Deep rust removal equipment for outer surface of steel pipe

A technology for outer surfaces and steel pipes, applied in metal processing equipment, grinding/polishing equipment, grinding machines, etc., can solve the problems of direct application of steel pipes, high material consumption, high cost of rust removal and processing, and achieve efficient and thorough rust removal Excellent effect, small footprint, good rust removal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order for those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

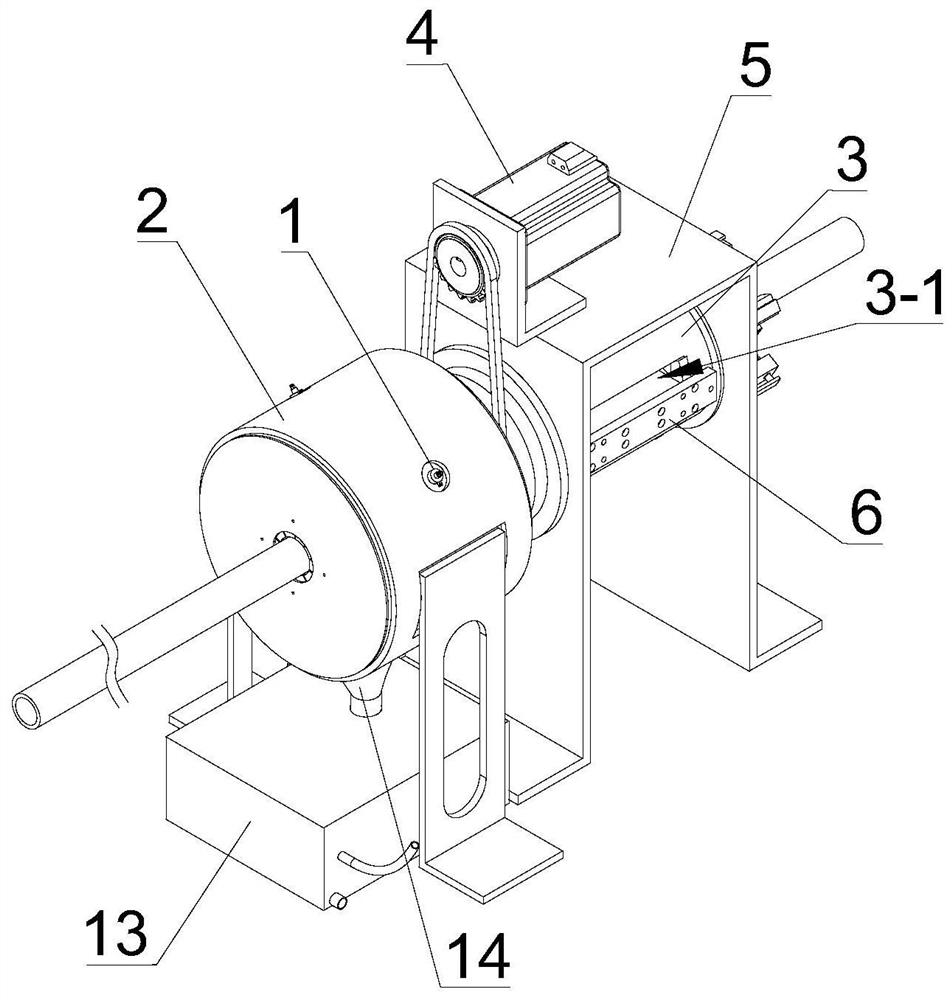

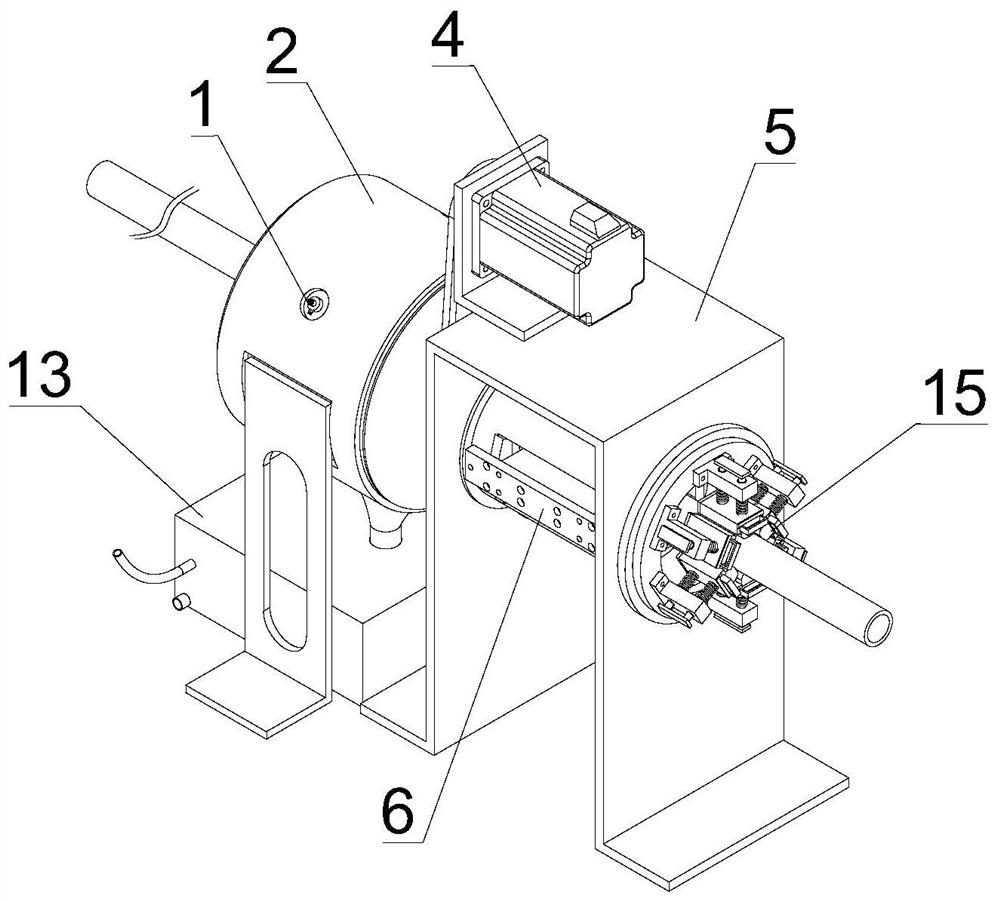

[0036]see Figure 1-2 , the steel pipe outer surface deep derusting equipment in the present embodiment comprises chemical derusting device, mechanical derusting device and cleaning device, along the conveying direction of steel pipe, described mechanical derusting device is positioned at the rear of chemical derusting device; The chemical derusting device includes an atomizing head 1 and a spray box 2, and the atomizing head 1 is arranged in the spray box 2 and communicated with a delivery pipeline for supplying a derusting liquid.

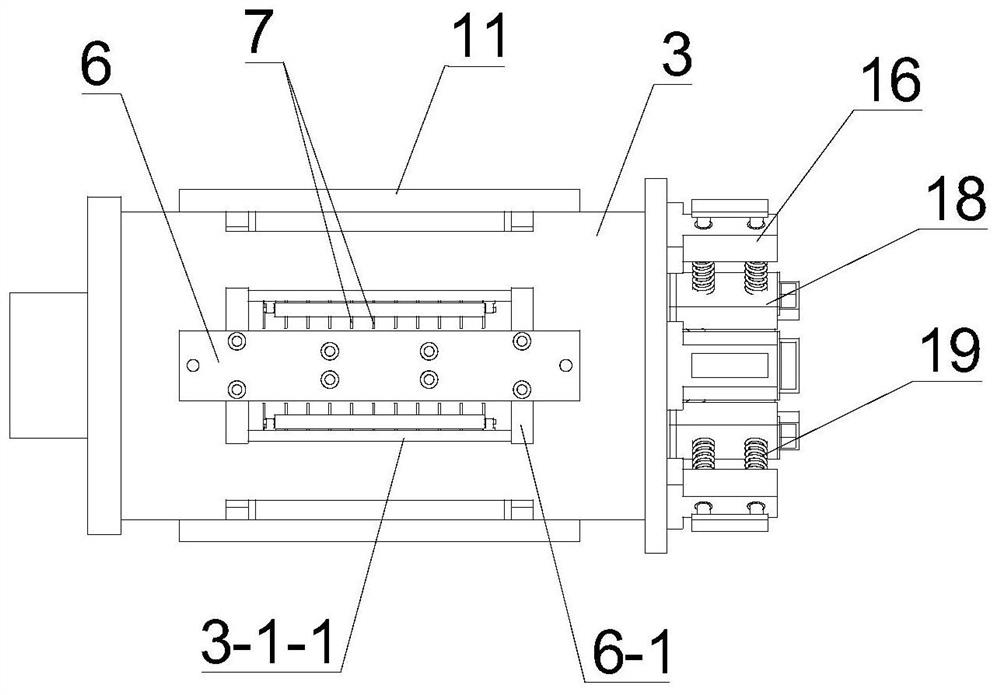

[0037] see Figure 1-9 , the mechanical derusting device includes a rotating drum 3, a rust brushing module arranged on the rotating drum 3, and a ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com