Closed efficient double-bin sifter

A double-chamber sieve and closed technology, which is applied in the fields of filtration, solid separation, chemical instruments and methods, etc., can solve the problems of external lifting, material pollution, and reduction of sieve grid area, so as to avoid material lifting and ensure cleanliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

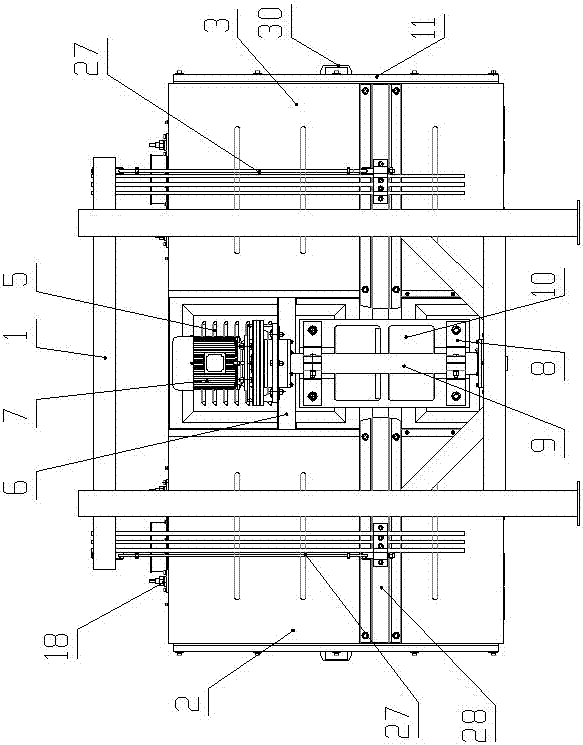

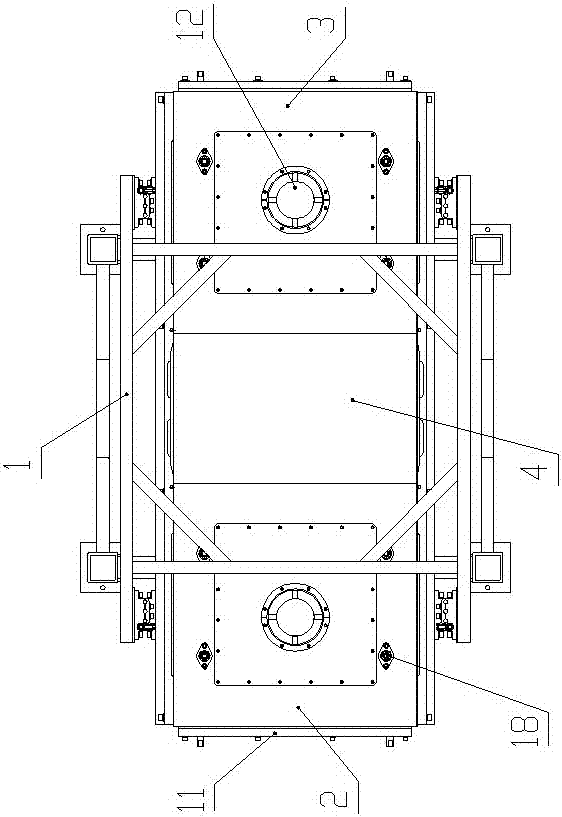

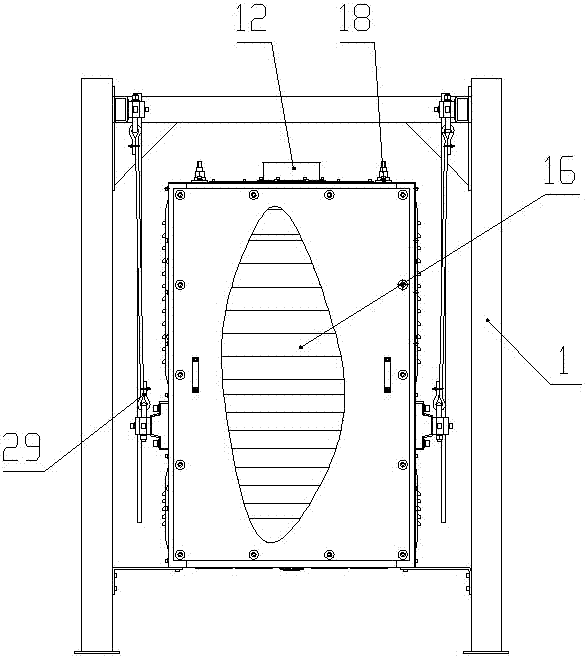

[0027] Such as Figure 1-5 As shown, a closed high-efficiency double-chamber screen of the present invention includes a frame 1 and a screen box, the screen box is fixedly connected in the frame 1 through a hanging device, and a left screen box 2 and a right screen box are arranged in the screen box. 3 and the transmission chamber 4, the transmission chamber 4 is located between the left sieve chamber 2 and the right sieve chamber 3, the front and rear sides of the transmission chamber 4 are provided with heat dissipation windows 5, the middle part of the transmission chamber 4 is horizontally provided with a fixed plate 6, and the upper part of the fixed plate 6 is fixed The drive motor 7 is connected, the fixed plate 6 and the bottom of the transmission chamber 4 are respectively flange-connected with a bearing seat 8, and a transmission shaft 9 is connected between the two bearing seats 8, and the transmission shaft 9 passes through the fixed plate 6 upwards, and the drive m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com