Noiseless dust-free electric saw with lifting system

A lifting system and silent technology, applied in the direction of circular saws, sawing equipment, bark area/debris/dust/waste removal, etc., can solve the problems of chainsaw noise and saw blade adjustment, to prevent dust from spreading, high economy Benefits and social benefits, the effect of reducing noise and dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

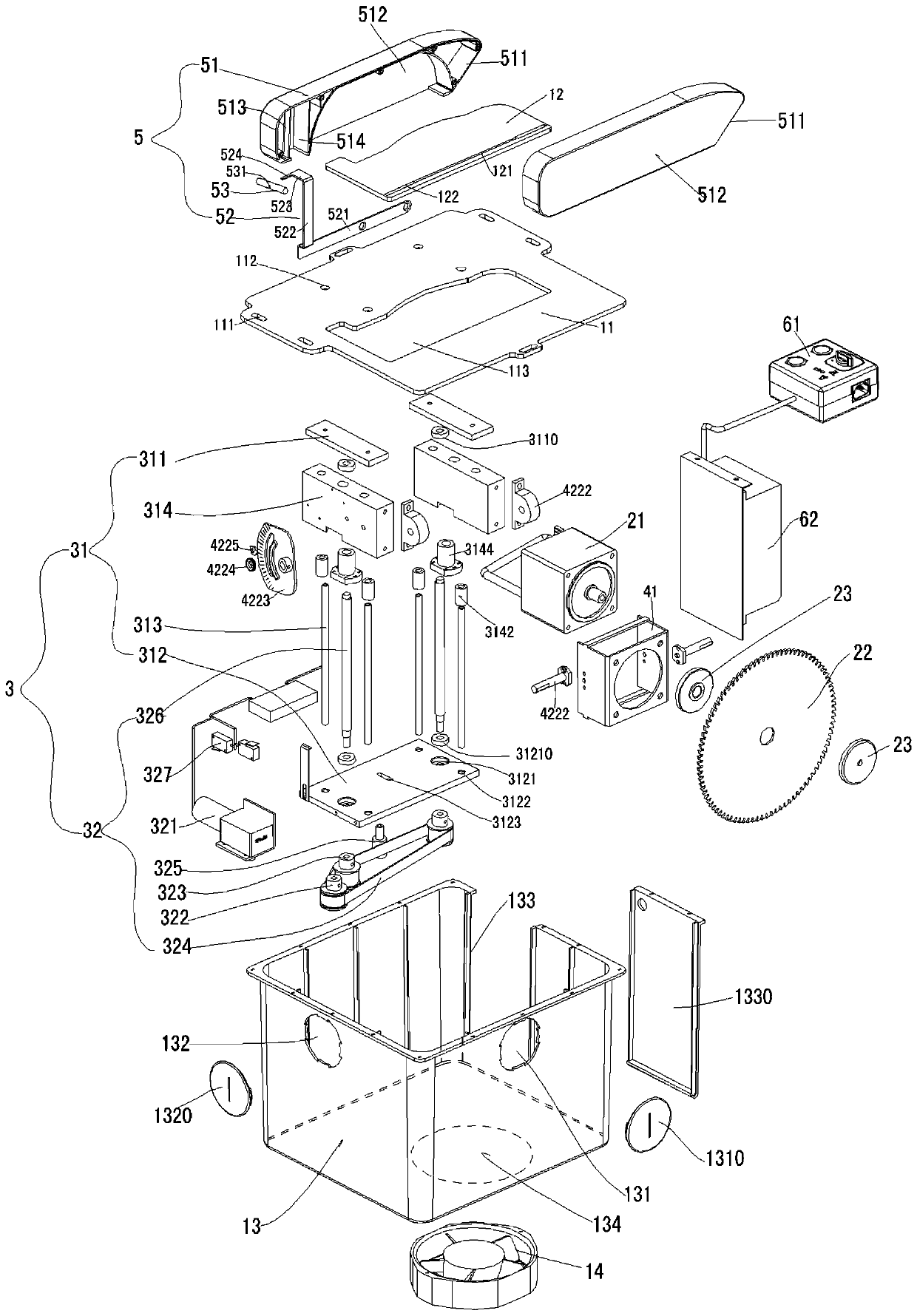

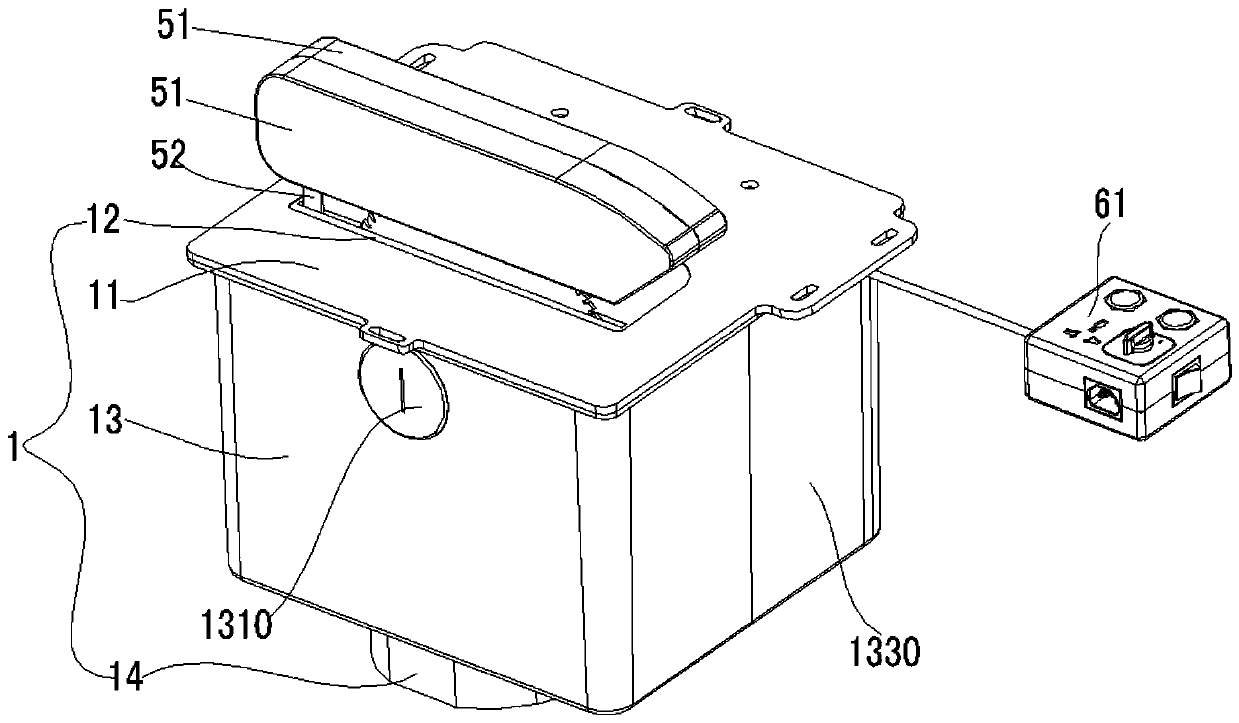

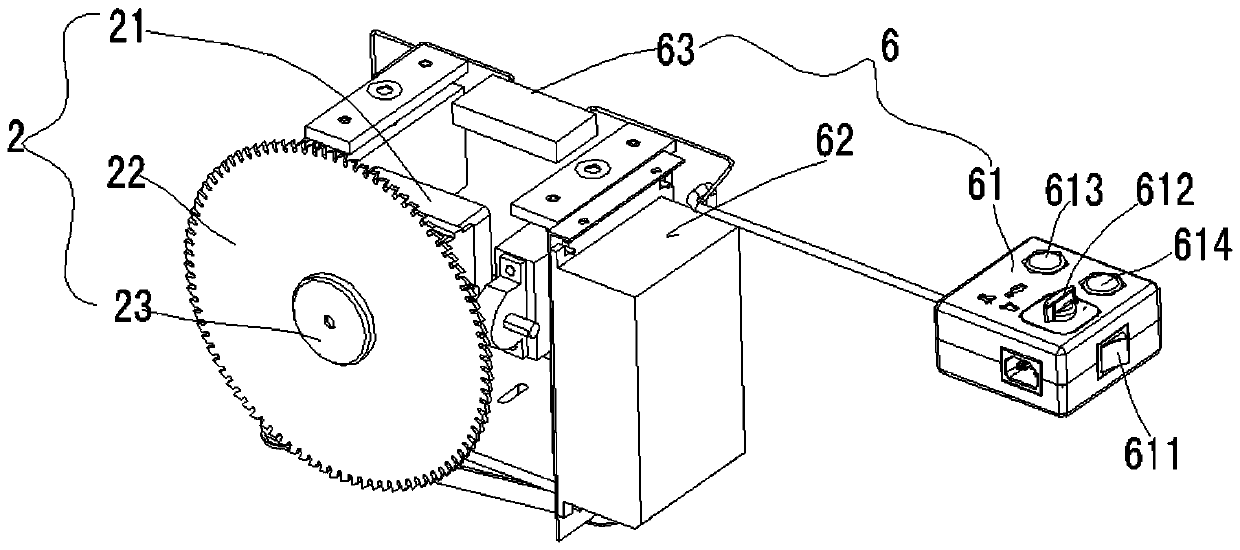

[0047] The present invention is implemented in the following ways: as Figure 1 to Figure 4 As shown, the silent and dust-free electric saw provided by the present invention includes a base system 1, a cutting system 2, a lifting system 3, an angle control system 4, a silent cover system 5, a power supply and a control system 6;

[0048] Such as figure 1 , figure 2 As shown, the base system 1 includes a base plate 11, a movable plate 12, a surrounding plate 13, and a dust collection fan 14; a mounting groove 111 is provided around the base plate 11, a lifting bracket fixing hole 112 is provided in the base plate 11, and a movable plate Groove 113, the movable plate 12 is embedded in the movable plate groove 113, and a saw blade groove 121 and a support rod through groove 122 are provided on the movable plate 12; In the casing, the front side of the coaming plate 13 is provided with a saw blade assembly hole 131, the left side is provided with an angle adjustment hole 132, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com