A method for removing rust with a steel wire brush inside a steel pipe

A technology of internal steel wire and steel wire brush, which is applied in the direction of brushes, brush bodies, wheels of working parts with flexible functions, etc. It can solve the problems of high cost, low efficiency and inconvenience of rust removal of metal pipes, and achieve low production cost , good rust removal quality and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The steel wire brush rust removal method inside the steel pipe of the present invention comprises the following steps:

[0033] A, make rolling wire brush, comprise the following steps;

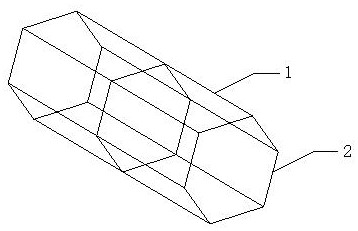

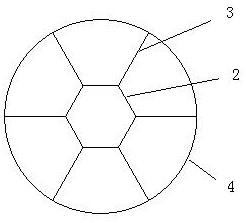

[0034] (1) Make the rotating shaft hole frame according to the inner diameter of the pipe. see now figure 1 , figure 1 It is a schematic diagram of the structure of the rotating shaft hole frame of the embodiment of the present invention. As shown in the figure, the rotating shaft hole frame is a regular hexagonal prism round steel bracket welded by round steel. The length of the side edge 1 of the regular hexagonal prism is 150mm. The length is 50mm, and a regular hexagonal round steel bracket with the same bottom surface is inlaid inside the middle of each side edge length to increase the strength of the rotating shaft hole frame; The plane where the steel bracket is located is perpendicular to the axis of the rotating shaft. The diameter of the round steel is 10mm.

[0035] (2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com