Dust-proof type belt conveyor discharge port

A belt conveyor and discharge port technology, applied in conveyors, loading/unloading, conveyor objects, etc., can solve problems such as pollution and dust leakage, achieve the effect of improving dust, prevent dust from rising, and be easy to use and maintain. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

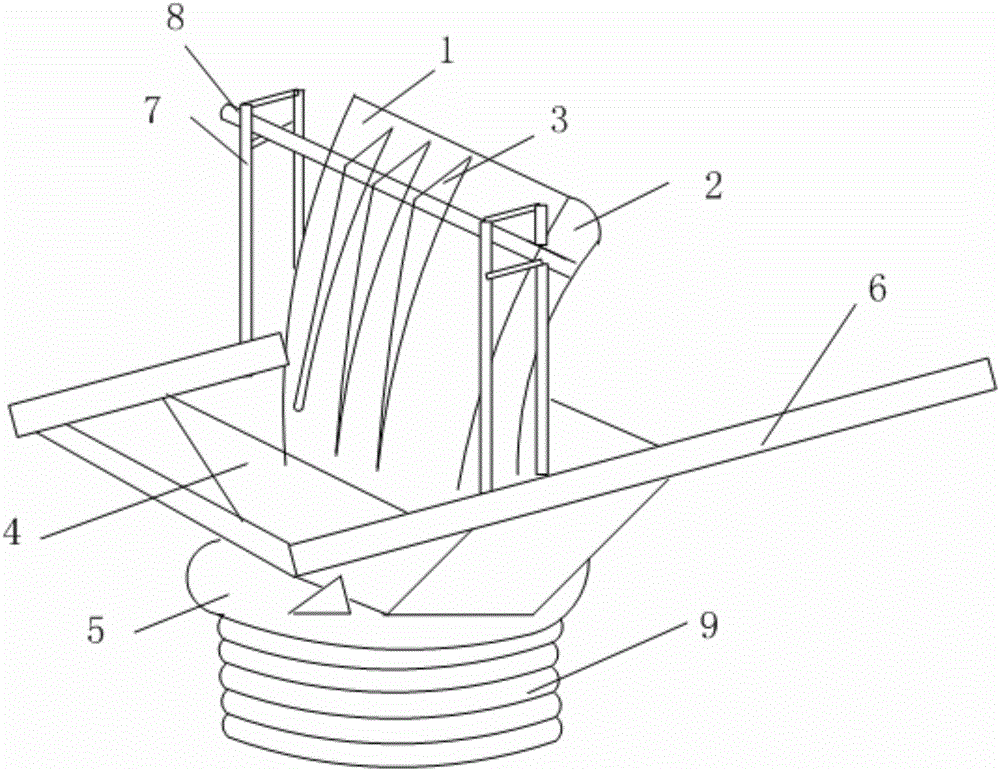

[0019] Example: such as figure 1 The discharge port of the dust-proof belt conveyor shown includes a material collection device, and its characteristics are: the lower end of the material collection device is equipped with a variable diameter device, a lifting device is installed on the variable diameter device, and the tail section of the variable diameter device A dustproof device is attached. In this way, in actual use, the material collection device is aligned with the belt conveyor to effectively collect materials.

[0020] As far as a preferred embodiment of the present invention is concerned, the material collecting device used is a collecting scoop 1 , the two sides of the collecting scoop 1 are provided with enclosures 2 , and the back of the collecting scoop 1 is provided with reinforcing ribs 3 . In this way, there will be no spilling and scattering when receiving the materials from the belt, which improves the completeness of collection.

[0021] In this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com