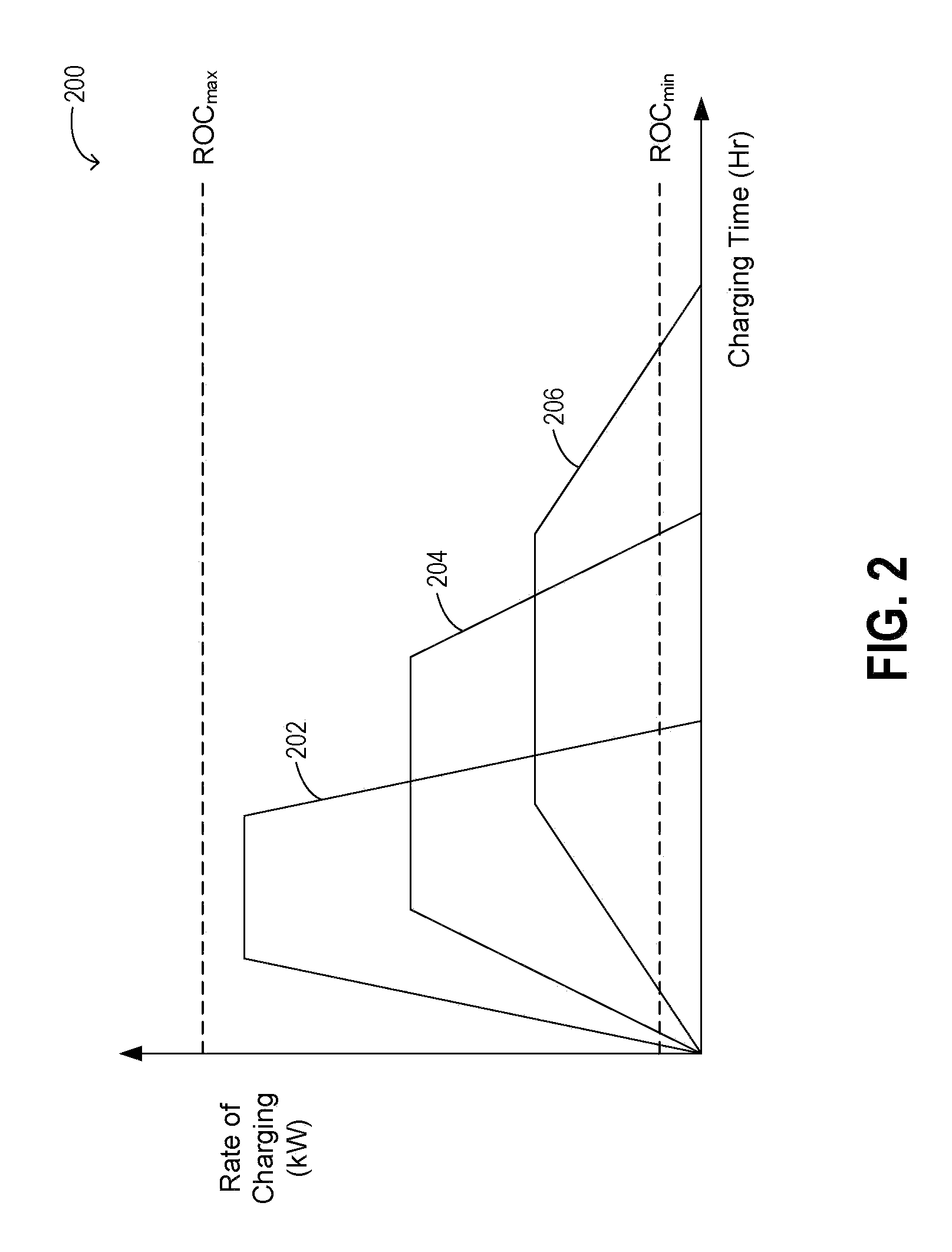

Method and system for extending life of a vehicle energy storage device

InactiveUS20100019718A1Reduce degradationFaster rateBatteries circuit arrangementsElectric devicesElectric power transmissionState of charge

Methods and systems are provided for controlling a power transfer rate in to and / or out of a vehicle energy storage device to affect a current state of charge of the energy storage device. The vehicle may be on a mission comprising a plurality of future power transfer opportunities. In one example, the method comprises adjusting the power transfer rate based on an estimated duration of a future power transfer opportunity. Further, the method may include, if the estimated duration of the future power transfer opportunity is different from a predetermined threshold, changing the power transfer rate at the future power transfer opportunity. The method allows the operating life of the energy storage device to be extended.

Owner:GENERAL ELECTRIC CO

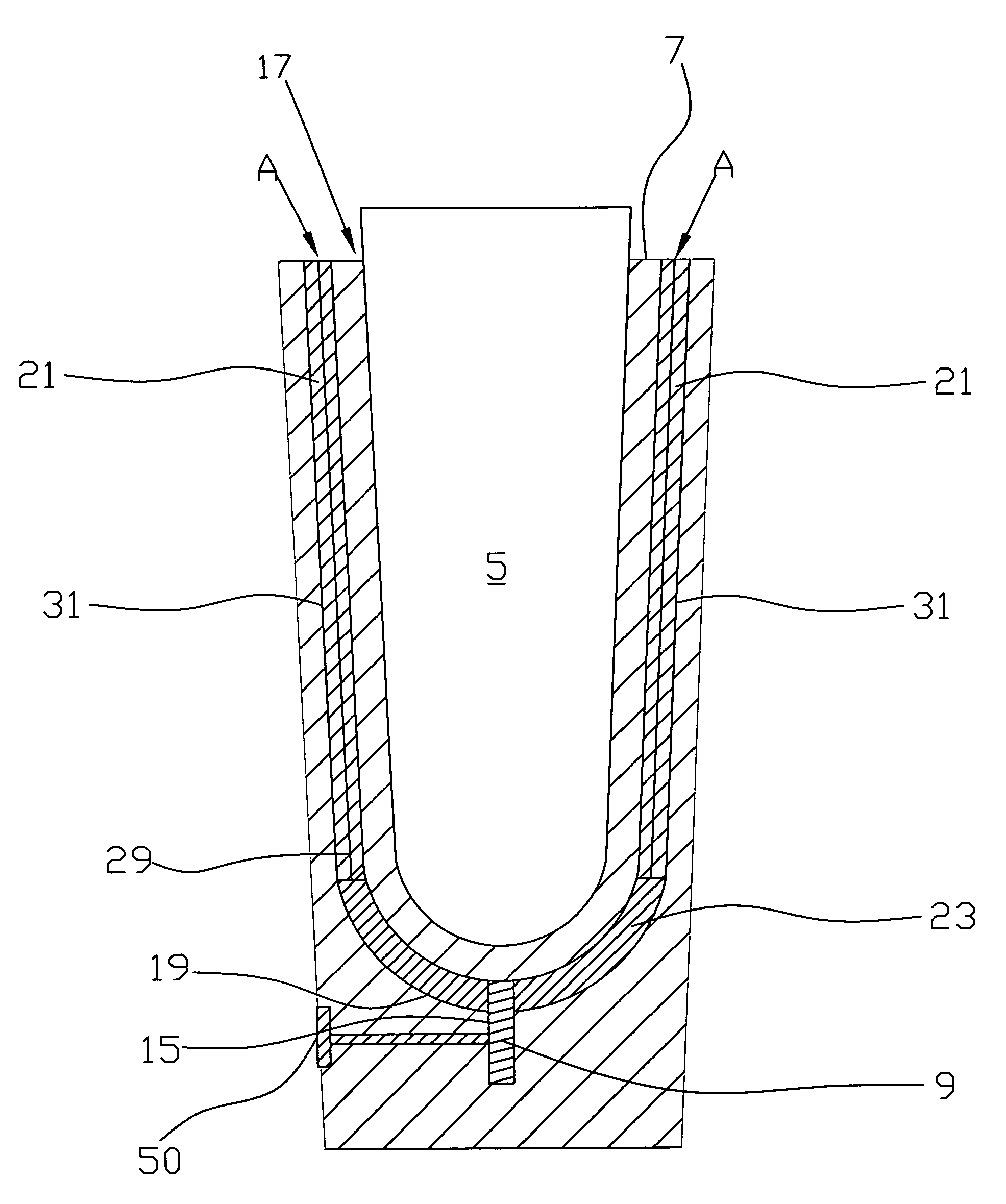

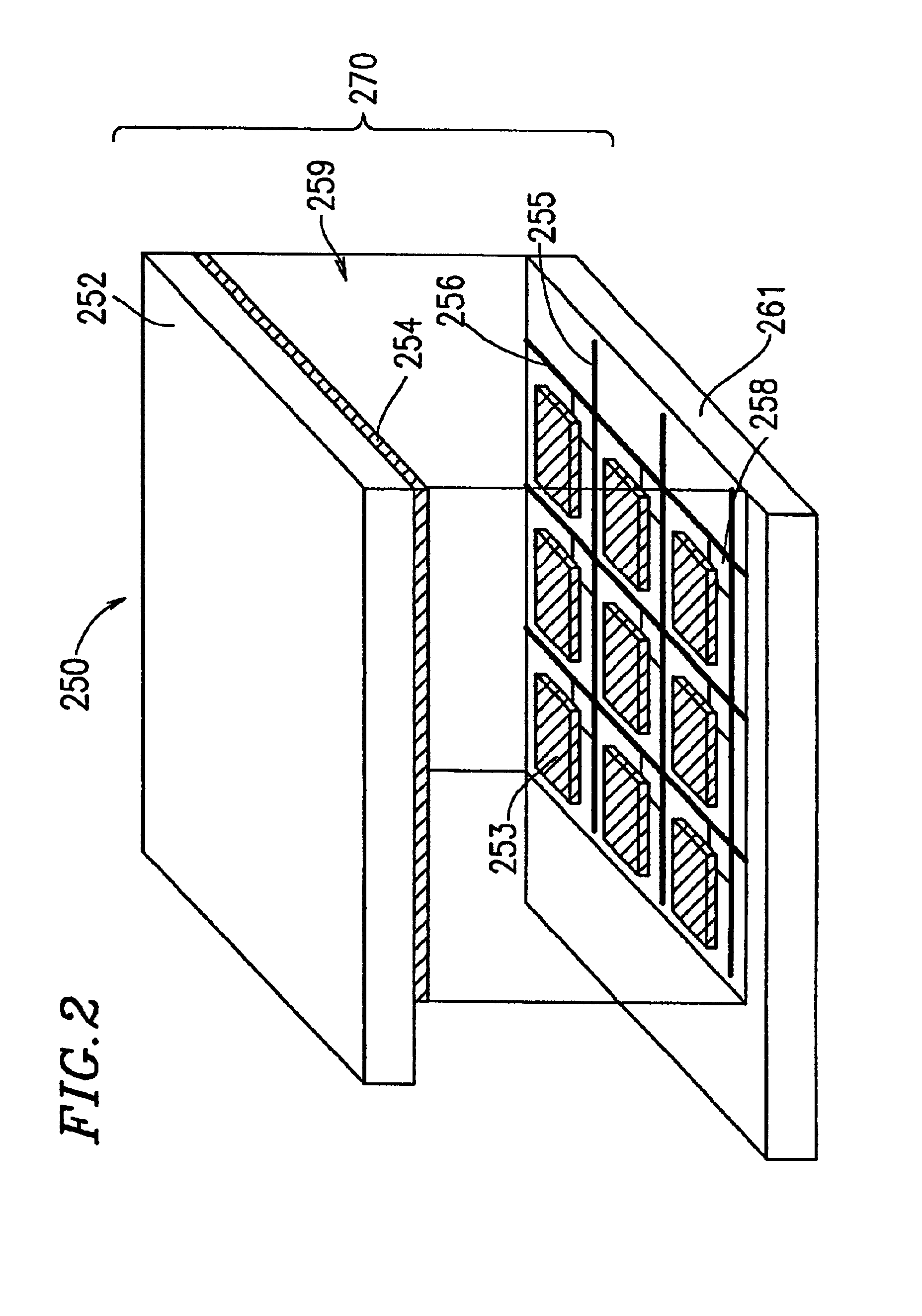

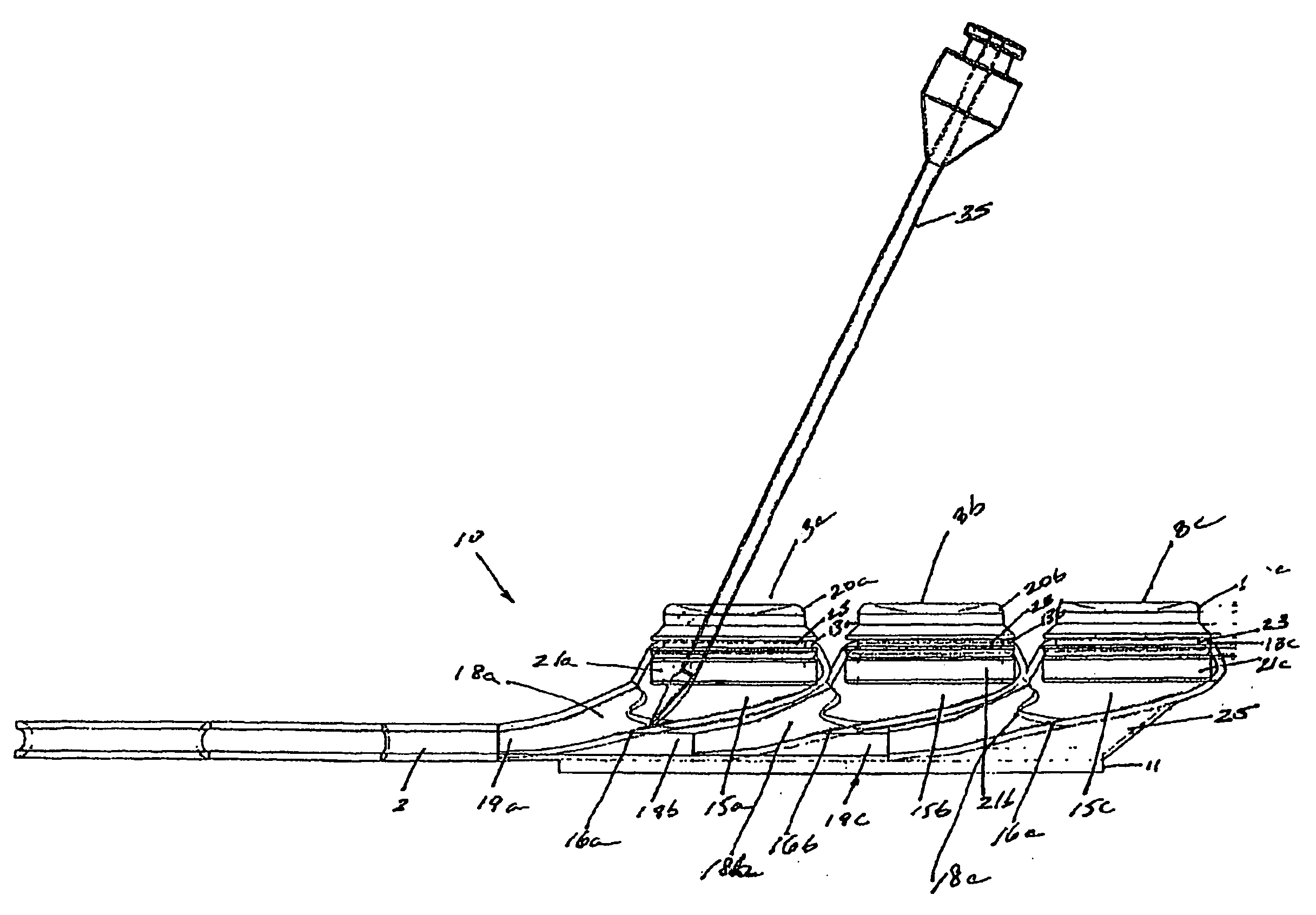

Implantable hemodialysis access device

InactiveUS20060058744A1Extend equipment lifeLess traumaMedical devicesHaemodialysis machineHemodialysis access

A implantable hemodialysis port including a housing and a septum. The housing is formed from a flexible material and includes a plurality of chambers. The chambers are fluidly interconnected with one another by integrated outlet passageways. Each of the chambers include a sidewall portion and a funnel portion tapering from the sidewall portion. The septum encloses each of the chambers.

Owner:VERSAGO VASCULAR ACCESS

Method and system for extending life of a vehicle energy storage device

InactiveUS8063609B2Reduce degradationFaster rateBatteries circuit arrangementsElectric devicesElectric power transmissionState of charge

Methods and systems are provided for controlling a power transfer rate in to and / or out of a vehicle energy storage device to affect a current state of charge of the energy storage device. The vehicle may be on a mission comprising a plurality of future power transfer opportunities. In one example, the method comprises adjusting the power transfer rate based on an estimated duration of a future power transfer opportunity. Further, the method may include, if the estimated duration of the future power transfer opportunity is different from a predetermined threshold, changing the power transfer rate at the future power transfer opportunity. The method allows the operating life of the energy storage device to be extended.

Owner:GENERAL ELECTRIC CO

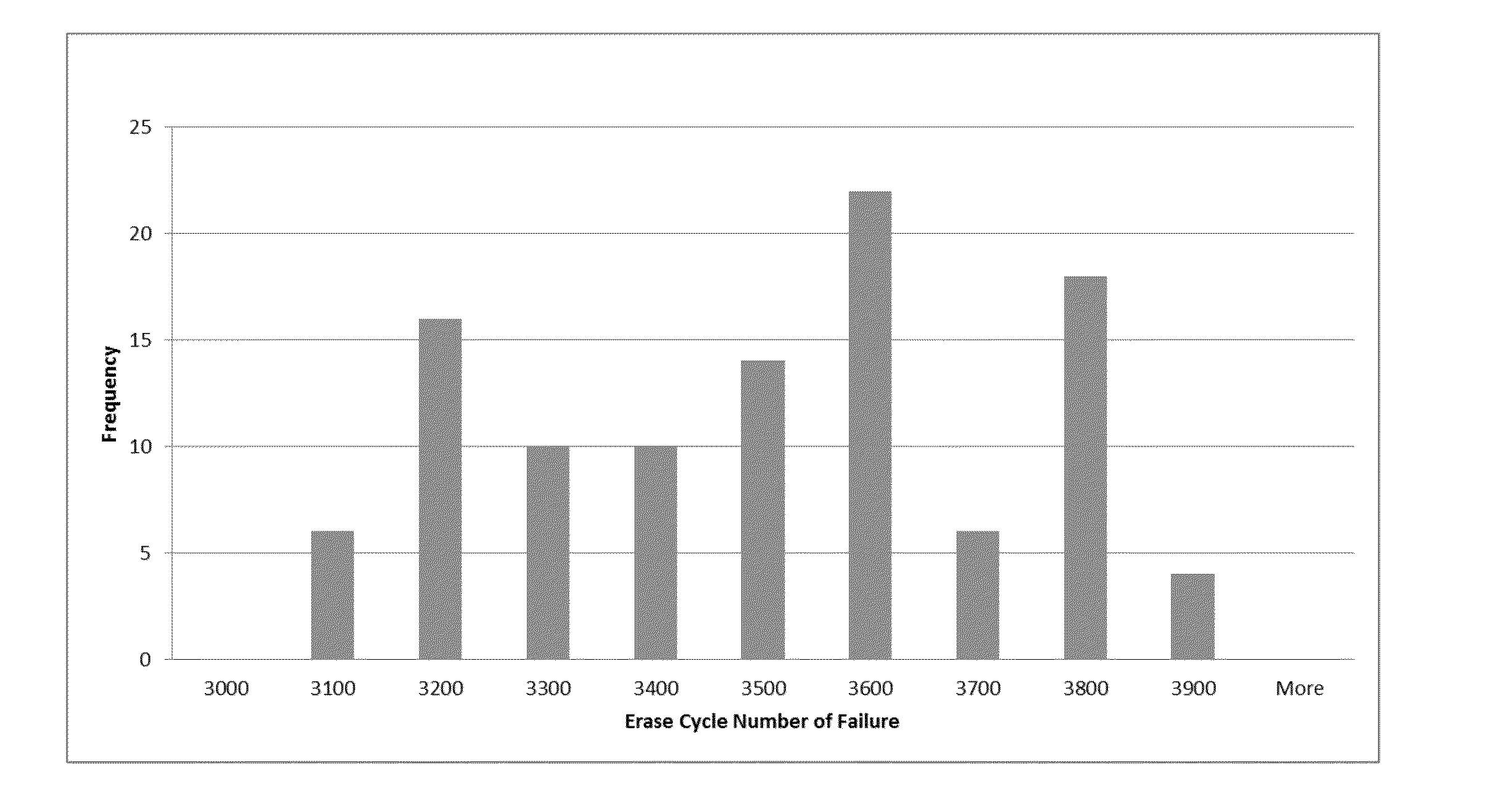

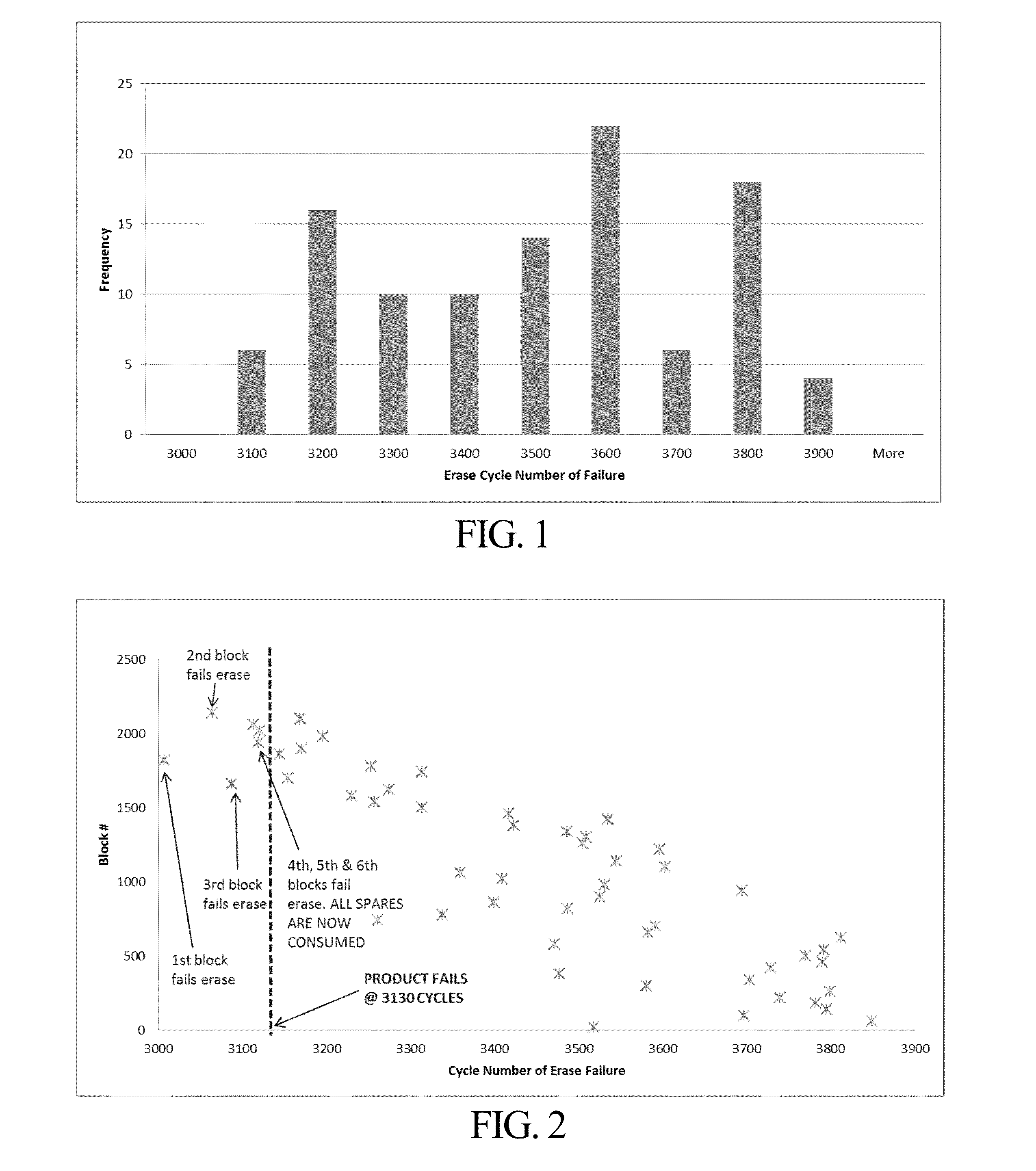

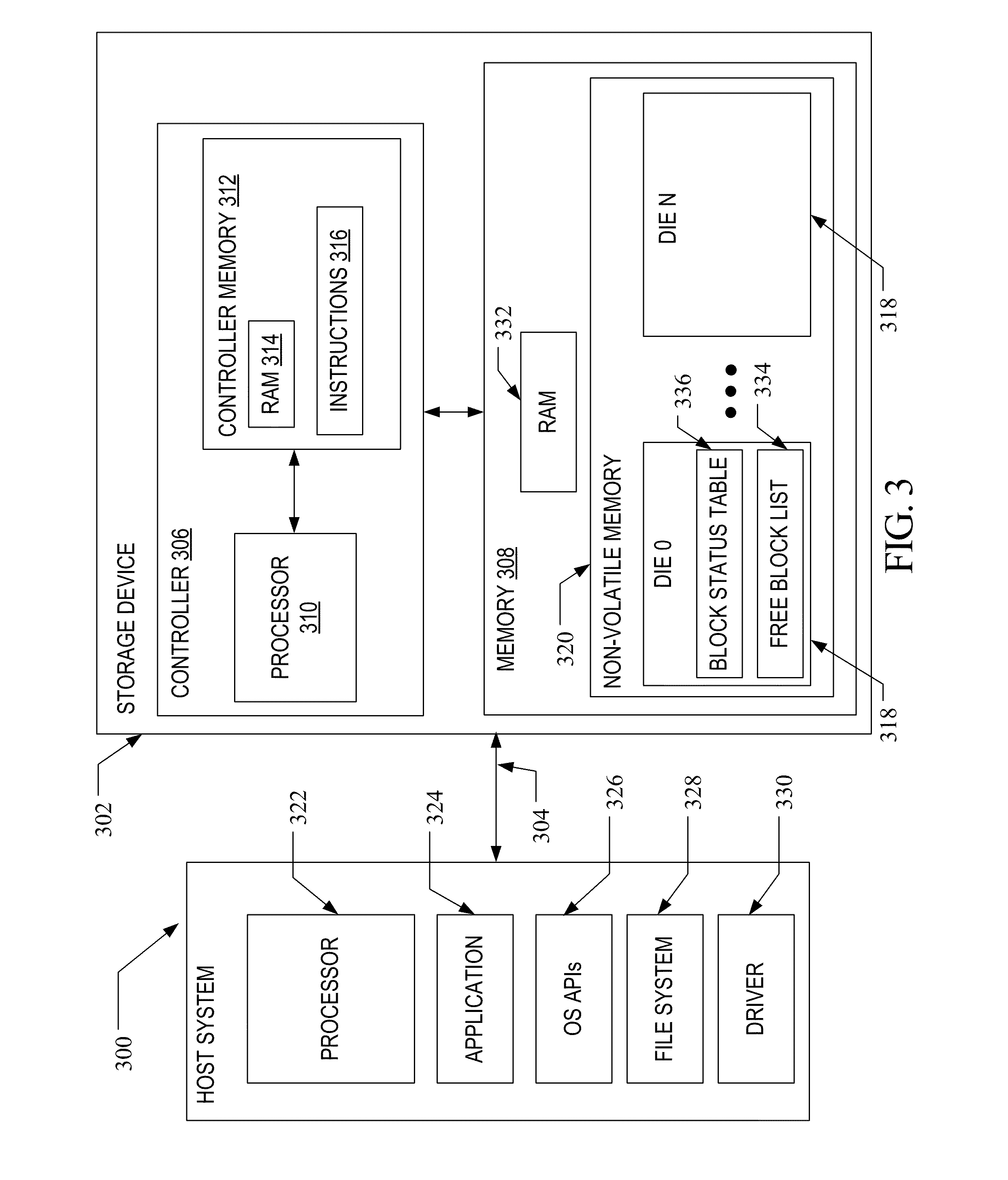

Method and system for predicting block failure in a non-volatile memory

ActiveUS20150186055A1Extend equipment lifeGreat burdenMemory architecture accessing/allocationInput/output to record carriersGarbage collectionReliability engineering

A method and system are disclosed for improved block erase cycle life prediction and block management in a non-volatile memory. The method includes the storage device tracking information relating to a first erase cycle count at which the block erase time exceeded a predetermined threshold relative to a first erase cycle at which this occurred in other blocks. Blocks having a later relative erase cycle at which the erase time threshold is exceeded are assumed to have a greater erase cycle life than those that need to exceed the erase time threshold at an earlier erase cycle. This information is used to adjust wear leveling in the form of free block selection, garbage collection block selection and other block management processes. Alternatively or in combination, the predicted erase cycle life information is used to adjust program and / or erase parameters such as erase voltage and time.

Owner:SANDISK TECH LLC

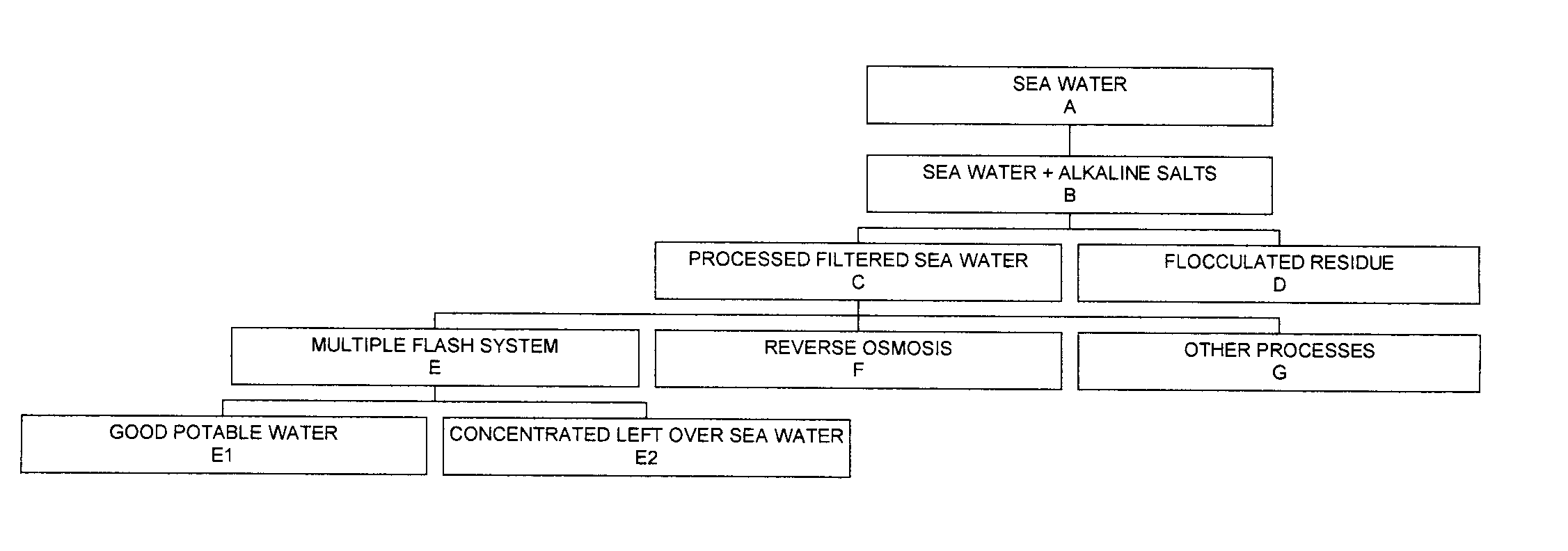

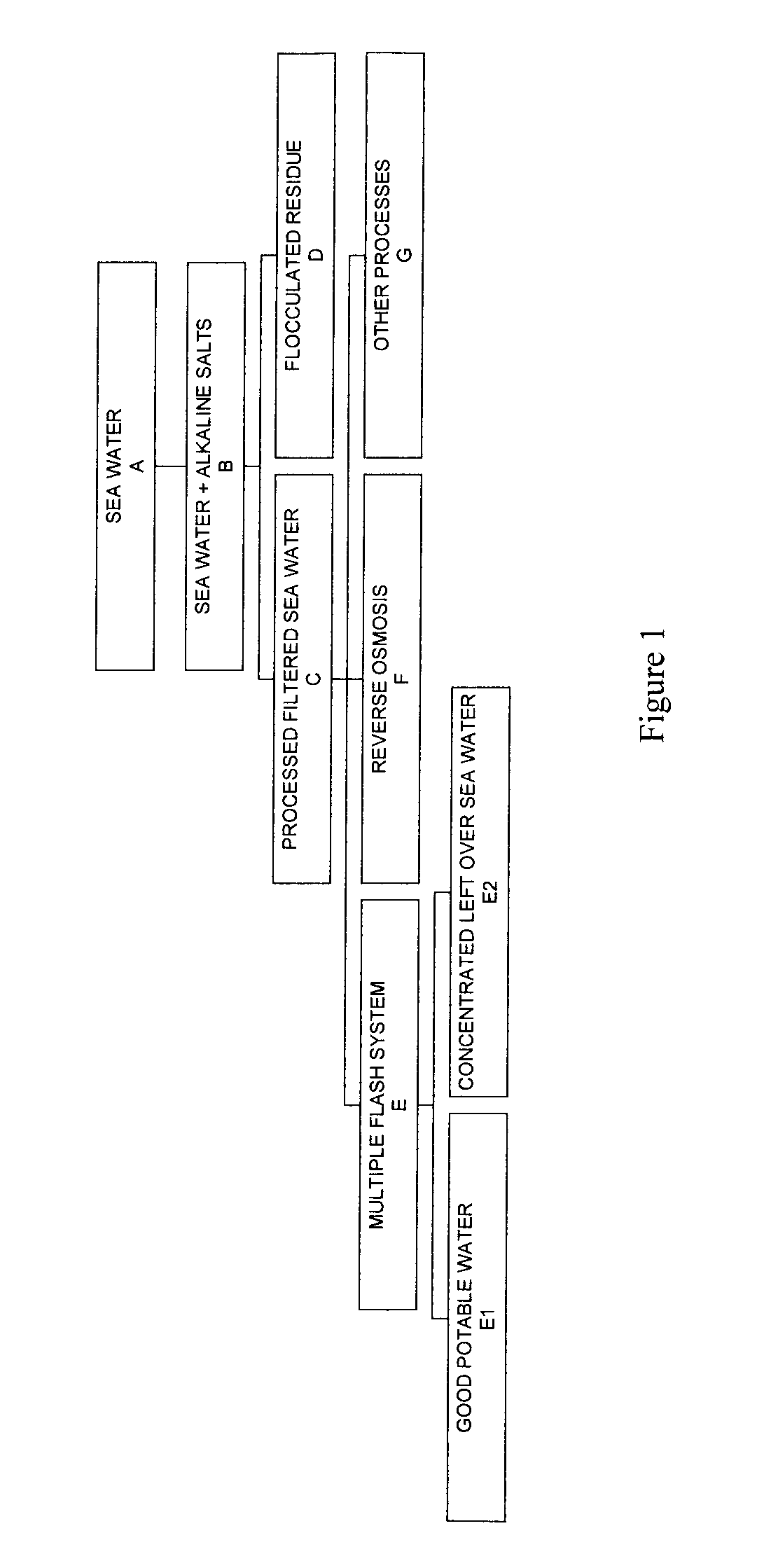

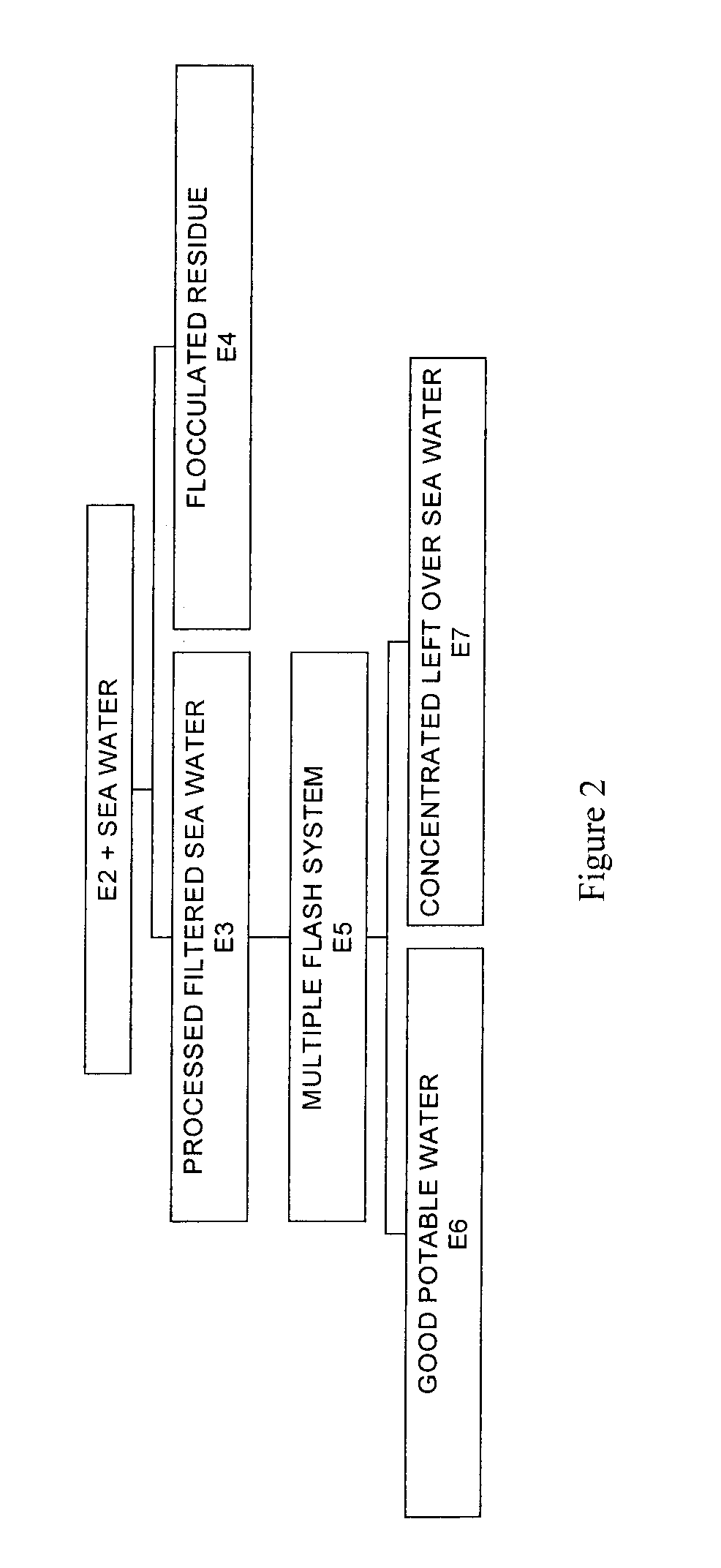

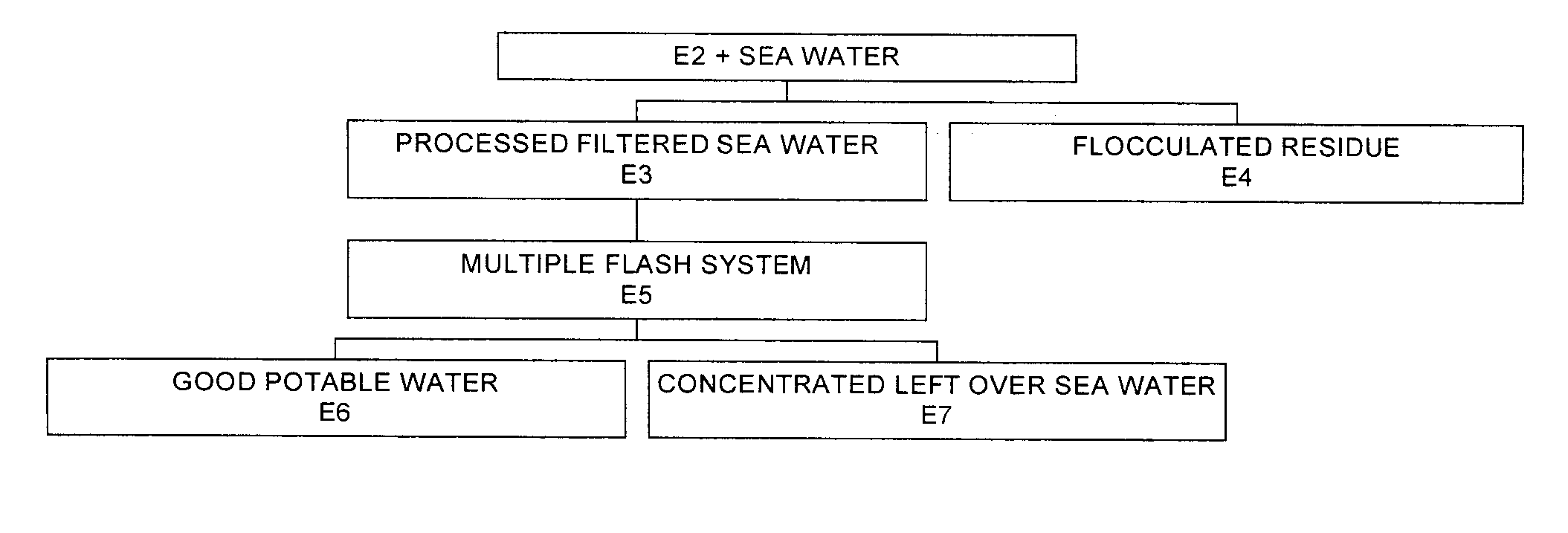

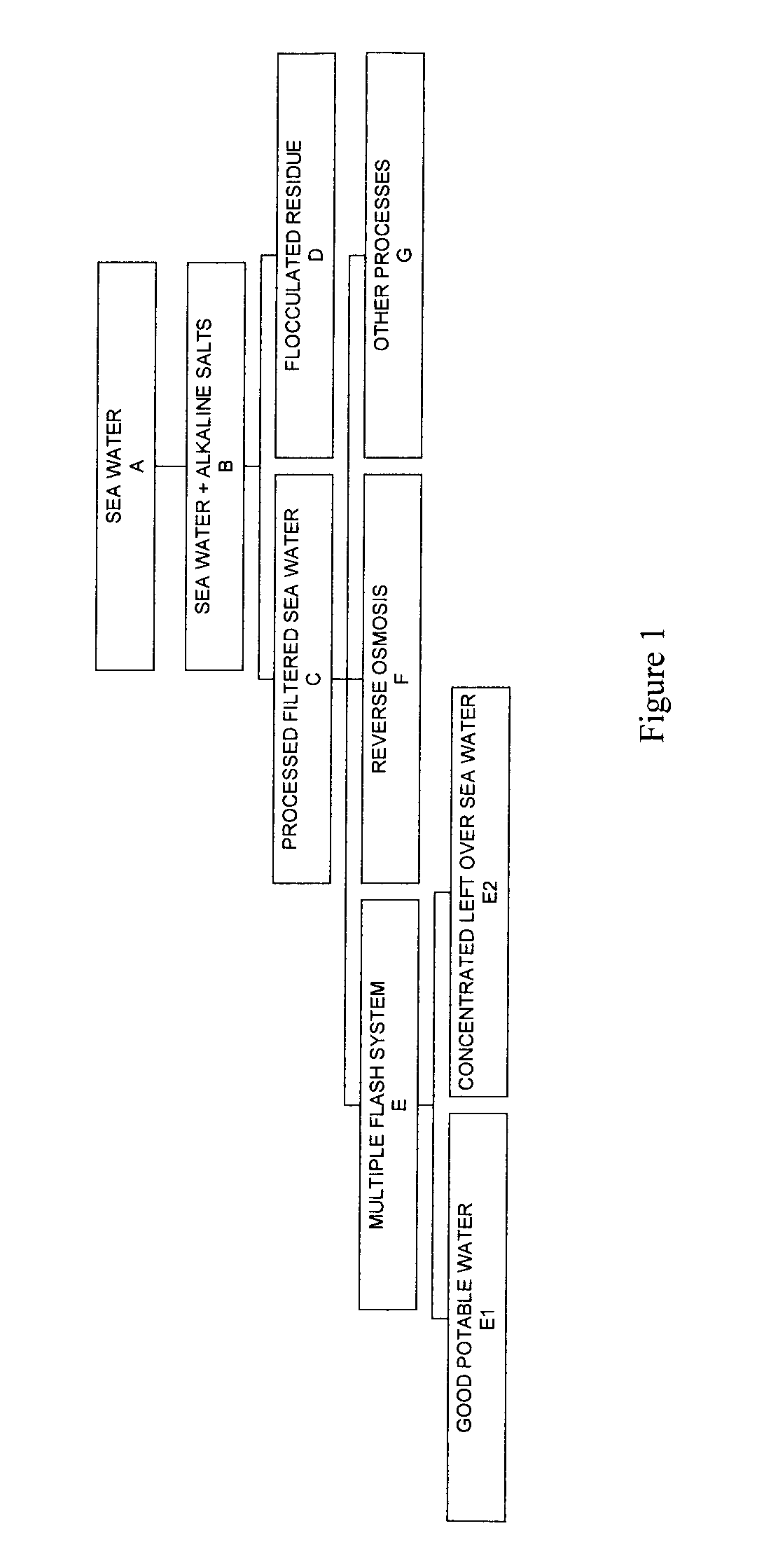

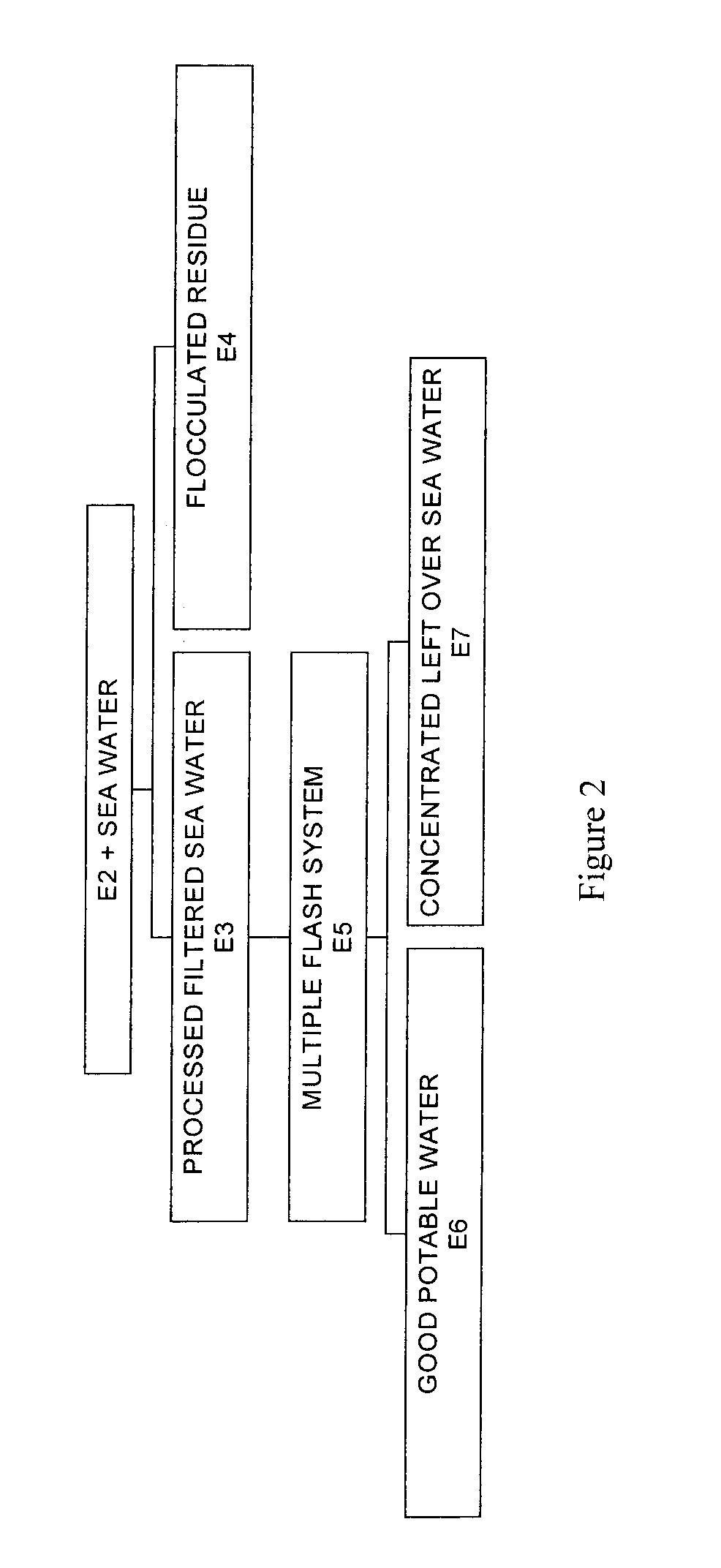

Process for pre-treating and desalinating sea water

ActiveUS20050098499A1Reduce maintenanceExtend equipment lifeGeneral water supply conservationSeawater treatmentCalcium bicarbonatePotassium hydroxide

Water containing dissolved salts, such as calcium sulfate, calcium chloride, magnesium sulfate, magnesium chloride, sodium carbonate, sodium chloride, sodium sulfate, calcium bicarbonate, and mixtures thereof, is treated to reduce the concentration of those salts. About 0.1 to about 60 g / L of sodium hydroxide, sodium carbonate, potassium hydroxide, potassium carbonate, calcium hydroxide, calcium carbonate, aluminum hydroxide, aluminum sulfate, aluminum potassium sulfate, and mixtures thereof is added to the water, whereby a precipitate forms in the water. The precipitate is separated from said water and the water is desalinated using reverse osmosis, flash evaporation, or another method. The process is preferably performed by first adding calcium oxide or calcium hydroxide, separating the precipitate that forms, then adding sodium hydroxide and sodium carbonate to form a second precipitate.

Owner:HUSSAIN MOHAMMED AZAM

Process for pre-treating and desalinating sea water

ActiveUS7198722B2Extend equipment lifeReduce maintenanceGeneral water supply conservationSeawater treatmentCalcium bicarbonateReverse osmosis

Owner:HUSSAIN MOHAMMED AZAM

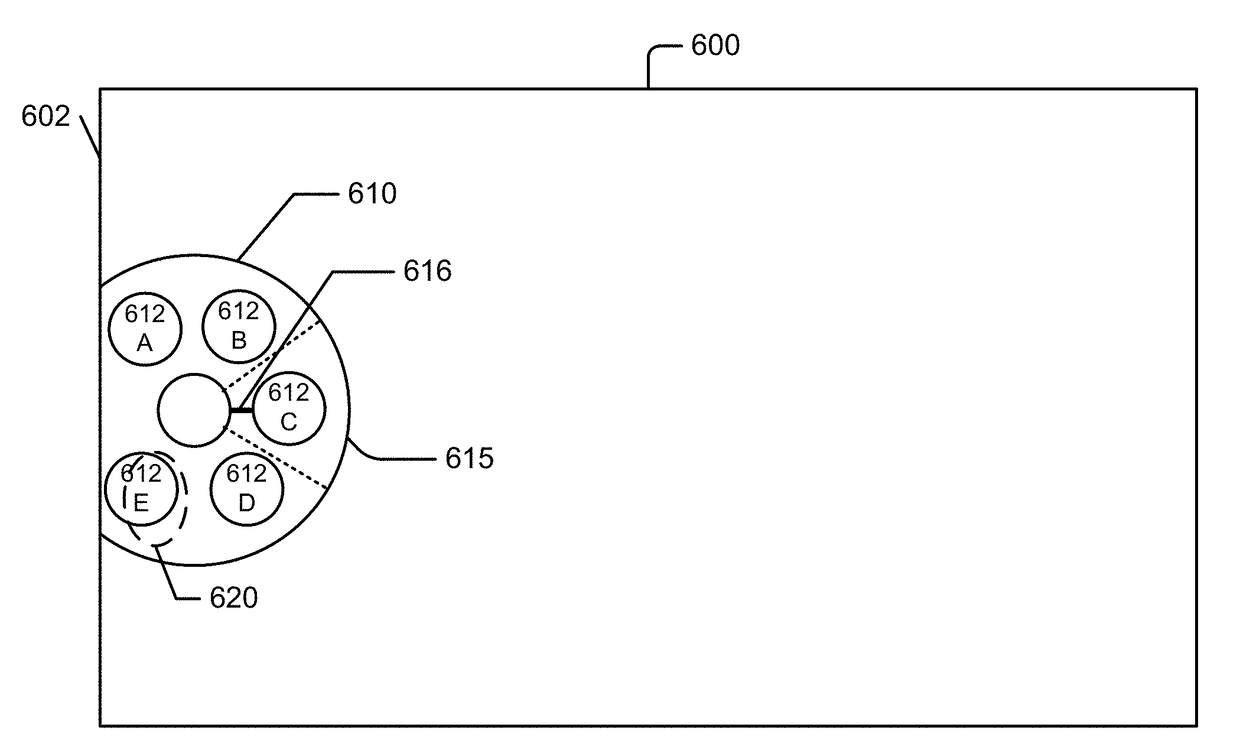

Device, Method, and Graphical User Interface for a Radial Menu System

ActiveUS20170192627A1Increase speedReduce energy useInput/output processes for data processingGraphicsGraphical user interface

Owner:APPLE INC

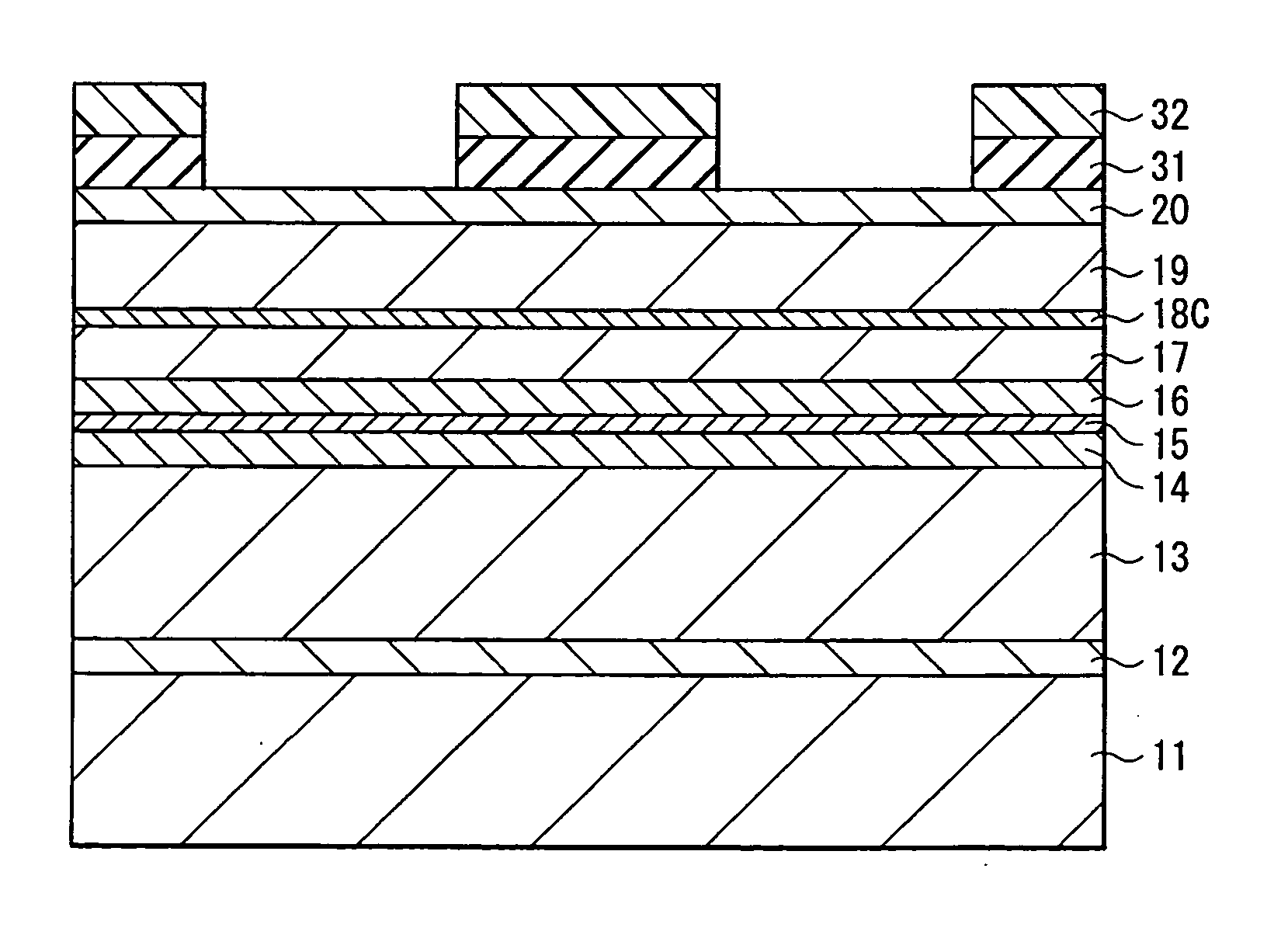

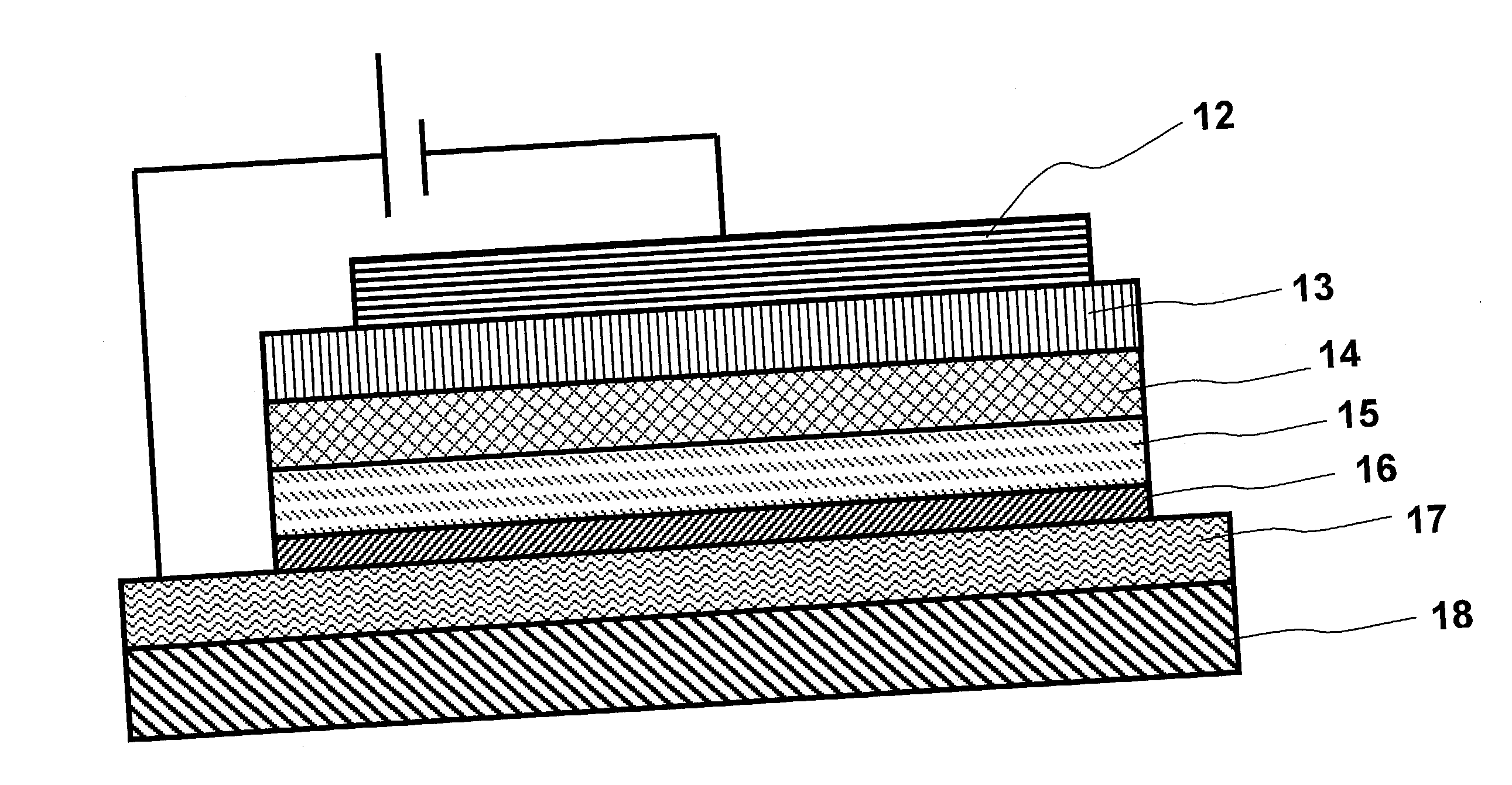

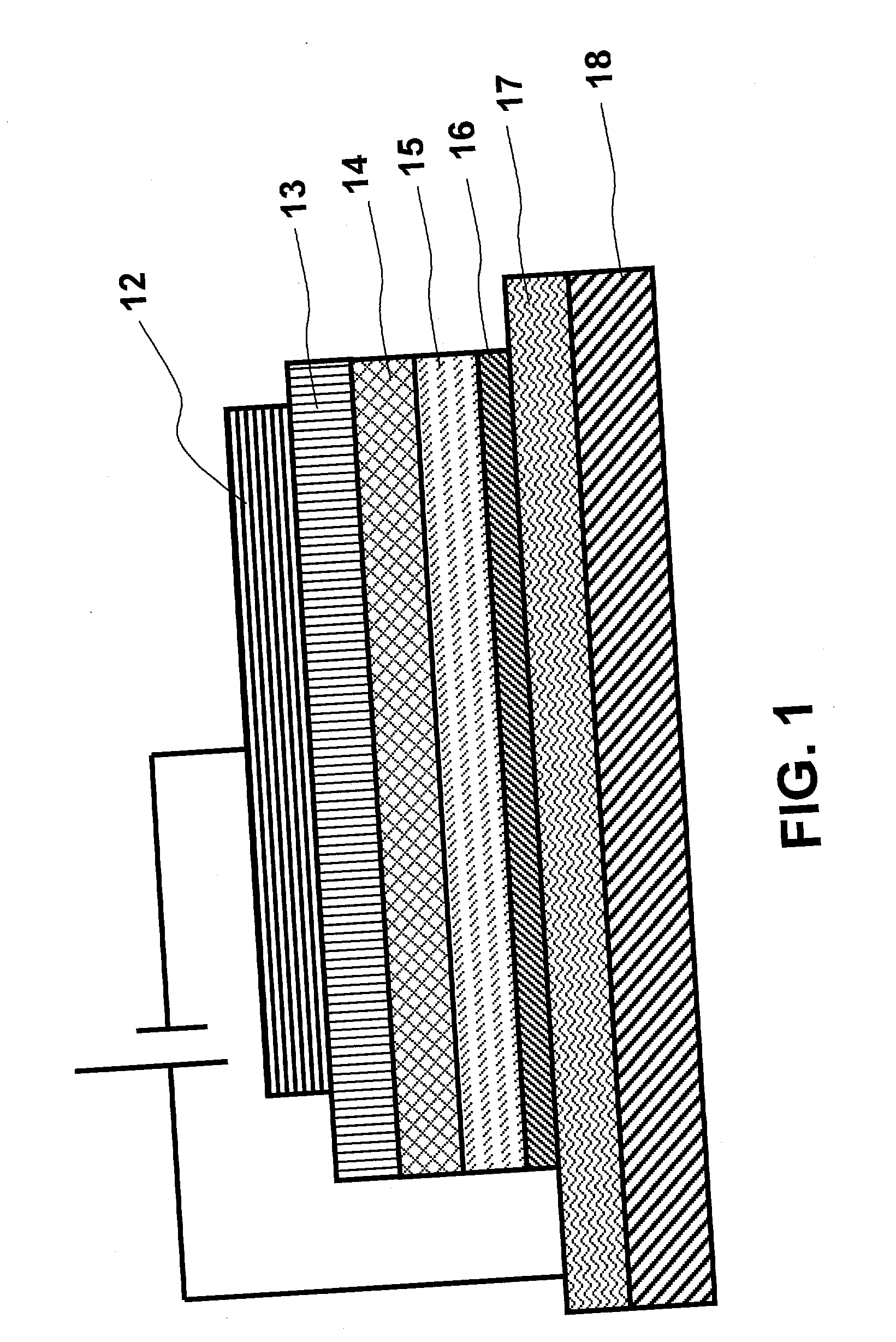

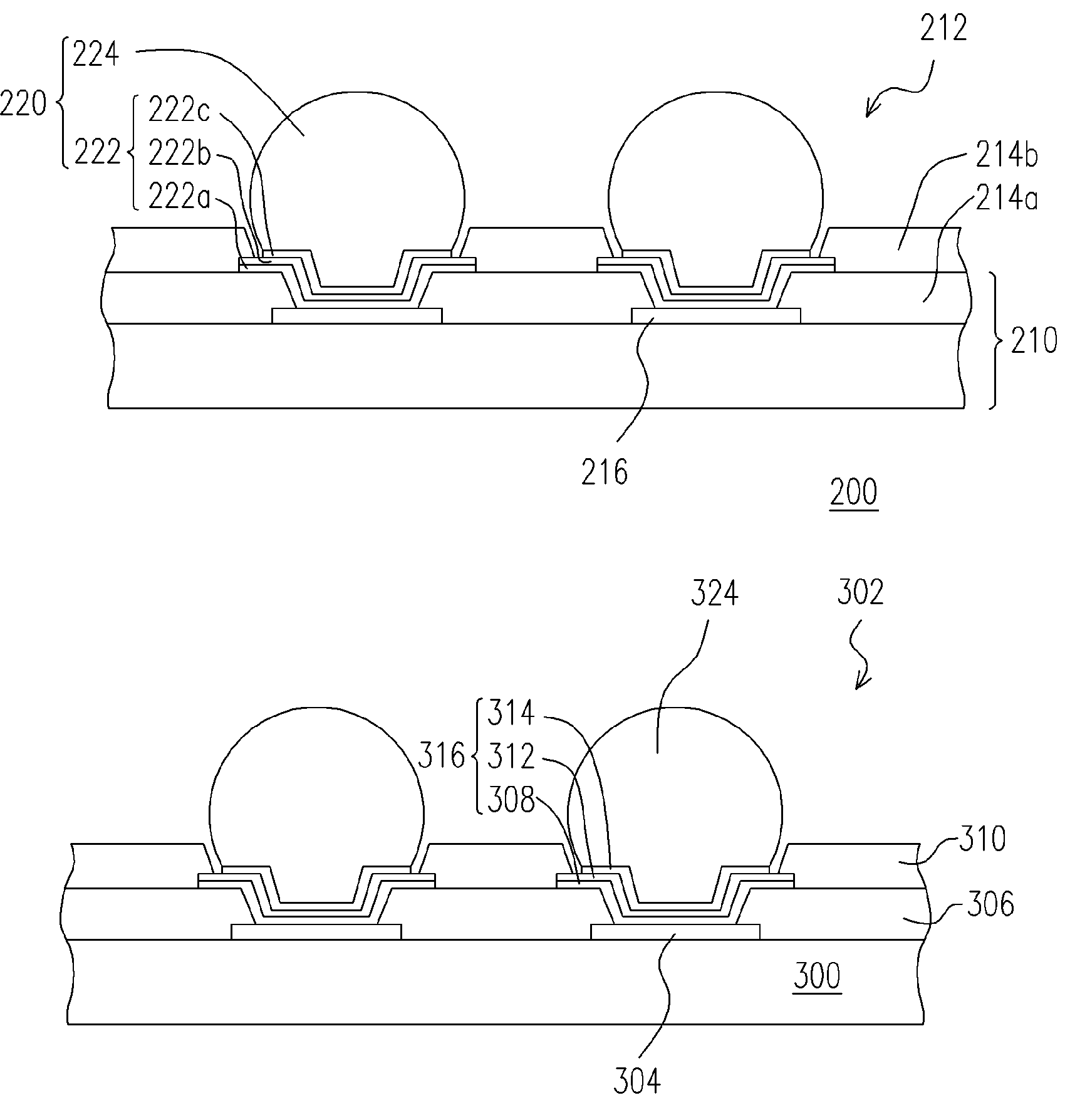

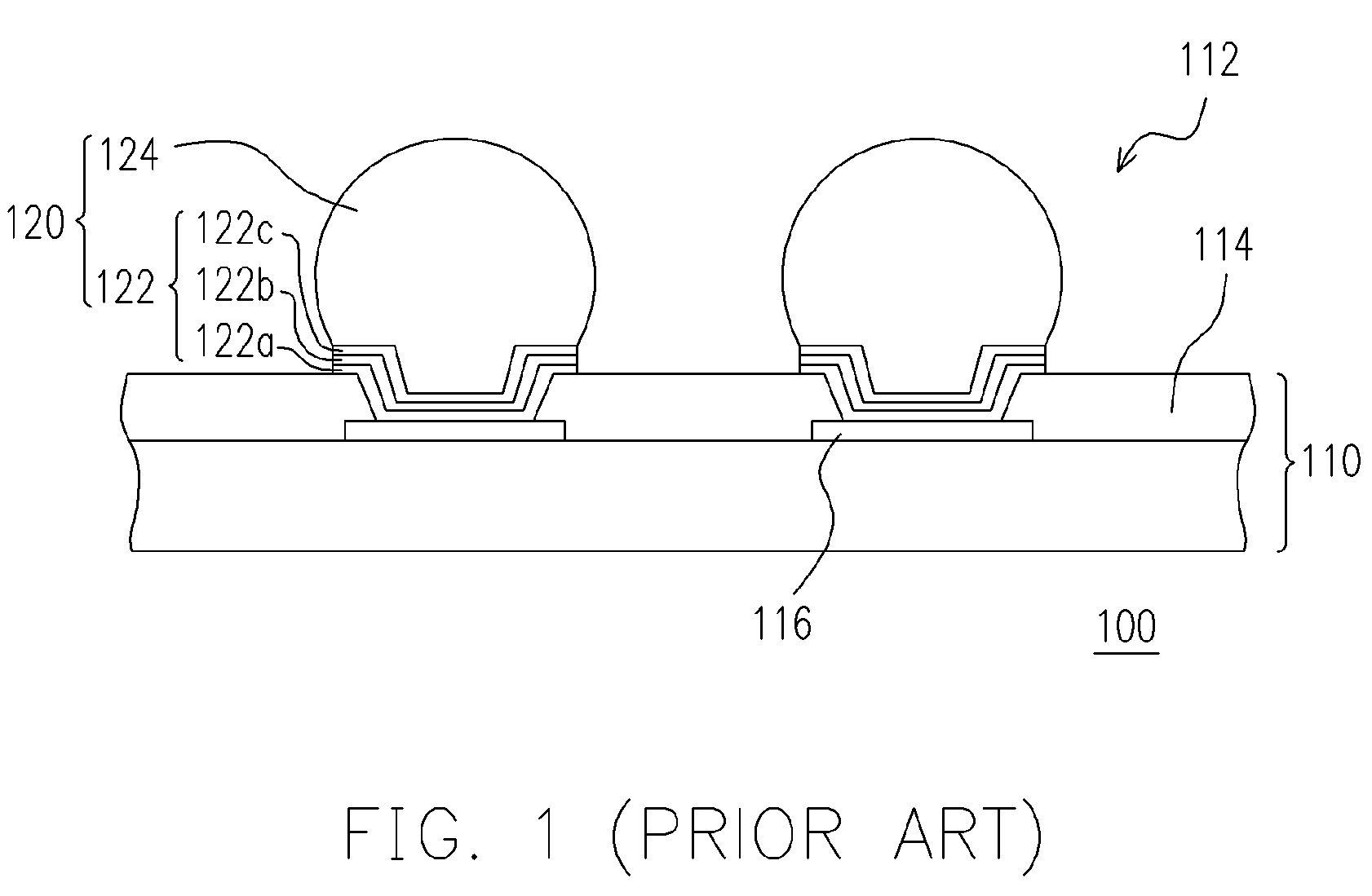

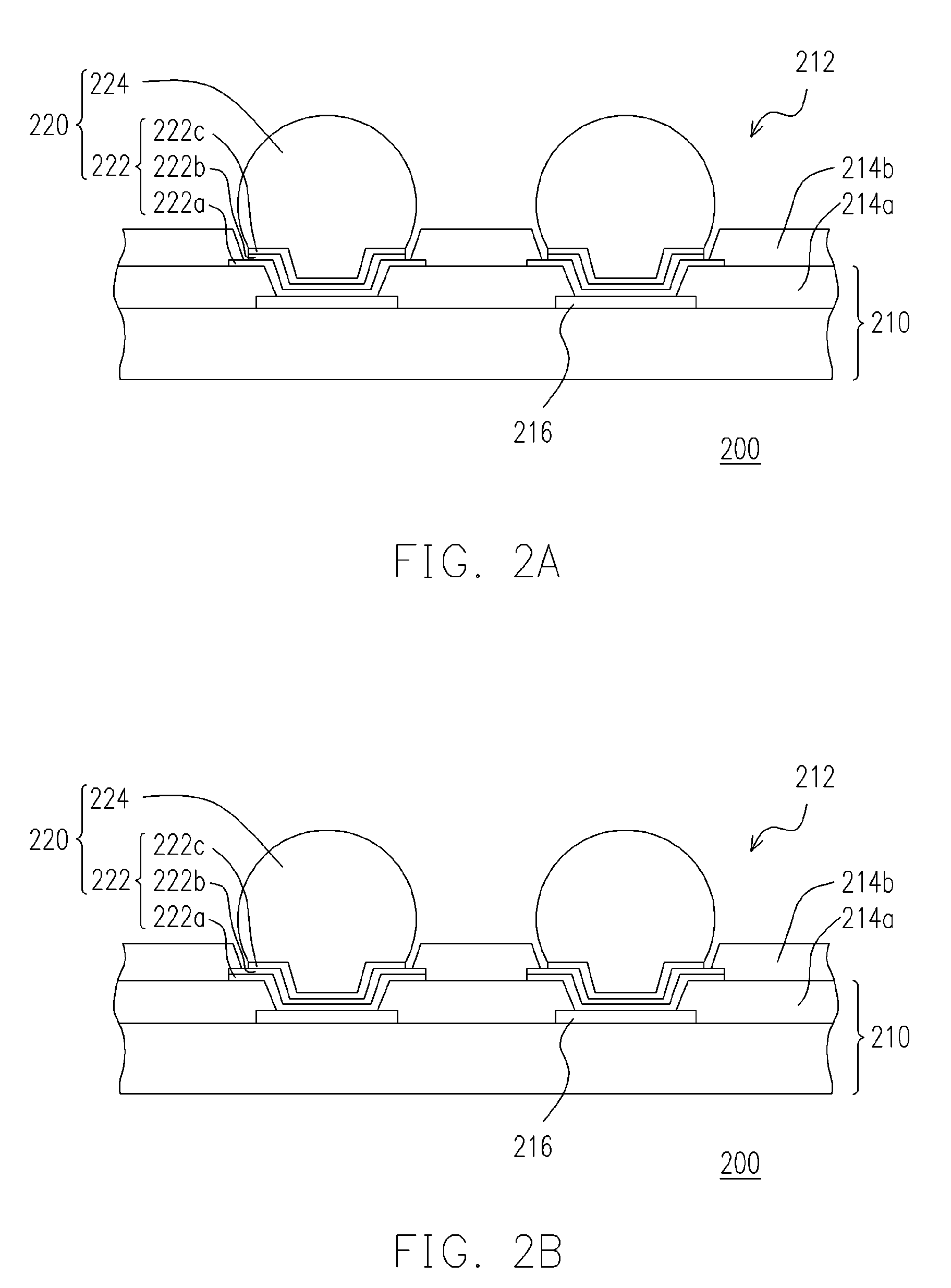

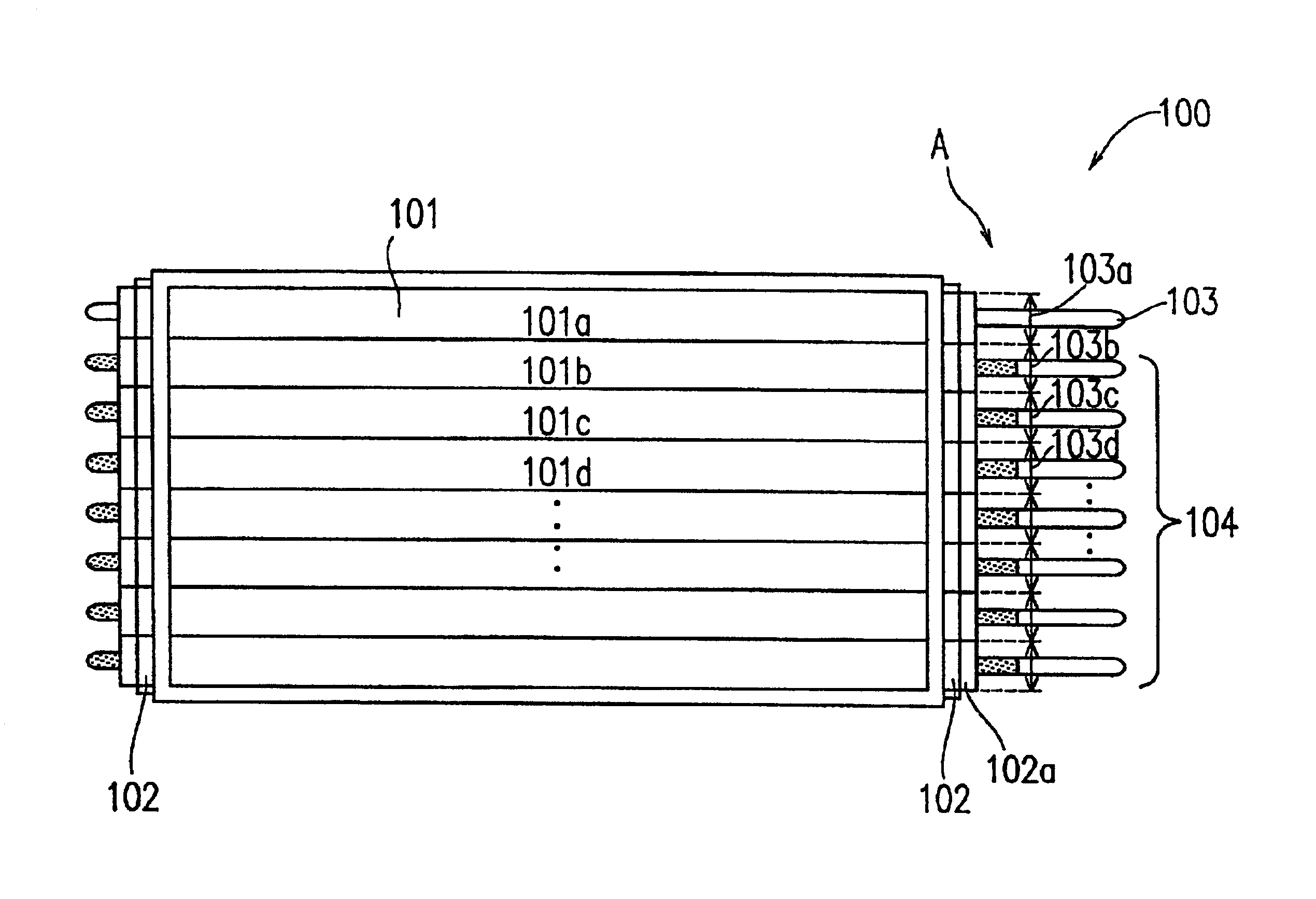

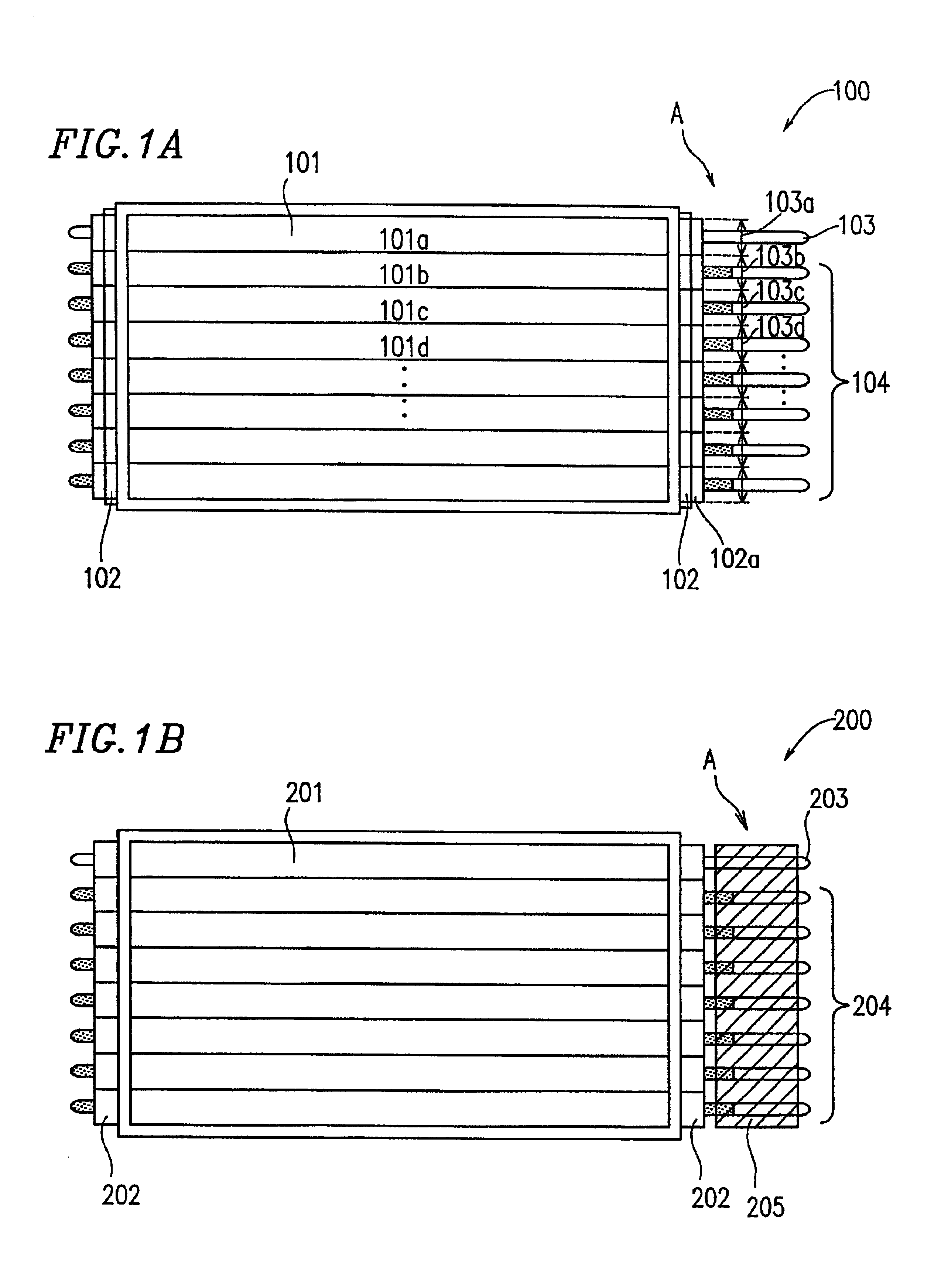

[wafer structure and bumping process thereof]

InactiveUS20050006759A1Improve adhesionExtend equipment lifeSemiconductor/solid-state device detailsSolid-state devicesEngineeringActive surface

The present invention provides a wafer structure having a plurality of bonding pad, an adhesion layer, a barrier layer, a wetting layer, a plurality of bump, a first passivation layer and a second passivation layer. The bonding pads are disposed on the active surface of the wafer and exposed by the first passivation layer. The second passivation layer is disposed on the first passivation layer and exposing the bonding pads. An adhesion layer is disposed on the bonding pad and covers a portion of the first passivation layer. The second passivation layer covers the first passivation layer and a portion of the adhesion layer. The barrier layer and the wetting layer are sequentially disposed on the adhesion layer and the bumps are disposed on the wetting layer.

Owner:ADVANCED SEMICON ENG INC

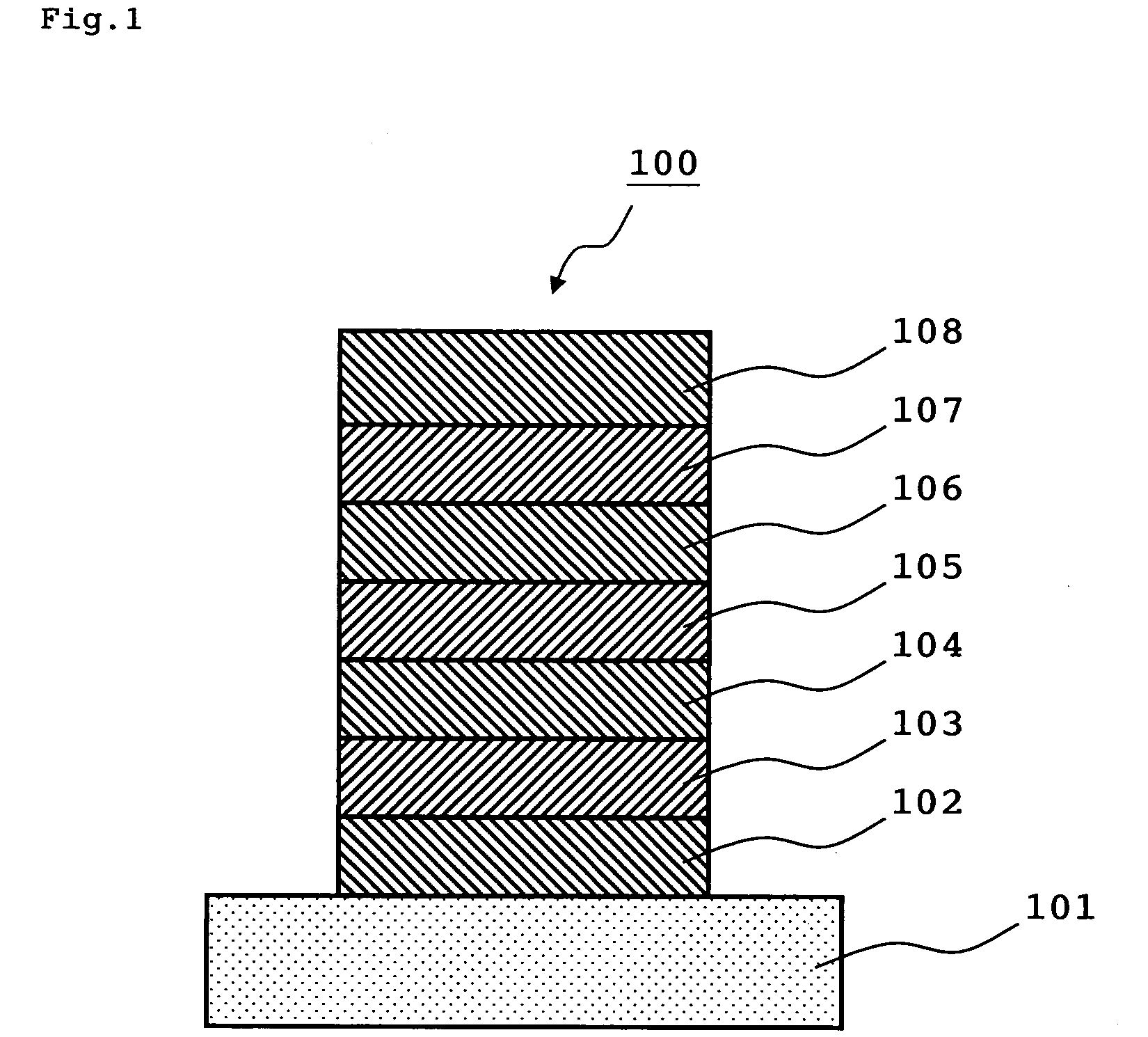

Separator for electrochemical device and method for producing the same

InactiveUS6905798B2Improves texture uniformityImprove thickness uniformityHybrid capacitor separatorsHybrid capacitor electrolytesPolymer scienceHeat resistance

The present invention provide a separator for an electrochemical device which comprises a wet nonwoven fabric comprising one or more kinds of fibrillated organic fibers which are at least partially fibrillated into a fiber diameter of 1 μm or less, and one or more kinds of unfibrillated organic fibers having a fineness of 0.5 dtex or less, which exhibits excellent heat resistance, electrolyte holding properties, internal short-circuit preventing property, and winding property, which results in a lowered internal resistance and prolonged life of an electrochemical device, and a method for producing the same and an electrochemical device.

Owner:MITSUBISHI PAPER MILLS LTD

Prosthetic interior casting process and product

InactiveUS7240414B2Low costExtend equipment lifeMetal rolling stand detailsArc welding apparatusShell moldingFurring

A method of sizing, resizing or reshaping the interior of a prosthetic device includes placing a lightweight moldable or shape assuming, pliable material that adheres and hardens on the interior sides of a socket of a prosthetic device. An end of a residual limb is placed into the socket causing the moldable material to conform to the shape of the residual limb. The limb is maintained in position for a few minutes in the socket until the moldable material has sufficiently hardened. After hardening, the molded material is dressed down, sanded or feathered to remove any burrs or sharp edges. Low spots or holes may be filled in with more moldable material and the fitting process repeated.

Owner:TAYLOR SR MATTHEW T

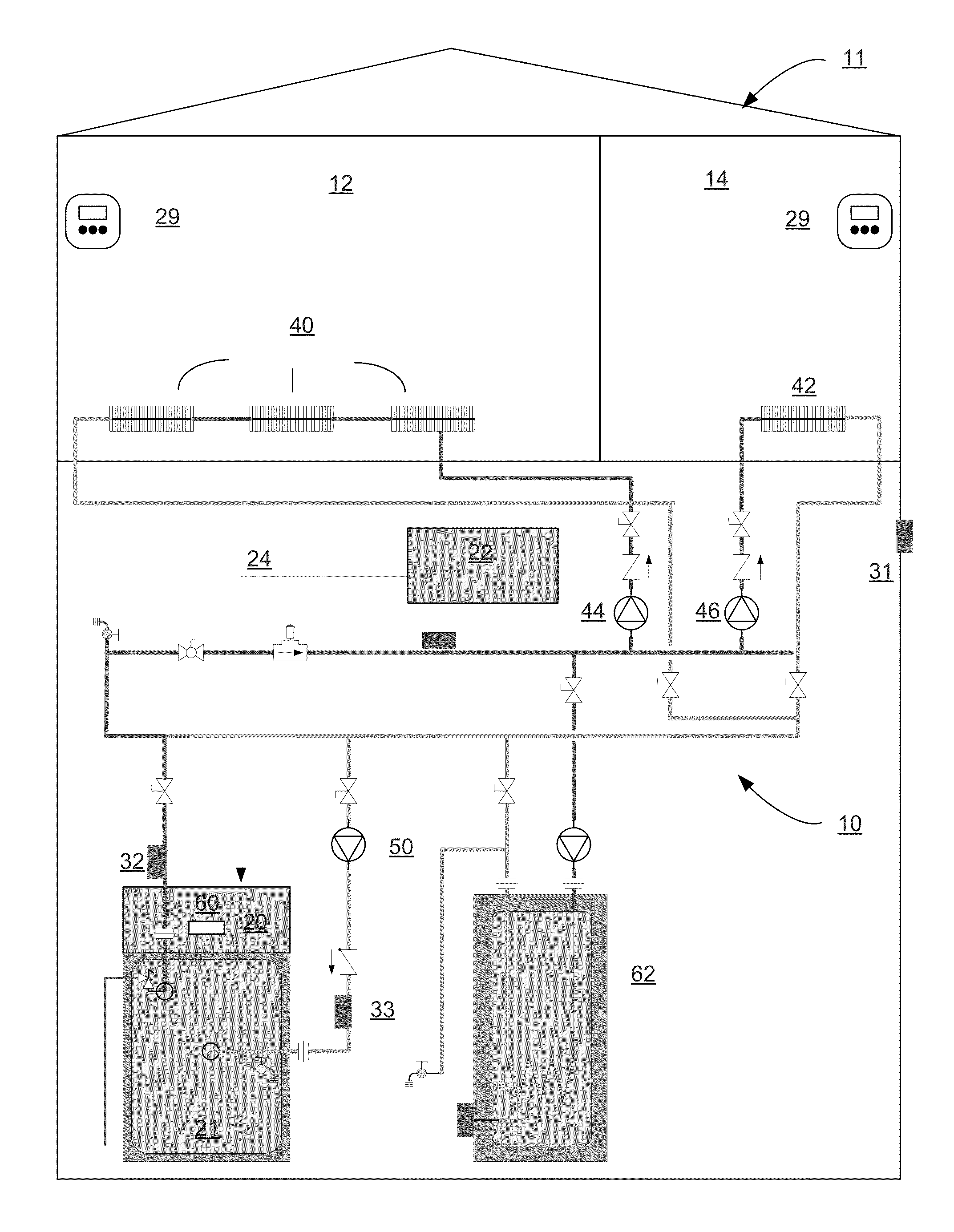

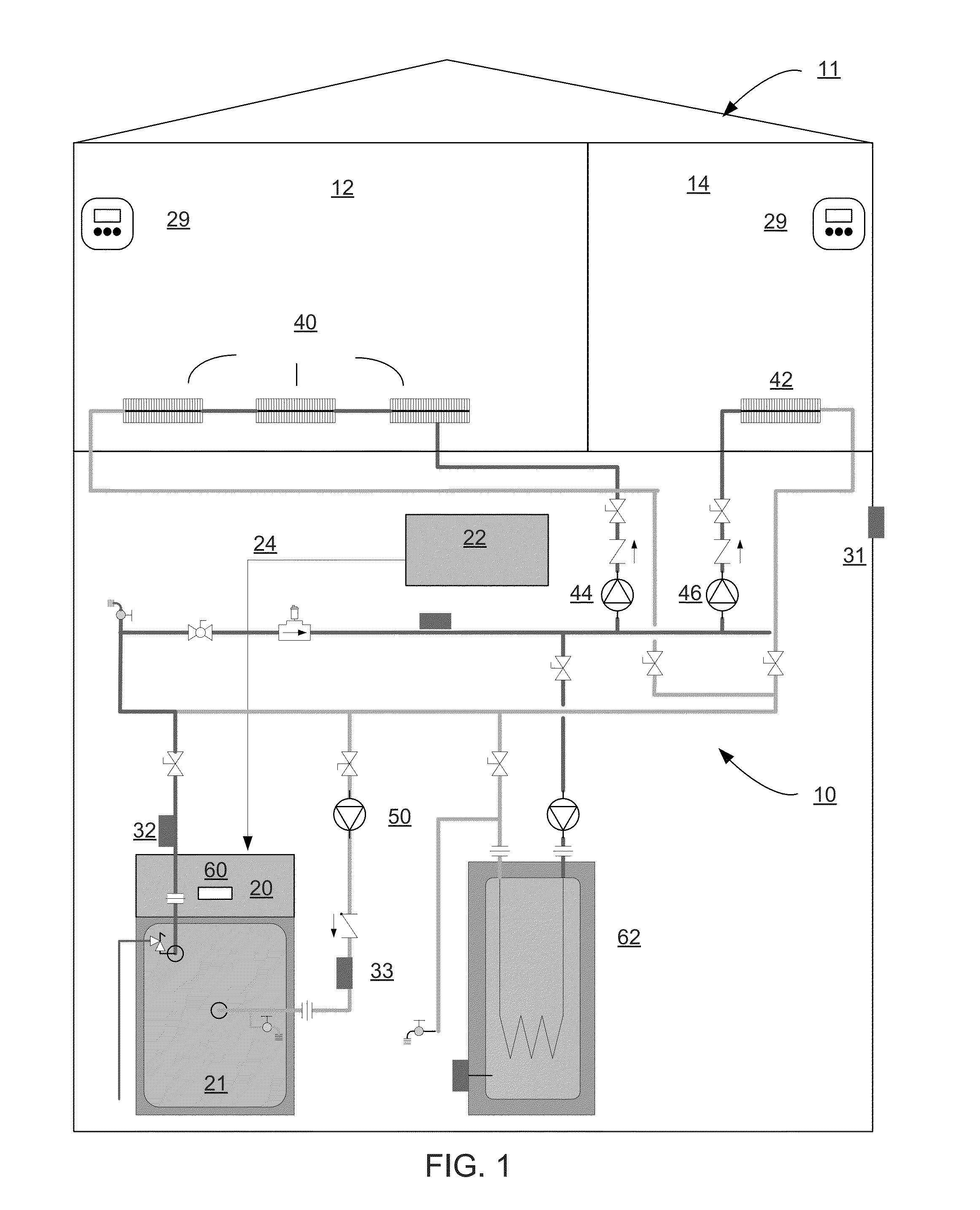

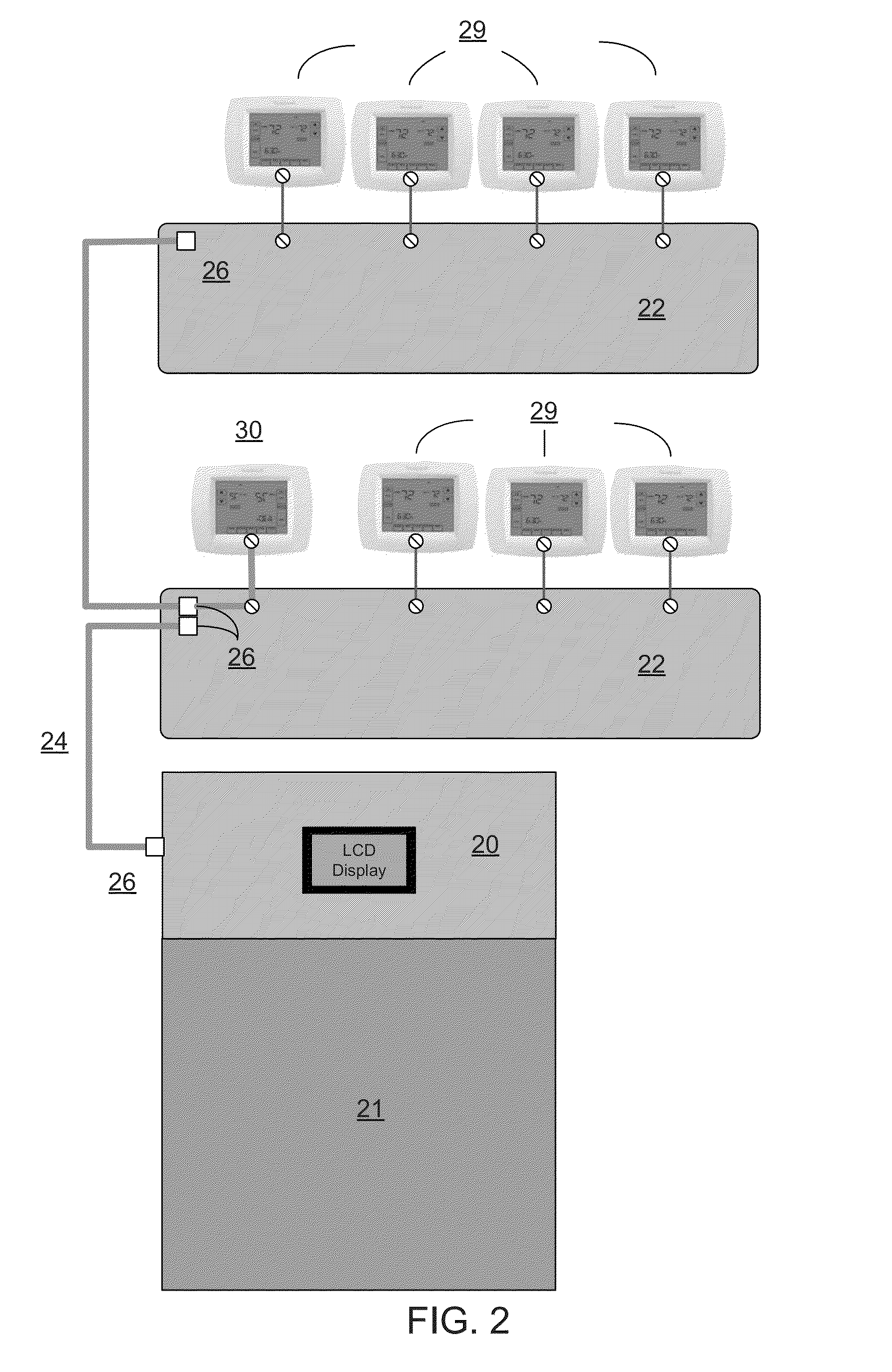

Multiple zone control system and method of operation

InactiveUS20150108230A1Optimizes condensing boiler firing rateAmount of timeMechanical apparatusTemperatue controlControl systemHeat losses

A multiple heating / cooling zone control system is disclosed. A heating / cooling system control device continuously monitors heating / cooling zone demand and matches the heating / cooling device output capacity to the total space or heat input required. Within the calculated heating / cooling device output capacity the heating / cooling device is modulated based on zone temperature setpoint to further adjust heating / cooling device output. As heat / cooling loss is increased heating / cooling device capacity and modulation are increased. Should heat / cooling loss decrease heating / cooling device capacity and modulation are decreased. Since heat / cooling output is adjusted based on the heat loss(gain) the heating / cooling device can be immediately adjusted to the proper or matching heating / cooling rate even before water / air temperature based adjustments can be made. Hence, the overall effect of the control device is a reduction in cycles of the heating / cooling device and the life of the heating / cooling device is extended and subsequent energy is saved.

Owner:BURNHAM SERVICES

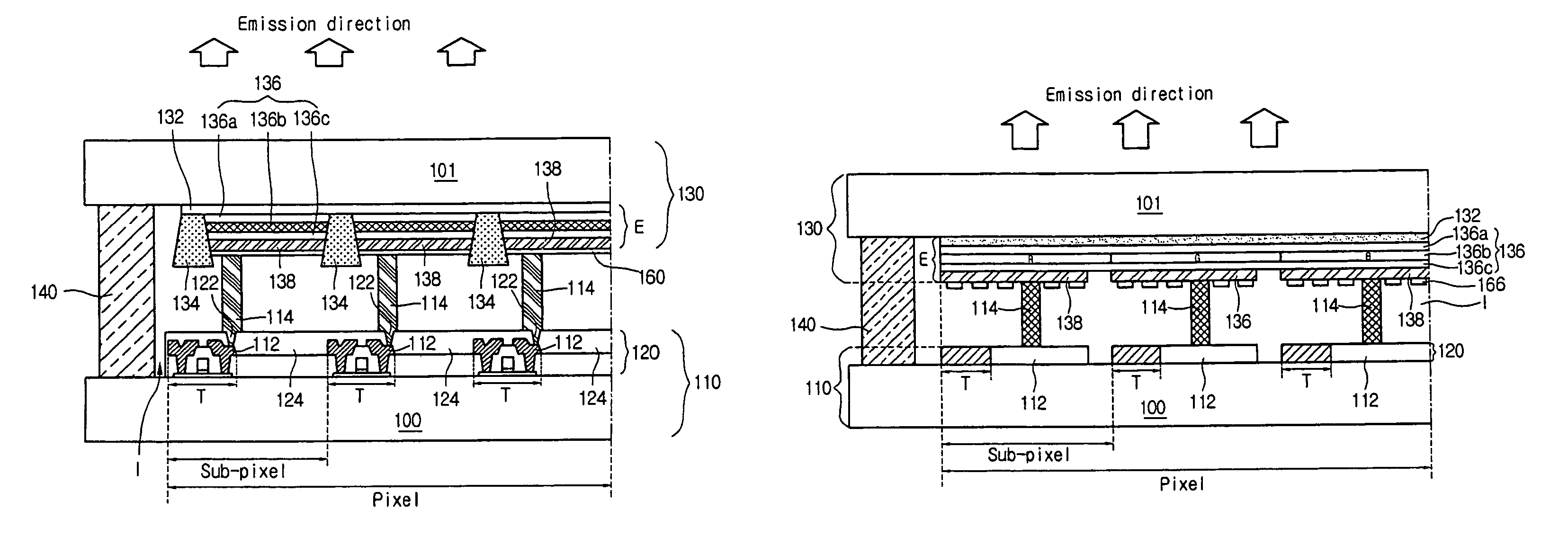

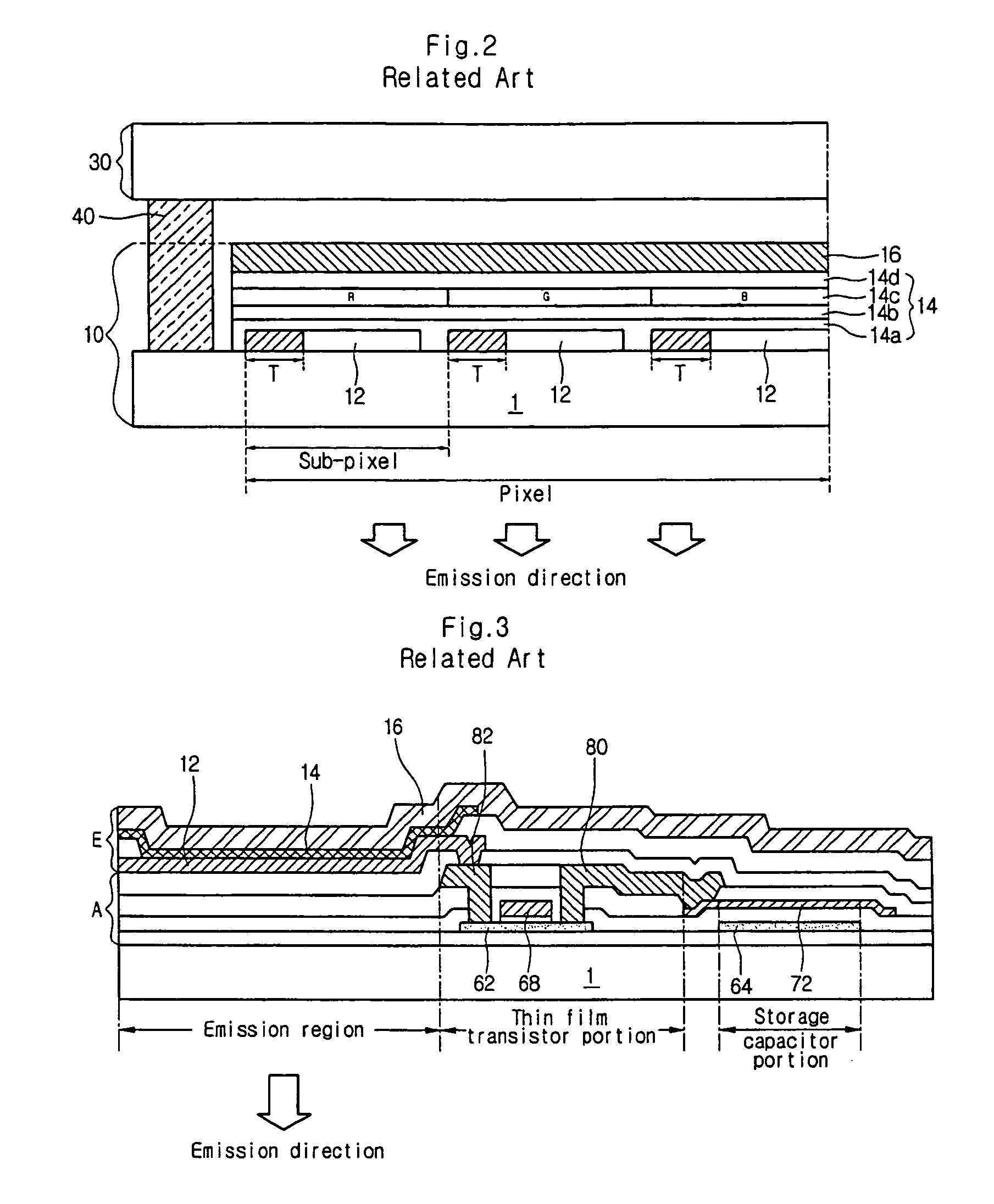

Organic electroluminescence device with absorbent film and fabrication method thereof

ActiveUS7402946B2Extend equipment lifeIncreased durabilityDischarge tube luminescnet screensElectroluminescent light sourcesMetallic materialsTransmittance

An organic electro luminescence device includes an array device having a thin film transistor formed in each of sub-pixel regions on a first substrate, a first electrode of an organic electro luminescence diode formed on a second substrate, the first electrode including a metallic material having light transmittance, a second electrode and an organic electro luminescence layer of the organic electro luminescence diode formed on the first electrode, and a thin film type absorbent formed on one of the first substrate and the second substrate, the first and second substrates being attached to each other with a predetermined distance therebetween having the array device facing the organic electro luminescence diode, and including a conductive spacer for electrically connecting the thin film transistor and the second electrode.

Owner:LG DISPLAY CO LTD

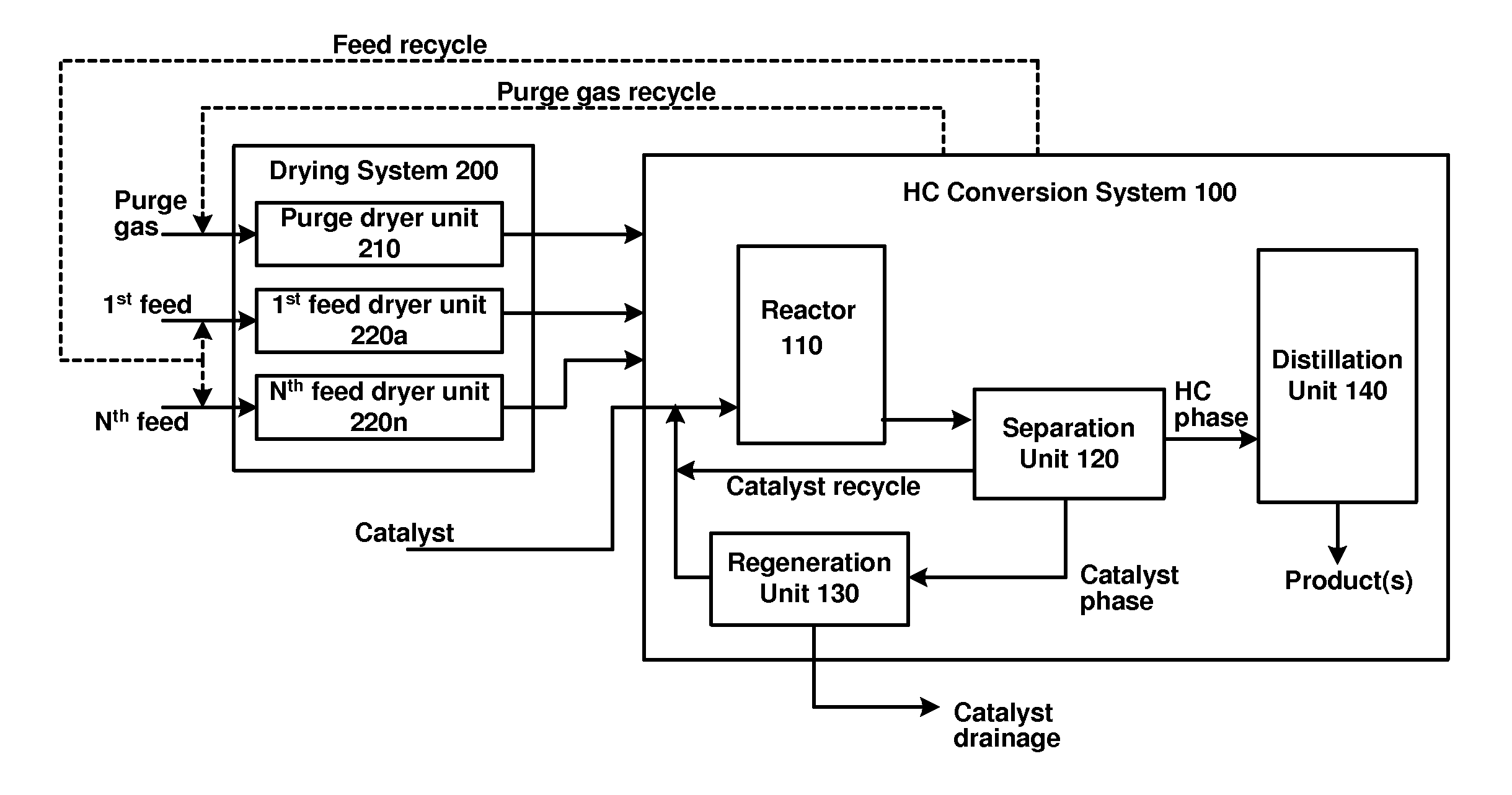

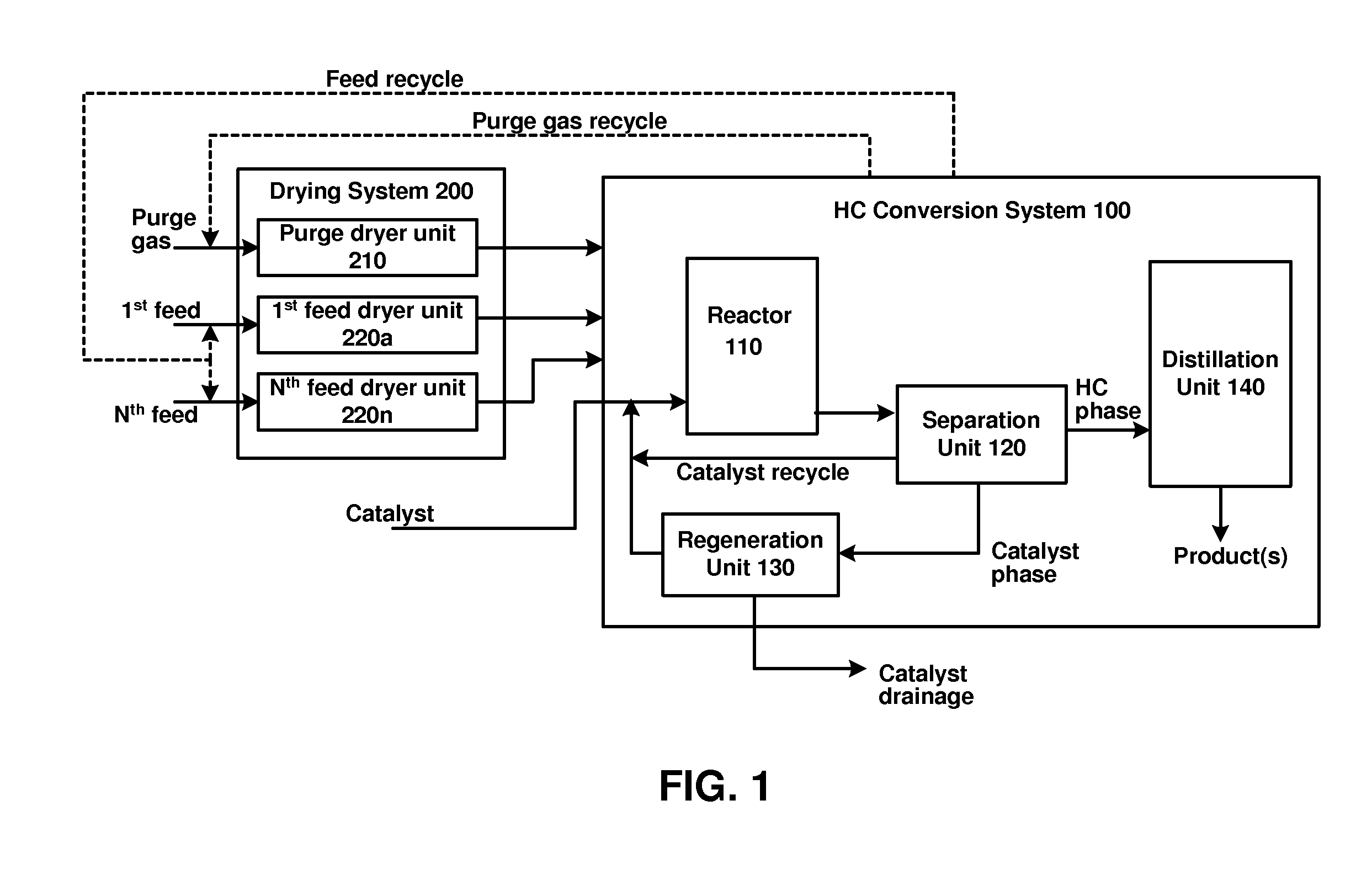

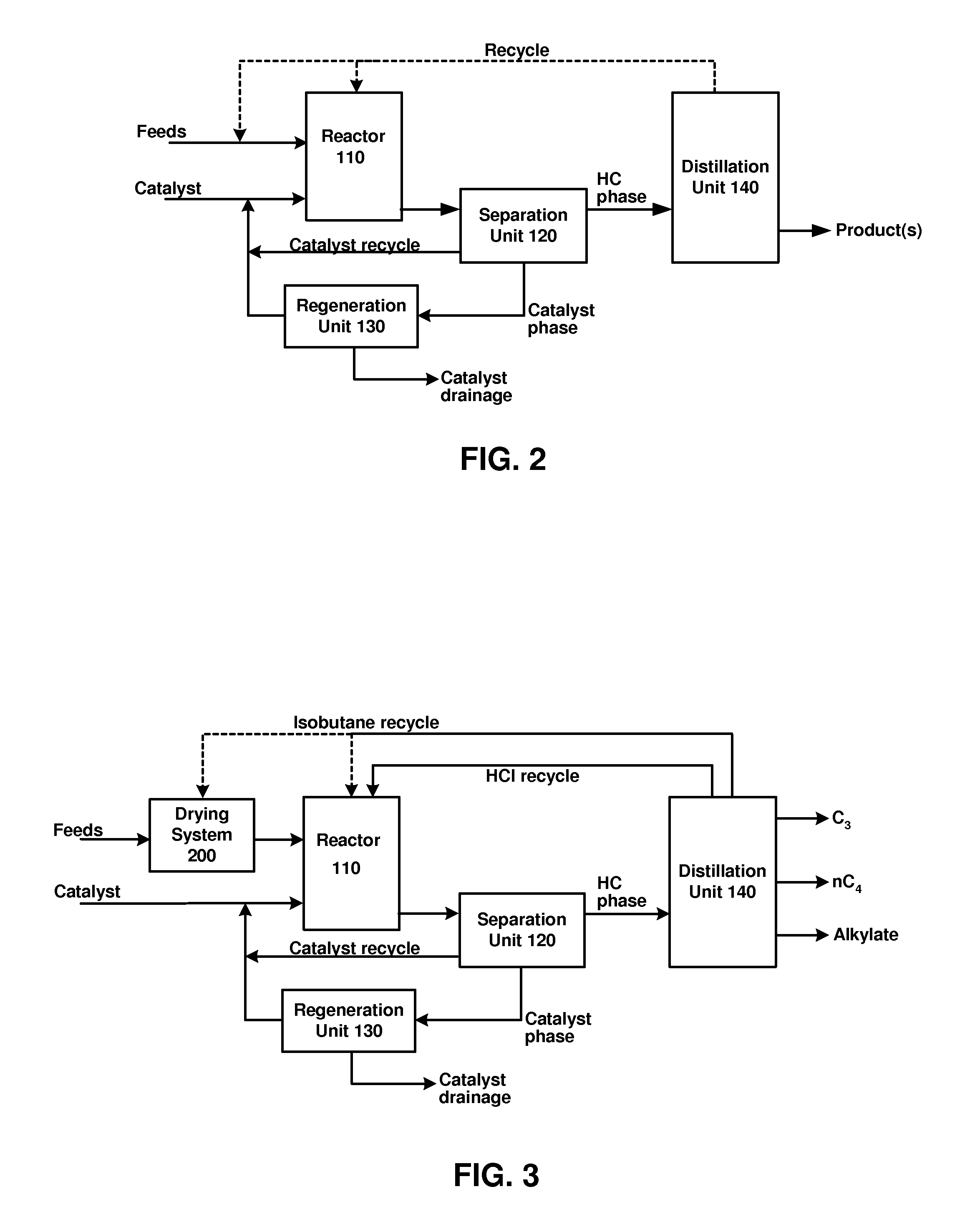

Startup procedures for ionic liquid catalyzed hydrocarbon conversion processes

ActiveUS20110319694A1Improve performanceReduce equipment maintenanceOrganic-compounds/hydrides/coordination-complexes catalystsDistillation purification/separationProcess efficiencyIonic liquid

Methods for starting and operating ionic liquid catalyzed hydrocarbon conversion processes and systems to provide maximum process efficiency, system reliability and equipment longevity may include: purging air and free water from at least a portion of the system; introducing at least one reactant into the at least a portion of the system; and re-circulating the at least one reactant through the at least a portion of the system, via at least one feed dryer unit, until the at least one reactant exiting the at least a portion of the system has a water content at or below a threshold value, prior to the introduction of an ionic liquid catalyst and / or additional reactant(s) and feeds into the system.

Owner:CHEVROU USA INC

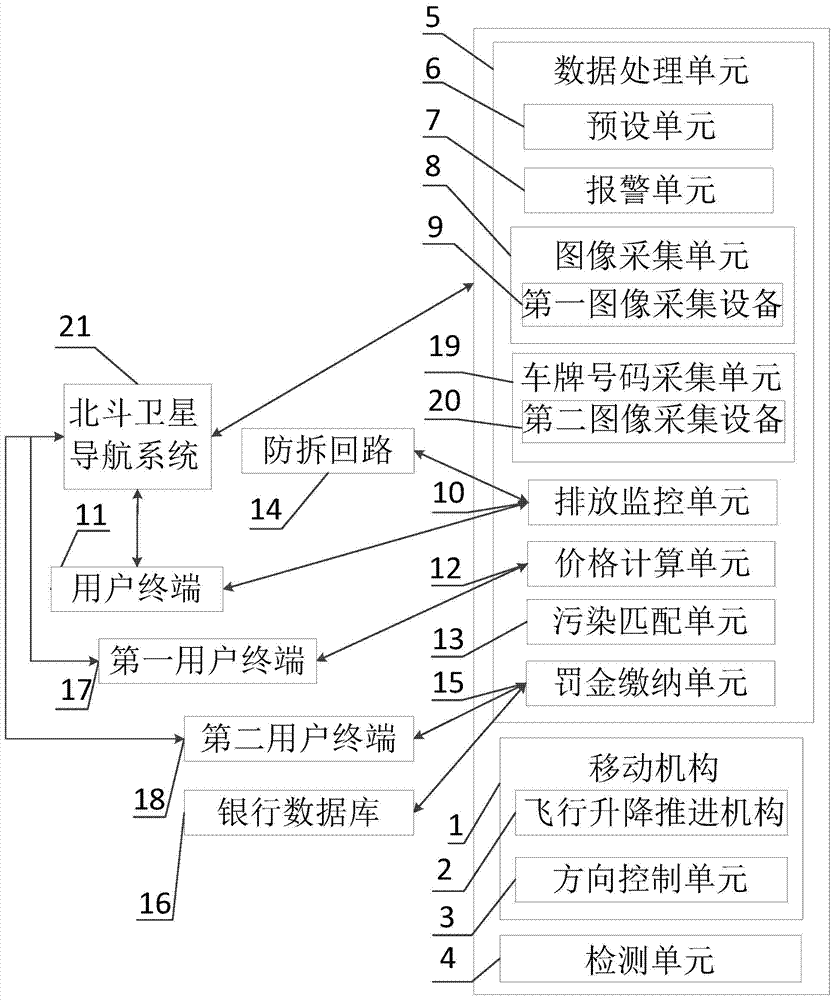

Air pollution monitoring system based on Beidou positioning

ActiveCN104849415ASave manpower, material resources and timeExtend equipment lifeMaterial analysisInhalable particlesChemical composition

The invention discloses an air pollution monitoring system based on Beidou positioning. The air pollution monitoring system comprises a mobile mechanism, a detection unit and a data processing unit, wherein the mobile mechanism is used for moving and comprises a fly lifting feed mechanism and a direction control unit; the detection unit is arranged on the mobile mechanism, is used for detecting air pollution indexes, comprises inhalable particles, chemical components and bacterium concentration, and is used for detecting the air direction and the air speed; the data processing unit is used for receiving the position information of the mobile mechanism, the air pollution indexes, the air direction and the air speed, used for generating an air pollution distribution diagram according to the air pollution indexes and the position information of the mobile mechanism, used for estimating the position of a pollution source according to the air pollution distribution diagram, the air direction and the air speed, and used for dividing pollution areas according to the preset air pollution concentration thresholds. Therefore, high-precision and high-reliability pollution positioning can be achieved, the air pollution distribution situation can be monitored in real time, and the pollution resources can be estimated according to the air pollution distribution diagram, the air direction and the air speed.

Owner:辽宁北斗平台科技有限公司

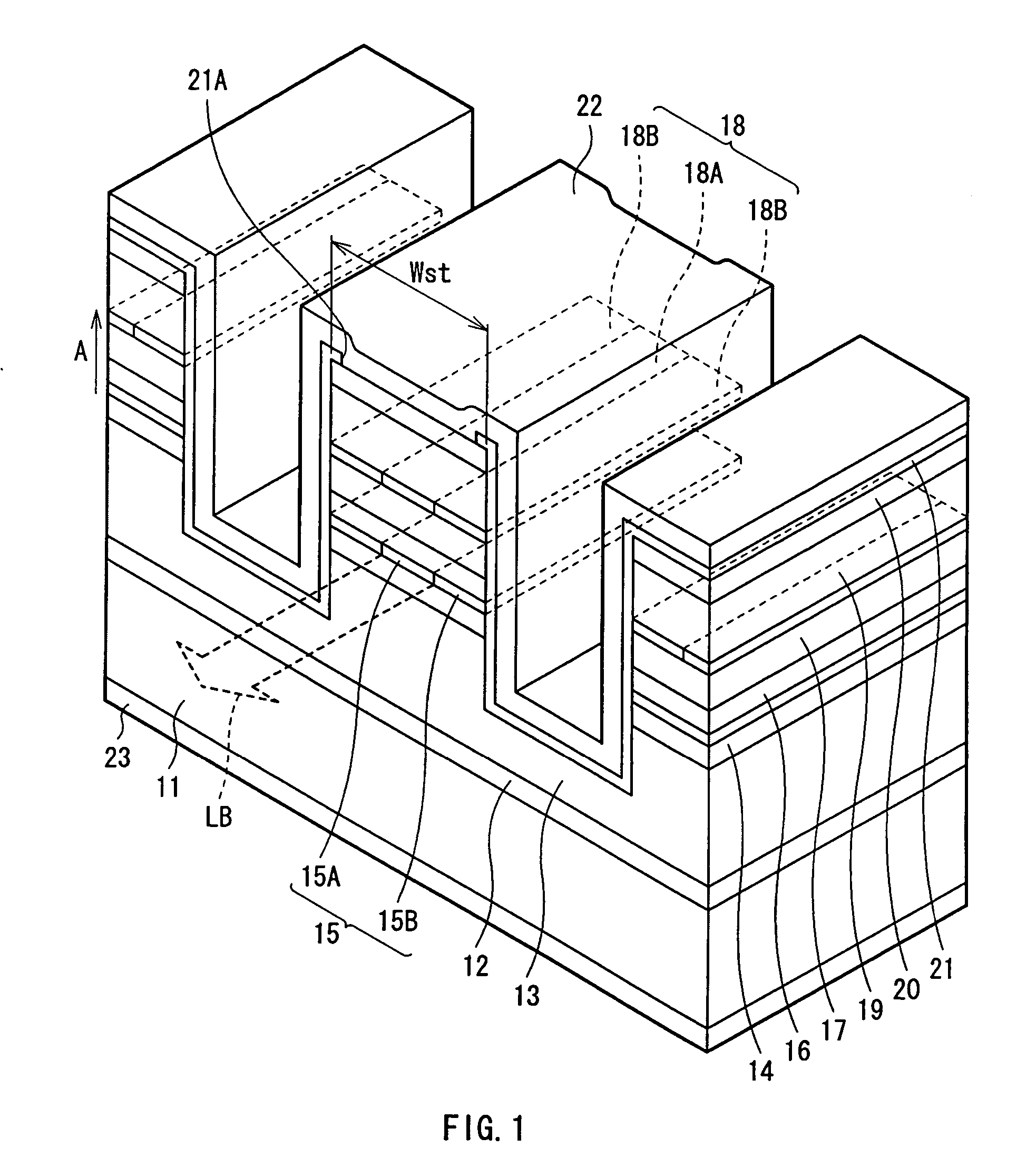

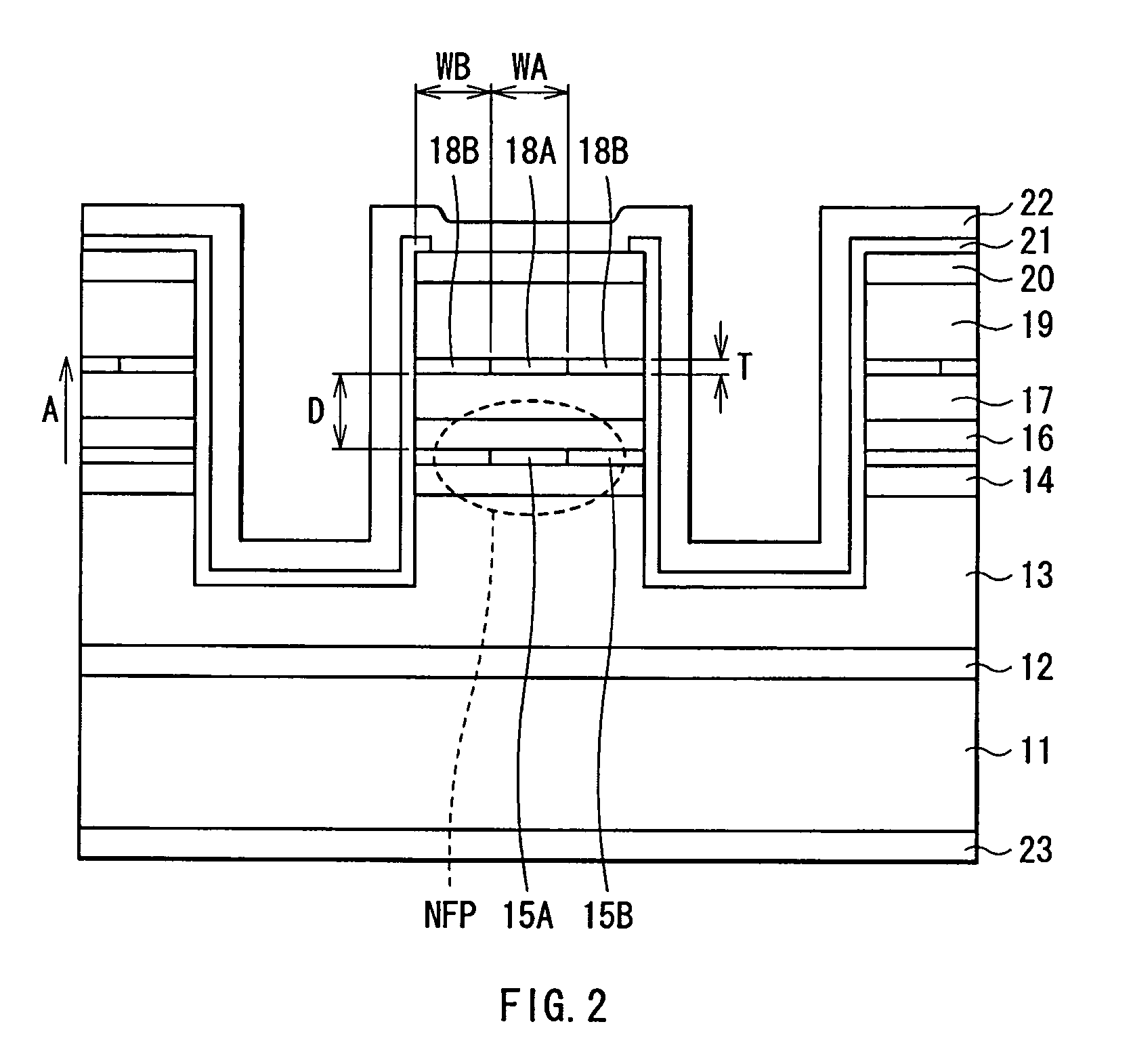

Semiconductor light-emitting device and method of manufacturing the same

InactiveUS20050139856A1Improve device characteristicsImproving device characteristicOptical wave guidanceLaser detailsCurrent limitingEngineering

A semiconductor light-emitting device capable of improving device characteristics such as life and reliability is provided. A current confinement layer includes a non-oxidized region made of AlAs or the like corresponding to a current injection region in an active layer, and an oxidized region made of aluminum oxide corresponding to a non-current injection region. The oxidized region is formed by forming a non-oxidized layer made of AlAs or the like and then oxidizing part of the non-oxidized layer at a temperature from 240° C. to less than 375° C. The thickness of the oxidized region is preferably from 10 nm to 1000 nm. The width of the one side of the oxidized region is one time or more of the width of the non-oxidized region or seven times or less thereof The distance between current confinement layer and the active layer is preferably 50 nm or more, or 500 nm or less, and more preferably 180 nm or more.

Owner:SONY CORP

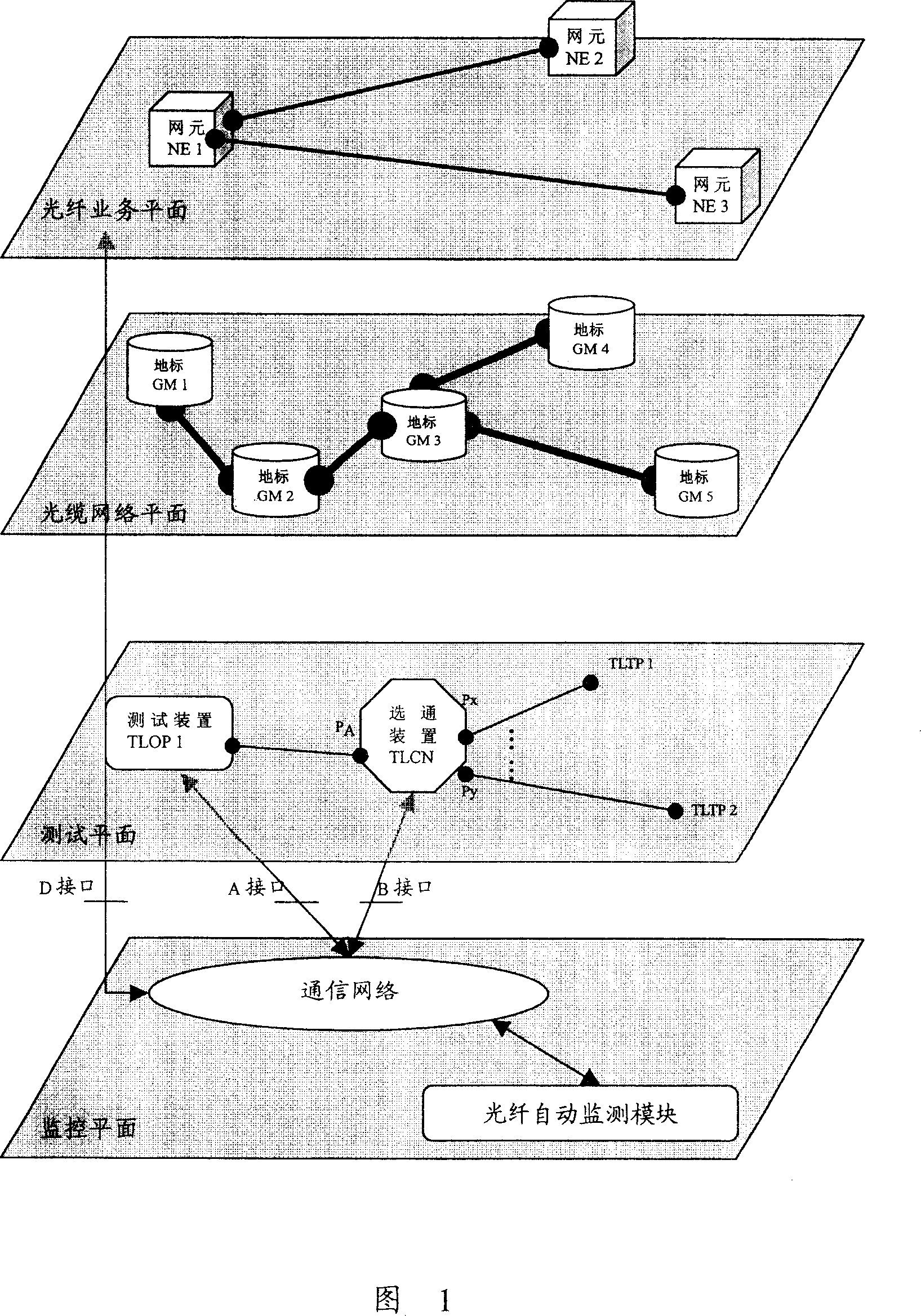

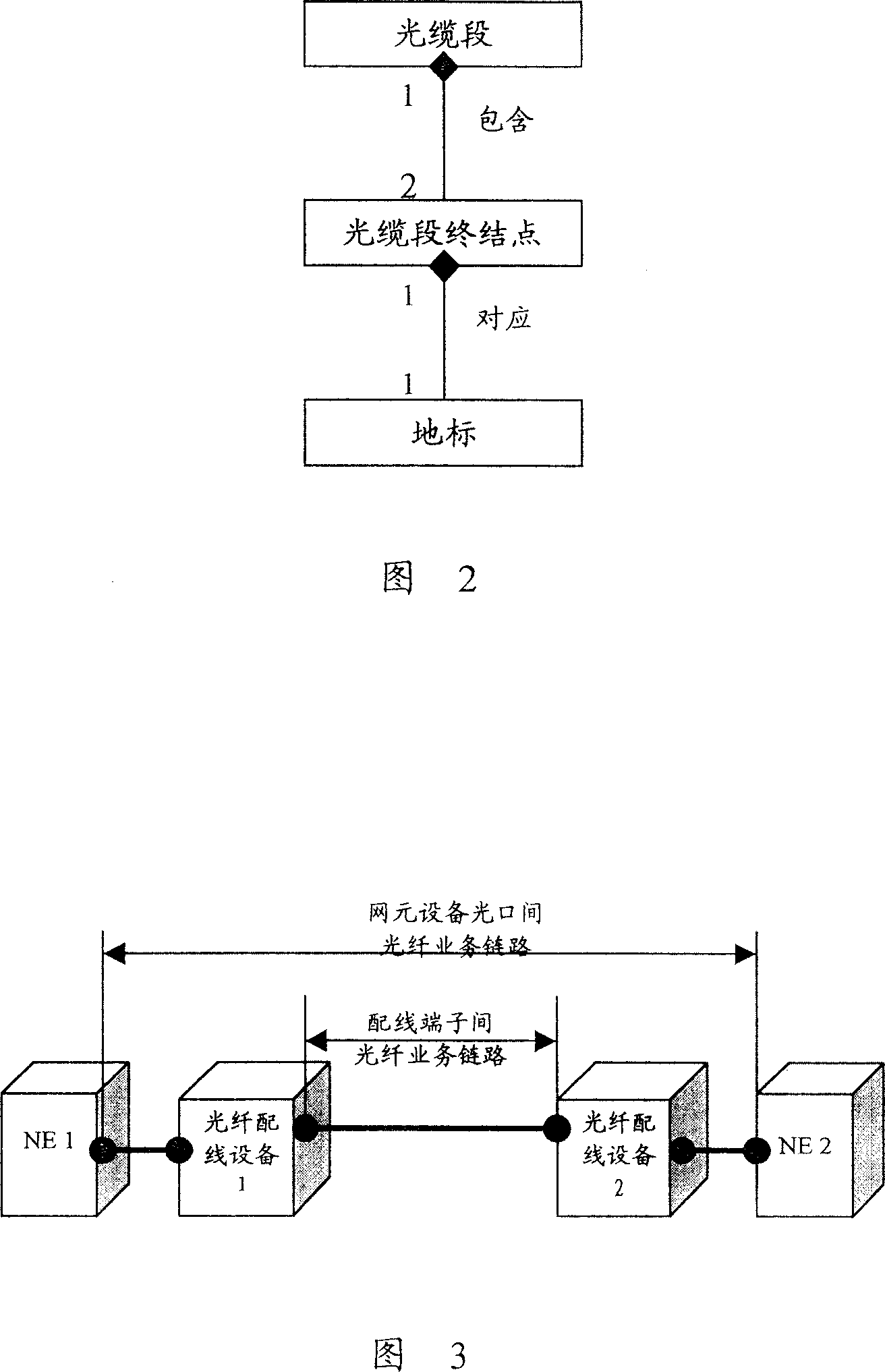

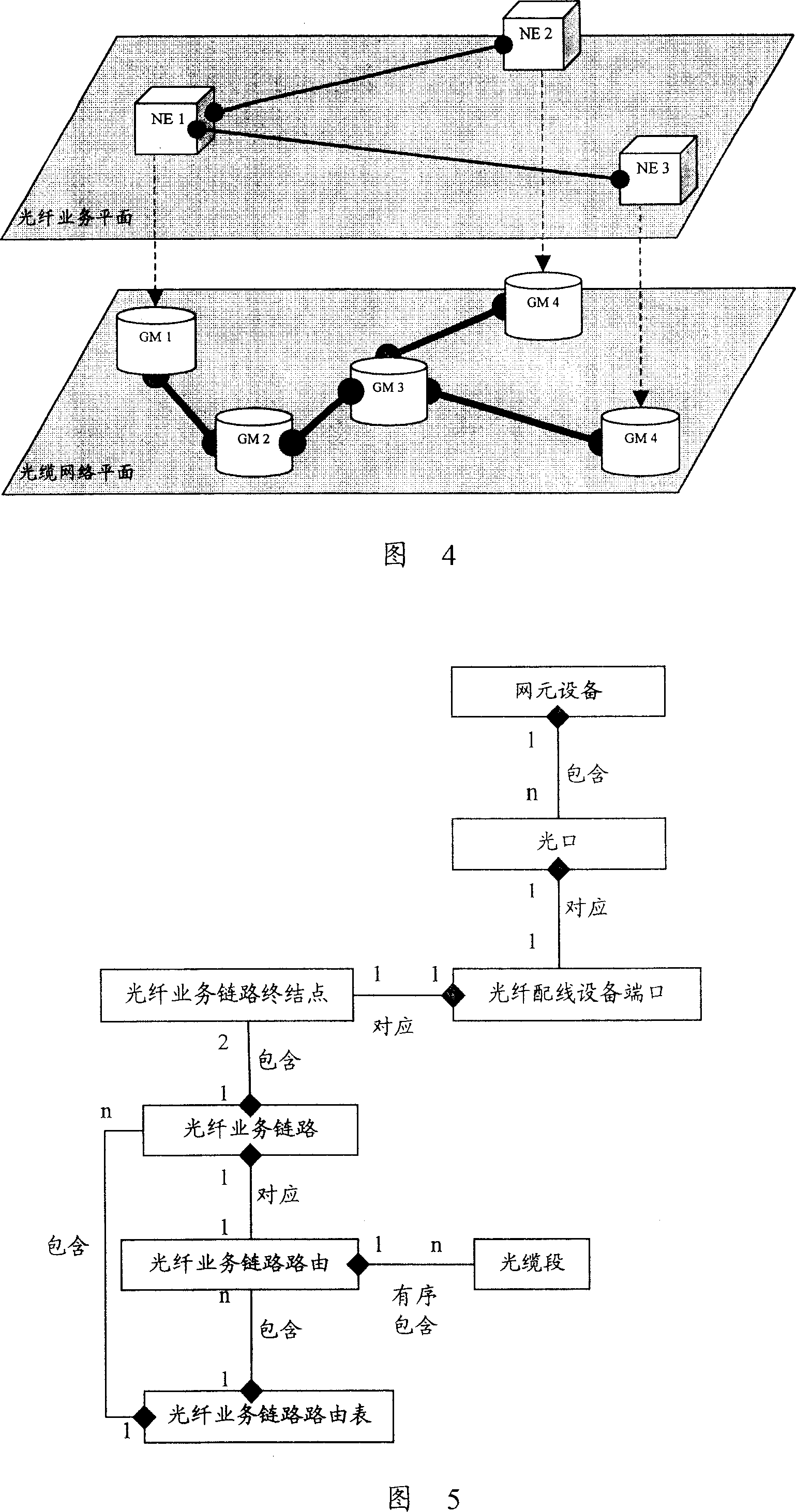

Optical fiber automatic monitoring system and method

InactiveCN101018089AImprove real-time performanceExtend equipment lifeElectromagnetic transmissionSystem serviceSystem testing

The disclosed fiber automatic monitor system comprises: a fiber network profile, an optical business profile to generate abnormal affair to trigger system testing, a detection profile, and a monitor profile to control the detection and thereby find out the fault position. This invention improves performance traditional technology obviously, and has better performance on real time and system service time.

Owner:HUAWEI TECH CO LTD

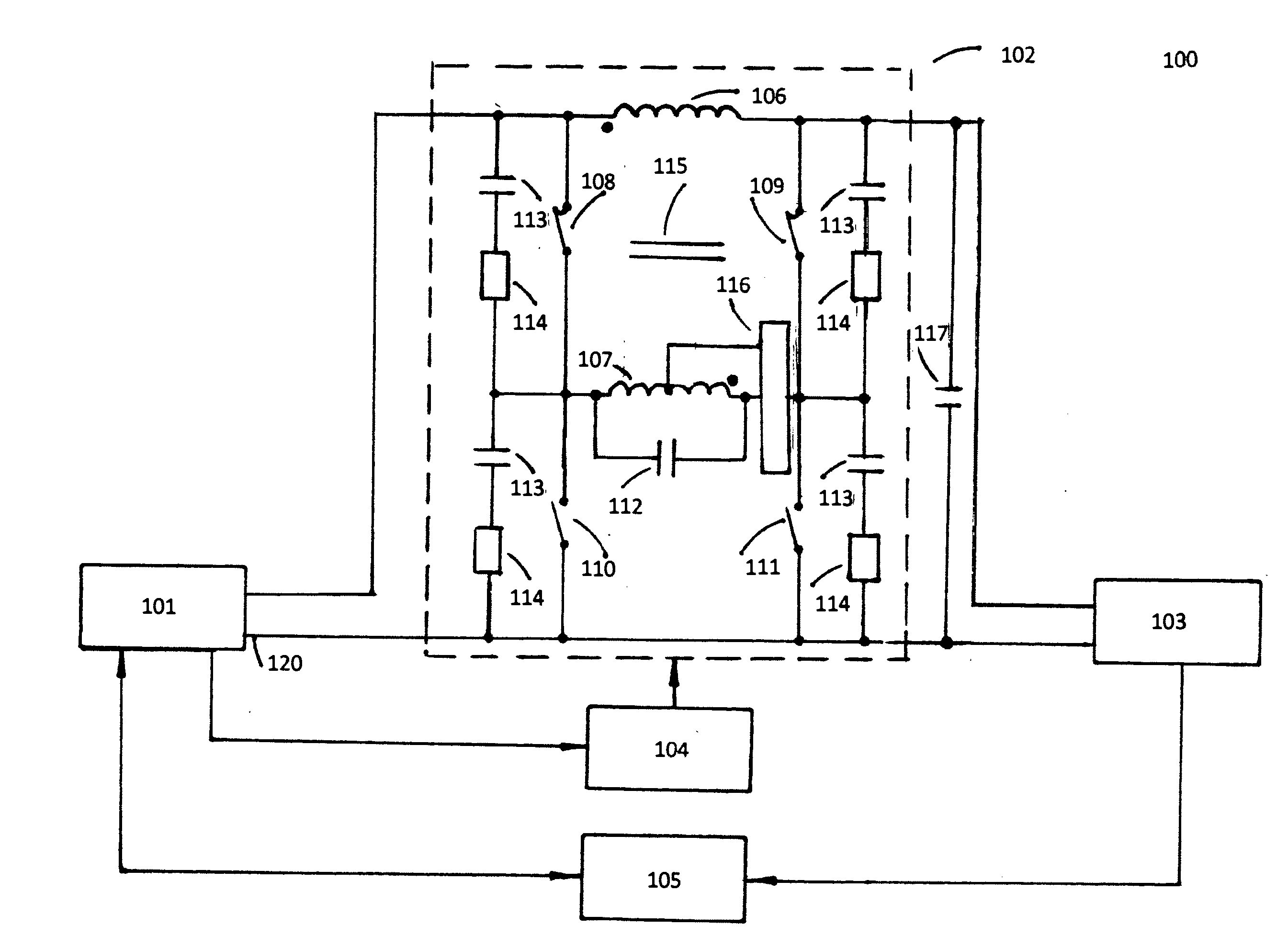

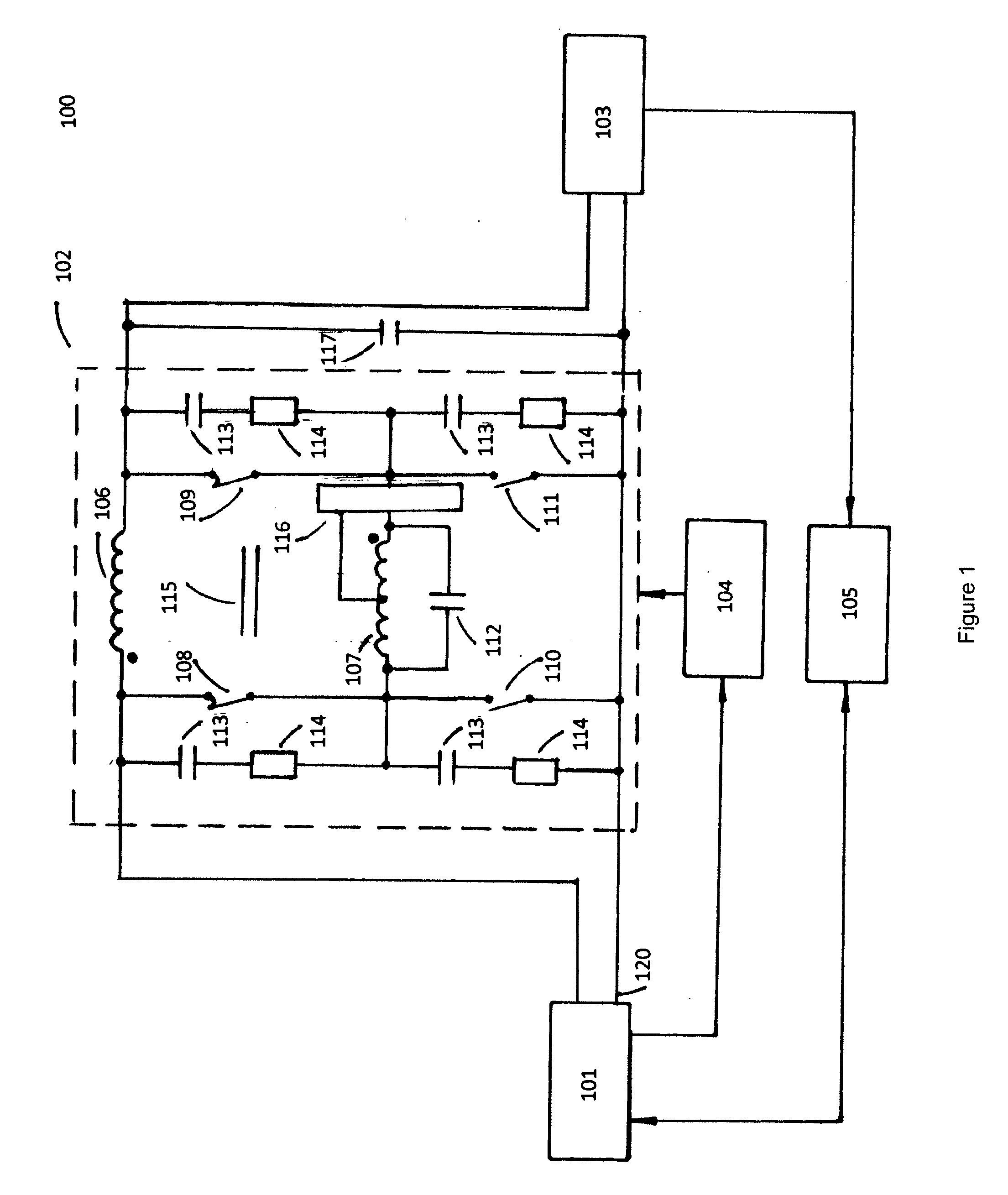

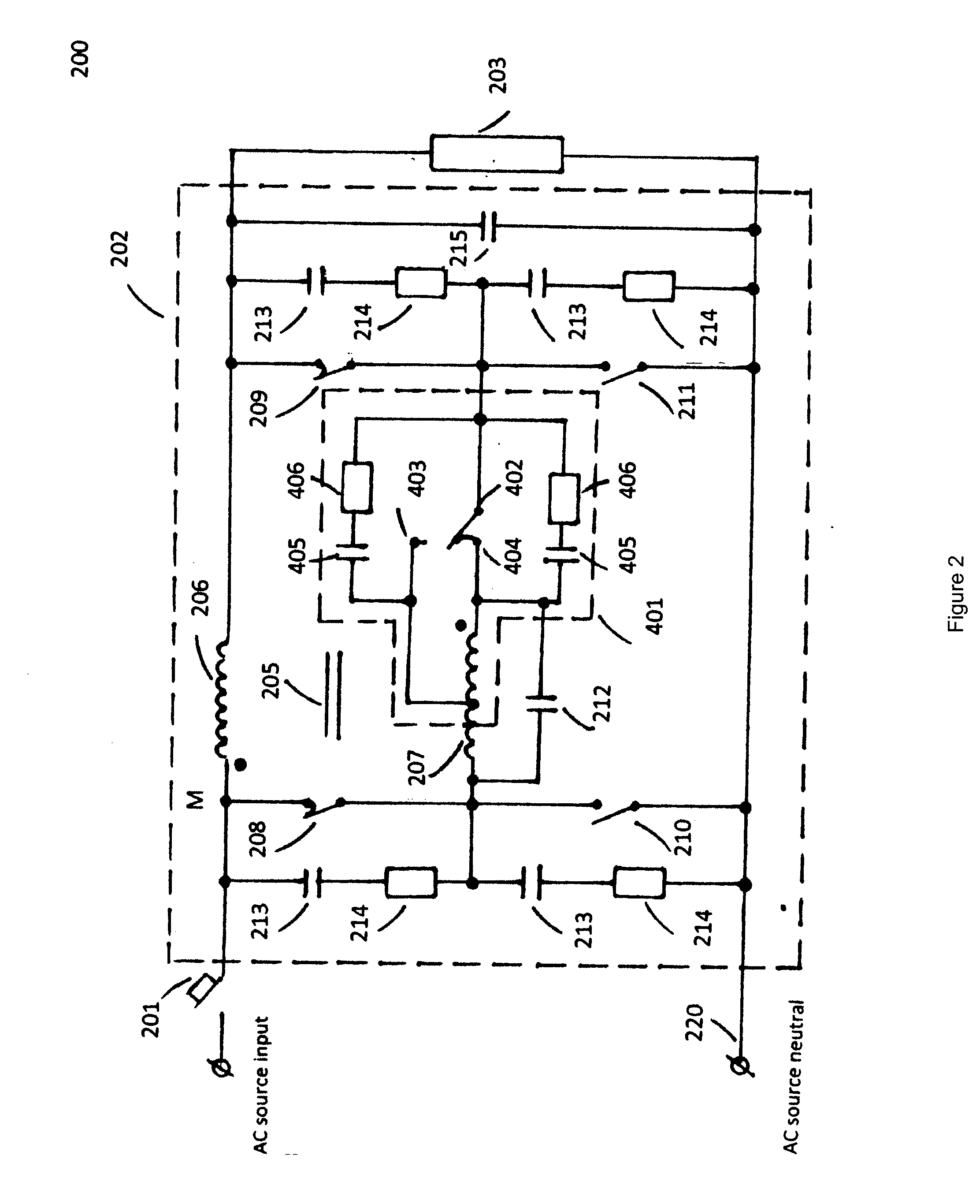

Method and apparatus for regulating voltage

InactiveUS20070296390A1Improve efficiencyReduce weightConversion without intermediate conversion to dcElectric variable regulationTransformerEngineering

An AC voltage regulator able to provide a desired voltage to any type of a given load within a predetermined range without any output power interruptions during any transition time, without distortion of the AC sine wave and without high current circulating through the circuit components during the voltage switching. The voltage regulator uses a single regulator transformer having a primary winding and a secondary winding. The secondary winding of the regulator transformer is connected in series between a power source and the load, while the primary winding of the regulator transformer is connected with the power source so that the primary and secondary windings have opposite polarities. The position of a plurality of switches can be variably set by the control circuit to control current flow through the primary winding and to provide a normal mode, a step-down mode, or a step-up mode.

Owner:ELECTRO CHANCE

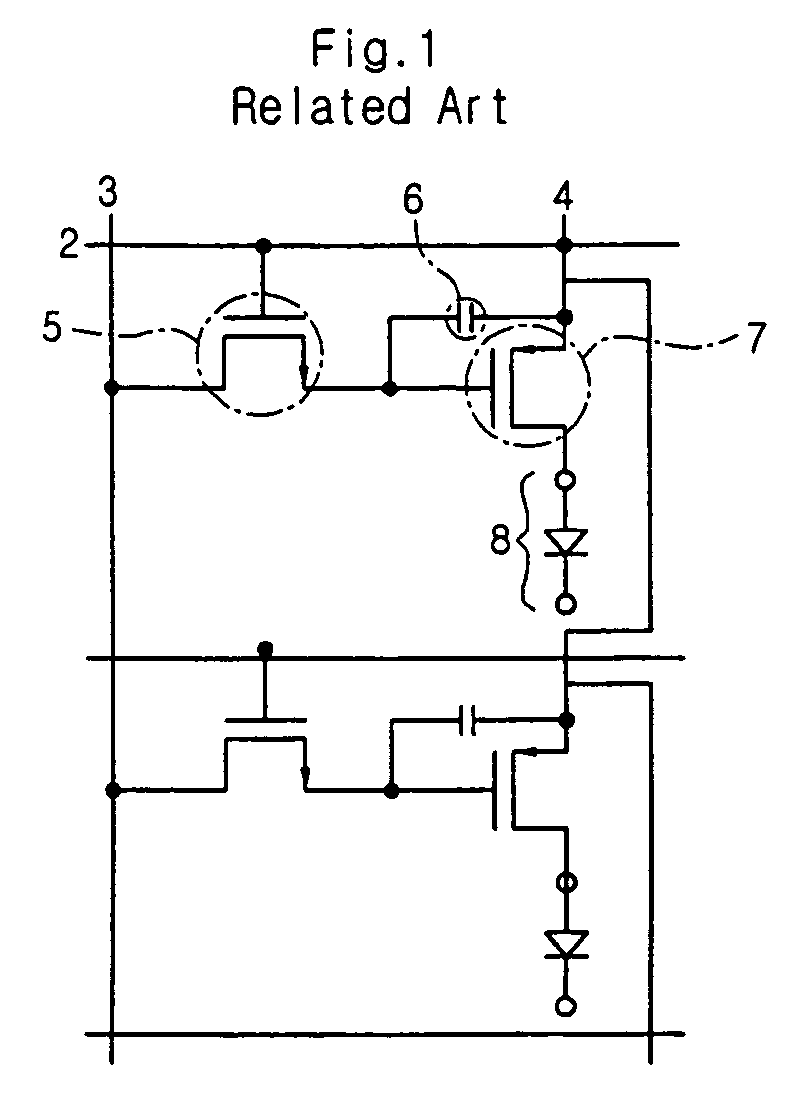

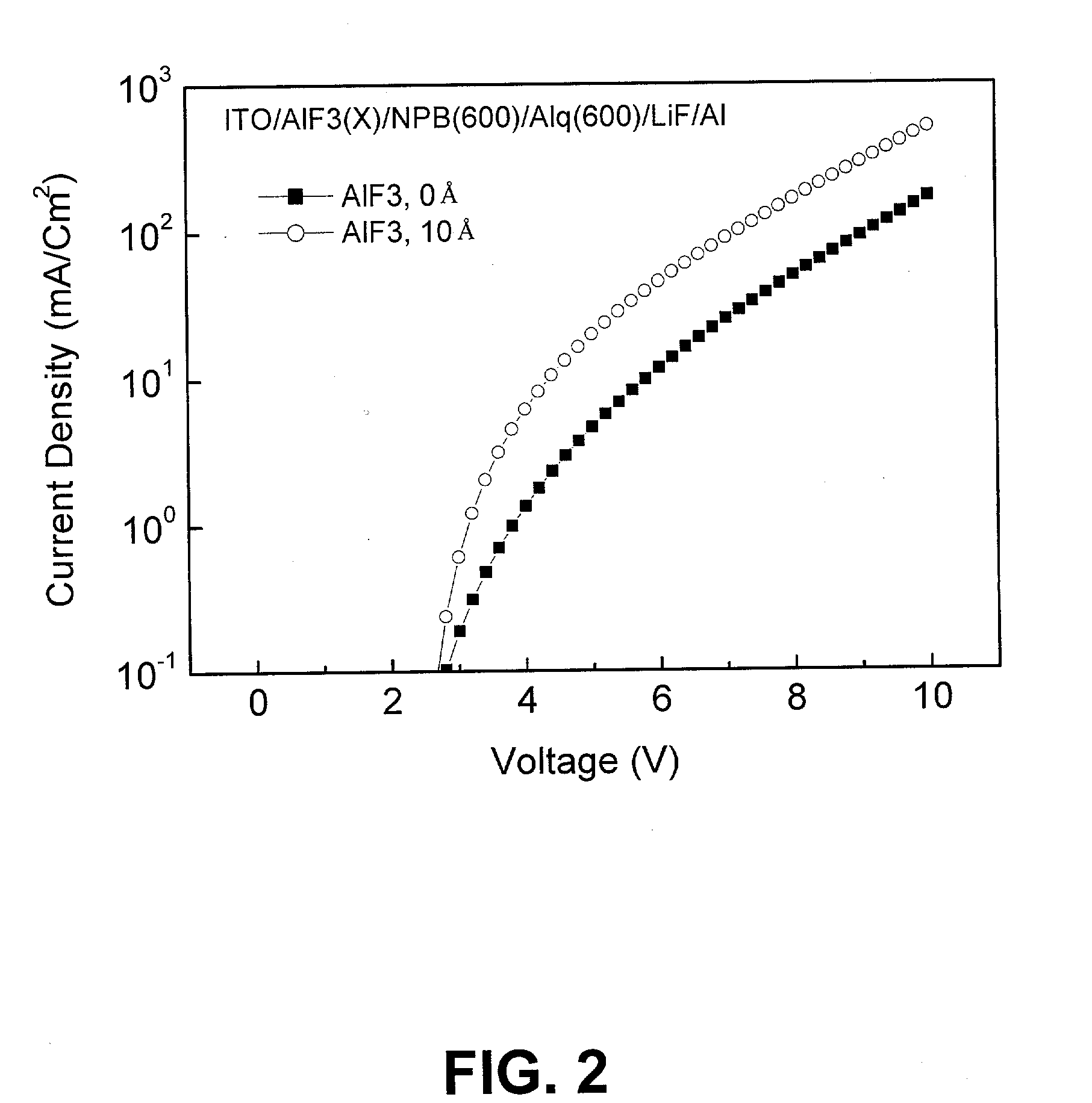

Organic electroluminescent device with a containing fluorine inorganic layer

InactiveUS20030107042A1Increase currentReduce the driving voltageElectroluminescent light sourcesSolid-state devicesOptoelectronicsOrganic electroluminescence

The present invention is to provide an organic electroluminescent device with a containing fluorine inorganic layer whose structure sequentially comprises a substrate, a transparent conductive layer (anode), a containing fluorine inorganic layer, a hole-transport layer, an organic light-emitting layer, an electron-transport layer, and a metallic conductive layer (cathode), wherein said a containing inorganic layer is made of metallic fluoride, and it can stabilize as well as increase the lifetime for an organic electroluminescent device.

Owner:IND TECH RES INST

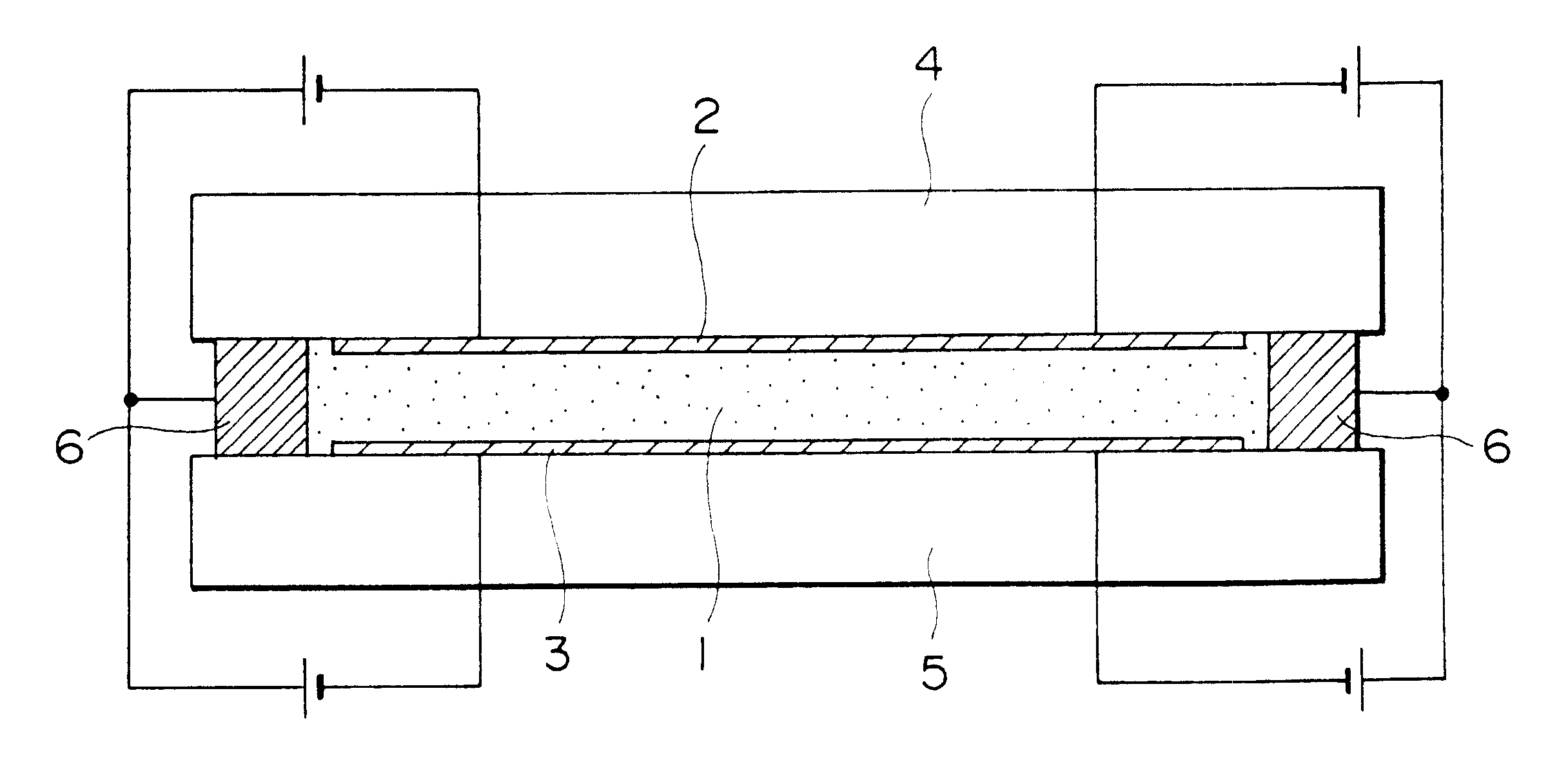

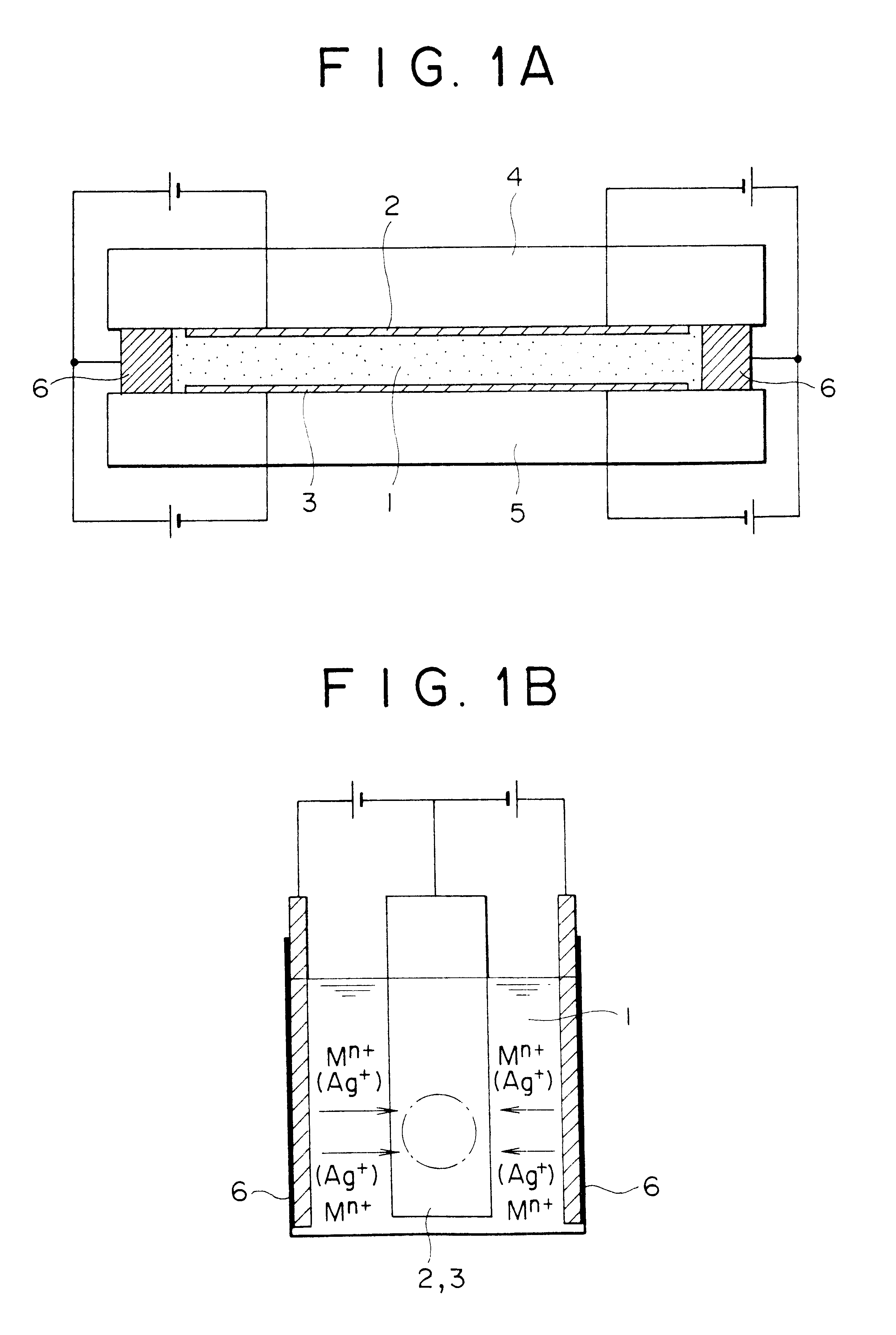

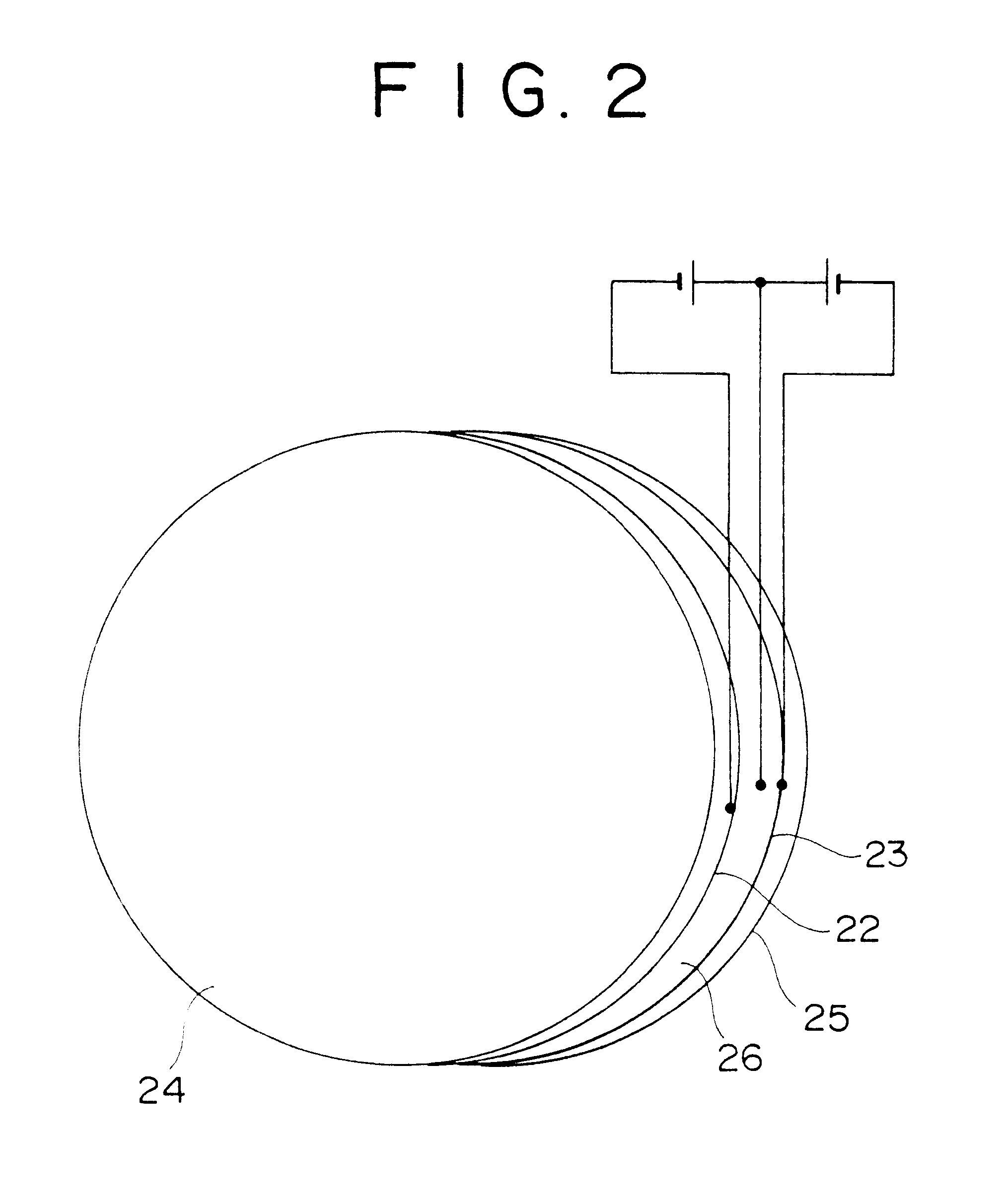

Optical device, a fabricating method thereof, a driving method thereof and a camera system

InactiveUS6336753B1Small sizeRemove image blurCamera diaphragmsNon-linear opticsGas phaseTransmittance

An optical device used for an optical filter or the like capable of controlling a light transmittance or light reflectance in a visible light region, a fabrication method thereof, a driving method thereof and a camera system are provided, including the optical device comprising a working electrode and a counter electrode in which an electrolyte is disposed in contact with both of the electrodes and light is controlled electrochemically by controlling an electric field applied to the electrolyte, and a first layer of the counter electrode present on the side of the electrolyte comprises a metal having a lower ionization tendency than that of a metal deposited at the working electrode, an optical device having a reference electrode having no direct concerns with oxidation / reduction reaction of the working electrode and the counter electrode for measuring the potential for one or both of the electrodes, a method of fabricating an optical device having a counter electrode and a reference electrode comprising a single layer or a laminate structure, comprising forming each of the layers by a gas phase film forming method or the like and forming each of the electrodes as a thin film of a predetermined pattern by etching, a method of driving the optical device by measuring the potential of the working electrode and the counter electrode to the reference electrode and controlling the supply of current as well as a camera system mounting the optical device.

Owner:SONY CORP

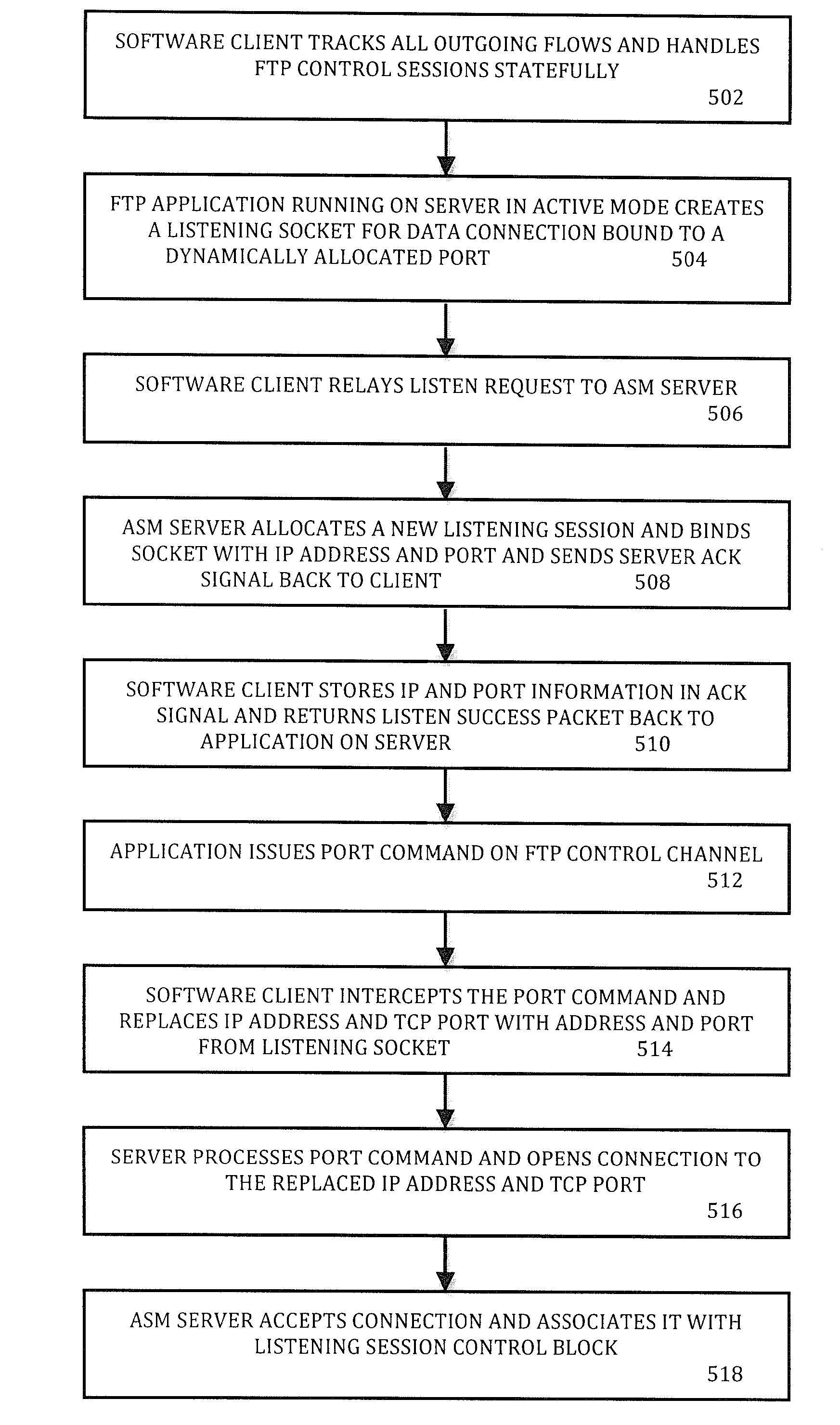

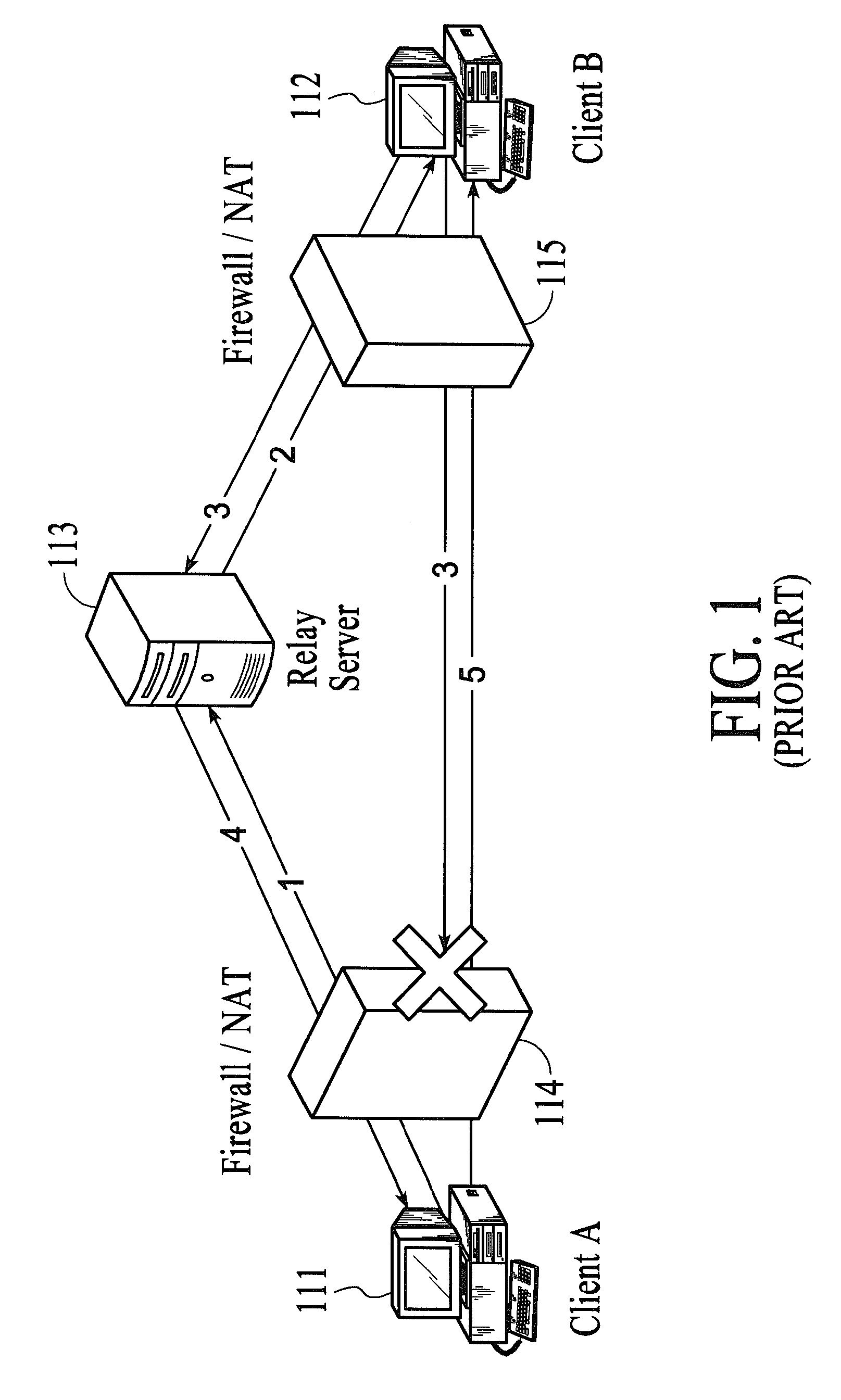

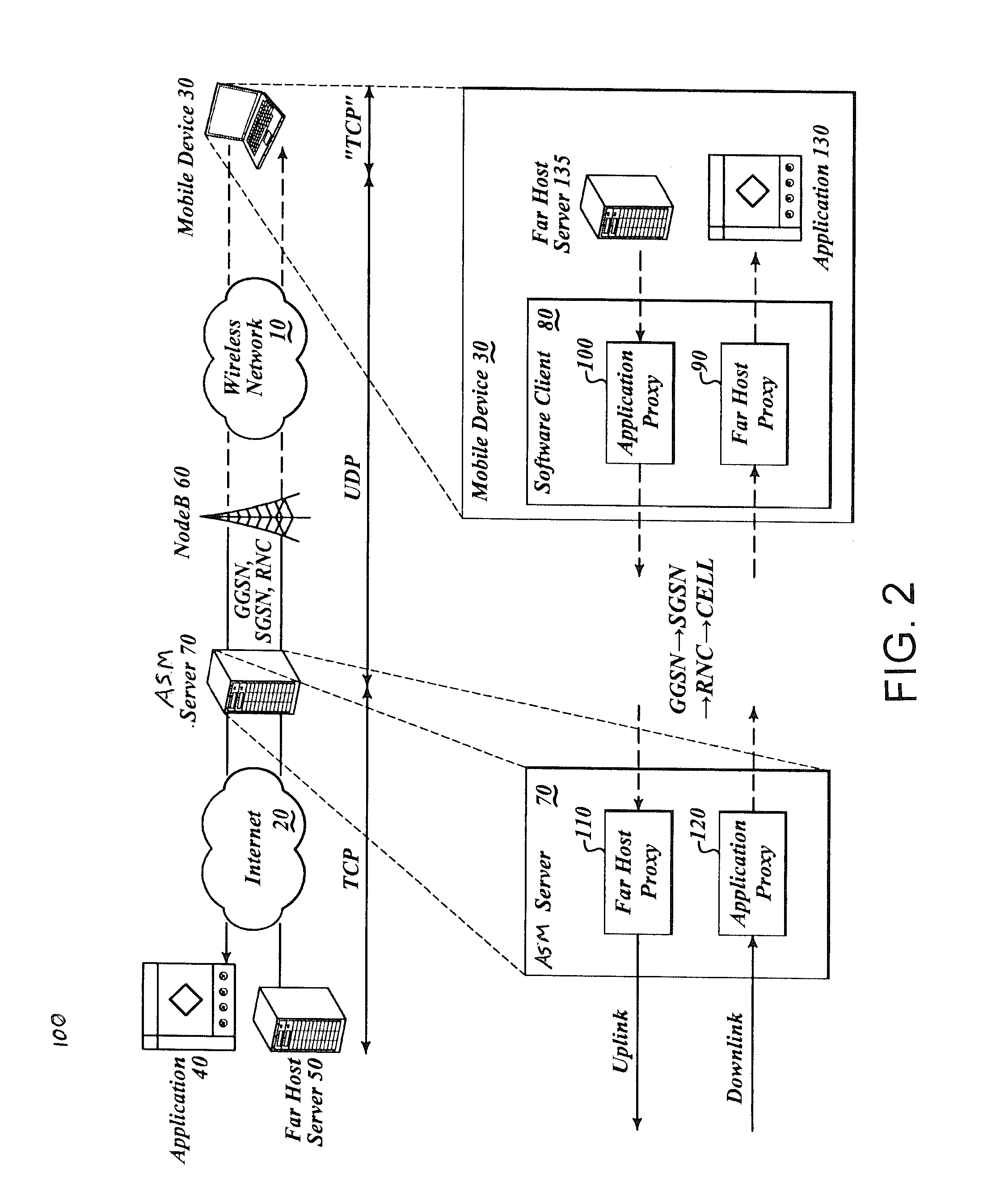

Method and system for client assisted stateful handling of packets in a communications network

InactiveUS20110219113A1Unduly burdensomeAvoiding indeterminismMultiple digital computer combinationsTransmissionNetwork packetClient-side

A method and system for stateful handling of packets in a network are described. In a client-server network environment, the stateful inspection of incoming protocols is offloaded from the server and distributed to the client device. The stateful inspection, as well as the provisioning of the client with the necessary functions required by the handlers, is referred to as Client Assisted Application Level Gateway (ALG). This version of ALG, in which the client performs or assists the server by performing at least some of the inspection and provisioning tasks, allows for a marked performance gain to the network gateway by reducing its packet inspection load.

Owner:MOBIDIA TECH

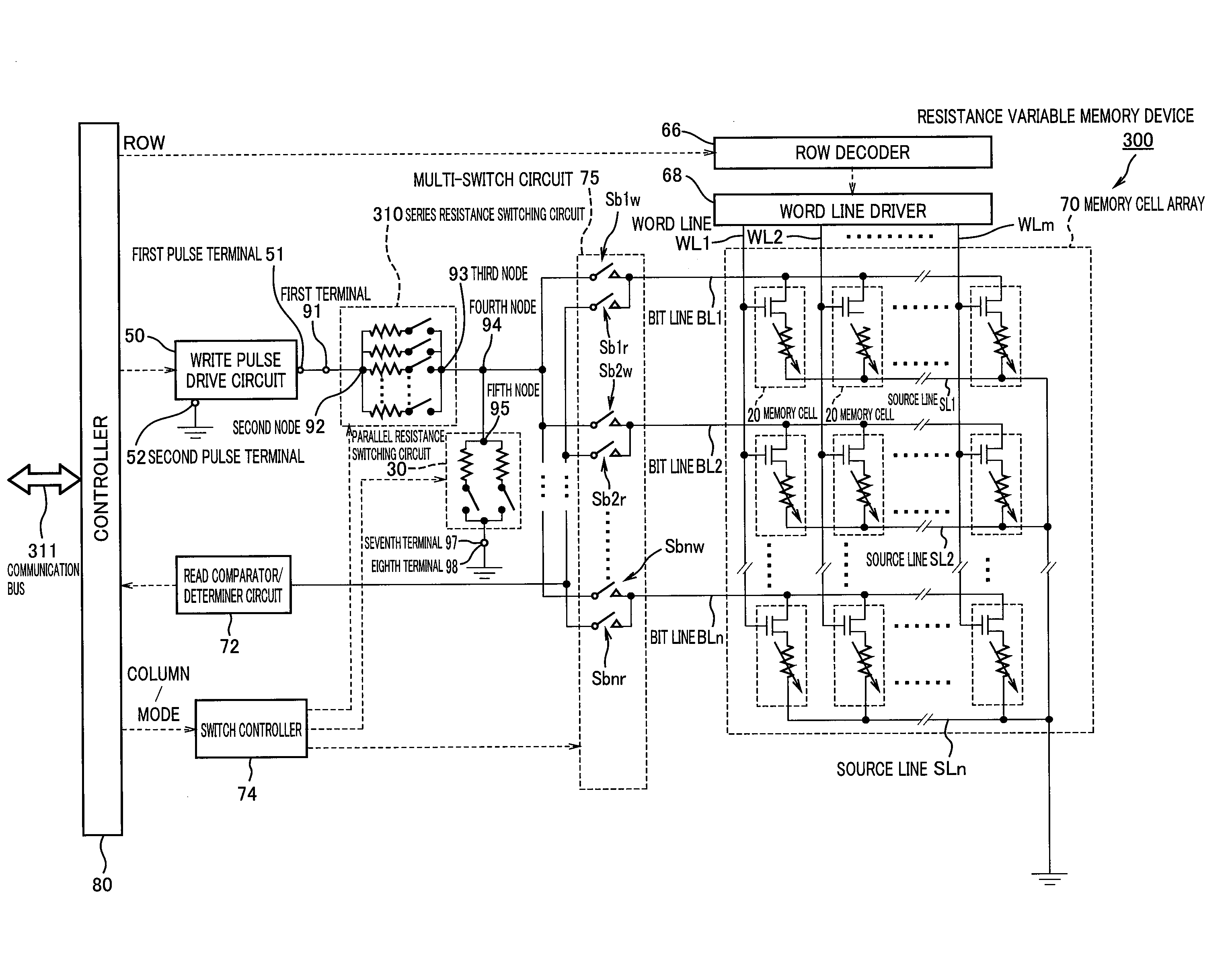

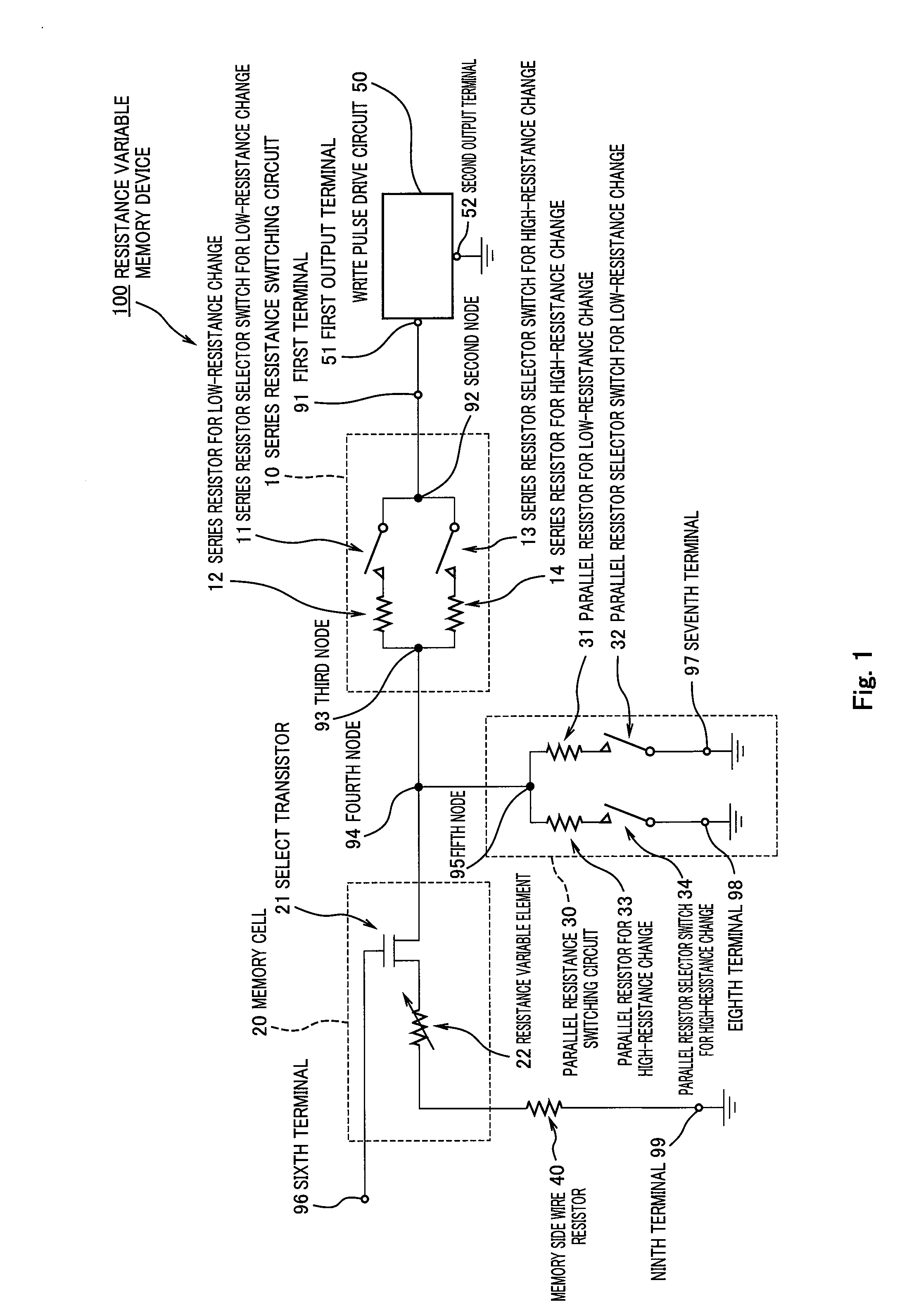

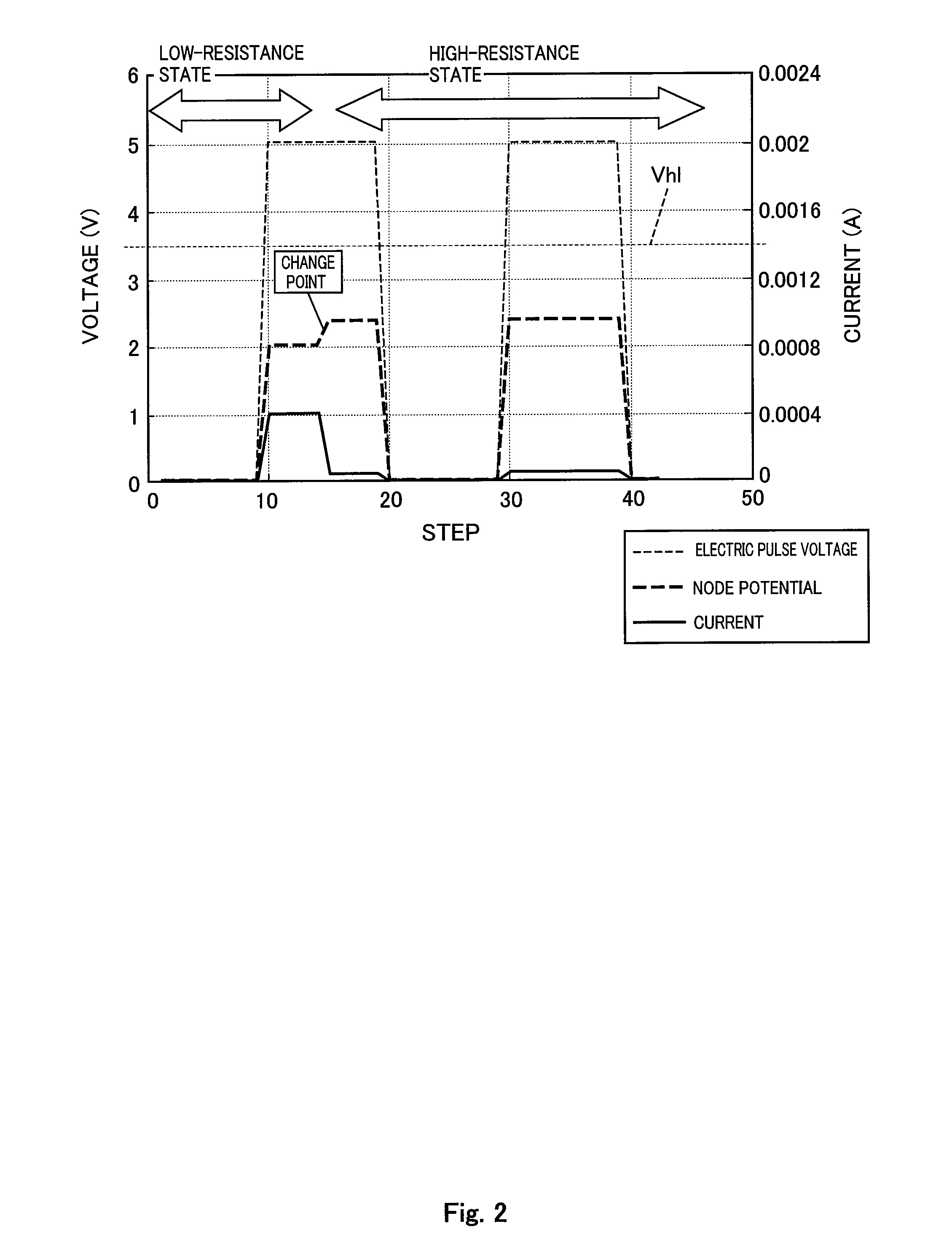

Nonvolatile memory device and method of writing data to nonvolatile memory device

ActiveUS20100202185A1Guaranteed uptimeExtend equipment lifeDigital storageHigh resistanceElectrical resistance and conductance

A nonvolatile memory device (300) is provided, including a memory cell array having plural resistance variable elements which are switchable between plural resistance states in response to electric pulses with the same polarity. A series resistance setting unit (310) is provided between the memory cell array (70) and an electric pulse application unit (50). The series resistance setting unit is controlled to change a resistance value of a series current path with a predetermined range with time in at least one of a case where the selected resistance variable element is switched from a low-resistance state to a high-resistance state and a case where the selected resistance variable element is switched from the high-resistance state to the low-resistance state.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

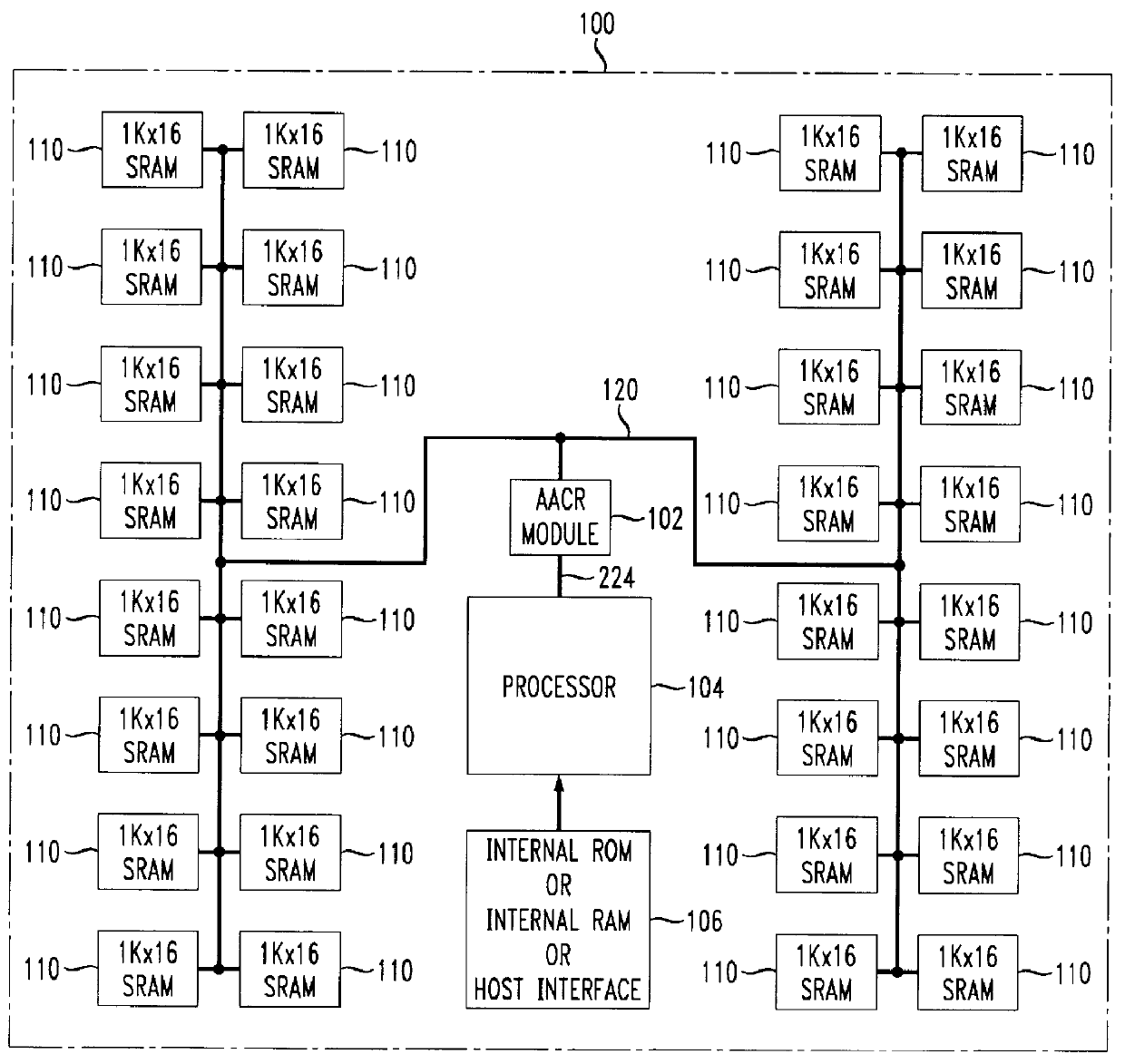

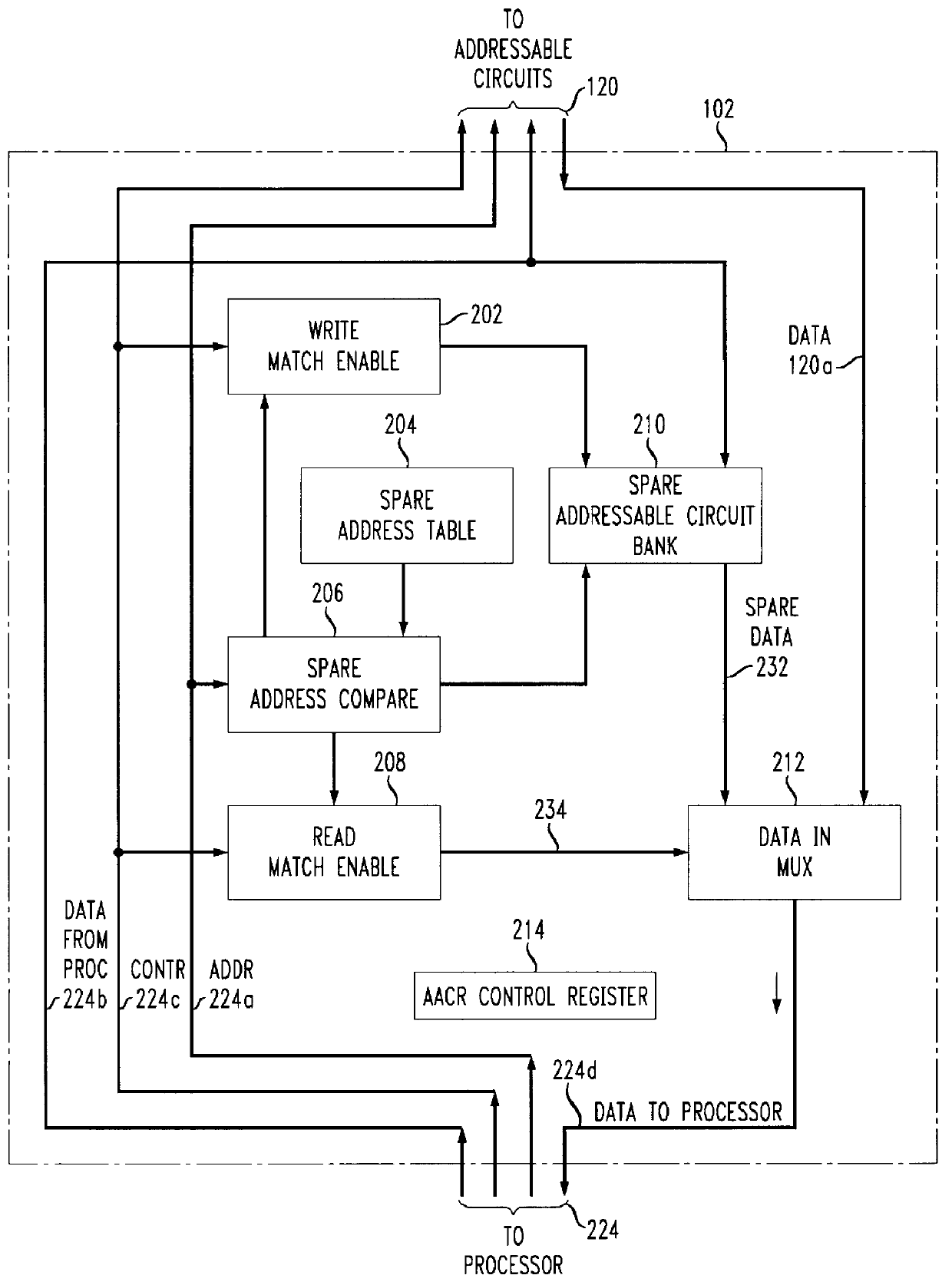

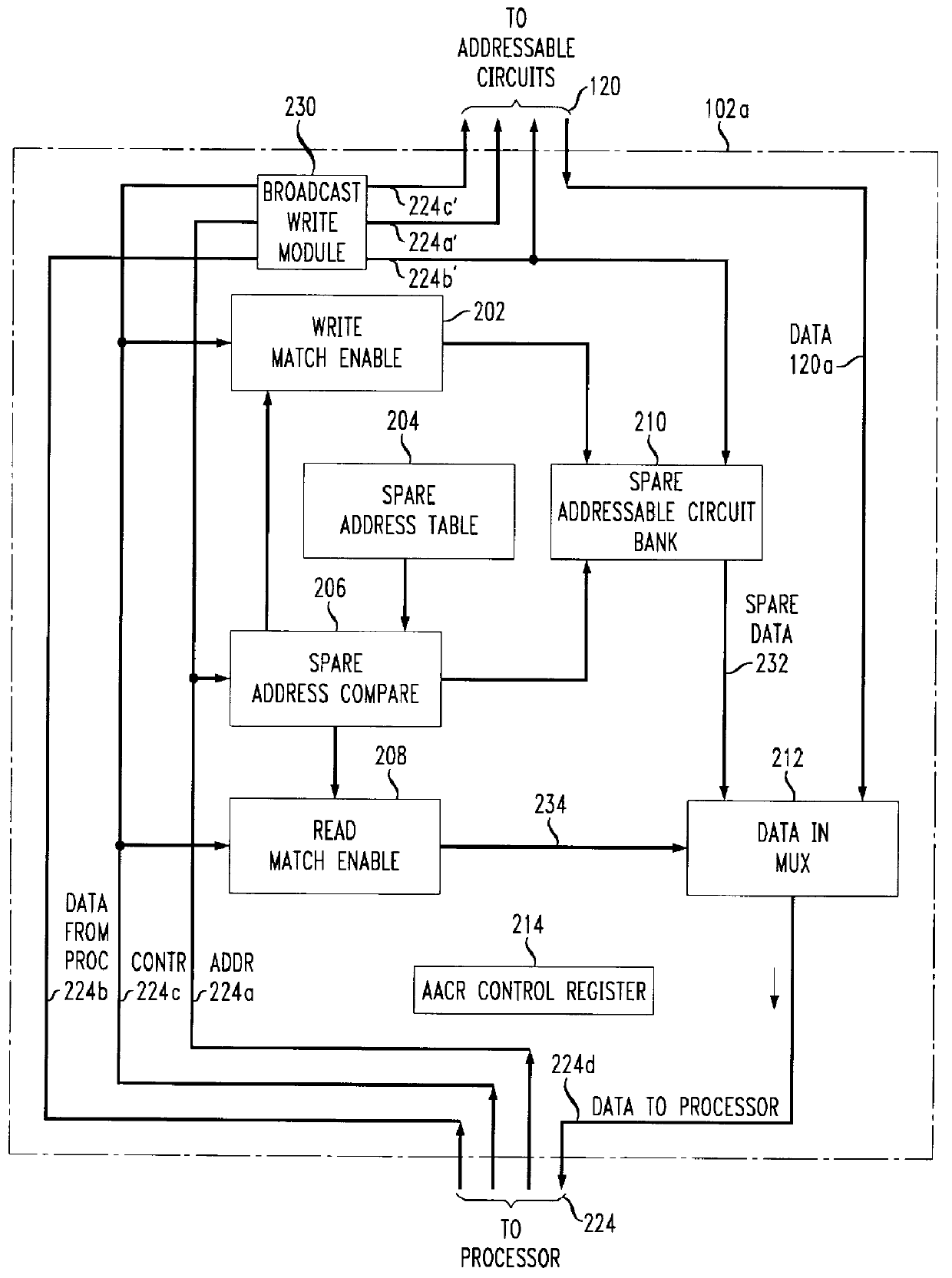

Adaptive addressable circuit redundancy method and apparatus

An adaptive addressable circuit redundancy method and apparatus, e.g., an adaptive memory redundancy method and apparatus, utilizes an on-chip processor to test, analyze and reassign spare addressable circuits to replace defective or intermittent addressable circuits. The present invention is applicable both in a manufacturing environment and / or in a field environment wherein the integrated circuit is operational. An adaptive addressable circuit redundancy module intercepts a data path between the on-chip processor and the addressable circuits to reassign defective addresses as necessary to utilize a spare addressable circuit bank. In another embodiment of the present invention, a broadcast write module cuts memory test time almost in half by writing a same data pattern to a significant portion or all of the addressable circuits, e.g., memory, substantially simultaneously.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE +1

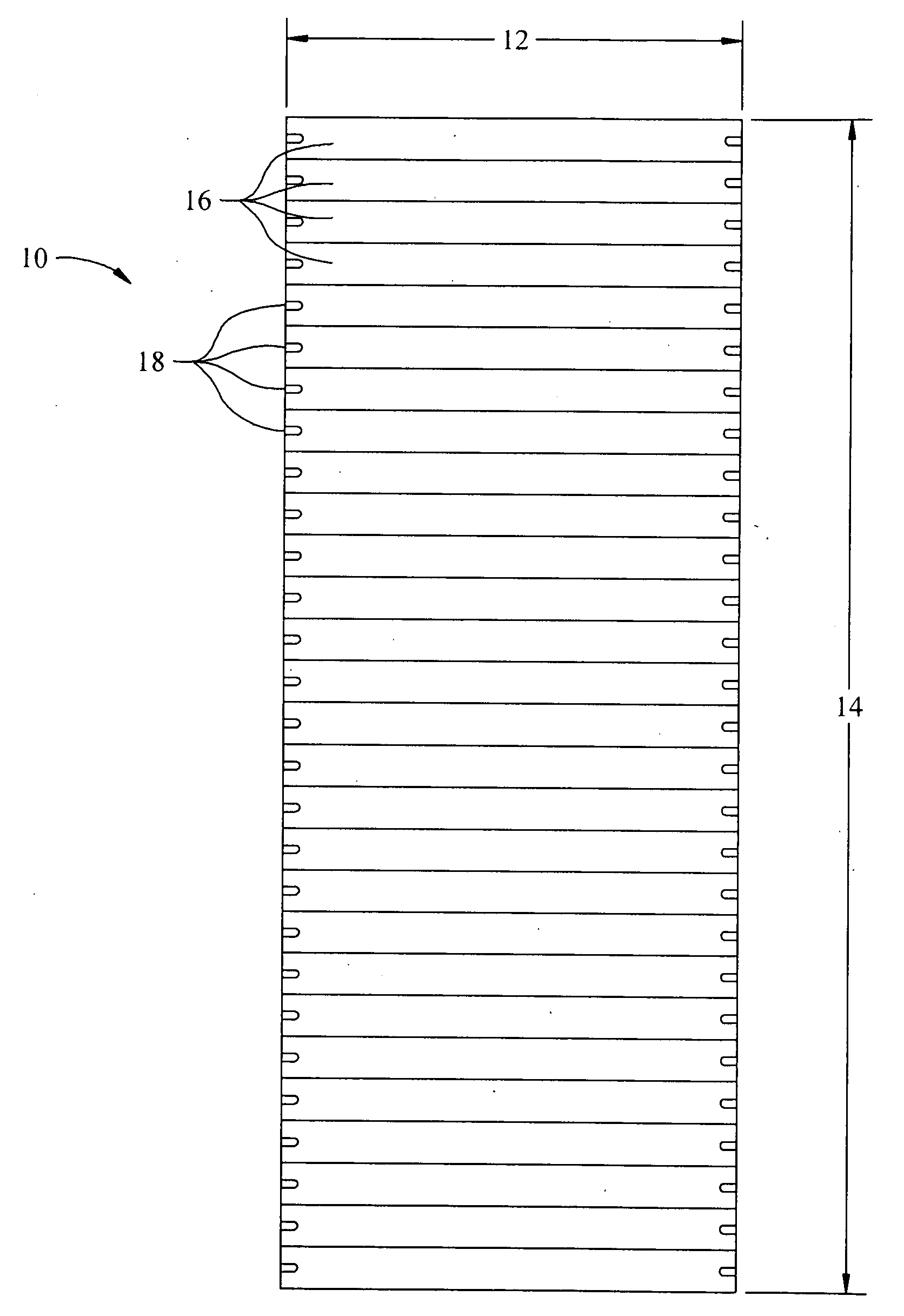

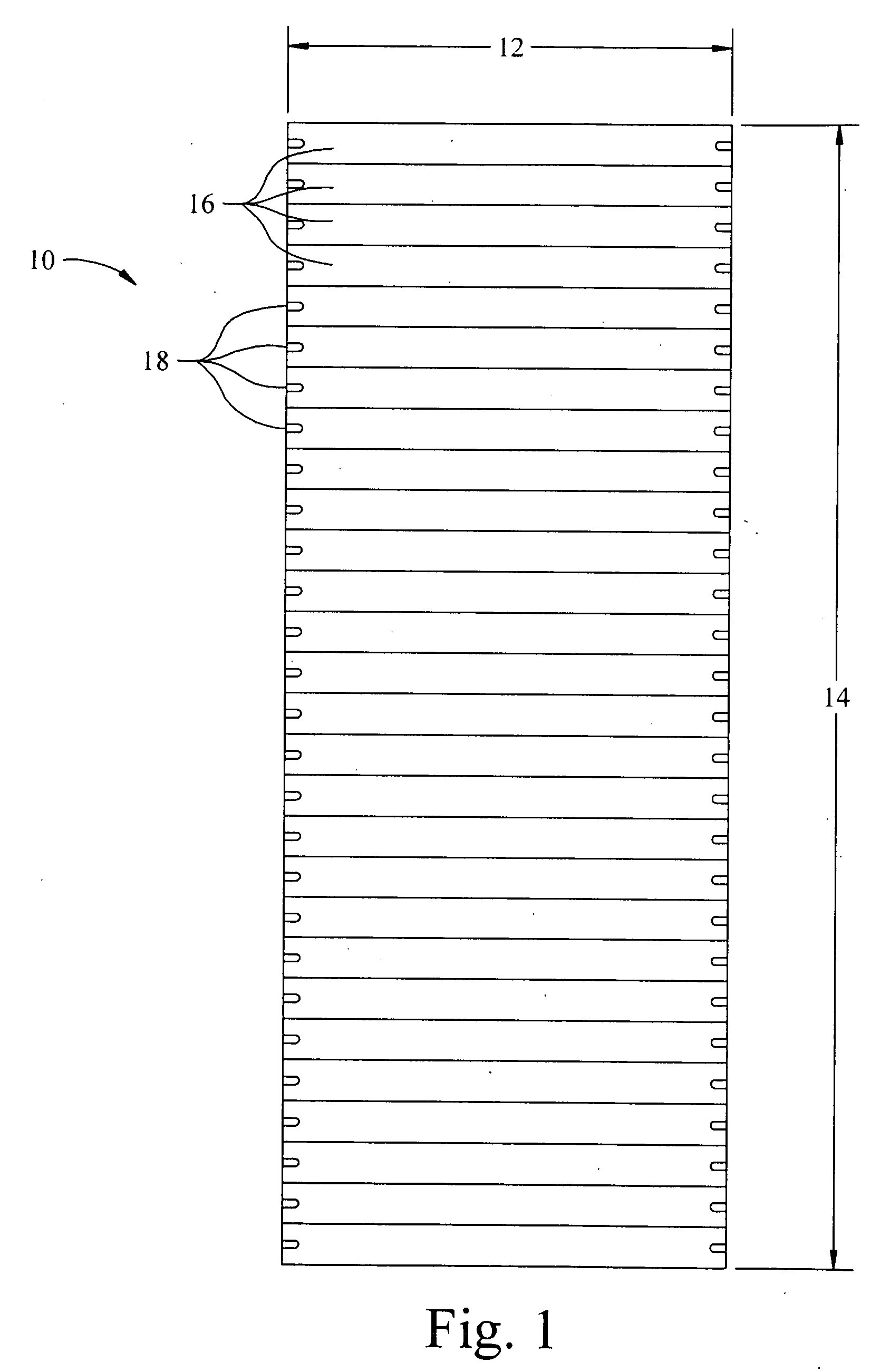

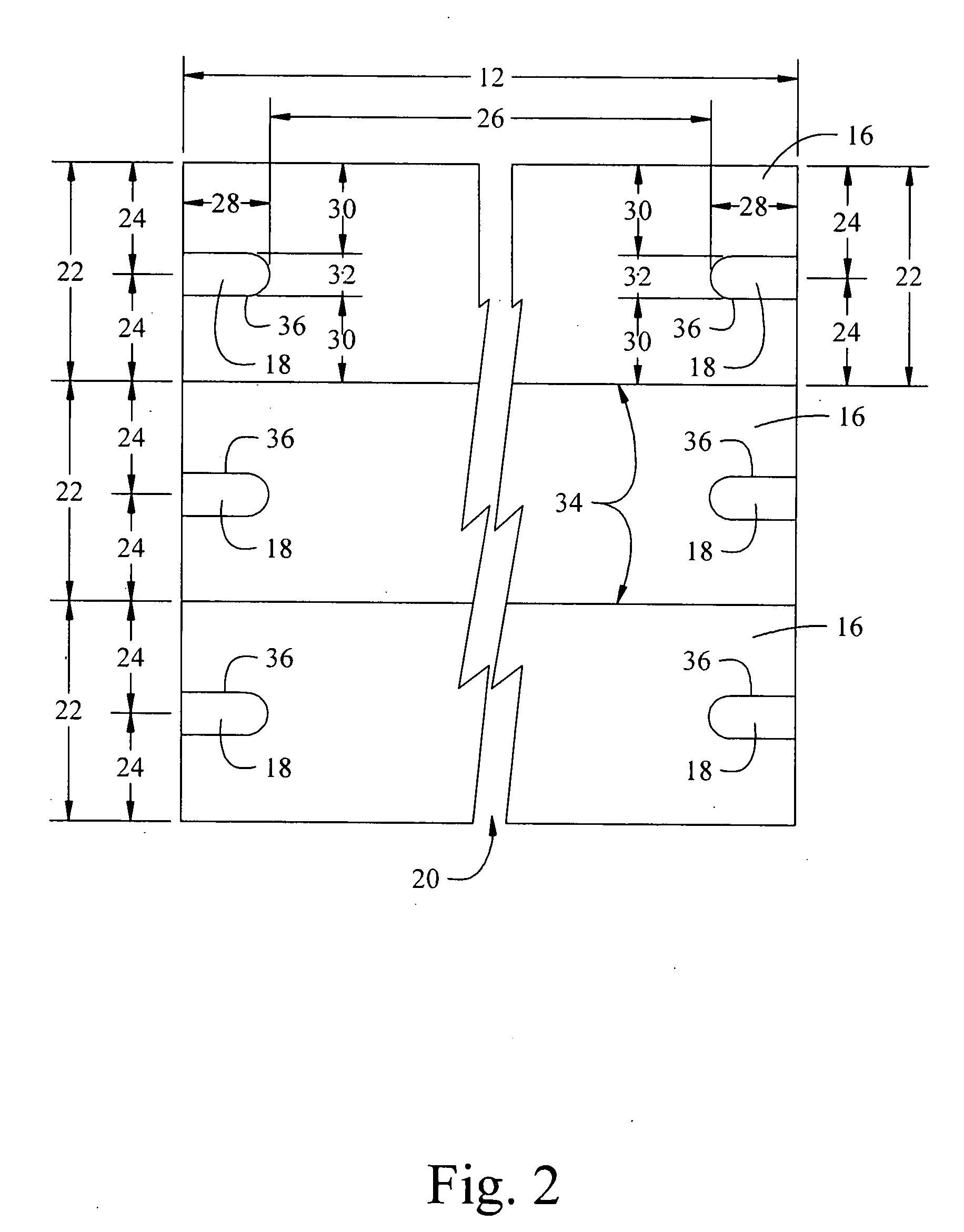

Server rack blanking panel and system

ActiveUS20090059486A1Easy to reconfigureExtend equipment lifeServersDigital data processing detailsEngineeringSurface plate

The present invention provides a system that allows for a single panel of the invention to be easily modified, preferably without the use of tools, to fit on a server rack, where the single panel is so modified as to cover the desired amount of open space on a server rack as a single piece, where the panel is preferably fire-rated, and where the modified panel may be easily installed onto the server rack to as to cover any open space thereon, and prevents the circular flow of warm air output from entering the cooler air input of the servers housed on the server rack.

Owner:COMPUSPACE LC

Bump electrodes having multiple under ball metallurgy (UBM) layers

InactiveUS7271498B2Improve adhesionExtend equipment lifeSemiconductor/solid-state device detailsSolid-state devicesEngineeringActive surface

The present invention provides a wafer structure having a plurality of bonding pad, an adhesion layer, a barrier layer, a wetting layer, a plurality of bump, a first passivation layer and a second passivation layer. The bonding pads are disposed on the active surface of the wafer and exposed by the first passivation layer. The second passivation layer is disposed on the first passivation layer and exposing the bonding pads. An adhesion layer is disposed on the bonding pad and covers a portion of the first passivation layer. The second passivation layer covers the first passivation layer and a portion of the adhesion layer. The barrier layer and the wetting layer are sequentially disposed on the adhesion layer and the bumps are disposed on the wetting layer.

Owner:ADVANCED SEMICON ENG INC

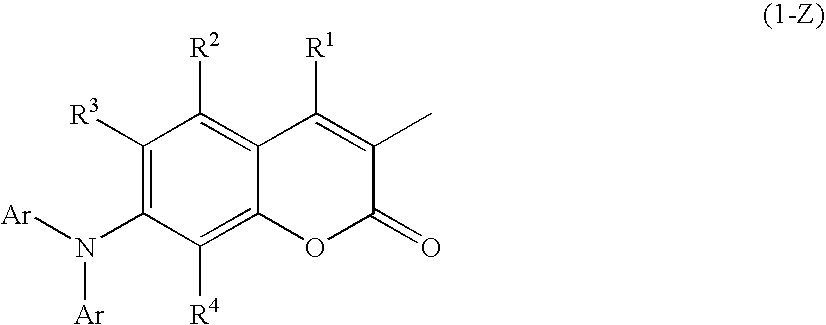

Coumarin compound, material for light emitting device and organic electroluminescent device

InactiveUS20070176544A1Solve low luminous efficiencyExtend equipment lifeOrganic chemistryDischarge tube luminescnet screensOrganic electroluminescenceLight emitting device

Provided are an organic electroluminescent device having better performances in luminous efficiency, device life and driving voltage, a display unit equipped with the same and a lighting instrument equipped with the same. The organic electroluminescent device comprises an electron transport layer containing a specific arylamine-substituted coumarin compound.

Owner:JNC CORP

Light modulation information display device and illumination control device

InactiveUS6956555B2Reduce the numberImproving display blurCathode-ray tube indicatorsMultiple discharge path lampsOptoelectronicsLight modulation

An illumination control device for illuminating an light modulation information display device with light includes: at least one illumination device for irradiating light which is generated through discharging; and a driving waveform generation section for controlling the light which is irradiated from the at least one illumination device to the light modulation information display device. The light modulation information display device is operable so as to have a first period and a second period during which an image is displayed. During the first period, the driving waveform generation section applies a first voltage to the at least one illumination device, the first voltage causing the at least one illumination device to be turned entirely-ON. During the second period, the driving waveform generation section applies a second voltage to at least a portion of the at least one illumination device.

Owner:SHARP KK

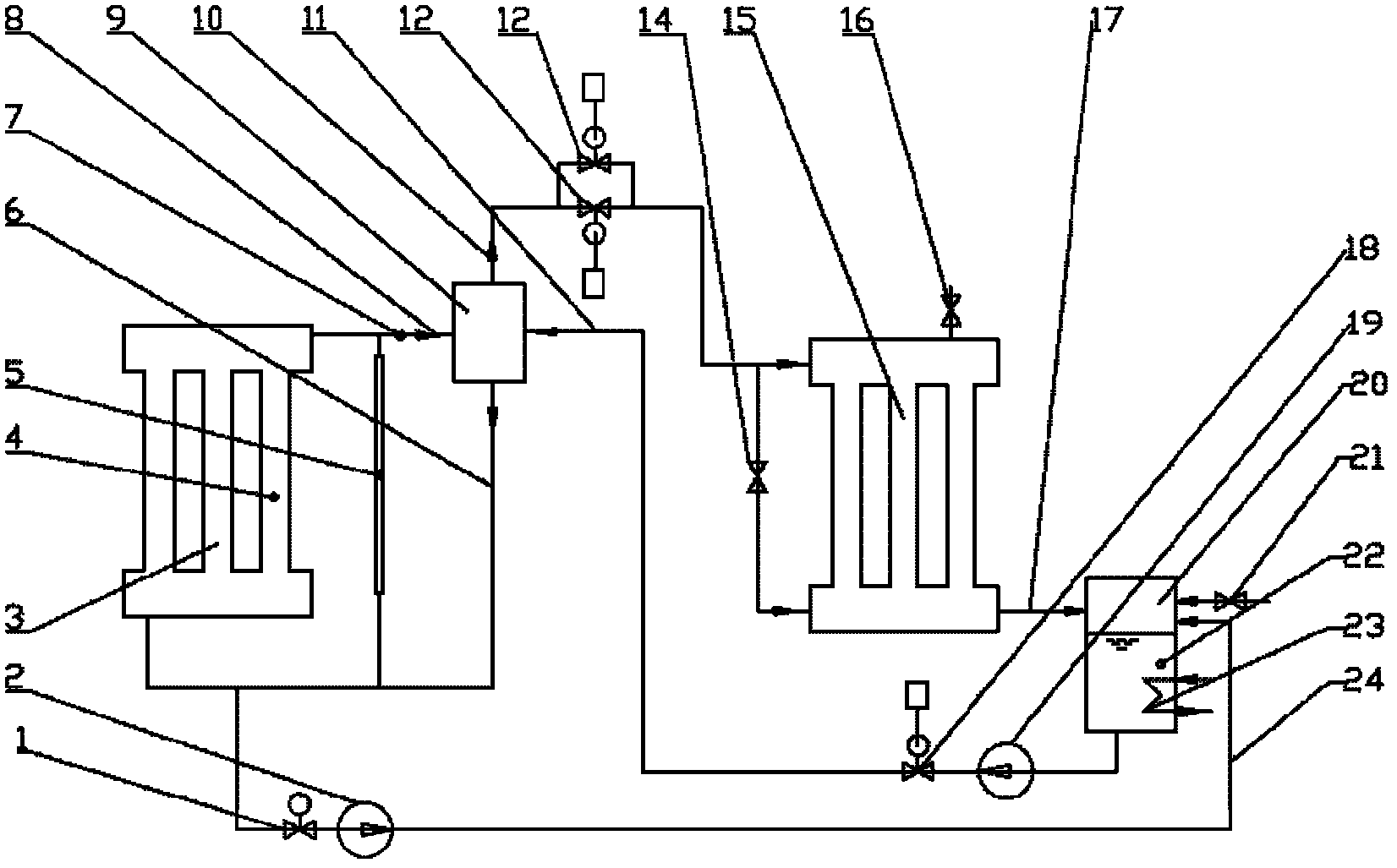

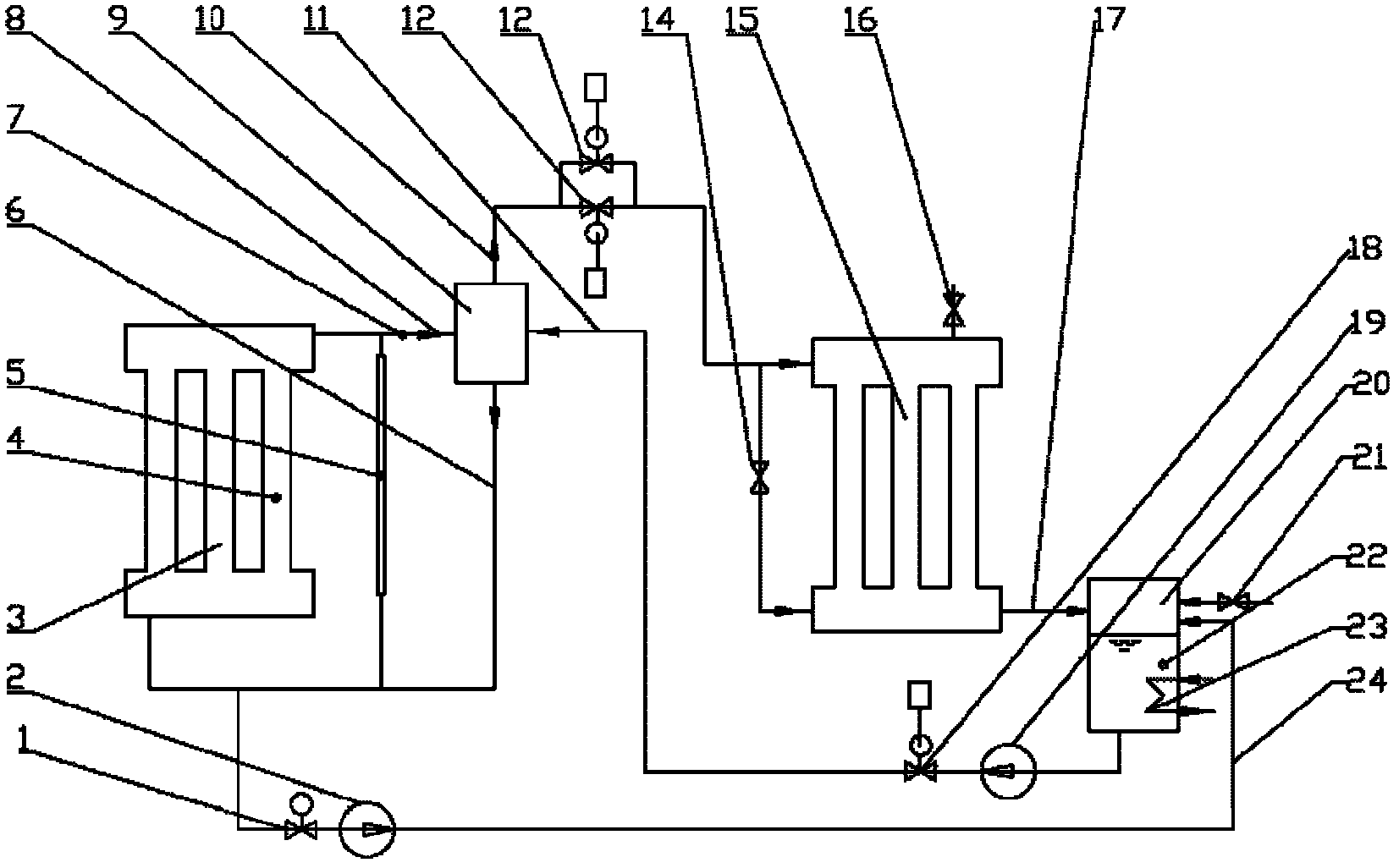

Branch control phase inversion heat exchange system and method based on vapor-liquid heat exchanger

ActiveCN102252543AWall temperature is not affectedReduce the chance of low temperature corrosionIndirect heat exchangersEngineeringLiquid storage tank

The invention relates to a branch control phase inversion heat exchange system and a branch control phase inversion heat exchange method based on a vapor-liquid heat exchanger. The system comprises a liquid storage tank (20), a heat source heat exchanger (3), a cold source heat exchanger (15) and a vapor-liquid heat exchanger (9); an upper collection tank of the heat source heat exchanger (3) is communicated with the vapor-liquid heat exchanger (9) through a heat exchanger inlet steam pipe (8); a vapor-liquid heat exchanger outlet steam pipe (10) which is arranged on the vapor-liquid heat exchanger (9) is divided into two branches which are communicated with an upper collection tank and a lower collection tank of the cold source heat exchanger (15); the lower collection tank of the cold source heat exchanger (15) is communicated with the upper part of the liquid storage tank (20) through a cold source heat exchanger liquid outlet pipe (17); the bottom of the liquid storage tank (20) is communicated with the vapor-liquid heat exchanger (9) through a heat exchanger inlet condensation liquid pipe (11); and the vapor-liquid heat exchanger (9) is communicated with a lower collection tank of the heat source heat exchanger (3) through a heat exchanger outlet condensation liquid pipe (6). The branch control phase inversion heat exchange system can solve the phenomena of overcooling and overheating and improve heat exchanging efficiency.

Owner:SHANXI SANHESHENG IND TECH

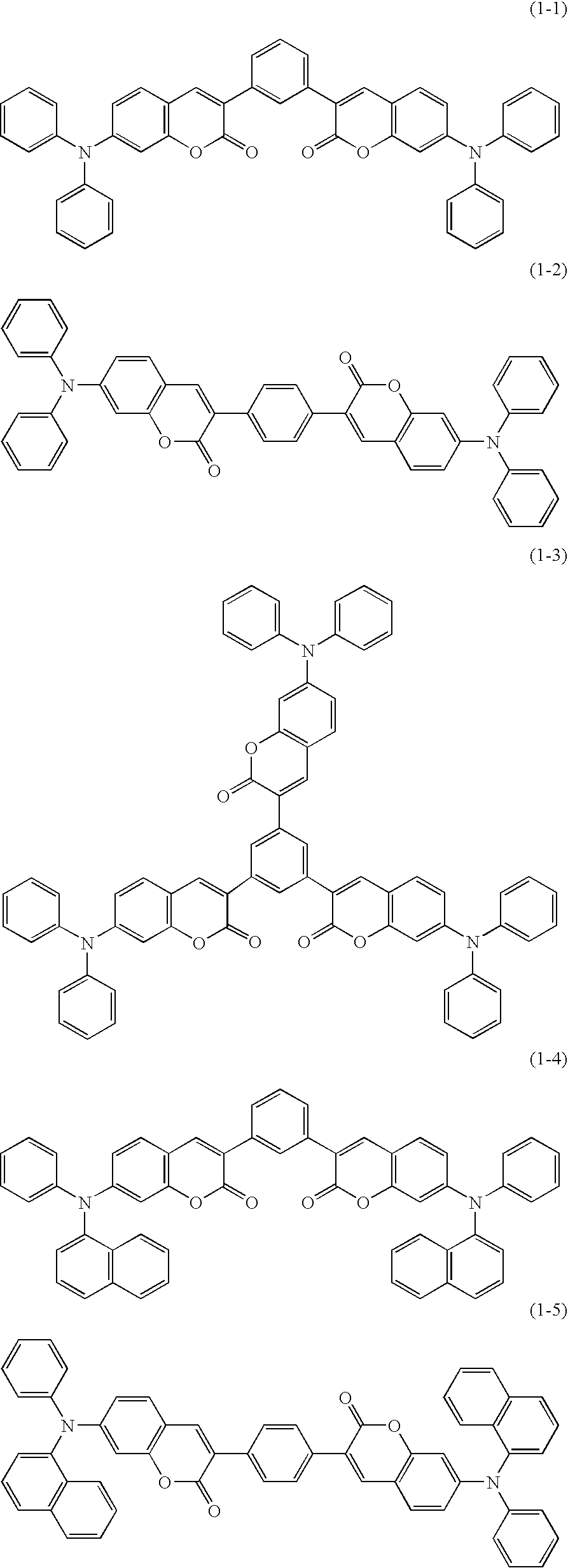

Novel organic electroluminescent compounds and organic electroluminescent device using the same

InactiveUS20100019657A1Improve luminous efficiencyExtend equipment lifeSilicon organic compoundsDischarge tube luminescnet screensOrganic electroluminescenceOrganic chemistry

The present invention relates to novel organic electroluminescent compounds, and organic electroluminescent devices employing the same as electroluminescent material. Specifically, the organic electroluminescent compounds according to the invention are characterized in that they are represented by Chemical Formula (1):Since the organic electroluminescent compounds according to the invention have good luminous efficiency and life property of material, OLED's having very good operation lifetime can be manufactured.

Owner:GRACEL DISPLAY INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![[wafer structure and bumping process thereof] [wafer structure and bumping process thereof]](https://images-eureka.patsnap.com/patent_img/a3553ac0-1a93-4187-89d5-ad0fce4e7d8e/US20050006759A1-20050113-D00000.png)

![[wafer structure and bumping process thereof] [wafer structure and bumping process thereof]](https://images-eureka.patsnap.com/patent_img/a3553ac0-1a93-4187-89d5-ad0fce4e7d8e/US20050006759A1-20050113-D00001.png)

![[wafer structure and bumping process thereof] [wafer structure and bumping process thereof]](https://images-eureka.patsnap.com/patent_img/a3553ac0-1a93-4187-89d5-ad0fce4e7d8e/US20050006759A1-20050113-D00002.png)