Multiple steel tube and reinforcing steel bar delivery and derusting device

A technology for steel pipes and steel bars, which is applied in the field of transmission and derusting devices for two steel pipes and steel bars, can solve the problems of single transmission and derusting of rigid tubular materials, and achieve the goal of avoiding steel shot throwing, avoiding dead ends, and high automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

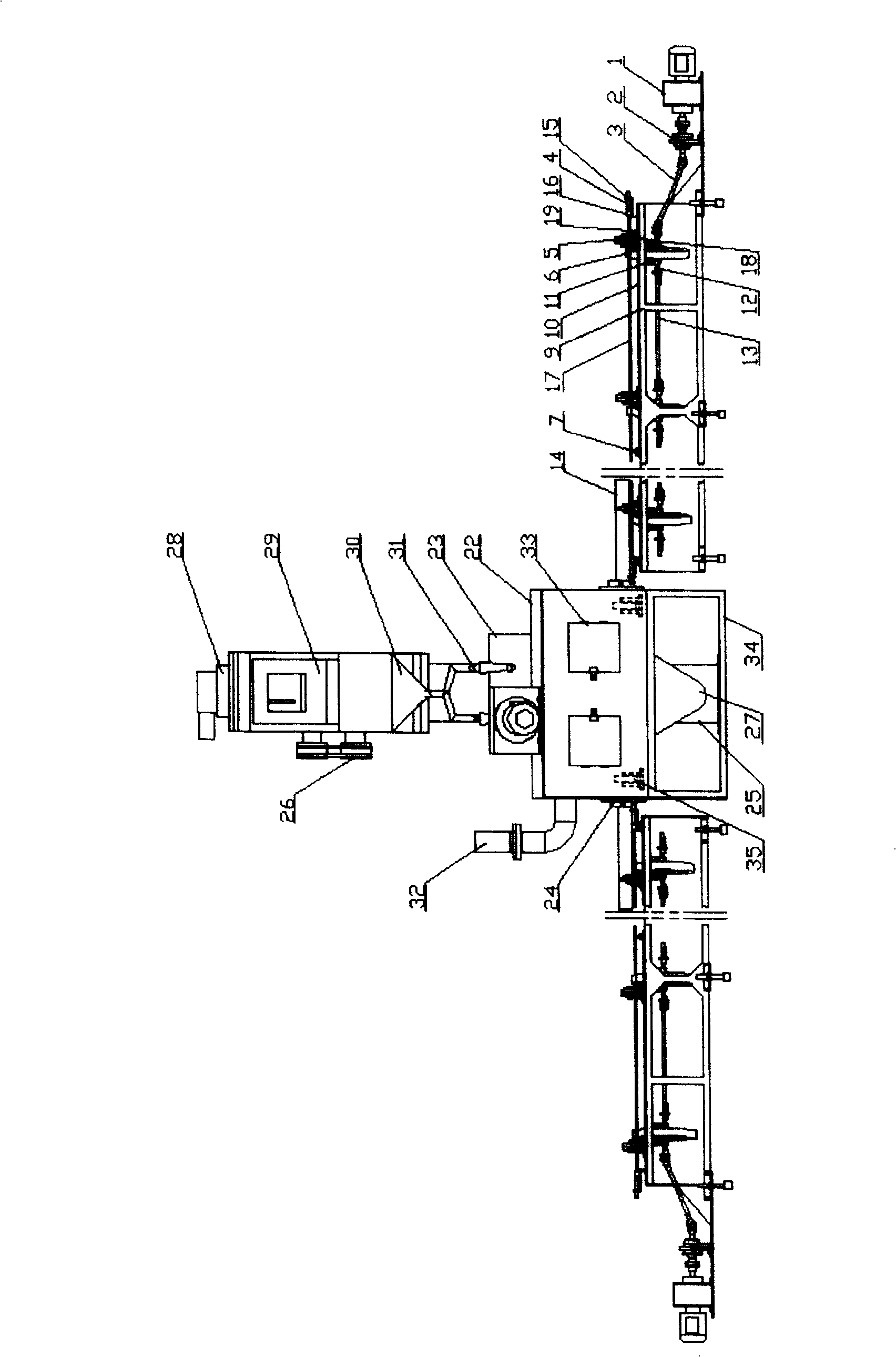

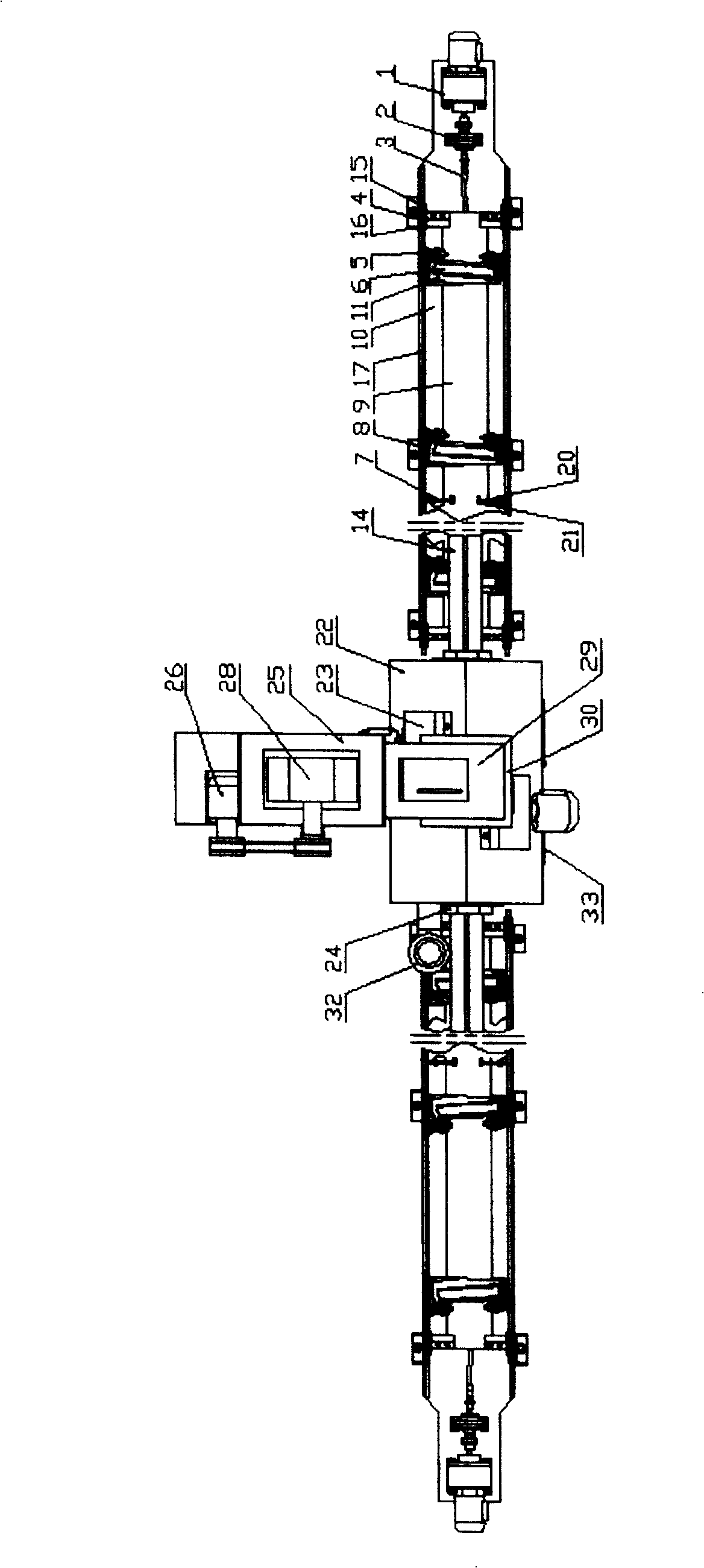

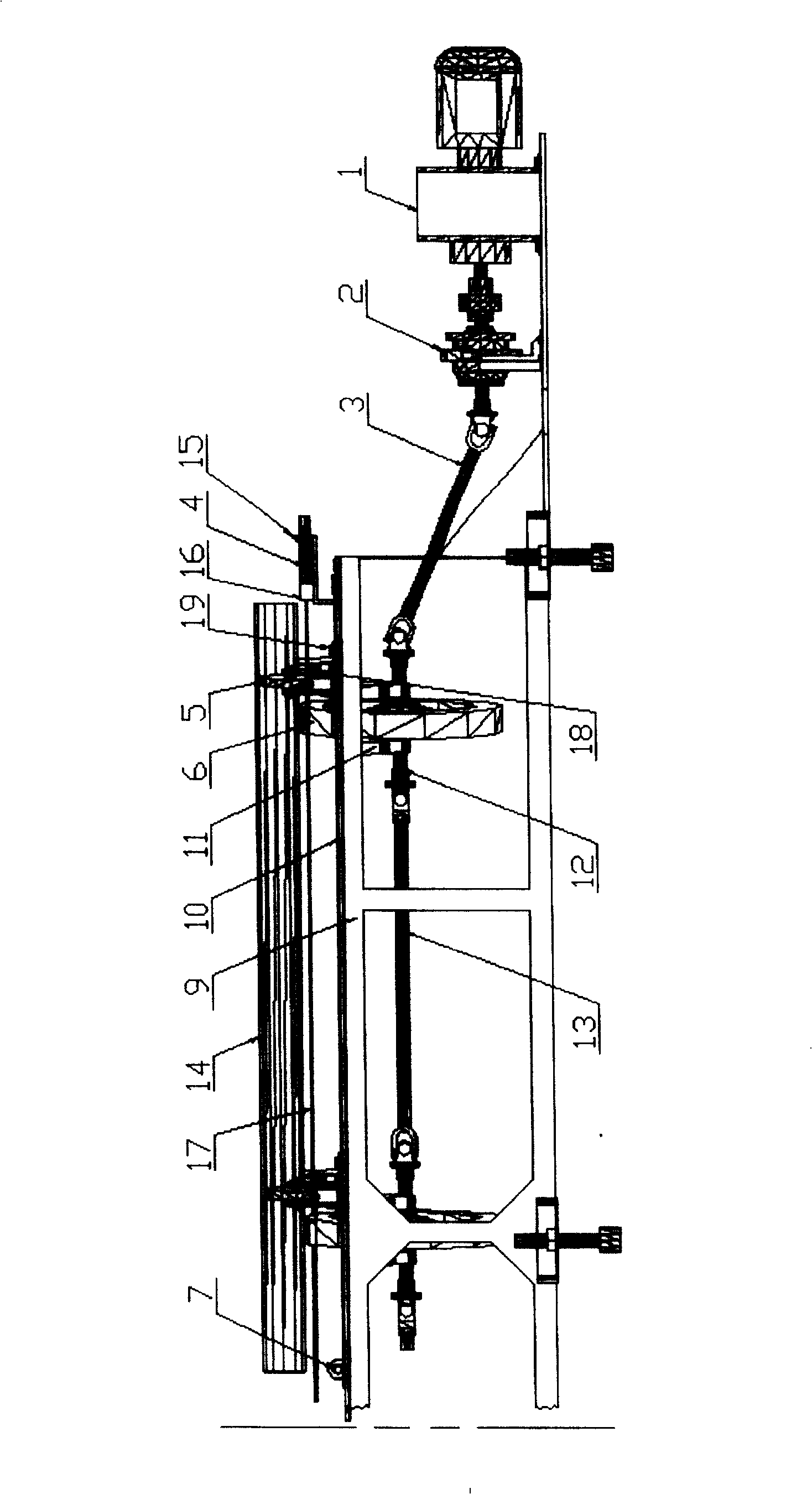

[0023]When the present invention is implemented, its designed main mechanism includes: a combination of two steel pipe steel bar transmission and derusting systems. The steel pipe transmission system mainly includes a motor 1, a reducer 2, a first universal coupling 3, and a driven wheel rotating screw 4 , driven wheel 5, driving wheel 6, driven wheel moving lead screw 7, driving wheel rotation fastening bolt 8, body 9, driven wheel moving platform 10, driving wheel rotating platform 11, the second universal coupling 12 and the third Universal coupling 13; in addition, steel pipe 14, rotating screw nut 15, screw slot 16, steel bar 17, driven wheel base 18, limit wrench 19, moving screw nut base 20 and moving screw Card slot 21. The output end of the motor 1 is connected to the input end of the reducer 2 through a coupling; the output end of the reducer 2 is connected to one end of the first universal coupling 3 through bolts; the other end of the first universal coupling 3 Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com