Bucket elevator

A bucket elevator and casing technology, which is applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of poor operating environment and large resistance of bucket elevators, avoid overload operation, increase quantity, and reduce dust. exaggerated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

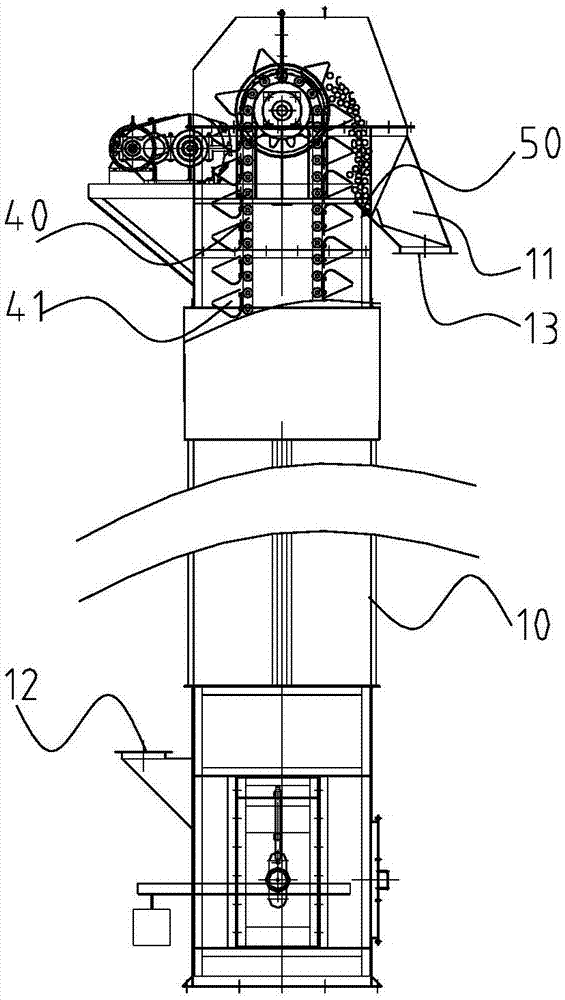

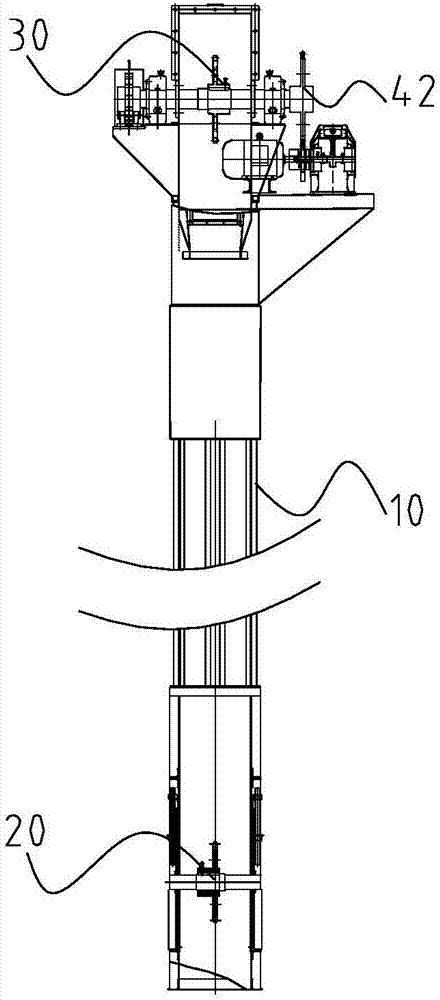

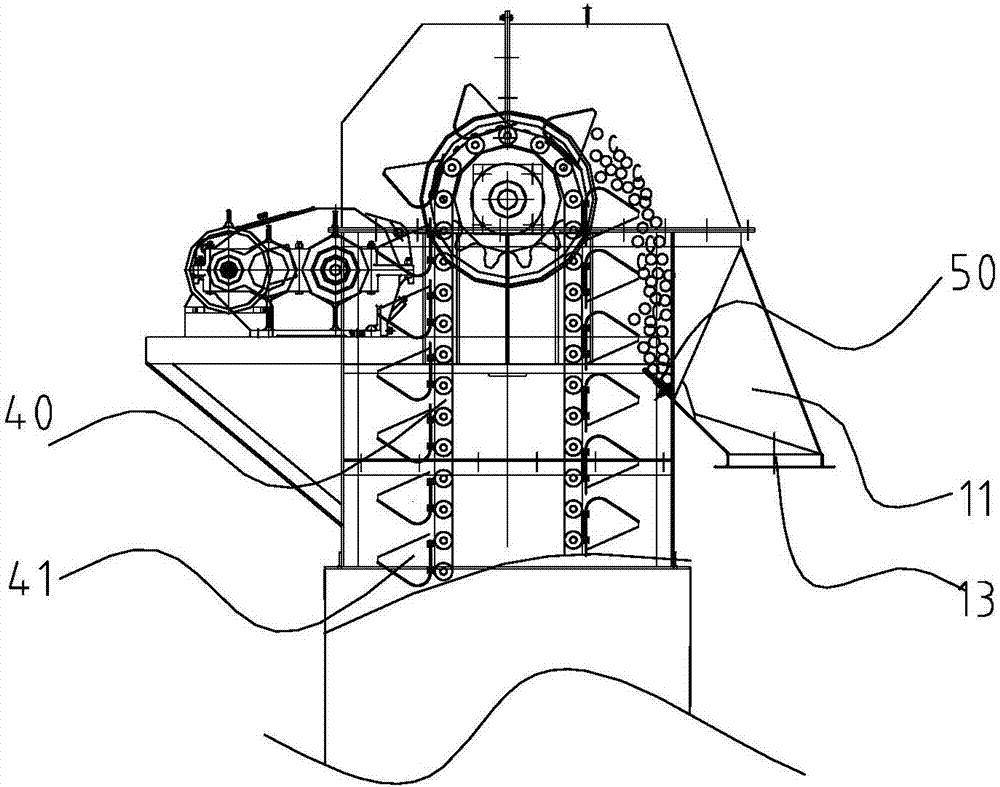

[0022] Such as figure 1 and figure 2 , image 3 as well as Figure 4 As shown, the present embodiment provides a bucket elevator, which includes a tail wheel 20 located at the bottom of the casing 10 and a head wheel 30 located at the top of the casing 10, the tail wheel 20 and the head wheel 30 are wound around There is a chain 40, and a plurality of hoppers 41 are uniformly fixed on the chain 40, and the top of the casing 10 is provided with a material receiving chute 11, and the material receiving chute 11 is located below the center of the head wheel 30, and the The material receiving chute 11 extends through the inner wall of the casing 10 to the outer wall, and the material receiving chute 11 extends toward the head wheel 30 and is provided with a material stopper 50, the material stopper 50 includes a material stopper rubber 51 and The baffles 52 located on both sides of the stopper rubber 51, wherein the end of the stopper rubber 51 adjacent to the baffle 52 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com